In the world of agricultural equipment, having a clear representation of the various elements that make up a machine is crucial. These visual guides serve as invaluable resources for operators and technicians alike, simplifying the process of identifying and accessing individual components. By comprehending how these parts interact and connect, users can enhance their maintenance practices and ensure optimal performance.

Accurate visualization of machinery components not only aids in repairs but also contributes to a deeper understanding of the equipment’s functionality. Each segment plays a specific role in the overall operation, and being able to recognize these parts can significantly reduce downtime during maintenance activities. This knowledge empowers users to tackle issues more efficiently, ultimately leading to better productivity in the field.

Furthermore, these detailed layouts can assist in the procurement of replacements, as users will know exactly what is needed when issues arise. A comprehensive grasp of the components fosters a proactive approach to maintenance, allowing for timely interventions before problems escalate. This resource is essential for anyone looking to maximize the longevity and efficiency of their agricultural machinery.

This section addresses frequent challenges encountered with specific machinery and provides practical remedies to enhance performance and longevity. Understanding typical problems can aid in prompt identification and resolution, ensuring efficient operation.

Frequent Challenges

- Engine performance issues

- Unresponsive controls

- Inconsistent cutting height

- Fuel efficiency concerns

- Excessive vibration during operation

Practical Solutions

- Regularly check and replace air filters to maintain optimal airflow.

- Inspect electrical connections to ensure controls are functioning correctly.

- Adjust cutting height settings based on the terrain and grass type.

- Monitor fuel levels and use high-quality fuel to improve efficiency.

- Examine and tighten loose components to reduce vibrations during use.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process when you know where to look. Many resources are available to help you find the necessary items to keep your machinery running smoothly. By exploring various options, you can ensure that you get the right replacements efficiently and at a competitive price.

Online Retailers

One of the most convenient ways to source components is through online vendors. Numerous websites specialize in providing a wide array of items for various machinery types. These platforms often feature detailed descriptions, customer reviews, and images to assist you in making informed choices.

Local Dealerships

Visiting local dealerships can also yield beneficial results. Authorized dealers typically carry a comprehensive selection of equipment items and can offer expert advice. Additionally, they may provide warranties or guarantees on the components they sell, ensuring peace of mind with your purchase.

Benefits of Using Original Parts

Choosing authentic components for machinery maintenance can significantly improve the longevity and efficiency of the equipment. These elements are specifically designed to fit perfectly, ensuring that the machine operates at its optimal level without unnecessary strain or wear.

High-quality materials used in original components guarantee better performance and durability. Unlike generic alternatives, these items are manufactured to meet the highest standards, making them more reliable for long-term use.

Another advantage is the compatibility of genuine components, which eliminates the risk of malfunction due to improper fitting. This ensures smoother operation and reduces the likelihood of breakdowns, which can save time and money in repairs.

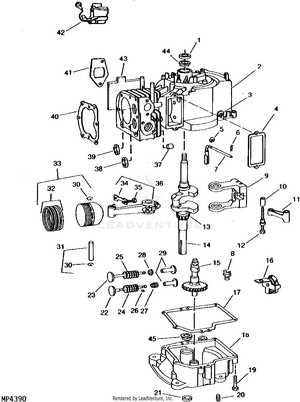

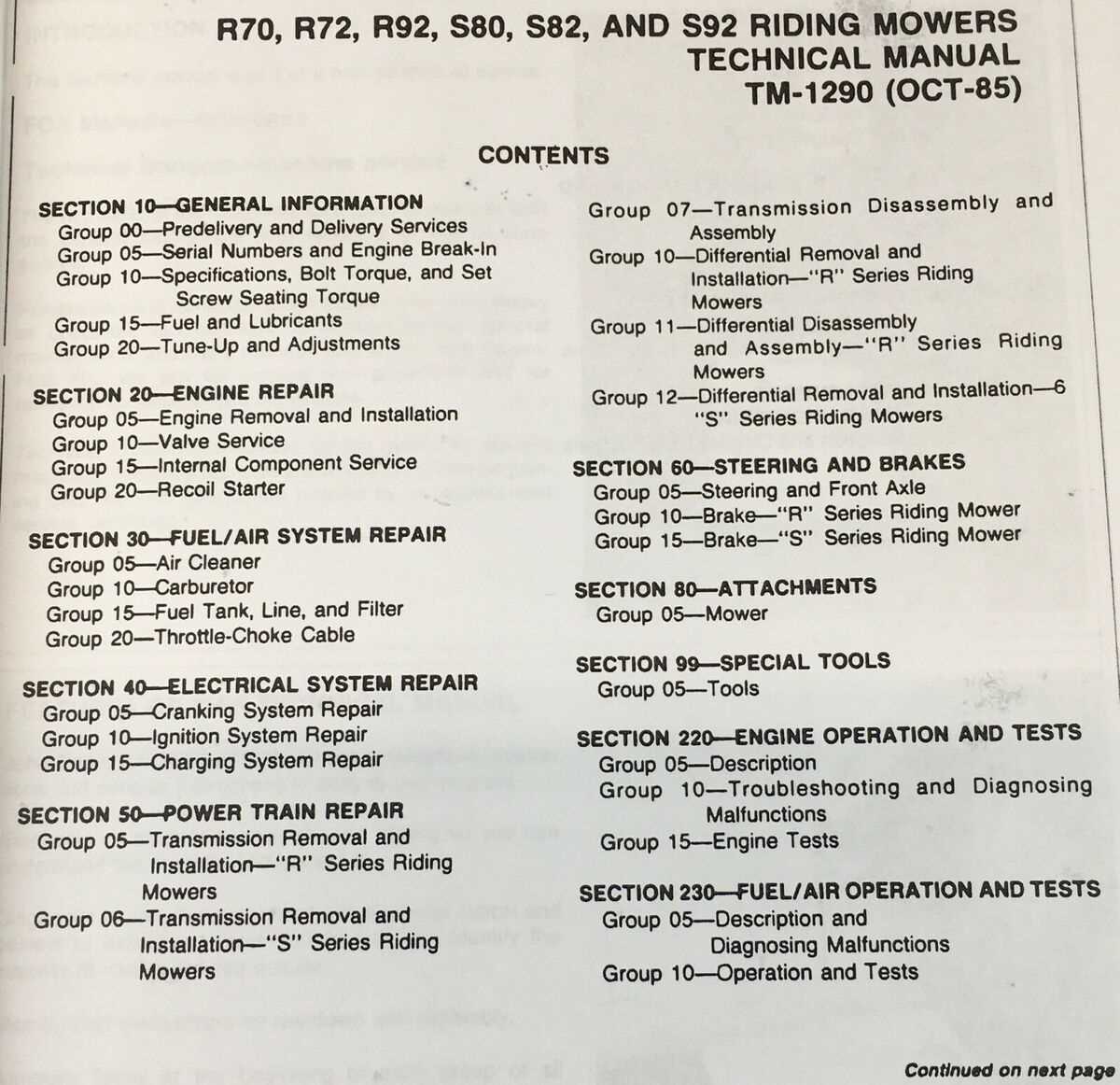

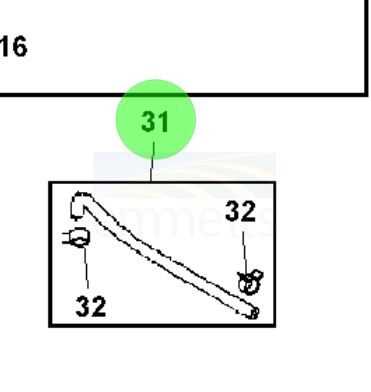

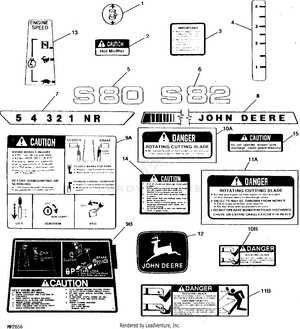

Visual Guide to S82 Parts

In this section, we provide a detailed overview of the essential components that make up this specific piece of machinery. Each element plays a vital role in ensuring smooth functionality and long-term reliability. By understanding these key elements, users can easily perform maintenance and repairs with confidence.

Main Components and Their Functions

The primary mechanical elements include various moving and fixed pieces designed for optimal performance. Each unit is carefully engineered to handle specific tasks, contributing to the overall efficiency of the machine. Learning the position and role of these components helps in identifying potential issues early.

How to Identify Critical Elements

Recognizing the critical elements is crucial for anyone working with the equipment. Familiarizing yourself with their placement and purpose will streamline the maintenance process, ensuring that everything runs smoothly and efficiently.

Frequently Asked Questions

In this section, we provide clear answers to common inquiries regarding equipment maintenance and component replacements. These questions aim to assist users in addressing typical concerns and understanding how to manage their machinery effectively.

What should I do if my machine isn’t functioning properly?

If your machine is not operating as expected, it is crucial to first check for any visible signs of wear or damage. Ensure all components are securely connected and inspect for any missing or malfunctioning elements that might affect performance.

How often should routine maintenance be performed?

Regular maintenance should be conducted according to the manufacturer’s recommendations, typically after a set number of operational hours. Frequent inspections and timely upkeep can prevent unexpected breakdowns and extend the lifespan of your machinery.