In the world of utility vehicles, comprehending the intricate arrangement of components is essential for optimal performance and maintenance. This section delves into the various elements that contribute to the functionality of these versatile machines, providing a visual representation to enhance understanding. By exploring the layout and relationships between different parts, users can better appreciate how each segment operates in harmony.

Effective maintenance relies on a thorough grasp of the underlying structure. Familiarity with each segment enables operators to identify potential issues swiftly and address them before they escalate. This proactive approach not only prolongs the lifespan of the vehicle but also ensures a reliable performance in demanding tasks.

Moreover, a detailed overview of the components facilitates the search for replacements or upgrades, empowering users to make informed decisions. Whether for casual use or heavy-duty applications, understanding these elements is crucial for anyone looking to maximize the capabilities of their utility vehicle.

Understanding John Deere Gator 4×2

This section explores a versatile utility vehicle designed for efficiency and adaptability in various terrains. Known for its robust construction, it provides reliable performance in both agricultural and recreational settings. Users appreciate its functionality, which allows for easy transport of tools and materials, making it an essential asset in numerous applications.

Key Features

One of the standout attributes of this model is its exceptional maneuverability, allowing operators to navigate tight spaces with ease. The vehicle’s sturdy frame is complemented by an efficient engine, providing ample power for hauling and towing tasks. Additionally, the comfortable seating arrangement enhances the user experience, making long working hours more manageable.

Maintenance Considerations

Regular upkeep is crucial for sustaining optimal performance. Users should be aware of common components that require attention, such as the drivetrain and suspension system. Ensuring these elements are in top condition not only prolongs the vehicle’s lifespan but also enhances safety during operation. Emphasizing preventive measures can significantly reduce the likelihood of unexpected breakdowns.

Key Features of the 4×2 Model

This model stands out in its category due to a blend of innovative design and functionality, making it a versatile choice for various tasks. Its robust build ensures reliability, while the thoughtful integration of features enhances user experience and performance.

Powerful Performance

Equipped with a reliable engine, this vehicle delivers impressive power and torque, allowing it to handle heavy loads effortlessly. The efficient drivetrain maximizes fuel economy without sacrificing capability, ensuring optimal performance in diverse environments.

Enhanced Versatility

The adaptable cargo bed allows for easy transportation of tools, equipment, or supplies. With an intuitive control system, users can navigate various terrains with confidence, making it an ultimate choice for both work and leisure activities.

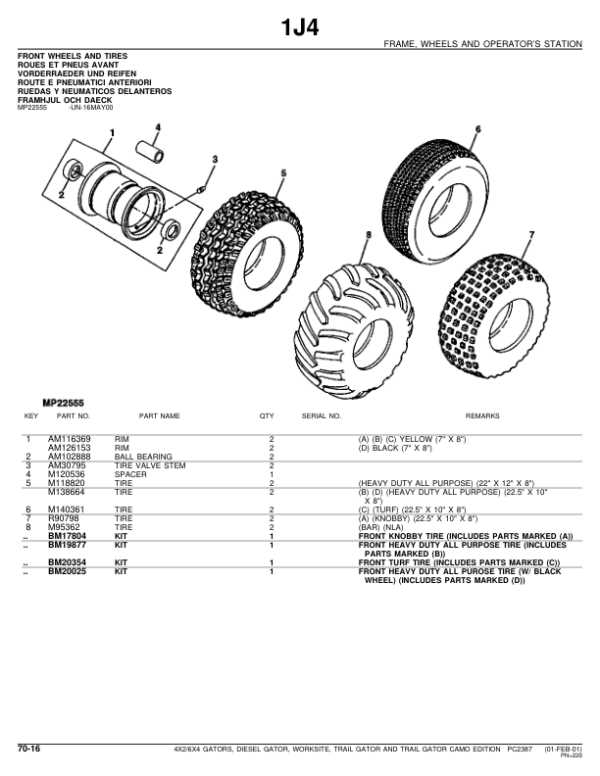

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repairs. Visual representations serve as invaluable resources, allowing users to identify individual elements, ensuring that every part functions optimally. This clarity aids in troubleshooting issues and enhances overall efficiency.

Benefits of Visual Aids

Visual aids simplify complex systems, making it easier for technicians and users alike to locate specific items. They enhance comprehension, leading to quicker resolutions during repairs and replacements.

Streamlining Maintenance Processes

Utilizing illustrations can significantly reduce downtime. By having a clear view of the assembly, users can prepare for maintenance tasks more efficiently and avoid unnecessary delays.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Clear identification of components and their functions. |

| Improved Efficiency | Quicker troubleshooting and repair processes. |

| Reduced Downtime | Faster preparation for maintenance tasks. |

Common Issues with Gator 4×2

Understanding the typical challenges faced by utility vehicles can greatly enhance maintenance and longevity. Various mechanical and operational concerns may arise, affecting performance and reliability. Awareness of these issues enables owners to take proactive measures for troubleshooting and repairs.

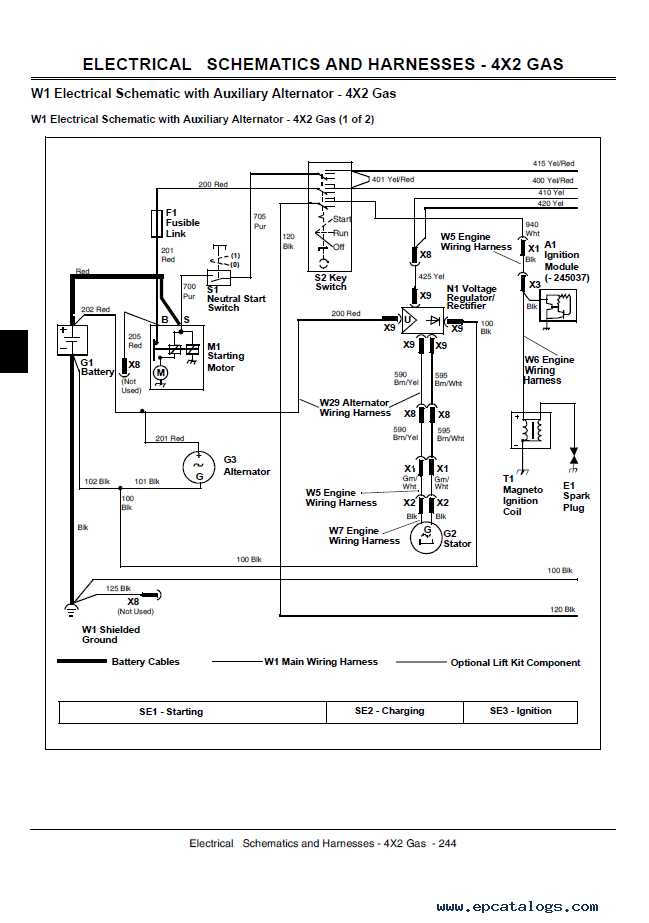

Electrical Problems

One of the most frequent complications involves the electrical system. Symptoms such as failure to start or intermittent power loss often indicate issues with the battery or wiring. Regular inspections and maintenance can help identify corroded connections or faulty components before they escalate into larger problems.

Transmission Troubles

Transmission difficulties can significantly hinder functionality. Common signs include slipping gears or unusual noises during operation. Ensuring proper fluid levels and addressing leaks promptly can mitigate wear and prolong the life of the transmission system. Regular servicing is essential for maintaining optimal performance.

Essential Components for Maintenance

Regular upkeep of utility vehicles is crucial for ensuring optimal performance and longevity. By understanding the key elements involved in maintenance, owners can effectively address potential issues before they escalate. This section highlights the fundamental components necessary for maintaining these versatile machines.

Key Maintenance Parts

Crucial components include filters, fluids, and belts. Filters help keep the engine clean, while proper fluid levels ensure smooth operation. Additionally, belts are vital for the functionality of various systems, requiring regular inspection and replacement as needed.

Tools for Effective Upkeep

Having the right tools on hand can significantly ease the maintenance process. Wrenches, screwdrivers, and diagnostic equipment are essential for addressing common repairs. Investing in quality tools not only saves time but also enhances the overall efficiency of maintenance tasks.

Where to Find Parts Diagrams

Locating visual schematics for specific machinery can significantly aid in maintenance and repair tasks. These illustrations provide a clear view of the components involved, helping users understand the assembly and disassembly processes more efficiently.

Here are several effective sources to obtain these valuable resources:

- Manufacturer Websites: Many companies provide downloadable resources directly on their official sites, including detailed visual guides.

- Online Retailers: Various online stores that sell machinery often host sections with diagrams to assist customers in identifying compatible components.

- Repair Manuals: Physical or digital repair manuals frequently contain comprehensive illustrations and descriptions that are beneficial for both novice and experienced users.

- Forums and Community Groups: Online forums dedicated to specific brands or types of equipment can be excellent places to find shared resources from fellow enthusiasts.

- YouTube Tutorials: Many content creators produce videos that not only show the machinery in action but also display parts and their configurations, which can serve as a useful reference.

Utilizing these resources can streamline your repair and maintenance efforts, ensuring that you have the correct information at your fingertips.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to addressing common issues encountered in utility vehicles. By following these organized steps, you can ensure that maintenance and repairs are performed efficiently and effectively, restoring functionality and enhancing the longevity of your vehicle.

Preparation and Safety Measures

Before beginning any repair, it is crucial to prepare the workspace. Ensure that you have all necessary tools at hand, including wrenches, screwdrivers, and safety gear. Always disconnect the power source to avoid accidents, and familiarize yourself with the vehicle’s manual for specific instructions related to your model.

Step-by-Step Repair Process

1. Identify the Problem: Start by diagnosing the issue. Listen for unusual noises, check for leaks, and inspect components for wear or damage.

2. Disassemble Affected Areas: Carefully remove any panels or parts obstructing access to the faulty components. Keep track of all screws and fasteners to ensure easy reassembly.

3. Replace or Repair Parts: Depending on the diagnosis, either replace the damaged parts or perform necessary repairs. Always use high-quality replacements to maintain performance.

4. Reassemble: Once repairs are complete, reattach all removed components in the reverse order of disassembly. Ensure everything is securely fastened and in the correct position.

5. Testing: After reassembly, reconnect the power source and conduct a thorough test. Check all functions to confirm that the repairs have resolved the issue.

6. Final Checks: Conduct a visual inspection to ensure that all tools are removed from the workspace and that no components were left loose. Proper maintenance will prolong the life of your utility vehicle.

Tips for Identifying Parts

Accurately recognizing components of machinery can enhance maintenance efficiency and ensure optimal performance. Familiarity with common identifiers and systematic approaches can make this process smoother.

Utilizing Reference Materials

- Consult manufacturer manuals for detailed descriptions.

- Explore online resources for visual aids and specifications.

- Join forums or communities focused on machinery for shared insights.

Visual Identification Techniques

- Examine shape and size for distinguishing characteristics.

- Look for serial numbers or model codes on components.

- Compare suspected items with known examples to confirm matches.

Upgrading Your Gator 4×2

Enhancing your utility vehicle can significantly improve its performance and functionality. Whether for work or leisure, thoughtful upgrades can transform your ride into a more efficient and enjoyable machine. This section will explore various options to elevate your vehicle’s capabilities.

Performance Enhancements

Consider modifying the engine and suspension for better handling and power. Upgrading to a high-performance air filter and exhaust system can boost efficiency, while enhancing the suspension will provide a smoother ride over rugged terrains. Investing in quality components is key to achieving the ultimate performance.

Utility Accessories

Adding accessories such as cargo beds, winches, and toolboxes can expand your vehicle’s utility. These enhancements not only increase storage options but also make your vehicle more versatile for various tasks. Customization allows you to tailor your ride to suit your specific needs, ensuring it meets your expectations on every outing.

Safety Precautions When Repairing

When undertaking maintenance or repairs on utility vehicles, ensuring safety is paramount. Proper precautions not only protect the individual performing the work but also safeguard the equipment from potential damage. Following guidelines can help mitigate risks associated with mechanical tasks.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Ensure the vehicle is turned off and parked on a stable surface before starting any work.

- Use tools correctly and ensure they are in good condition to prevent accidents.

- Keep the work area clean and organized to avoid tripping hazards.

By adhering to these safety measures, individuals can delve into repairs confidently, knowing they are taking the ultimate steps to ensure a safe working environment.

Comparing Parts with Other Models

Understanding the components of various utility vehicles can provide valuable insights for owners and enthusiasts alike. By examining how specific elements compare across different models, one can assess compatibility, performance, and maintenance requirements. This knowledge can be crucial for making informed decisions when it comes to repairs or upgrades.

Key Component Comparisons

When looking at different vehicles, it is essential to identify the key components that often show variance in design and functionality. Below is a comparison table highlighting some of the critical elements:

| Component | Model A | Model B | Model C |

|---|---|---|---|

| Engine Type | V-twin | Inline 4 | Single Cylinder |

| Transmission | Automatic | Manual | CVT |

| Suspension System | Independent | Leaf Spring | Multi-Link |

Implications of Differences

The distinctions in these components can significantly affect the vehicle’s performance, handling, and overall user experience. For instance, a model with a V-twin engine might provide more torque for heavy-duty tasks, while one equipped with a CVT may offer smoother acceleration. By comparing these aspects, users can better understand the strengths and weaknesses of their vehicles relative to others on the market.

Using OEM vs. Aftermarket Parts

The choice between original and alternative components can significantly influence performance and longevity. Each option offers distinct advantages and drawbacks that can affect overall functionality.

- OEM Components:

- Manufactured by the original maker.

- Ensures perfect fit and compatibility.

- Typically comes with a warranty.

- Aftermarket Components:

- Produced by third-party manufacturers.

- Often more affordable, providing cost savings.

- Variety of options available, allowing for customization.

Ultimately, the decision should be based on individual needs, budget constraints, and desired outcomes. Evaluating both types can help users delve into which route best suits their requirements.

Benefits of Regular Maintenance

Regular upkeep of machinery and equipment plays a crucial role in ensuring optimal performance and longevity. By adhering to a consistent maintenance schedule, owners can significantly reduce the risk of unexpected failures and enhance the reliability of their units.

One of the primary advantages of routine servicing is improved efficiency. Well-maintained equipment operates more smoothly, consuming less energy and yielding better results. This efficiency translates into cost savings over time, as fuel and operational expenses decrease.

Additionally, regular maintenance helps to identify potential issues before they escalate into major problems. Early detection of wear and tear allows for timely repairs, minimizing downtime and extending the lifespan of the machinery. This proactive approach can lead to significant financial benefits and ensures that operations run without interruption.

Another key benefit is the safety of both the equipment and its operators. Regular inspections and servicing can prevent accidents caused by malfunctions, providing peace of mind to users. By prioritizing maintenance, businesses demonstrate a commitment to safety standards and protect their workforce.

Finally, consistent care of machinery can enhance resale value. Well-documented maintenance records serve as proof of proper handling, making the equipment more attractive to potential buyers. This can lead to a higher return on investment when it comes time to upgrade or sell.