In the realm of power tools, comprehending the intricate layout of components is essential for effective maintenance and repair. A thorough analysis of each element allows users to identify potential issues and enhance the longevity of their equipment. This knowledge empowers operators to tackle repairs confidently, ensuring optimal performance during every project.

Exploring the various sections that make up these tools reveals the engineering behind their functionality. Each component plays a crucial role, contributing to the overall efficiency and reliability. By familiarizing oneself with these structures, users can better appreciate the craftsmanship involved and recognize the importance of quality in their equipment.

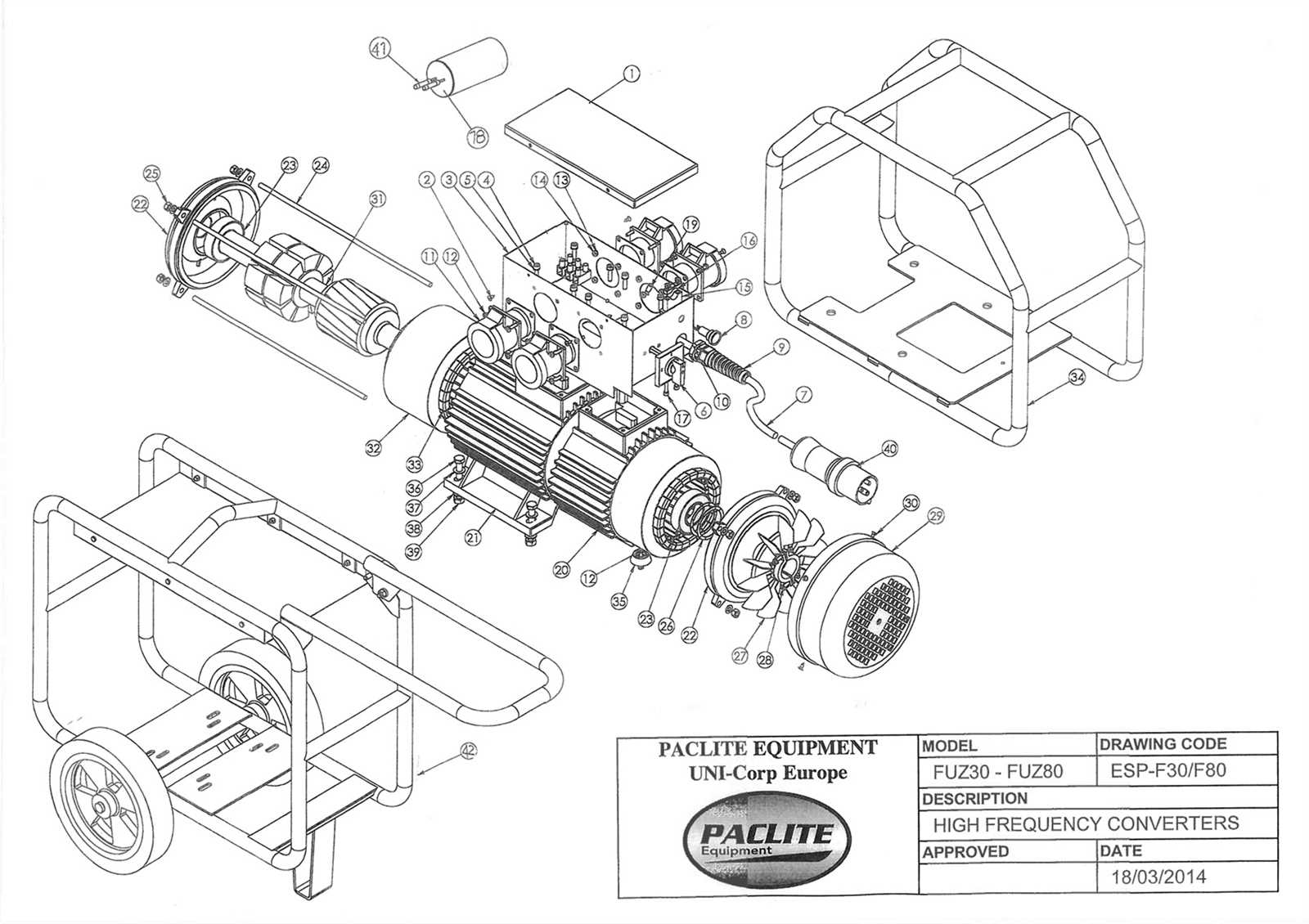

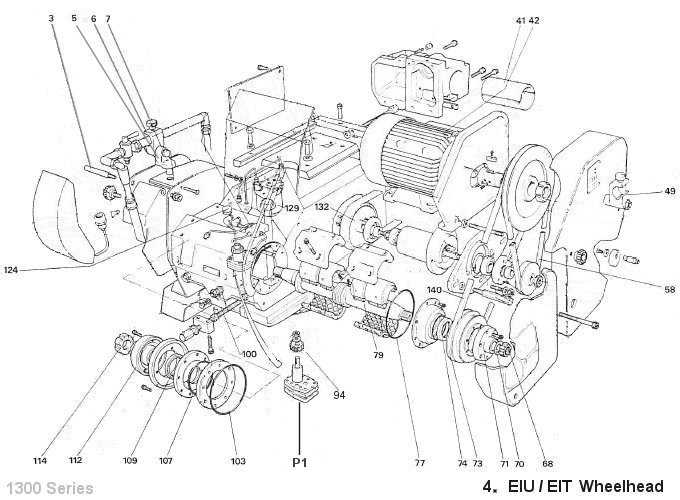

Moreover, having access to a visual representation of the assembly can significantly streamline the process of identifying parts. Such insights can assist both professionals and DIY enthusiasts alike in their endeavors, fostering a deeper understanding of how to maintain and troubleshoot their tools effectively. Emphasizing the need for such knowledge highlights its impact on performance and user experience.

Dewalt D55146 Overview

This section provides a comprehensive examination of a robust compressor model designed for efficient performance in various tasks. With a focus on reliability and user-friendliness, this equipment caters to both professionals and DIY enthusiasts, ensuring optimal results across a wide range of applications.

Key Features

Notable attributes include its powerful motor, which facilitates quick recovery times and sustained pressure levels. Additionally, the compact design enhances portability, making it suitable for job sites or home use. The durable construction ensures longevity, while safety features protect users during operation.

Applications

This versatile device is ideal for powering pneumatic tools, inflating tires, and completing various household projects. Its efficiency and ease of use make it an essential addition to any toolkit, ultimately streamlining workflows and enhancing productivity.

Importance of Parts Diagrams

Understanding the intricacies of machinery often requires visual aids that break down components into manageable sections. These illustrations serve as crucial references, facilitating the identification and organization of individual elements within a complex system. By providing a clear view of how each part interacts with others, they enhance comprehension and streamline maintenance processes.

Enhanced Troubleshooting

When issues arise, having a visual representation can significantly expedite the diagnostic process. Technicians can quickly locate the source of a problem by consulting these illustrations, allowing for more efficient repairs and reduced downtime. This clarity not only aids in identifying faults but also empowers users to perform routine checks with confidence.

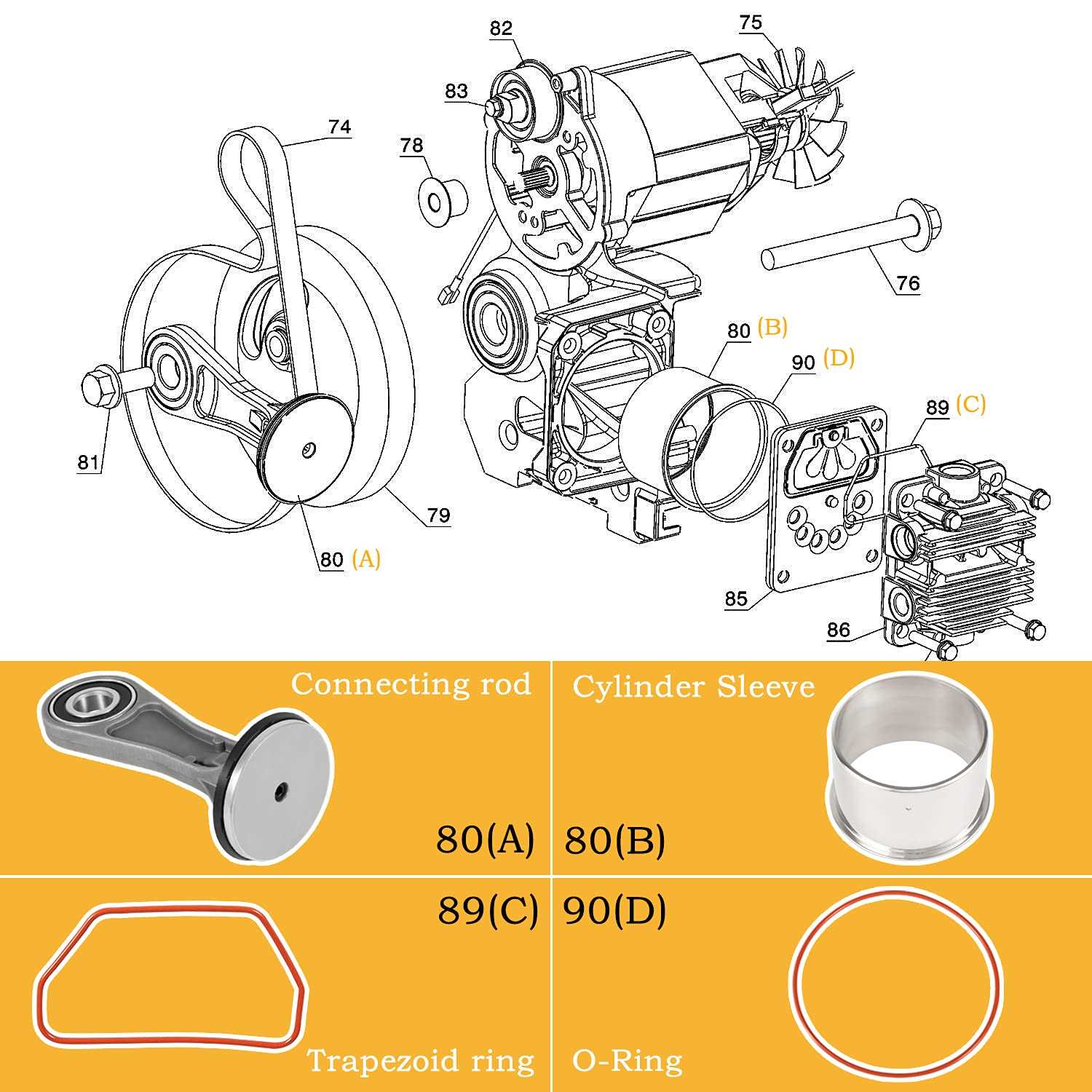

Facilitating Repairs and Upgrades

These visual guides are invaluable when it comes to disassembling and reassembling equipment. By following the layout provided, individuals can ensure that each component is returned to its correct position, minimizing the risk of errors. Furthermore, they assist in understanding compatibility for upgrades, making it easier to replace or enhance elements without compromising overall functionality.

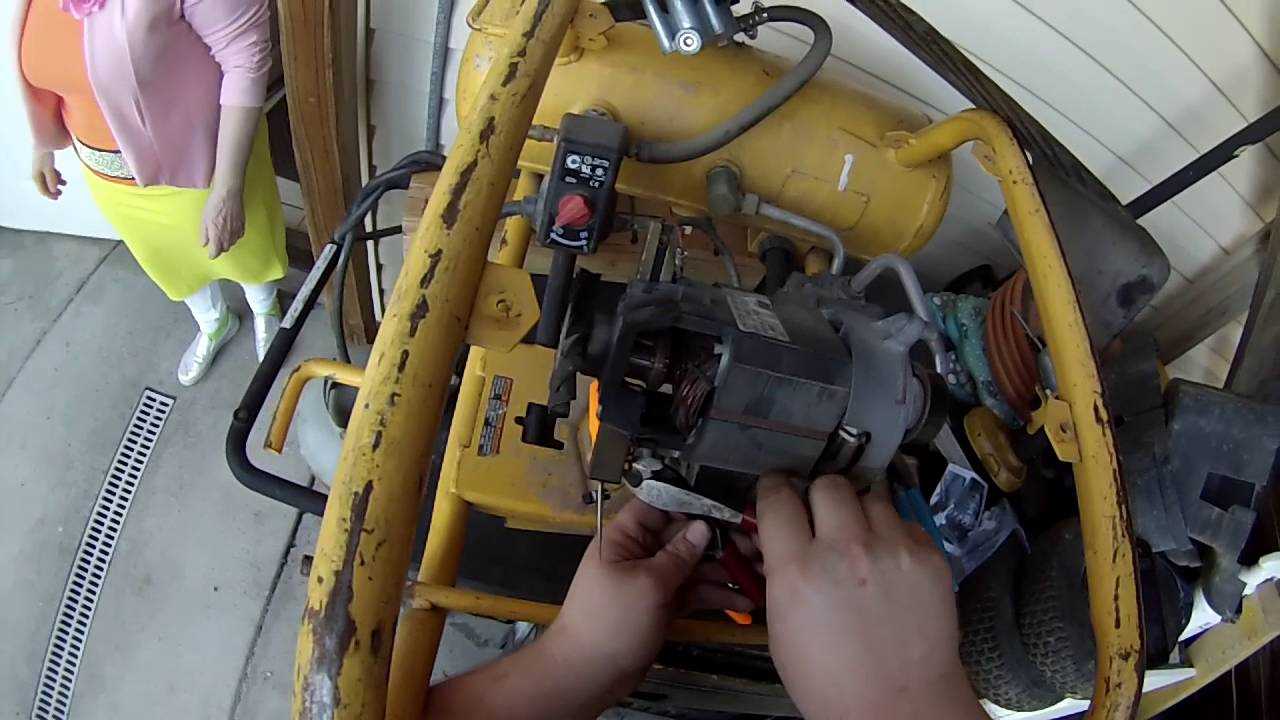

Common Issues with Dewalt D55146

Many users encounter typical challenges with their pneumatic tools, leading to performance issues and frustration. Understanding these common problems can help in troubleshooting and ensuring optimal functionality. Below are some prevalent concerns associated with these devices and potential solutions.

Air Leaks

One of the most frequent issues involves air leaks, which can significantly reduce efficiency. These leaks often occur in the hose or around fittings. Regular inspection and maintenance of connections can help identify and resolve these leaks before they impact performance.

Inconsistent Pressure

Users may also experience inconsistent air pressure, which affects the tool’s operation. This can stem from a malfunctioning regulator or a clogged filter. Ensuring that the regulator is functioning properly and replacing filters as needed can mitigate this problem, leading to smoother operation.

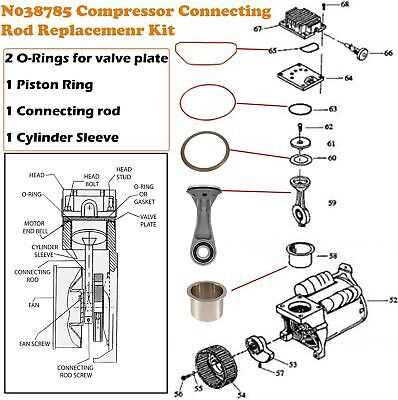

Identifying Replacement Parts

Understanding how to locate suitable components for your equipment is essential for maintaining its functionality and longevity. By recognizing key elements, users can efficiently source the necessary replacements without unnecessary complications.

Common Signs of Wear

Observing the operational performance can provide insights into which components may need attention. Look for signs such as unusual noises, decreased efficiency, or visible damage, which often indicate specific areas requiring new pieces.

Resources for Sourcing Components

Utilizing online resources and manufacturer catalogs can greatly simplify the process. Websites often feature comprehensive listings and images, enabling users to match their needs with available items accurately. Engaging with community forums can also yield valuable advice from experienced individuals.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment and ensuring optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and reliability over time.

Start by keeping the device clean and free from debris, as dirt can impede functionality. Regularly inspect and replace worn components to avoid further damage. Lubrication of moving parts helps reduce friction, promoting smoother operation.

Ensure that all connections are secure and check for any signs of wear or corrosion. Storing the equipment in a dry, sheltered environment protects it from the elements. Lastly, following the manufacturer’s guidelines for maintenance schedules can significantly contribute to the ultimate durability of your tools.

Where to Buy Parts Online

Finding replacement components for your equipment can be straightforward if you know where to look. Numerous online retailers specialize in providing high-quality items for various tools and machinery. These platforms not only offer a wide selection but also ensure that you can easily locate what you need with just a few clicks.

Start by exploring dedicated websites that focus on tool accessories and replacements. These sites often categorize items by brand and type, making it simpler to find specific components. Additionally, major online marketplaces frequently have a vast inventory of products, sometimes at competitive prices. It’s advisable to check user reviews and ratings to ensure the reliability of the parts you consider purchasing.

Moreover, manufacturer websites can be valuable resources for original components. They usually provide a comprehensive catalog, complete with detailed descriptions, ensuring you select the correct item for your requirements. For even more options, consider looking into third-party sellers who might offer compatible alternatives, often at a lower cost.

Lastly, don’t overlook local repair shops that might have an online presence. They can be an excellent source for parts, especially for older models, and may offer expert advice on installation and compatibility.

Understanding the Parts Layout

Comprehending the configuration of various components is essential for efficient maintenance and repair tasks. A well-organized overview allows users to quickly identify each element’s function and significance within the overall assembly. This knowledge not only aids in troubleshooting but also enhances the effectiveness of any service performed.

Identifying Key Components: Each section of the layout typically represents critical elements that work in unison. Recognizing these parts enables users to understand their roles and interactions. For instance, some pieces are designed for power generation, while others may be focused on air compression or delivery.

Functional Relationships: It is important to observe how these individual components relate to one another. Analyzing the connections can provide insights into potential issues and help in strategizing repairs or replacements. Understanding the flow of energy or material between parts can also improve overall performance.

Maintenance Considerations: Familiarity with the layout is invaluable when it comes to routine upkeep. Knowing which components require regular inspection or replacement can save time and enhance longevity. Users can proactively address wear and tear by referring to the layout as a guide.

In summary, a clear grasp of the arrangement of various elements not only supports effective repairs but also promotes better operational efficiency. By studying the configuration, users equip themselves with the knowledge needed for successful maintenance endeavors.

Safety Precautions During Repairs

When undertaking any maintenance tasks on tools and equipment, ensuring safety should be the top priority. Proper precautions can significantly reduce the risk of accidents and injuries, making the repair process smoother and more efficient.

Firstly, always wear appropriate personal protective equipment (PPE). This includes safety goggles to protect your eyes from debris, gloves to prevent cuts, and sturdy footwear to shield your feet. Taking these simple steps can safeguard you against common hazards associated with repair work.

Additionally, ensure that the workspace is clean and organized. A cluttered environment can lead to trips and falls, as well as misplacement of tools. Keep all necessary equipment within reach and securely store any unused items to minimize distractions and potential hazards.

Moreover, disconnect power sources before beginning any repairs. This simple action can prevent electric shock or unintended activation of machinery while you are working. Always double-check that the equipment is powered down and properly locked out to avoid accidents.

Lastly, familiarize yourself with the tools and their operating instructions. Understanding how each tool functions and the specific risks involved can help you navigate repairs more safely. If unsure about any procedure, consult the manufacturer’s guidelines or seek professional assistance.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and repair of tools. Here, you will find essential information to assist you in understanding your equipment better and ensuring its optimal performance.

-

What should I do if my tool is not functioning properly?

First, check the power source and connections. If the issue persists, consult the manual for troubleshooting tips or consider professional assistance.

-

How often should I perform maintenance on my equipment?

Regular maintenance is crucial. It is recommended to inspect and clean your tool after every use, and perform more thorough checks at least once a month.

-

Where can I find replacement components?

Replacement components can be found through authorized retailers, online stores, or directly from the manufacturer’s website. Ensure you have the model number for accurate matching.

-

Are there any safety precautions I should follow?

Always wear appropriate personal protective equipment, read the user manual carefully, and follow all safety guidelines provided to minimize risks during operation.

-

Can I upgrade my tool with new features?

Many tools have upgrade options available. Check the manufacturer’s website for compatible accessories or enhancements that can improve functionality.

Comparing with Similar Models

When evaluating tools within the same category, it’s essential to analyze key features and specifications that differentiate them. This comparison can highlight strengths and weaknesses, aiding in informed decision-making for potential buyers.

| Model | Power Output | Tank Size | Weight | Price |

|---|---|---|---|---|

| Model A | 5.0 HP | 4.5 gallons | 60 lbs | $299 |

| Model B | 4.5 HP | 4.0 gallons | 55 lbs | $279 |

| Model C | 5.5 HP | 6.0 gallons | 65 lbs | $329 |

By examining these models, consumers can better determine which option aligns with their specific needs, whether it be power, portability, or budget constraints.