The efficient operation of farming machinery relies heavily on the interplay of its individual components. A comprehensive grasp of these elements is essential for optimizing performance and ensuring longevity. This knowledge empowers users to make informed decisions regarding maintenance, repairs, and upgrades.

In the realm of agricultural machinery, certain models have gained prominence due to their reliability and effectiveness. Familiarizing oneself with the structure and function of these machines aids in troubleshooting and enhances overall productivity. By examining the intricate assembly of such equipment, one can appreciate the engineering behind modern farming practices.

This section delves into the essential components that contribute to the functionality of specific machinery used in agriculture. Through a detailed exploration, users can identify each element’s role, facilitating better understanding and more efficient handling of their equipment.

Precise identification of components plays a crucial role in the maintenance and functionality of agricultural machinery. Understanding the specifics of each element ensures seamless operation, reduces downtime, and extends the lifespan of the equipment. A meticulous approach to recognizing every individual part contributes significantly to overall efficiency and productivity.

When working with complex machinery, several factors highlight the necessity of accurate component recognition:

- Efficiency in Repairs: Quick and accurate identification allows for timely repairs, minimizing operational delays.

- Cost-Effectiveness: Understanding exact specifications helps avoid unnecessary purchases and ensures that the right components are sourced, reducing costs.

- Optimal Performance: Utilizing the correct elements ensures that machinery operates at its best, enhancing productivity.

- Safety Considerations: Proper identification minimizes the risk of malfunctions, which can pose safety hazards during operation.

In summary, investing time in accurately identifying components not only supports efficient maintenance but also safeguards the equipment’s performance and longevity. A systematic approach to component recognition is essential for anyone involved in the care and operation of agricultural machinery.

Key Features of the 7200 Model

The advanced agricultural implement is designed for optimal efficiency and precision in crop cultivation. Its innovative design integrates several key components that enhance functionality, ensuring a smoother planting process and improved yield potential.

| Feature | Description |

|---|---|

| Robust Frame | The sturdy structure provides durability and stability, allowing for reliable operation in various field conditions. |

| Adjustable Row Spacing | Allows customization of row width to suit different crop types and farming practices, promoting optimal growth. |

| Efficient Seed Placement | Ensures accurate positioning of seeds, leading to better germination rates and uniform crop development. |

| Advanced Metering System | Utilizes cutting-edge technology to regulate seed distribution, minimizing waste and enhancing planting precision. |

| Versatile Attachments | Compatible with various implements, allowing farmers to tailor their equipment setup for specific agricultural tasks. |

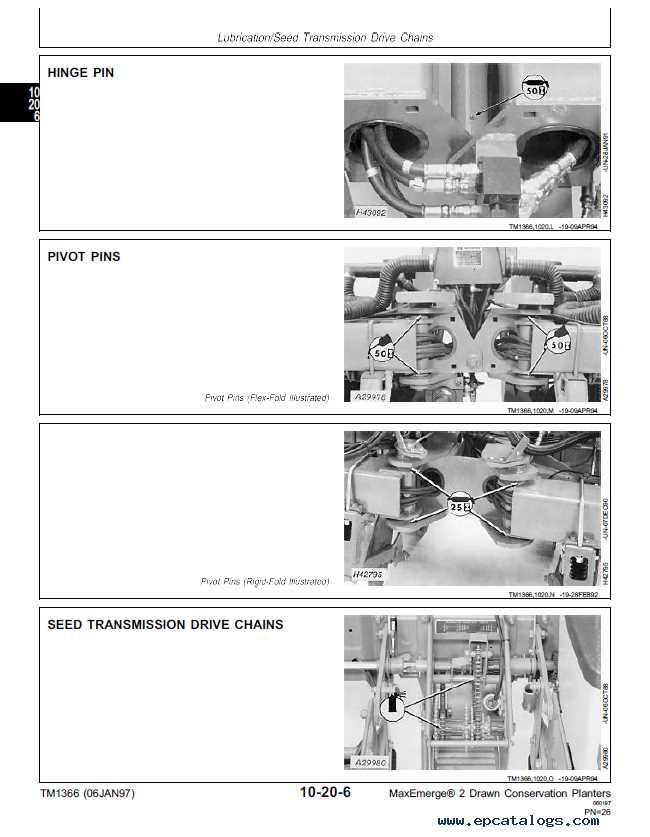

Common Wear Parts and Maintenance

In agricultural equipment, certain components experience frequent usage, leading to wear over time. Regular maintenance of these elements is essential to ensure optimal performance and longevity. Understanding which components are prone to degradation and how to care for them can significantly enhance efficiency during operations.

Key Components Subject to Wear

Several critical components require attention during routine maintenance. These include:

- Seals and Gaskets: These components are vital for preventing leaks and maintaining pressure. Regular inspection is necessary to detect any signs of wear or damage.

- Blades and Discs: Cutting edges endure significant stress and can dull or chip over time. Sharpening or replacement is recommended to maintain effective cutting action.

- Bearings: These elements support rotational movement and can wear out due to friction. Lubrication and periodic checks can extend their lifespan.

Maintenance Practices

To ensure optimal functionality, certain maintenance practices should be implemented:

- Regular Inspections: Conduct frequent assessments to identify wear signs before they escalate into more significant issues.

- Lubrication: Proper lubrication of moving parts reduces friction and extends the life of components.

- Timely Replacements: Replacing worn parts promptly prevents potential failures during critical operational periods.

Understanding Seed Delivery Mechanisms

The effective distribution of seeds is crucial in ensuring optimal crop yields. Various systems are designed to facilitate the accurate and efficient placement of seeds within the soil, taking into consideration factors such as seed type, soil condition, and planting depth. These mechanisms can significantly influence germination rates and overall plant health, highlighting their importance in agricultural practices.

Types of Seed Delivery Systems

Seed delivery mechanisms can be broadly categorized into several types, each tailored to meet specific agricultural needs. Gravity-fed systems rely on the weight of the seeds to move them through a series of tubes and into the soil. In contrast, vacuum-based systems utilize suction to hold seeds in place until they are released at the desired depth, providing greater precision during planting.

Factors Influencing Seed Delivery Efficiency

Several factors play a vital role in the efficiency of seed delivery systems. Seed size and shape affect how seeds flow through delivery mechanisms, while soil moisture content can influence how easily seeds penetrate the ground. Additionally, the speed of operation must be optimized to ensure that seeds are placed accurately without causing damage to the delicate seeds or the emerging plants.

Frame and Structure Analysis

The framework and structural components of agricultural equipment play a crucial role in ensuring efficiency and durability during operations. This section delves into the essential elements that contribute to the overall performance of these machines, highlighting their design and functionality.

Key Structural Elements

Several critical components form the backbone of agricultural machinery. These elements include beams, supports, and connectors that are engineered to withstand significant stresses while maintaining stability. The selection of materials, such as high-strength steel or aluminum alloys, greatly influences the machine’s longevity and resilience against harsh environmental conditions.

Impact on Operational Efficiency

The design of the framework directly affects the ease of use and maneuverability of the equipment. A well-structured machine allows for better weight distribution and balance, enhancing performance during planting or harvesting tasks. Additionally, incorporating innovative features can lead to improved adaptability to various field conditions, thus optimizing overall productivity.

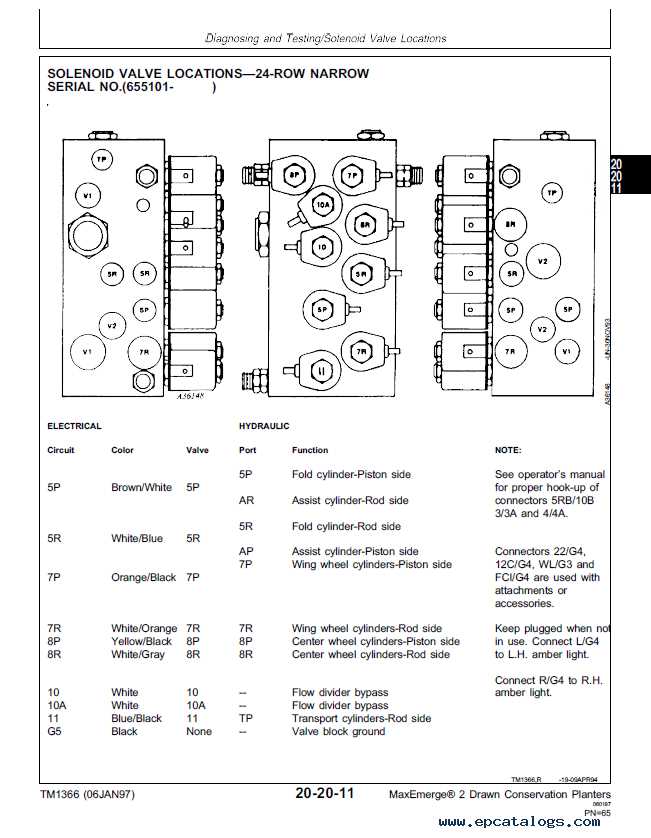

Hydraulic System Functionality Explained

The hydraulic system in agricultural machinery plays a vital role in enhancing efficiency and performance. By utilizing fluid power, this mechanism allows for precise control of various components, facilitating seamless operation during planting and other farming activities. Understanding the intricacies of this system is essential for optimizing functionality and ensuring the longevity of the equipment.

Core Components of Hydraulic Systems

A hydraulic system consists of several key elements that work together to achieve desired movements. These components include pumps, cylinders, valves, and fluid reservoirs, each contributing to the overall effectiveness of the system. Proper functioning of these parts is crucial for maintaining operational integrity.

Working Principles

Hydraulic systems operate based on fundamental principles of fluid dynamics. When fluid is pumped into a cylinder, it creates pressure that drives the piston, resulting in linear motion. This motion can be harnessed to control various mechanisms, such as lifting or lowering attachments. The ability to modulate this pressure allows for versatile applications across different tasks.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure by moving fluid |

| Cylinder | Converts hydraulic energy into mechanical force |

| Valve | Regulates fluid flow and direction |

| Reservoir | Holds hydraulic fluid for system operation |

Electrical Components and Their Roles

The intricate system of electrical elements within agricultural machinery plays a crucial part in enhancing operational efficiency. These components work in harmony to ensure optimal functionality, enabling precise control and monitoring of various processes. Understanding their roles helps users maintain equipment effectively and achieve better performance during farming operations.

Wiring Harness: The wiring harness acts as the nervous system of the machinery, connecting various electrical parts and facilitating communication between them. It ensures reliable transmission of power and signals, essential for the overall functionality of the system.

Sensors: Sensors are pivotal in providing real-time data regarding various parameters, such as soil moisture and planting depth. This information allows for timely adjustments, promoting accuracy and efficiency during operation.

Control Units: These units serve as the brain of the electrical system, processing input from sensors and sending commands to different components. They play a vital role in automating functions, enhancing user convenience and operational precision.

Actuators: Actuators convert electrical signals into physical movement, controlling elements like seed placement and row spacing. Their responsiveness is crucial for achieving desired planting specifications, contributing significantly to overall productivity.

Recognizing the importance of each electrical element empowers operators to troubleshoot effectively and perform maintenance, ensuring sustained performance and longevity of the equipment.

Adjustments for Optimal Performance

Achieving the best results from agricultural equipment requires precise calibration and fine-tuning. By making the right modifications, operators can enhance the effectiveness and efficiency of their machinery, leading to improved crop yield and reduced wear over time. This section will outline key areas where adjustments can be beneficial for maximizing functionality.

Calibration of Seed Depth

One of the most crucial aspects to consider is the depth at which seeds are placed in the soil. Proper calibration ensures that seeds receive adequate moisture and nutrients while minimizing competition from weeds. To achieve optimal seed placement, follow these guidelines:

| Adjustment Type | Recommended Setting |

|---|---|

| Seed Depth | 1.5 to 2 inches |

| Row Spacing | 30 inches |

| Seed Pressure | 5-10 PSI |

Fertilizer Distribution

Even distribution of fertilizers is vital for promoting healthy plant growth. Adjusting the application rate can significantly influence nutrient uptake and overall plant health. Operators should regularly check the calibration of their equipment to ensure consistent output across the field. Proper settings for fertilizer application include:

| Fertilizer Type | Application Rate (lbs/acre) |

|---|---|

| Granular Fertilizer | 200-300 |

| Liquid Fertilizer | 15-25 |

Upgrading Parts for Enhanced Efficiency

Improving components within agricultural machinery can lead to significant enhancements in productivity and performance. Upgrades can optimize operations, reduce downtime, and increase the overall effectiveness of the equipment. Understanding which elements to enhance is crucial for achieving desired outcomes.

Identifying Key Components for Improvement

When considering enhancements, focus on the following critical elements:

- Seed delivery systems

- Frame and structure integrity

- Hitch and towing apparatus

- Calibration tools

Benefits of Upgrading

Implementing upgrades offers numerous advantages, such as:

- Increased precision in planting

- Improved durability of machinery

- Enhanced user comfort and ergonomics

- Greater adaptability to various soil types

Repair Tips for Common Issues

When it comes to maintaining agricultural equipment, encountering issues is often inevitable. Understanding typical problems and their solutions can save time and enhance productivity. This section provides practical advice to address frequent challenges that may arise during operation.

Identifying Common Malfunctions

Recognizing symptoms of malfunction is crucial for timely repairs. Common indicators include unusual noises, inconsistent performance, or failure to engage properly. Observing these signs early can help prevent more severe damage and costly repairs.

Effective Troubleshooting Strategies

To effectively troubleshoot issues, a systematic approach is essential. Begin by inspecting components for visible wear or damage. Consult the equipment’s manual for guidance on specific adjustments. Utilizing a checklist can help ensure that no step is overlooked during the inspection process.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Inconsistent performance | Clogged components | Clean or replace affected parts |

| Unusual noises | Loose connections | Tighten connections and inspect for damage |

| Failure to engage | Worn out mechanisms | Replace or repair worn components |

Resources for Replacement Parts

Finding reliable sources for component replacements is essential for maintaining agricultural equipment. Quality components ensure optimal performance and longevity. This section highlights various resources where one can acquire necessary components, ensuring a smooth operation of your machinery.

Online Retailers

Numerous online platforms offer a wide selection of components for agricultural machinery. These retailers often provide detailed descriptions, images, and user reviews to assist in making informed purchasing decisions. Some popular options include:

| Website | Description |

|---|---|

| www.agri-parts.com | A comprehensive marketplace specializing in agricultural equipment components. |

| www.farmingsupply.com | Offers an extensive range of replacement components along with competitive pricing. |

| www.equipmentparts.com | Provides a user-friendly interface for searching and ordering equipment components. |

Local Dealers

Connecting with local suppliers can also be advantageous. These dealers often carry components specifically tailored to your machinery. Establishing a relationship with local vendors can lead to personalized service and timely availability of components.

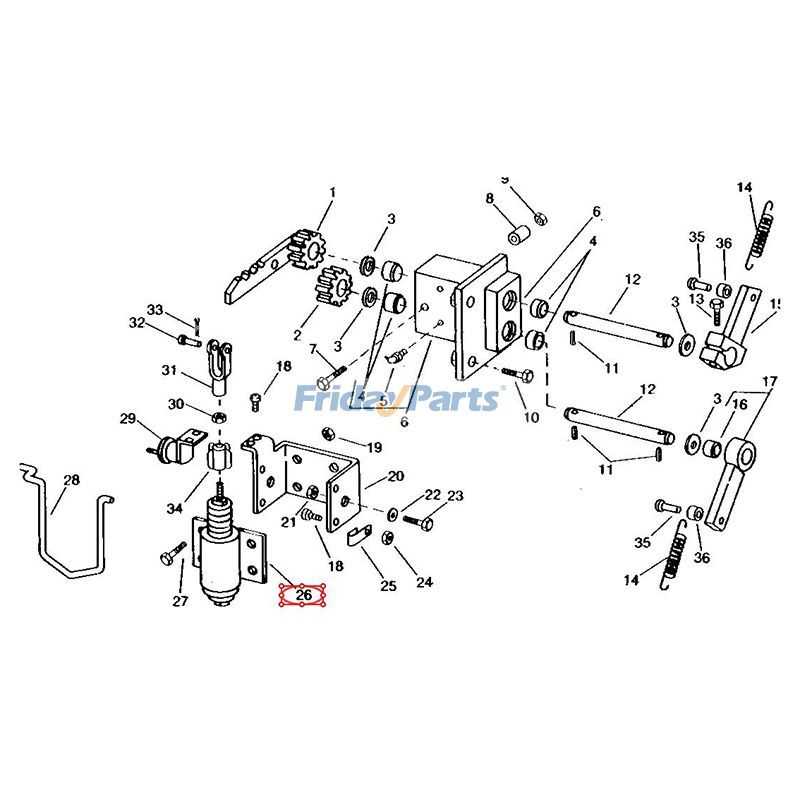

Visual Reference for Parts Diagram

This section aims to provide an informative overview of the components associated with the agricultural machinery in question. A clear visual reference can significantly enhance understanding and facilitate effective repairs and maintenance.

Understanding the Components

Familiarizing oneself with the various elements of the equipment is crucial for optimal performance. Each component plays a vital role in ensuring smooth operation and efficiency. Below is a table outlining the key features and their functions:

| Component Name | Function |

|---|---|

| Frame Assembly | Provides structural support and stability. |

| Row Unit | Facilitates the planting of seeds at precise depths. |

| Drive System | Transfers power from the tractor to the machine. |

| Seed Hopper | Holds and dispenses seeds during operation. |

| Gauge Wheel | Maintains accurate depth control throughout the planting process. |

Utilizing the Visual Reference

By referring to the visual representation of these components, operators can quickly identify and troubleshoot issues. This resource serves as an essential tool for anyone looking to enhance their understanding of the machinery’s functionality.