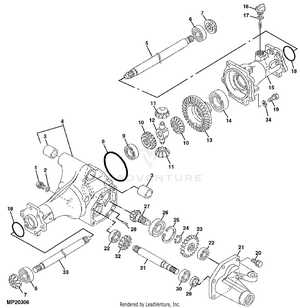

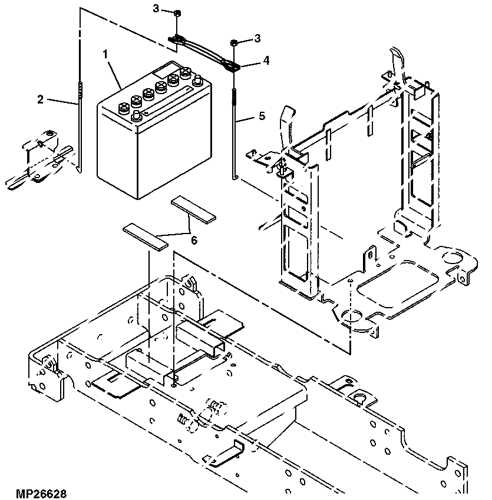

The intricate design of agricultural machinery requires a deep understanding of its various elements. Recognizing how each segment contributes to overall functionality is essential for effective maintenance and repair. A comprehensive overview of these elements aids users in maximizing efficiency and longevity.

In this section, we will explore a detailed visual representation that highlights the essential components of a well-known model. By examining these details, operators can better appreciate the synergy between parts, ensuring optimal performance.

With this knowledge, one can navigate the complexities of machinery upkeep with confidence. Whether you’re a seasoned technician or a novice user, grasping the layout of these components can lead to informed decision-making and enhanced productivity.

Understanding the John Deere 4115 Model

This section explores the essential characteristics and functionality of a well-regarded compact utility vehicle, providing insights into its design and applications. It is crucial for users to grasp the features that make this machine a reliable choice for various tasks, from agricultural activities to landscaping projects.

Key Features

- Robust engine performance

- Efficient fuel consumption

- Versatile attachment compatibility

- Compact size for maneuverability

Applications

- Agricultural maintenance

- Landscaping and gardening

- Light construction work

- Property management tasks

Understanding these elements helps users maximize the utility of their vehicle, ensuring optimal performance in a variety of settings.

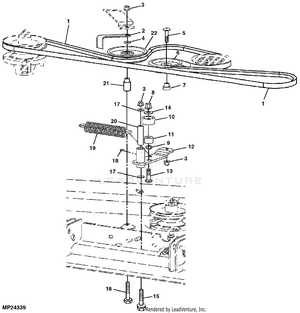

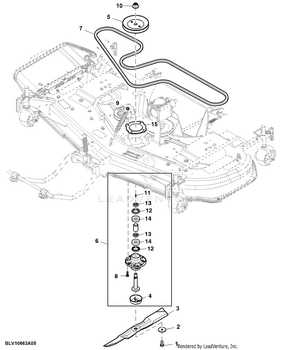

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that aid in identifying various elements, ensuring that tasks are performed accurately and efficiently.

Benefits of Visual Representations

- Enhances comprehension of complex assemblies.

- Facilitates quick identification of individual elements.

- Improves communication among technicians and operators.

- Streamlines the repair process, minimizing downtime.

Key Considerations

- Ensure clarity and accuracy in the representation.

- Utilize them as references during maintenance tasks.

- Update regularly to reflect any modifications in design.

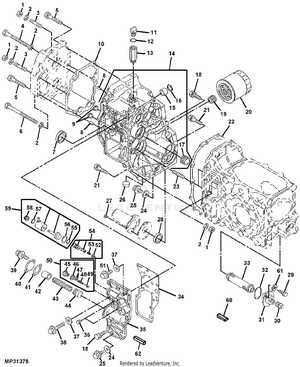

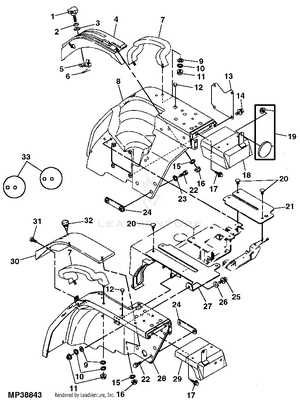

Overview of John Deere 4115 Components

This section provides a comprehensive look at the essential elements that contribute to the functionality of the machine. Each component plays a vital role in ensuring optimal performance, reliability, and efficiency. Understanding these parts can aid in maintenance and troubleshooting, enhancing the user experience and prolonging the lifespan of the equipment.

The engine serves as the powerhouse, delivering the necessary energy for various operations. Coupled with the transmission system, it facilitates smooth movement and control, essential for effective handling in diverse conditions.

The hydraulic system is crucial for implementing attachments and enabling various functionalities. Its design ensures that tasks such as lifting and digging can be performed with ease and precision.

Additionally, the chassis provides the structural integrity of the equipment, supporting all other components and allowing for stable operation across various terrains. The quality of materials used in its construction significantly impacts durability and performance.

Common Issues with 4115 Parts

When dealing with machinery components, various challenges may arise that affect overall performance and reliability. Understanding these common issues can aid in maintenance and prolong the lifespan of equipment. Below are some frequent concerns that operators encounter.

Frequent Problems

- Wear and Tear: Continuous use can lead to deterioration of components, affecting efficiency.

- Corrosion: Exposure to moisture and harsh environments can cause rust and degradation.

- Improper Fit: Incorrect installation may lead to misalignment, causing additional strain on related systems.

- Fluid Leaks: Seal failures can result in hydraulic fluid leaks, impacting operational capabilities.

Maintenance Tips

- Regularly inspect components for signs of damage.

- Ensure proper lubrication to reduce friction and wear.

- Replace worn seals and gaskets promptly to prevent leaks.

- Follow manufacturer guidelines for installation to ensure correct fit.

Addressing these issues proactively can lead to smoother operation and reduced downtime, enhancing the overall efficiency of your equipment.

Where to Find Parts Diagrams

Finding accurate illustrations of components for machinery can greatly enhance maintenance and repair efforts. Various resources are available to help enthusiasts and professionals locate detailed schematics that showcase the arrangement and specifications of essential elements. Utilizing both online platforms and physical resources ensures that users have access to the information they need for efficient troubleshooting and part replacement.

Online databases and manufacturer websites often host a wealth of information, including user manuals and reference charts. Additionally, forums and community groups dedicated to specific equipment can provide valuable insights and shared experiences. Don’t overlook local retailers or authorized service centers, which may also offer printed resources or direct assistance in obtaining these essential visuals.

Identifying Key Components Easily

Understanding the essential elements of machinery is crucial for efficient maintenance and repair. By familiarizing oneself with the various components, users can enhance their troubleshooting skills and streamline their workflow. This knowledge ultimately leads to more effective operation and longer equipment lifespan.

Common Elements to Recognize

Familiarity with typical components such as engines, transmissions, and hydraulic systems is vital. Each part plays a significant role in the overall function, and recognizing them can simplify maintenance tasks.

Tips for Efficient Identification

Utilizing visual aids and detailed manuals can significantly aid in pinpointing key components. Taking the time to delve into diagrams and descriptions can help users become proficient in understanding their machinery, ensuring they are well-equipped to handle any challenges.

Maintenance Tips for 4115 Users

Proper upkeep of machinery is essential for optimal performance and longevity. Regular maintenance not only ensures reliability but also enhances efficiency, ultimately leading to cost savings.

Routine Checks

- Inspect fluid levels regularly, including oil and coolant.

- Examine filters and replace them as needed to ensure clean operation.

- Check tire pressure and tread wear for safe handling.

Seasonal Maintenance

- Prepare the equipment for winter storage by draining fuel and checking for rust.

- Clean all components thoroughly before the busy season starts.

- Inspect belts and hoses for any signs of wear or damage.

Aftermarket vs. Original Parts

When it comes to machinery maintenance, choosing between alternative and genuine components is a pivotal decision. Each option presents distinct advantages and potential drawbacks that can impact performance and longevity.

Alternative components often offer:

- Cost savings compared to genuine parts.

- Wider availability from various suppliers.

- Compatibility with a range of models.

However, original components provide:

- Assured quality and reliability.

- Manufacturer warranties and support.

- Perfect fit for specific models.

Ultimately, the choice hinges on individual needs, budget, and the importance of quality versus cost-effectiveness in machinery upkeep.

Cost Considerations for Replacement Parts

When maintaining heavy machinery, evaluating the expenses associated with component substitution is crucial. Various factors influence these costs, impacting overall operational efficiency and budgeting.

Quality vs. Price: It’s essential to weigh the benefits of high-quality components against their higher price tags. Cheaper alternatives may save money initially but could lead to increased wear and tear, necessitating more frequent replacements.

Availability: The ease of obtaining specific items can also affect expenses. Components that are readily available often come at lower costs due to reduced shipping fees and shorter lead times.

Compatibility: Ensuring that replacements fit properly with existing machinery can prevent additional expenses. Mismatched items may require modifications, leading to unexpected costs.

Long-Term Investment: While upfront costs are important, considering the long-term value of replacements is vital. Investing in durable components can enhance performance and reduce future repair expenses.

Visual Guides for Assembly and Repair

Effective assembly and maintenance are essential for maximizing the performance and longevity of machinery. Utilizing visual resources can significantly enhance the understanding of complex components and procedures, making the tasks easier and more efficient.

Benefits of Visual Aids

Illustrated manuals and step-by-step videos provide clarity, allowing users to grasp intricate details at a glance. These guides can demystify the process, ensuring that both novice and experienced individuals can successfully navigate repairs and assemblies.

Choosing the Right Resources

When selecting visual materials, consider those that are clear, detailed, and user-friendly. High-quality illustrations and concise explanations can help prevent errors, saving time and reducing frustration during the repair process.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their specifications, providing clarity and guidance for users seeking assistance with their machinery. Understanding these elements is crucial for effective maintenance and operation.

What should I consider when selecting components?

When choosing components, it’s essential to evaluate compatibility with your equipment, quality standards, and availability. Ensuring these factors align will lead to optimal performance and longevity.

How can I find the right specifications?

To locate the correct specifications, refer to the user manual, consult with manufacturers, or explore online resources. Researching thoroughly helps in making informed decisions and avoiding potential issues.

Resources for Parts and Manuals

Accessing reliable resources for maintenance components and user guides is essential for ensuring optimal performance and longevity of your machinery. Various platforms and services can assist you in locating the necessary materials quickly and efficiently.

- Manufacturer’s Website: The official website often provides downloadable manuals and schematics specific to various models.

- Online Retailers: E-commerce sites frequently feature a wide range of components, along with detailed descriptions and compatibility information.

- Forums and Community Groups: Engaging with online communities can yield valuable insights and recommendations for sourcing specific items.

- Local Dealers: Authorized dealers typically have access to original equipment and can provide expert advice on replacements.

Utilizing these resources can significantly simplify the process of finding the right components and documentation, ensuring your equipment remains in peak condition.

Community Forums for Support and Advice

Engaging with community forums is an excellent way to seek assistance and share knowledge regarding machinery and equipment maintenance. These platforms provide users with the opportunity to connect with others who have similar interests or face comparable challenges. By participating in discussions, individuals can gain valuable insights, troubleshoot issues, and learn from the experiences of seasoned operators.

Benefits of Joining Community Forums

One of the primary advantages of these online communities is the diverse range of expertise available. Members often include professionals, hobbyists, and those with years of hands-on experience. This collective knowledge can significantly enhance problem-solving capabilities. Moreover, forums typically feature dedicated sections for specific topics, allowing users to find relevant information quickly.

How to Make the Most of Your Forum Experience

To maximize your experience, consider actively contributing to discussions. Sharing your own insights or solutions can help others while also solidifying your understanding of various concepts. Additionally, don’t hesitate to ask questions. Most members are eager to assist and offer advice based on their own experiences. Remember to follow forum guidelines and maintain a respectful tone to foster a positive environment for all.