When it comes to maintaining and operating high-quality outdoor machinery, having a clear overview of its essential components is crucial. Each element plays a vital role in ensuring optimal performance and longevity. This section will provide valuable insights into the various parts and their functions, offering a comprehensive guide to enhancing your understanding of your equipment.

By familiarizing yourself with the specific elements that make up your lawn machinery, you can more effectively troubleshoot issues and perform necessary maintenance. This knowledge not only improves efficiency but also aids in making informed decisions regarding repairs and replacements. The following details will serve as a helpful reference for anyone looking to deepen their grasp of these integral mechanisms.

Moreover, recognizing the relationship between different components will empower you to undertake preventative measures, ultimately leading to a more reliable and durable machine. The insights shared here will be beneficial for both novices and seasoned users alike, as understanding the intricacies of your machinery can greatly enhance its performance and lifespan.

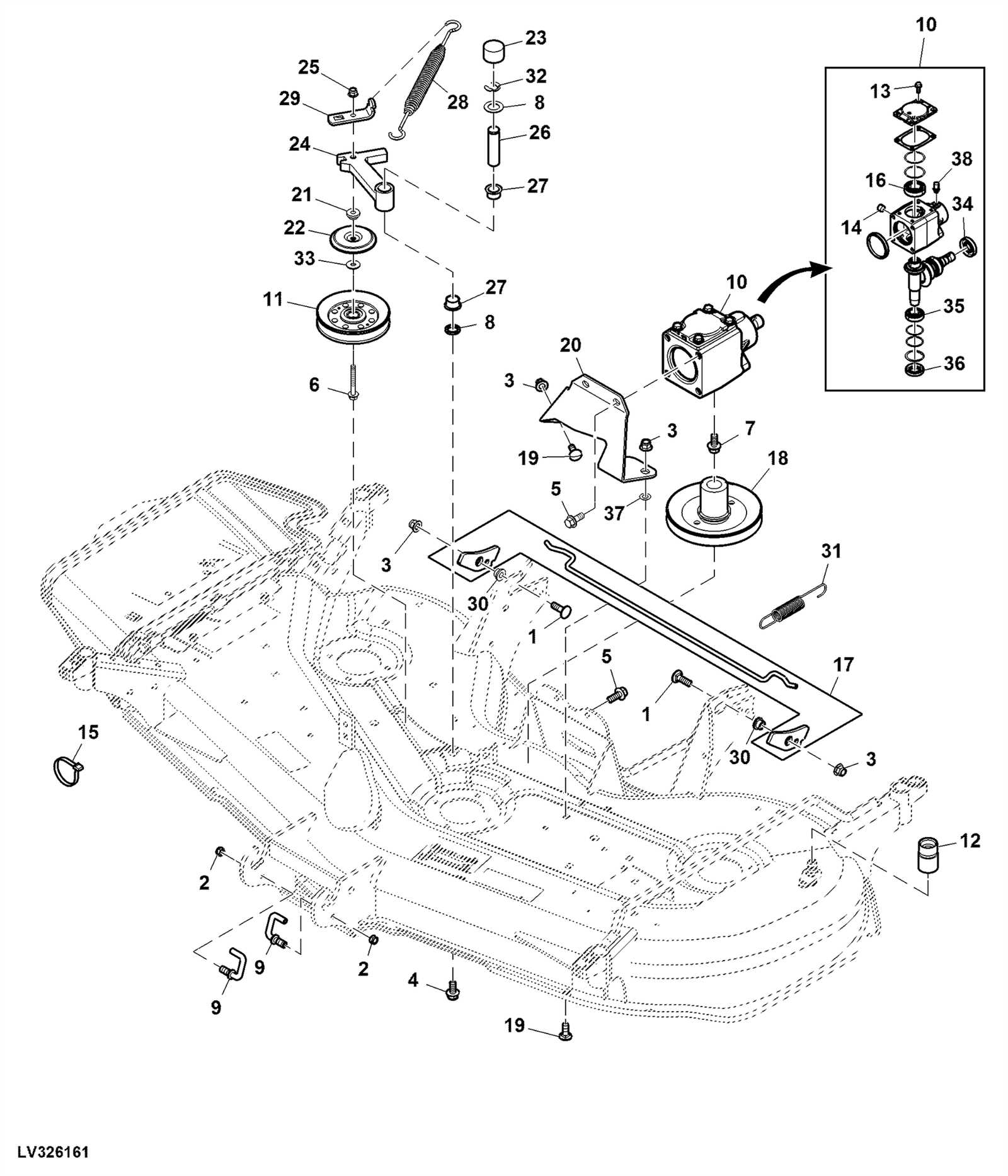

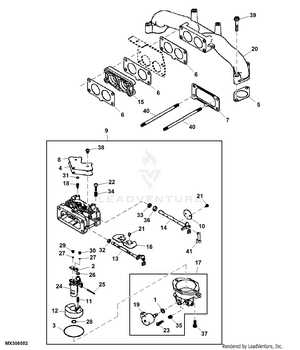

Understanding the visual representation of components is essential for efficient maintenance and repair. This guide will help you navigate through the various elements presented in the illustration, enabling you to identify each section and its corresponding features effectively.

Typically, these visual aids are organized systematically, with each component labeled clearly. Familiarizing yourself with the layout will enhance your ability to locate the necessary items quickly. Below is a basic outline to help you interpret the illustration:

| Label | Description |

|---|---|

| A | Indicates the main assembly group. |

| B | Shows the connecting elements. |

| C | Represents the specific parts needed for assembly. |

| D | Denotes the operational features. |

By following these guidelines and referencing the corresponding labels, you will be better equipped to tackle any maintenance tasks confidently.

Common Repairs and Parts Replacement

Regular maintenance and timely replacements are essential for the longevity and efficiency of outdoor equipment. Understanding typical repairs can help operators effectively manage their machinery and minimize downtime. This section outlines some frequent repair tasks and the components that often require replacement, ensuring your equipment operates smoothly.

Typical Repair Tasks

Some of the most common maintenance activities include replacing worn-out components, adjusting settings, and lubricating moving parts. For example, blades might need sharpening or replacing to maintain optimal cutting performance. Additionally, routine checks on belts and filters can prevent larger issues down the line.

Essential Components for Replacement

Knowing which components may need replacement can save time and enhance productivity. Below is a table outlining key parts that are often replaced, along with their typical functions:

| Component | Function |

|---|---|

| Blades | Ensure clean and efficient cutting of grass or other vegetation. |

| Filters | Prevent debris from entering the engine, ensuring proper airflow and performance. |

| Batteries | Provide the necessary power to start the engine and operate electronic systems. |

| Belts | Transfer power from the engine to various components, affecting overall operation. |

Importance of Genuine Parts

Utilizing authentic components is crucial for ensuring optimal performance and longevity of machinery. These original items are specifically designed and manufactured to meet the exact specifications of your equipment, resulting in enhanced reliability and efficiency.

Benefits of Authentic Components

- Enhanced Performance: Genuine items provide better compatibility and functionality, leading to improved overall performance.

- Increased Durability: Original components are built to last, reducing the need for frequent replacements.

- Warranty Protection: Using authentic parts helps maintain the warranty of your machinery, safeguarding your investment.

Potential Risks of Imitation Parts

- Substandard Quality: Imitation items may not meet the same quality standards, potentially compromising the efficiency of the equipment.

- Increased Repair Costs: Poorly made components can lead to more significant damage, resulting in higher repair expenses.

- Reduced Safety: Non-genuine parts can pose safety risks, endangering both the operator and the equipment.

Visual Guide to Z930A Parts

This section provides an overview of the components related to a specific model of riding machinery. Understanding the different elements is essential for maintenance and repairs, ensuring optimal performance and longevity. A visual reference can greatly assist in identifying and locating each component.

Essential Components Overview

Each machinery model is equipped with a variety of essential parts that contribute to its functionality. From the cutting mechanism to the driving system, each element plays a critical role in the overall operation. Familiarity with these components allows users to effectively troubleshoot and service their equipment.

Component Reference Table

| Component | Description |

|---|---|

| Cutting Blade | Designed for efficient grass cutting and trimming. |

| Drive Belt | Transmits power from the engine to the wheels. |

| Fuel Tank | Stores the fuel required for engine operation. |

| Deck | Housing that contains the cutting blades and supports the entire assembly. |

| Wheel Assembly | Supports mobility and stability of the machine. |

Maintenance Tips for Z930A Owners

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also helps prevent costly repairs down the line. This section outlines effective strategies for owners to keep their machines in excellent condition.

Routine Checks and Adjustments

Conducting frequent inspections can significantly contribute to the reliability of your equipment. Focus on the following areas during your routine checks:

| Component | Maintenance Action | Frequency |

|---|---|---|

| Blades | Sharpen or replace | Every 25 hours of use |

| Oil Level | Check and refill | Every use |

| Air Filter | Clean or replace | Every 50 hours of use |

| Tires | Inspect and adjust pressure | Monthly |

Storage Practices

Proper storage is vital for maintaining the condition of your machinery. Ensure that your equipment is stored in a dry and sheltered area to protect it from the elements. Additionally, consider using protective covers to shield it from dust and debris.

Finding Z930A Parts Online

Locating components for your equipment can be a straightforward task if you know where to search. The internet offers a vast array of resources that can help you identify and acquire the necessary elements for maintenance or repairs. Utilizing various online platforms can streamline this process and ensure that you find the right items quickly.

Useful Online Resources

- Official Manufacturer Websites

- Third-Party Retailers

- Specialized Online Marketplaces

- Community Forums and Groups

Tips for Successful Searching

- Utilize specific keywords related to your needs.

- Check multiple sources to compare prices and availability.

- Read customer reviews to gauge the reliability of sellers.

- Consider the shipping options and return policies before making a purchase.

Installation Instructions for Key Parts

This section provides essential guidance for the installation of crucial components, ensuring proper functionality and performance. Following these instructions will help achieve a seamless assembly process, enhancing the overall efficiency of the equipment.

Preparation Steps

Before commencing the installation, gather all necessary tools and components. Ensure the work area is clean and organized to facilitate an efficient workflow. Familiarize yourself with the specific components to be installed, paying attention to any alignment markers or fitting requirements.

Installation Process

Begin by securing the main component in its designated location. Use appropriate fasteners and tighten them according to the specified torque settings. Double-check all connections and ensure they are snug yet not over-tightened, as this can cause damage. Once the primary part is in place, proceed to attach any ancillary components, following the sequence outlined in the user manual.

Final Checks: After installation, conduct a thorough inspection to confirm that everything is properly aligned and secure. Test the functionality of the system before returning it to regular use.

Frequently Asked Questions About Z930A

This section addresses common inquiries related to the specific model, focusing on essential information that users often seek. The following questions cover a range of topics, from maintenance to troubleshooting, providing clarity for current and prospective owners.

- What maintenance should be performed regularly?

Regular upkeep includes checking fluid levels, inspecting blades, and ensuring tires are properly inflated. Following a scheduled maintenance routine enhances performance and longevity.

- How can I troubleshoot common issues?

If experiencing difficulties, first check fuel levels and battery connections. Common problems may also include blade performance and cutting height adjustments.

- Where can I find replacement components?

Replacement components can be sourced from authorized dealers or trusted online retailers specializing in outdoor equipment.

- What are the recommended operating procedures?

To ensure safe and efficient use, always refer to the manufacturer’s guidelines. Familiarizing oneself with controls and features is crucial for optimal operation.

Resources for Z930A Parts Support

For those seeking assistance with components related to their mowing equipment, various resources can be invaluable. Accessing reliable information ensures that owners can maintain and repair their machinery efficiently.

Online platforms, including manufacturer websites, often provide detailed guides and user manuals, offering insights into compatible components and maintenance procedures. Additionally, engaging with forums and community groups dedicated to equipment enthusiasts can foster valuable exchanges of tips and experiences.

Furthermore, authorized service centers and local dealers serve as essential contacts for acquiring original replacement items. They not only offer products but also professional advice tailored to specific models. Utilizing these resources helps users enhance the performance and longevity of their machinery.