The efficient operation of machinery relies heavily on its various components, each playing a crucial role in functionality and performance. A comprehensive understanding of these elements not only aids in maintenance but also enhances the user’s ability to troubleshoot and optimize equipment usage.

In this section, we will explore the intricate layout of essential elements associated with a specific model of lawn and garden machinery. By delving into the configuration and arrangement of these components, users can better appreciate how each part contributes to the overall operation.

Furthermore, recognizing the significance of each element allows for informed decision-making when it comes to repairs and replacements. This knowledge empowers users to maintain their machinery effectively, ensuring longevity and reliability in its performance.

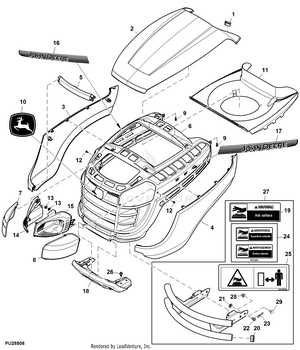

Understanding John Deere E160 Components

This section delves into the essential elements that make up the machinery in question, providing insights into their functions and interconnections. Grasping the arrangement and purpose of these components is crucial for effective maintenance and operation.

Key Elements and Their Functions

Every mechanism consists of various integral parts, each serving a specific role. Understanding these elements enables operators to troubleshoot issues efficiently and ensure optimal performance.

Maintenance and Care Tips

Regular upkeep of these components is vital for longevity and reliability. Familiarity with their functions can guide users in implementing preventive measures and identifying potential problems early.

Key Parts of the E160 Model

The essential components of this particular lawn care equipment play a crucial role in its functionality and efficiency. Understanding these elements helps users appreciate the overall design and maintenance of the machine.

Engine: This is the heart of the device, providing the necessary power for various tasks.

Transmission: A vital mechanism that enables smooth movement and control, enhancing user experience during operation.

Deck: This structure is responsible for cutting grass and maintaining a neat appearance of the lawn.

Wheels: Essential for mobility, they ensure stability and ease of movement across different terrains.

Battery: Powers the electrical components and ensures reliable start-up and operation.

Maintenance Tips for E160 Machinery

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. By following best practices, operators can prevent costly repairs and maintain optimal performance throughout the equipment’s lifespan.

Routine Checks

- Inspect fluid levels regularly, including oil, coolant, and hydraulic fluids.

- Examine belts and hoses for signs of wear or damage.

- Clean air filters to ensure proper airflow.

Seasonal Maintenance

- Change oil and filters every specified hours of operation.

- Sharpen or replace cutting blades as needed.

- Lubricate moving parts to minimize friction and wear.

Common Issues and Solutions

This section addresses typical challenges encountered with lawn maintenance machinery, providing practical solutions to enhance performance and longevity. Understanding these common problems can help users maintain their equipment efficiently.

Performance Problems

One frequent issue is reduced efficiency during operation. This can stem from several factors, including dull blades or clogged air filters. Regular maintenance and timely replacements are essential to ensure optimal functionality.

Electrical Malfunctions

Electrical issues can also arise, such as difficulty in starting or erratic behavior during use. Checking connections and ensuring the battery is charged can often resolve these problems quickly.

| Issue | Possible Cause | Solution |

|---|---|---|

| Reduced efficiency | Dull blades | Sharpen or replace blades |

| Difficulty starting | Weak battery | Charge or replace battery |

| Clogged air filter | Debris accumulation | Clean or replace filter |

Importance of Original Parts

Utilizing authentic components is crucial for maintaining the performance and longevity of machinery. These elements are designed specifically for compatibility, ensuring optimal functionality and safety.

Key benefits of using genuine components include:

- Enhanced reliability and performance.

- Reduced risk of malfunction or breakdown.

- Longer lifespan of the equipment.

- Better warranty coverage and support.

Choosing original items over generic alternatives can prevent costly repairs and downtime, making it a wise investment for any operator.

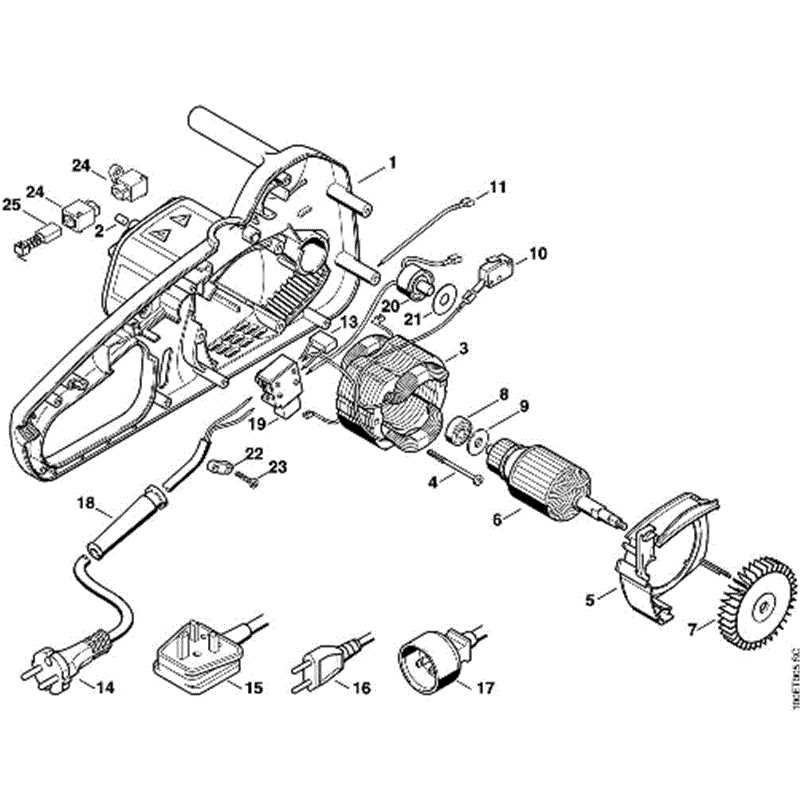

Tools for E160 Repair Tasks

Maintaining and fixing machinery requires the right set of instruments to ensure efficiency and effectiveness. Selecting appropriate tools not only simplifies tasks but also enhances safety during repairs. Whether for routine maintenance or more complex issues, having the correct equipment is crucial for optimal performance.

Essential Hand Tools

Hand tools are fundamental for various repair jobs. Wrenches, screwdrivers, and pliers are indispensable for adjustments and replacements. Quality hand tools can make a significant difference in both ease of use and the longevity of your equipment.

Power Equipment and Accessories

In addition to hand tools, power equipment can accelerate repair processes. Drills, grinders, and impact wrenches allow for faster completion of tasks, reducing manual effort. Using the right accessories with power tools can further enhance their utility and effectiveness.

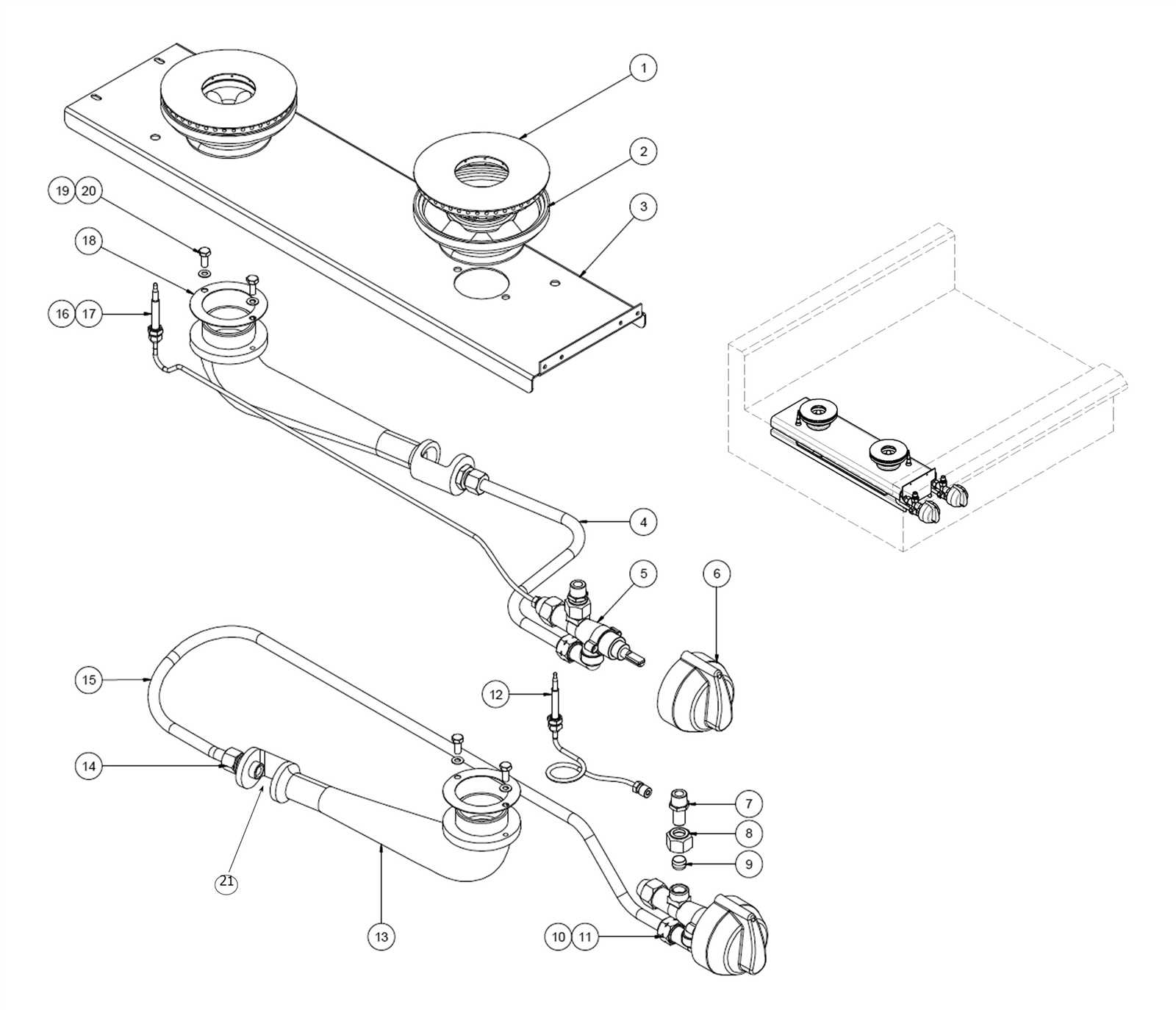

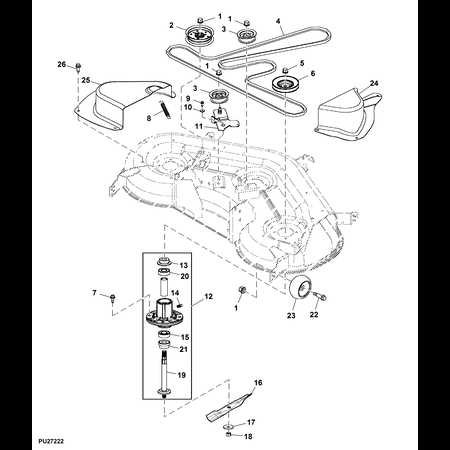

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide a clear layout of various elements, helping users identify and locate specific pieces within a machine.

Key Elements to Consider

- Symbols: Familiarize yourself with common icons and their meanings.

- Labels: Pay attention to descriptions that indicate the function of each item.

- Connections: Note how different components interact and connect with one another.

Steps for Effective Interpretation

- Start with a broad overview of the layout.

- Identify the main sections and their respective functions.

- Cross-reference the diagram with a list of components to verify details.

- Use the illustration to assist in locating and replacing parts.

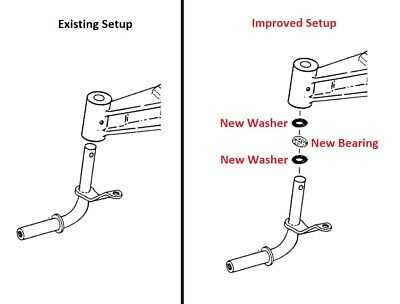

Upgrading E160 with Aftermarket Parts

Enhancing your lawn care equipment with alternative components can significantly improve performance and extend its lifespan. By exploring various aftermarket options, you can achieve tailored functionality suited to your specific needs.

Benefits of Aftermarket Enhancements

Opting for alternative components often provides a cost-effective solution, allowing for superior durability and performance. Many aftermarket options are designed to exceed the original specifications, ensuring enhanced efficiency and reliability.

Choosing Quality Components

When selecting alternative parts, prioritize reputable brands known for their reliability. Researching customer reviews and comparing specifications can guide you in making informed decisions that ultimately lead to a more efficient and effective machine.

Safety Precautions for Maintenance

When performing upkeep on machinery, adhering to safety measures is crucial to ensure the well-being of individuals and the integrity of the equipment. Proper protocols can prevent accidents and enhance operational efficiency.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure the machine is turned off and cooled down before starting any maintenance tasks.

- Use tools that are specifically designed for the task at hand to avoid injuries.

- Keep the workspace clean and free from obstacles to minimize risks of tripping or falling.

Preparation Steps

- Review the manufacturer’s instructions and safety guidelines prior to beginning maintenance.

- Gather all necessary tools and materials in advance to avoid distractions during the process.

- Inform others in the vicinity about the maintenance work to prevent unexpected interruptions.

Finding Reliable Parts Suppliers

Locating trustworthy suppliers for components is essential for maintaining equipment efficiency. A dependable source ensures not only quality but also timely delivery, which can significantly impact operational success. When searching for suppliers, consider several key factors to ensure you make informed choices.

- Reputation: Research potential vendors through online reviews and testimonials. A solid reputation among customers often indicates reliability.

- Certifications: Verify if suppliers have relevant certifications that guarantee quality standards. This is crucial for ensuring that components meet necessary specifications.

- Customer Support: Assess the level of support provided by suppliers. A responsive customer service team can be invaluable when issues arise.

- Price Comparison: Compare pricing across various suppliers to ensure you are getting a fair deal. However, be cautious of prices that seem too good to be true.

- Return Policy: Check the return policies to understand the process if components do not meet your expectations. A favorable return policy can provide peace of mind.

By focusing on these factors, you can identify suppliers who are reliable and capable of providing the necessary components for your equipment.

Comparing E160 with Other Models

This section explores the distinctions and similarities among various lawn care machines, focusing on performance, features, and overall efficiency. Understanding these differences can assist potential users in making informed decisions based on their specific needs and preferences.

When evaluating the machine in question against its counterparts, key aspects such as engine power, cutting capabilities, and user-friendly design come into play. While some models may offer advanced technology and additional attachments, others might excel in simplicity and ease of maintenance.

Ultimately, a thorough comparison allows buyers to identify which model best aligns with their landscaping requirements, ensuring optimal performance and satisfaction in their outdoor tasks.