The internal organization and interconnected systems of complex machinery play a vital role in ensuring peak performance. When examining the various elements that contribute to the functionality of modern equipment, it is essential to understand how individual sections interact to form a cohesive whole. This understanding can significantly enhance both maintenance and repair processes, ultimately extending the life of the machine.

Each mechanism is made up of crucial units that work together seamlessly, contributing to the overall operation. Whether it’s maintaining smooth motion, ensuring fuel efficiency, or providing stability, every detail matters. Knowing how to identify these essential pieces and understanding their relationships with one another can make a difference when fine-tuning or troubleshooting your equipment.

By breaking down the system into its key sections, we can gain insights into the purpose and placement of each component. This comprehensive overview allows users to better manage upkeep, prevent unexpected failures, and optimize performance, all while having a clear roadmap of the equipment’s

Understanding the Components of the S220

In this section, we will explore the key elements that make up the machinery, providing a better understanding of how various pieces work together. By recognizing the purpose and function of each unit, it becomes easier to maintain and ensure optimal performance.

Core Mechanical Structures

- Engine Assembly: The heart of the machine, responsible for generating the power necessary to drive operations.

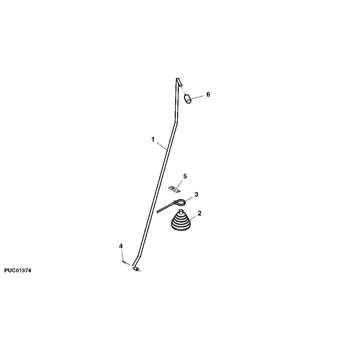

- Transmission System: This component ensures that power is efficiently transferred to the wheels, enabling smooth movement across different terrains.

- Cutting Deck: Designed to handle various conditions, this part adjusts to maintain consistent performance and precision.

Additional Functional Elements

- Hydraulic Controls:

Key Elements in John Deere S220 Machinery

Understanding the primary components of agricultural equipment is crucial for efficient maintenance and optimal performance. Each element plays a specific role in ensuring the overall system functions smoothly, enhancing productivity and longevity of the machine.

Core Mechanical Components

The machinery relies on several critical mechanical elements that contribute to its functionality. These parts ensure smooth operation and allow the equipment to handle demanding tasks in various conditions.

- Engine: The powerhouse of the machine, driving all key functions and providing the necessary energy for operation.

- Transmission: A vital part that regulates speed and power, enabling precise control during work.

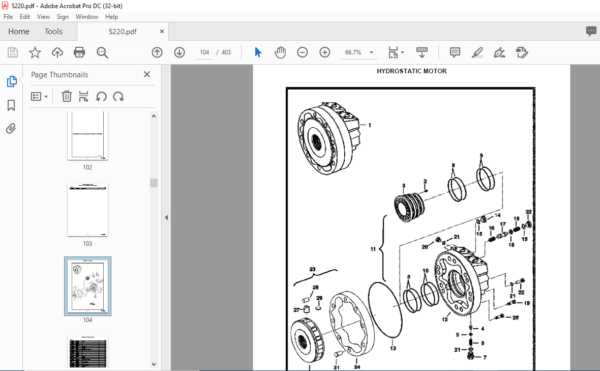

- Hydraulic System: This system powers attachments and adjusts operational settings, enhancing

Locating Vital Parts for Maintenance

Understanding the layout of key components is crucial for efficient upkeep. Proper identification of essential elements ensures that regular service can be carried out smoothly and accurately. By familiarizing yourself with the placement of these components, you can prevent delays and streamline your work.

Below is a helpful reference that outlines the primary elements and their respective locations to simplify your maintenance tasks:

Component Location Maintenance Frequency Engine Filter Front compartment, right side Every 200 hours Hydraulic System Rear compartment, left side Every 500 hours How to Identify Critical Parts

Understanding which components are essential to the smooth functioning of your machine is vital. The ability to identify the most crucial elements ensures that maintenance and repair efforts focus on preventing costly breakdowns. In this section, we will explore methods to recognize these key elements efficiently.

Visual Cues for Essential Components

Many critical elements often stand out due to their placement or wear indicators. Look for signs such as frequent usage or higher

Ensuring Compatibility with Replacement Parts

When selecting new components for a machine, it is crucial to ensure that each element integrates smoothly with the existing system. Compatibility is key to maintaining optimal performance and preventing issues that may arise from mismatched replacements.

Understanding the Original Setup

The first step in finding the right replacements is to have a thorough understanding of the machine’s original configuration. This includes recognizing the dimensions, materials

Exploring Commonly Replaced S220 Elements

In any heavy-duty machinery, certain components naturally experience more wear and tear over time, necessitating regular replacement. Understanding which parts tend to need the most attention helps operators maintain efficient and smooth operation, reducing potential downtime. This section delves into the most frequently updated elements, offering insights on their role and importance in the overall system.

High-Wear Components

- Filters: Air and fuel filters are often among the first to require replacement. Their role in protecting the engine from contaminants makes them critical for overall performance.

- Blades:

Efficient Maintenance through Proper Part Selection

Effective upkeep of machinery relies on the thoughtful choice of components that ensure long-term performance and reliability. By carefully evaluating each element, users can prevent unexpected issues and minimize the frequency of repairs, leading to a smoother operation and prolonged lifespan of equipment.

Key Considerations for Optimal Component Selection

To make informed decisions, it is crucial to focus on compatibility, durability, and availability. Ensuring that all replacements are suited for the specific system guarantees seamless integration and reduces the risk of malfunction. Durability is equally important, as higher-quality materials tend to withstand wear and tear better, resulting in less frequent changes.

Factor Importance Compatibility Ensures smooth integration and function Guidelines for S220 Component Upgrades

When considering enhancements for your equipment, it is essential to focus on the performance and efficiency of various elements. Upgrading specific components can lead to improved functionality and longevity, making your machine more effective in its operations.

Research Compatibility: Before proceeding with any upgrades, it is crucial to investigate whether the new components are compatible with your existing system. Understanding the specifications of both the current and potential parts will help you make informed decisions.

Prioritize Quality: Investing in high-quality components is vital for ensuring optimal performance. While it may be tempting to opt for cheaper alternatives, low-quality parts can lead to frequent repairs and decreased efficiency in the long run.

Consult Professionals: Engaging with experts in the field can provide valuable insights into the best upgrade options for your needs. Professional advice can guide you in selecting components that enhance functionality without compromising the integrity of your equipment.

Plan for Installation: Proper installation is critical to the success of any upgrades. Ensure that you have the necessary tools and knowledge or seek professional assistance to guarantee that the components are installed correctly.

Monitor Performance: After completing the upgrades, regularly monitor the performance of your equipment. This will help you identify any issues early on and make further adjustments as needed, ensuring that your enhancements deliver the desired results.

Troubleshooting Malfunctions in S220 Systems

Identifying and resolving issues within machinery systems is essential for maintaining optimal performance and longevity. This section focuses on common problems encountered in various components and offers practical solutions to ensure efficient operation.

Common Issues and Solutions

One frequent challenge involves irregular operation or failure to start. Inspecting the power supply is the first step; ensure that connections are secure and the battery is adequately charged. If the issue persists, consider examining the ignition components, as wear and tear can lead to insufficient spark generation.

Maintenance Tips for Optimal Functionality

Routine maintenance plays a crucial role in preventing malfunctions. Regularly cleaning air filters and checking fluid levels can help avoid overheating and ensure proper air intake. Additionally, inspecting belts and hoses for signs of wear can prevent potential breakdowns and extend the lifespan of the equipment.

Finding Genuine Parts for John Deere S220

Locating authentic components for your equipment is essential for maintaining its performance and longevity. Genuine elements ensure optimal functionality and compatibility, reducing the risk of malfunctions. When searching for replacements, it is important to consider reliable sources that guarantee the quality of the items offered.

One effective approach is to utilize authorized retailers and certified dealers, as they typically provide a selection of original components. These sources often have knowledgeable staff who can assist in identifying the right items for your specific model. Additionally, exploring the manufacturer’s official website can provide valuable insights and direct links to trustworthy suppliers.

Online marketplaces can also be useful; however, exercising caution is necessary. Always verify the credibility of the sellers and ensure that the components meet the required specifications. Checking customer reviews and ratings can provide further assurance of quality.

For those who prefer a hands-on approach, visiting local stores specializing in equipment can be beneficial. Engaging with professionals in these establishments can lead to personalized recommendations and guidance. Building relationships with these suppliers can also enhance your experience and provide ongoing support for future needs.

Lastly, consider joining online forums or communities dedicated to equipment enthusiasts. These platforms often share valuable information regarding where to find quality components and can offer firsthand experiences from fellow users. Engaging with these communities can enhance your knowledge and assist in making informed decisions.

Understanding the Role of Each Part

Every component within a machine contributes significantly to its overall function and efficiency. Recognizing how these elements interact can enhance maintenance and improve performance. By examining the various sections, we can appreciate their individual responsibilities and the collective impact they have on the operation.

Component Function Engine Drives the machine, providing power for various operations. Transmission Transfers power from the engine to the wheels, allowing for movement and speed control. Chassis Provides the structural framework that supports the entire machine. Control Panel Enables the operator to manage and monitor the functions of the equipment. Wheels Facilitates mobility, allowing the equipment to navigate various terrains.