The intricacies of agricultural machinery often require a detailed exploration of their various elements. A comprehensive overview of these components can significantly enhance the efficiency and longevity of the equipment. Familiarity with each section contributes to better maintenance and informed decision-making for users.

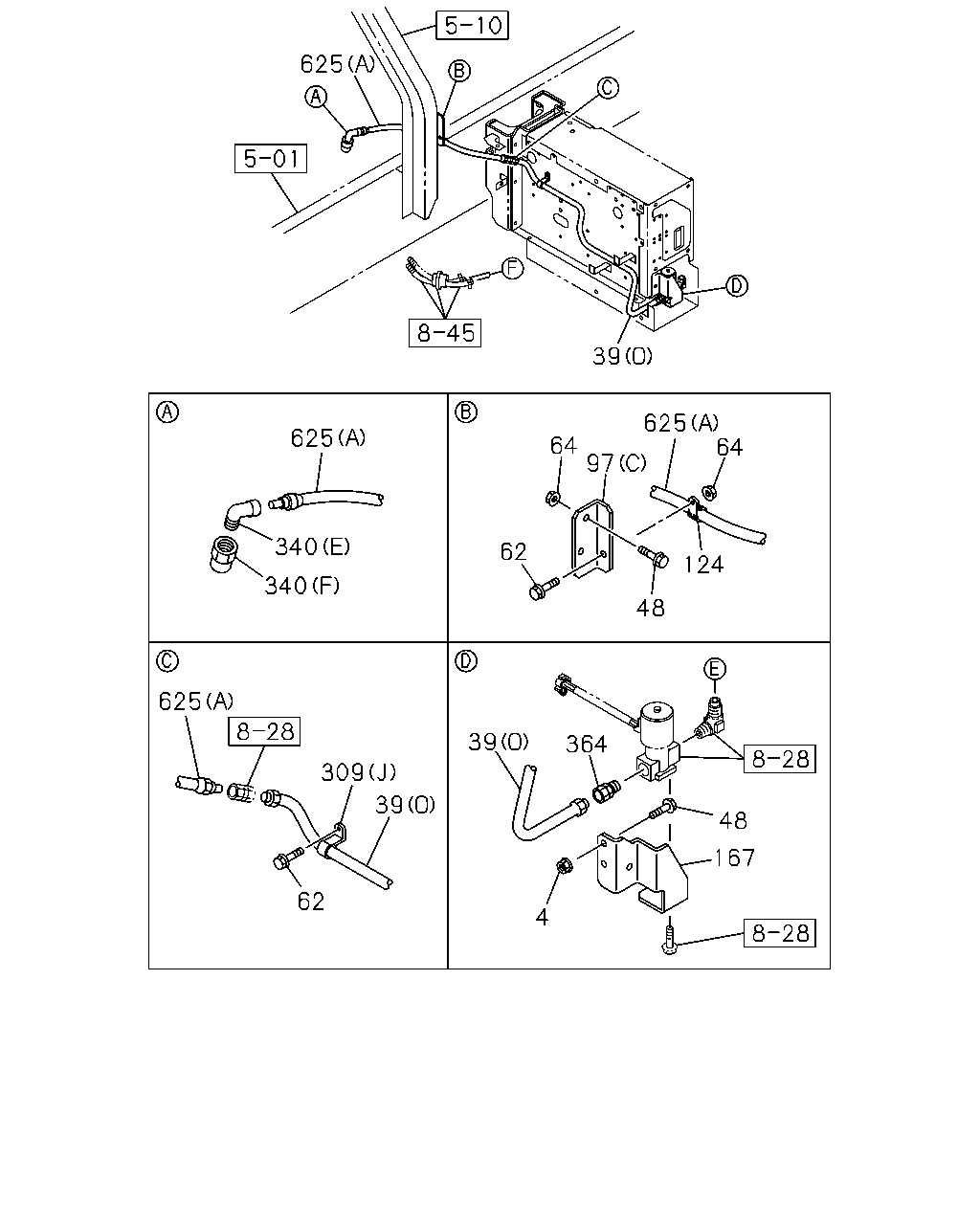

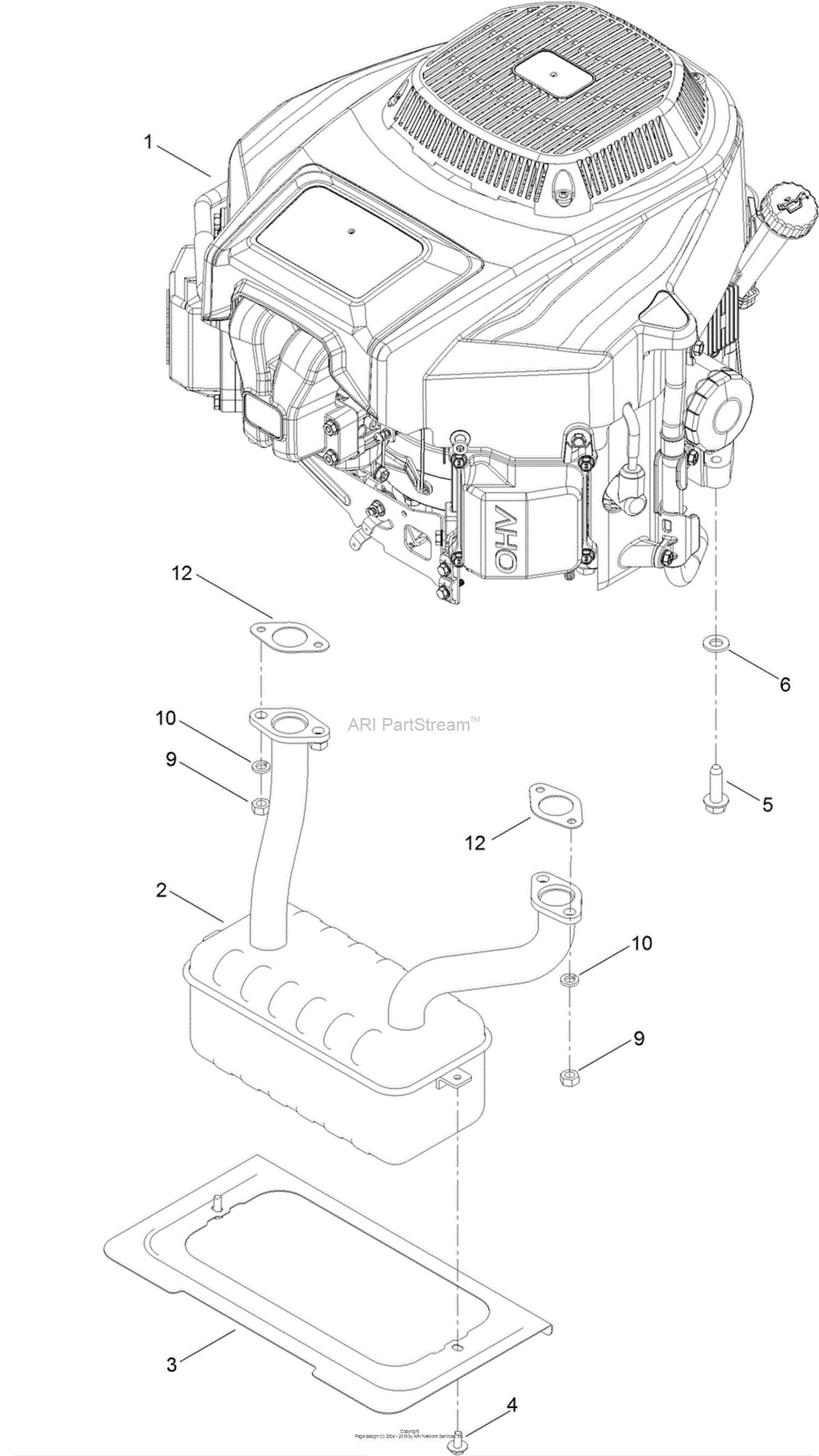

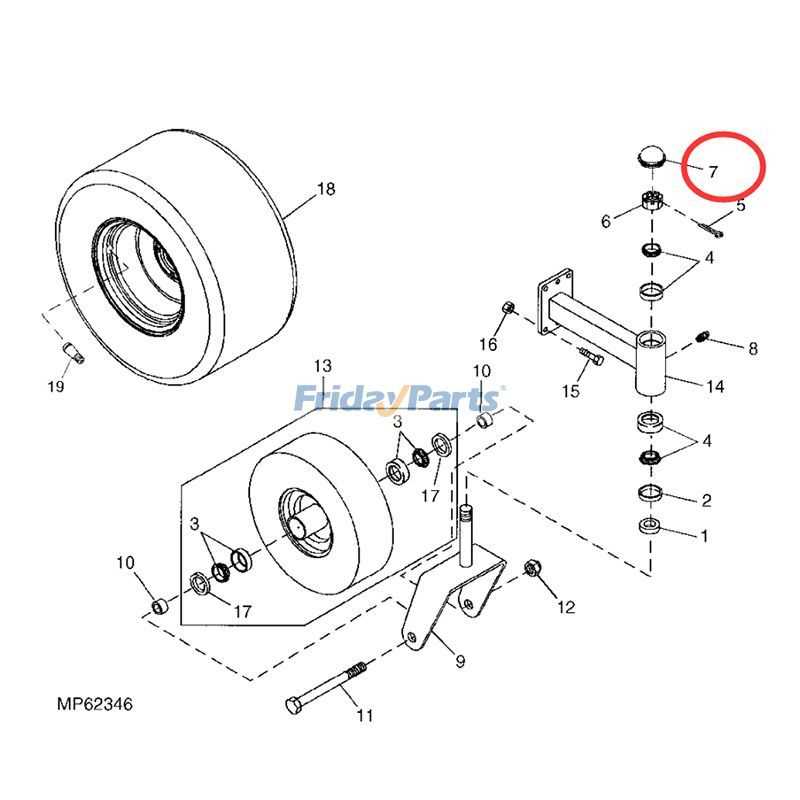

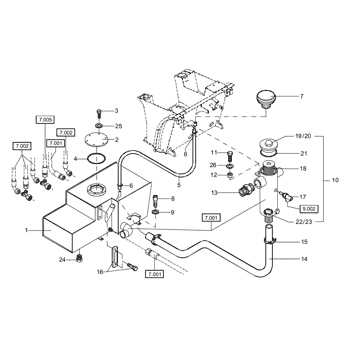

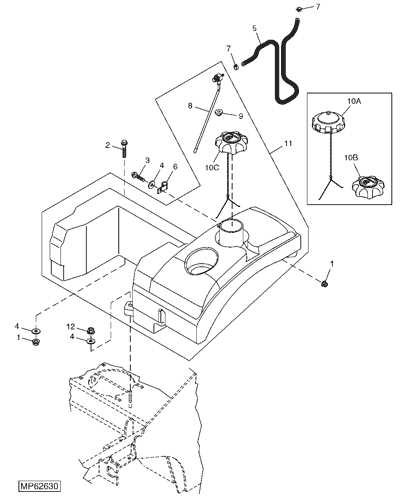

In the realm of farming tools, visual representations serve as invaluable resources. They provide clarity regarding the relationship between individual components, simplifying the identification of each element’s role. Such illustrations not only facilitate easier repairs but also assist in understanding the assembly and functionality of these machines.

Moreover, having access to these visuals aids operators in troubleshooting common issues. By recognizing how each part interacts with others, users can develop a more intuitive grasp of their machinery. This understanding empowers them to take proactive measures, ensuring optimal performance during critical farming operations.

Finding the right components for machinery can be a straightforward process with the right approach. Understanding how to locate and identify necessary replacements can save time and ensure efficient maintenance.

Here are some strategies to simplify the identification of required elements:

- Utilize Online Resources: Many websites provide extensive catalogs that include detailed descriptions and images. These can help in matching items accurately.

- Consult Manuals: Equipment manuals often contain diagrams and specifications that clarify the characteristics of components.

- Join Community Forums: Engaging with online communities can offer valuable insights from other users who have faced similar challenges.

- Visit Local Dealers: Establishing a relationship with local suppliers can provide immediate access to parts and expert advice.

By employing these techniques, you can enhance your ability to find the correct replacements quickly and efficiently, ensuring your equipment operates smoothly.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your machinery requires regular care and attention. By implementing proactive maintenance strategies, you can extend the lifespan of your equipment and enhance its operational reliability. Here are some essential practices to keep in mind.

- Regular Inspections: Conduct frequent assessments to identify any wear and tear or potential issues before they escalate.

- Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent premature damage.

- Cleanliness: Maintain a clean working environment by removing debris and dirt that can cause blockages or affect performance.

- Fluid Checks: Regularly monitor and replace fluids, ensuring that levels remain within the recommended ranges for optimal operation.

- Filter Replacement: Change air and oil filters according to the manufacturer’s guidelines to promote efficiency and protect engine components.

By adopting these practices, you can significantly improve the longevity and effectiveness of your machinery, ultimately leading to better performance and reduced operational costs.

Resources for Finding Parts

Locating components for machinery can be a straightforward task when you know where to look. Several valuable resources are available to assist enthusiasts and professionals alike in their search for specific elements. Understanding these avenues can save time and enhance the maintenance experience.

Online Retailers: Numerous e-commerce platforms specialize in various components, offering a wide range of options. These websites typically feature search functions, allowing users to input specific models or types to find suitable replacements quickly.

Manufacturer Websites: Visiting the official websites of manufacturers can provide direct access to detailed information about available components. Many manufacturers offer catalogs and resources to assist users in identifying and ordering the correct items.

Community Forums: Engaging with online communities dedicated to machinery can be beneficial. These platforms often have experienced members who share advice on sourcing specific components and may even recommend trusted suppliers.

Local Dealers: Established dealers in your area can be a valuable resource. They often have a stock of essential components and can provide expert guidance on compatible replacements for your equipment.

Trade Shows and Expos: Attending industry-related events can open opportunities to connect with suppliers and manufacturers directly. These gatherings often showcase the latest products and innovations, making it easier to find necessary components.

Common Issues and Solutions

In the realm of machinery, operational challenges can arise, affecting efficiency and performance. Understanding typical problems and their remedies is essential for maintaining optimal functionality. Here are some prevalent concerns and suggested solutions.

Engine Performance Problems

Issues with engine functionality can manifest as reduced power output or unexpected stalling. Regular maintenance, including checking fuel levels and replacing air filters, can often resolve these issues. Additionally, ensuring that all connections are secure and free from corrosion may enhance engine reliability.

Hydraulic System Failures

When hydraulic systems exhibit leaks or reduced pressure, performance can be severely hindered. Inspecting hoses for cracks and ensuring proper fluid levels are vital steps in troubleshooting. Replacing worn components promptly can prevent more significant failures and maintain system efficiency.

Comparing Models and Parts

When evaluating different machinery models, it’s essential to analyze their components and how they influence performance. A thorough examination can provide insights into compatibility, durability, and efficiency. This section highlights the importance of understanding variations among different models and their respective elements.

Several factors contribute to the differences in design and functionality:

- Specifications: Each model comes with unique specifications that dictate its operational capabilities.

- Compatibility: Some components may be interchangeable between models, while others are designed specifically for individual types.

- Quality: The materials used in the construction of parts can significantly affect the longevity and reliability of the machinery.

- Performance: Different configurations can impact overall performance, including speed, power output, and efficiency.

In conclusion, analyzing the distinctions among various machinery models and their elements is crucial for making informed decisions regarding repairs, upgrades, or replacements.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and components of specific machinery models. Here, we provide clarity on typical concerns that users may encounter during their operational activities.

| Question | Answer |

|---|---|

| What are the common issues faced with this equipment? | Users often report challenges such as wear and tear on critical components, which can affect overall performance. |

| How can I identify worn-out elements? | Regular inspections and listening for unusual sounds during operation can help in spotting deteriorated parts. |

| Where can I find replacement components? | Authorized dealers and online retailers specializing in machinery supplies typically offer a wide selection of replacements. |

| How often should maintenance be performed? | It is advisable to follow the manufacturer’s guidelines, usually recommending maintenance every 100 operating hours. |