In the realm of outdoor machinery, comprehending the intricate elements that contribute to functionality is essential for maintenance and repairs. A well-organized reference detailing various components allows users to easily identify and troubleshoot issues that may arise. This guide aims to illuminate the critical aspects of specific machinery, enhancing the user experience through knowledge and understanding.

Each piece of equipment consists of numerous parts, each serving a unique purpose that contributes to the overall operation. By familiarizing oneself with these components, owners can ensure their machinery operates smoothly and efficiently. The following sections provide insights into the various elements, their arrangements, and how they interact to deliver optimal performance.

With a solid grasp of these essential components, users can approach repairs with confidence. Understanding the layout and relationships between parts empowers operators to make informed decisions, prolonging the lifespan of their machinery and ensuring it remains in top condition.

This section aims to provide an in-depth exploration of the fundamental components and their relationships within a specific model of lawn and garden machinery. By understanding how these elements interact, users can gain valuable insights into the maintenance and repair processes necessary for optimal performance.

| Component | Description |

|---|---|

| Engine Assembly | Key unit providing power and performance to the equipment. |

| Transmission System | Mechanism that transfers power from the engine to the wheels. |

| Deck | Housing that protects and supports the cutting mechanism. |

| Wheels and Tires | Components that provide mobility and stability on various terrains. |

| Electrical System | Network responsible for the ignition and lighting functionalities. |

Key Features of the D160 Model

This model stands out in its category, offering a range of innovative attributes that enhance both functionality and user experience. Designed for optimal performance, it integrates advanced technology and durable components, making it suitable for various tasks.

Some notable characteristics include:

- Powerful Engine: Equipped with a robust engine that ensures reliable performance in different conditions.

- Comfortable Seating: Features an ergonomic seat design that provides comfort during extended use.

- Intuitive Controls: User-friendly interface that simplifies operation and enhances efficiency.

- Versatile Attachments: Compatible with various accessories, allowing users to customize functionality according to their needs.

- Durable Construction: Built with high-quality materials to withstand rigorous use and environmental challenges.

These features collectively contribute to the model’s reputation as a reliable and efficient option for homeowners and professionals alike.

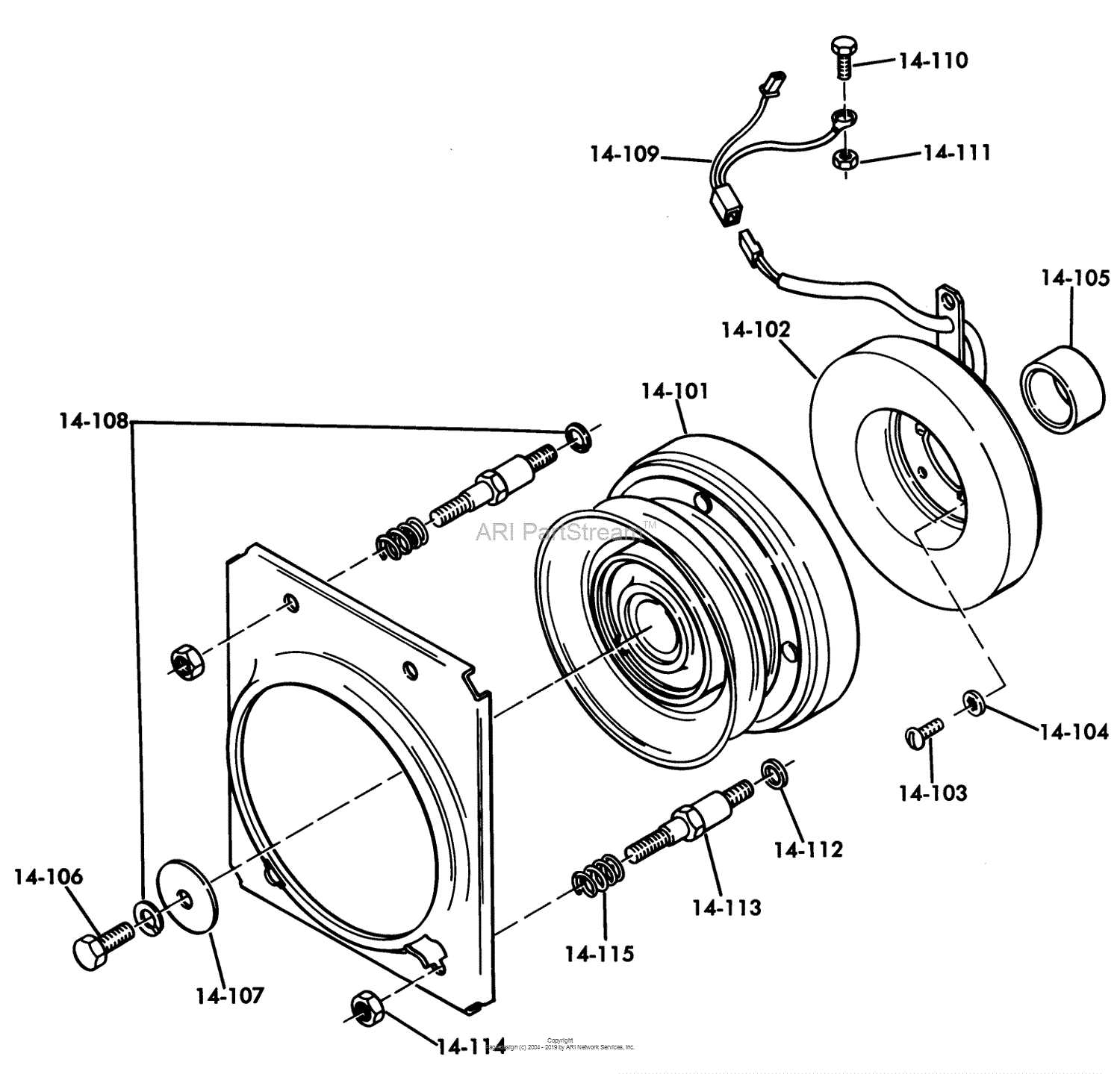

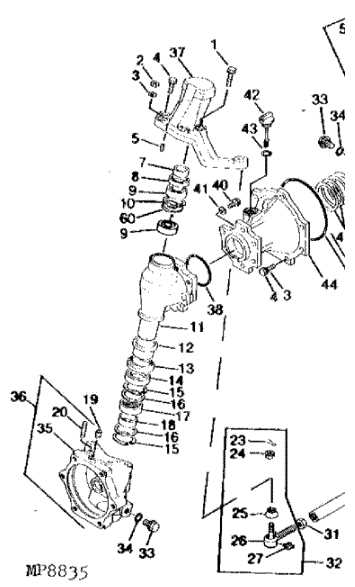

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations that outline the various elements within a system can greatly enhance the user’s ability to identify and address issues. These illustrations serve as valuable tools for both novice and experienced technicians, facilitating a more straightforward approach to equipment care.

Enhancing Maintenance Efficiency

Utilizing visual guides allows for quicker identification of necessary components, streamlining the process of troubleshooting. When a specific element fails, having an accurate representation aids in determining the correct replacement or repair procedure. This leads to reduced downtime and improved operational efficiency.

Supporting Effective Communication

These visual aids foster better communication between service personnel and clients. When discussing repairs or replacements, referring to a graphical representation minimizes misunderstandings, ensuring that all parties have a clear understanding of what is being addressed. This clarity is vital for building trust and satisfaction in service interactions.

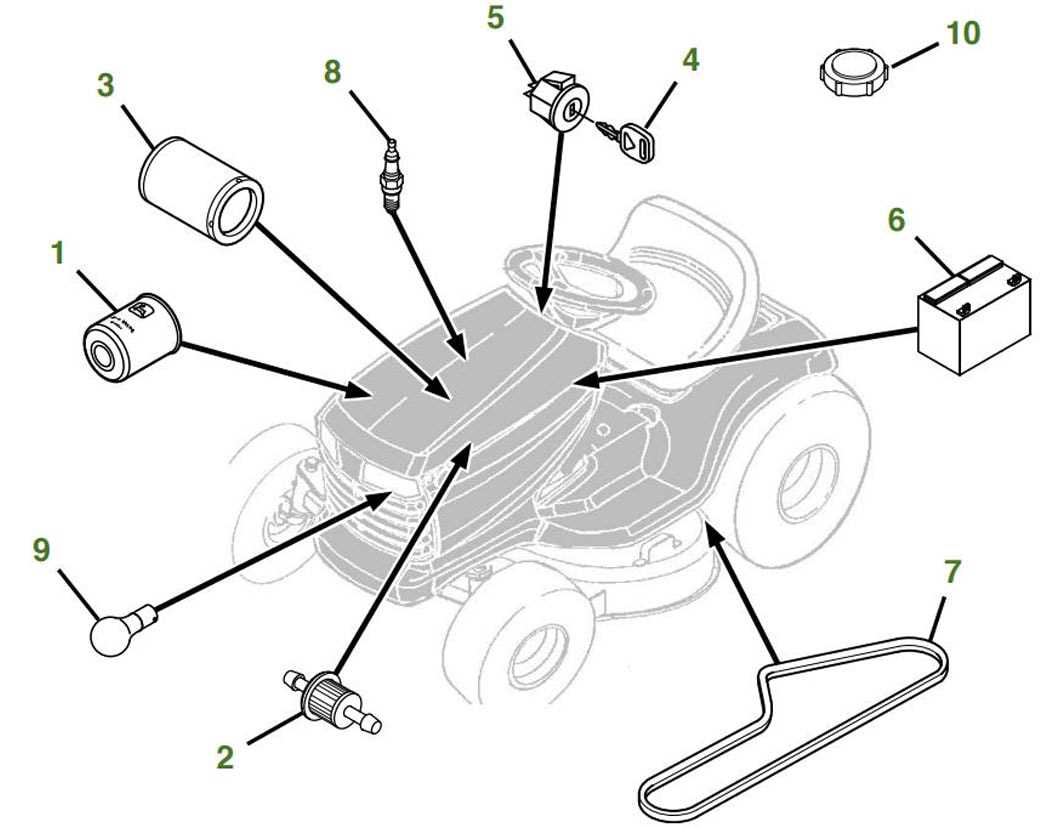

Common Replacement Parts for D160

Maintaining machinery requires a keen understanding of essential components that may need periodic replacement. Identifying these elements ensures optimal performance and longevity of the equipment. Regular checks and timely substitutions help in avoiding unnecessary downtime and costly repairs.

| Component | Description | Signs of Wear |

|---|---|---|

| Battery | Supplies electrical power to the engine and other systems. | Slow cranking, dim lights, or corrosion on terminals. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. | Engine sputtering or reduced power during operation. |

| Belts | Transfers power from the engine to various components. | Fraying, cracks, or squealing noises during operation. |

| Air Filter | Prevents dirt and debris from entering the engine. | Decrease in performance or black smoke from the exhaust. |

| Spark Plug | Ignites the air-fuel mixture in the engine cylinders. | Misfiring engine or difficulty starting. |

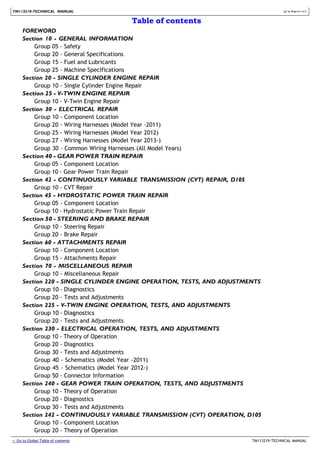

How to Use Parts Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These visual representations simplify the identification of components and their relationships, making it easier for users to find the necessary elements for service or replacement. Whether you’re a professional technician or a DIY enthusiast, mastering the art of reading and utilizing these illustrations can significantly enhance your efficiency.

Identifying Components

To effectively utilize schematics, start by familiarizing yourself with the layout. Each section typically highlights various elements, often accompanied by reference numbers or labels. Pay attention to these annotations, as they direct you to specific components and their corresponding locations.

Locating Replacement Items

Once you identify the components needed for maintenance, the next step is to locate the appropriate replacement items. Utilizing reference numbers from the schematic allows you to search online or in stores for the correct parts. Always ensure that the replacements match the specifications outlined in the illustration for optimal performance.

| Component | Description | Reference Number |

|---|---|---|

| Engine | Primary power unit | 101 |

| Transmission | Power transfer mechanism | 102 |

| Wheels | Mobility support | 103 |

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Knowing where to locate these genuine replacements can save you time and ensure reliability in your machinery.

Authorized Dealers

One of the most reliable sources for obtaining authentic components is through authorized dealerships. These establishments often provide:

- Expert advice from knowledgeable staff

- Access to exclusive products that meet manufacturer specifications

- Warranty options for additional peace of mind

Online Retailers

The internet is a valuable resource for finding genuine replacements. Several reputable online platforms specialize in offering high-quality items, including:

- Official manufacturer websites

- Trusted third-party retailers with positive customer reviews

- Online marketplaces that verify the authenticity of sellers

Troubleshooting with Parts Diagrams

When it comes to maintaining and repairing machinery, visual aids play a crucial role in identifying issues. These visual representations serve as a roadmap, guiding users through various components and their interconnections. By understanding the layout and functionality of different parts, operators can quickly pinpoint malfunctions and streamline the repair process.

Utilizing these resources allows for a more efficient diagnosis of problems. For instance, when faced with an unexpected failure, a quick glance at a well-structured illustration can reveal the exact location of a fault. This not only saves time but also minimizes the risk of overlooking critical areas during inspection.

| Common Issues | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine Won’t Start | Fuel blockage or electrical failure | Check fuel lines and battery connections |

| Excessive Vibration | Worn bearings or imbalanced components | Inspect bearings and replace damaged parts |

| Overheating | Coolant leak or faulty thermostat | Check coolant levels and thermostat operation |

Incorporating these illustrations into regular maintenance practices can significantly enhance the efficiency of troubleshooting. Operators who familiarize themselves with the visual layouts are better equipped to address issues promptly, ensuring optimal performance and longevity of their equipment.

Maintenance Tips for D160 Owners

Proper upkeep of your outdoor equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only helps in identifying potential issues early on but also enhances the overall efficiency of your machine. Below are some practical suggestions to help you maintain your equipment effectively.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 50 hours | Replace the oil and filter to ensure smooth operation and prevent engine wear. |

| Air Filter Cleaning | Every 25 hours | Inspect and clean the air filter to maintain airflow and engine efficiency. |

| Blade Sharpening | At least twice per season | Sharpen blades regularly to achieve a clean cut and promote healthy grass growth. |

| Tire Pressure Check | Monthly | Ensure that tires are properly inflated for improved traction and stability. |

| Belt Inspection | Every 25 hours | Check belts for wear and tension to prevent breakdowns during operation. |

Following these maintenance guidelines will help ensure your equipment remains reliable and efficient for many seasons to come. Regular attention to these tasks will not only extend the life of your machinery but also enhance your overall experience while using it.

Identifying Parts by Diagram

Understanding the components of machinery through visual representations is crucial for efficient maintenance and repair. These illustrations serve as valuable resources, allowing users to easily locate and identify different elements. By interpreting these graphical guides, one can enhance their familiarity with the equipment and streamline the process of obtaining the necessary replacements or adjustments.

Benefits of Visual Guides

Utilizing graphical references offers numerous advantages. First, they provide a clear overview of the machinery, making it simpler to pinpoint specific sections. Furthermore, these visuals can help in avoiding errors during repairs, ensuring that the correct items are selected. This method not only saves time but also minimizes the risk of damaging components due to incorrect identification.

Enhancing Maintenance Skills

Familiarity with these visual aids can significantly improve one’s maintenance skills. Regular practice in interpreting these illustrations enables operators to quickly identify wear and tear, facilitating proactive measures. Ultimately, mastering the use of these references leads to a more efficient and effective approach to machinery upkeep.

Online Resources for Parts Information

In today’s digital age, accessing information about equipment components has never been easier. A variety of online platforms provide users with comprehensive data, including specifications, schematics, and compatibility details. These resources are invaluable for anyone looking to maintain or repair machinery efficiently.

Manufacturer Websites

Official manufacturer websites often serve as the primary source of information. They typically offer detailed catalogs of available components, including technical specifications and user guides. By visiting these sites, users can ensure they are accessing the most accurate and up-to-date information directly from the source.

Online Forums and Communities

Participating in online forums and community groups can greatly enhance your understanding of equipment maintenance. These platforms allow users to share experiences, ask questions, and receive advice from seasoned professionals and fellow enthusiasts. Utilizing these resources can lead to valuable insights that enhance your repair and maintenance practices.

DIY Repairs for D160 Components

Engaging in self-repair for machinery components can be a rewarding and cost-effective approach. Understanding the various elements involved allows you to troubleshoot issues effectively and extend the lifespan of your equipment. This section will guide you through the fundamental aspects of performing repairs on your machine’s critical components, ensuring optimal functionality.

Identifying Common Issues

Before embarking on repairs, it is crucial to recognize the typical problems that may arise with machinery components. Symptoms such as unusual noises, decreased performance, or fluid leaks often indicate underlying issues. Regular inspection and maintenance can prevent minor problems from escalating into more significant repairs. Keep an eye out for wear and tear on belts, filters, and electrical connections, as these are frequent trouble spots.

Essential Tools for Repairs

Having the right tools at your disposal can significantly simplify the repair process. Basic tools such as wrenches, screwdrivers, and pliers are essential for most tasks. Additionally, specialized tools like torque wrenches and diagnostic equipment may be necessary for more complex repairs. Investing in quality tools ensures you have what you need to tackle repairs efficiently, providing peace of mind during the process.

Frequently Asked Questions about D160 Parts

This section addresses common inquiries regarding the components and assemblies of a specific lawn care machine. Understanding the various elements and their functions can greatly enhance maintenance and repair efforts.

Below are some frequently asked questions along with their answers:

| Question | Answer |

|---|---|

| What are the essential components to inspect regularly? | Key elements include the blades, belts, and filters, which should be checked frequently for wear and tear. |

| How can I identify if a component needs replacement? | Signs of damage, unusual noises, or decreased performance are indicators that a part may need to be replaced. |

| Where can I find reliable replacements for these components? | Reputable retailers, authorized service centers, and online marketplaces often carry quality replacements. |

| Is it necessary to use original components for repairs? | While original components are recommended for optimal performance, compatible aftermarket options can also be effective if they meet quality standards. |