Maintaining equipment often involves understanding its intricate systems and how various elements work together to ensure smooth operation. Identifying and familiarizing oneself with the essential mechanisms of a device allows for efficient troubleshooting, enhancing its longevity and performance. A clear understanding of how individual components contribute to the overall function is crucial for those looking to extend the life of their machinery.

Each machine consists of multiple interconnected elements, each playing a vital role in ensuring proper operation. From compressors to regulators and other internal mechanisms, recognizing these parts and their roles is essential for effective maintenance and repair. A detailed breakdown can offer a deeper insight into how all these elements interact, providing clarity and simplifying the repair process.

By analyzing the internal structure and organization of components, one can not only identify potential issues but also gain a better understanding of how to address common malfunctions. Familiarity with the layout and arrangement of these elements can significantly improve the ability to maintain, replace, or repair the necessary pieces when needed.

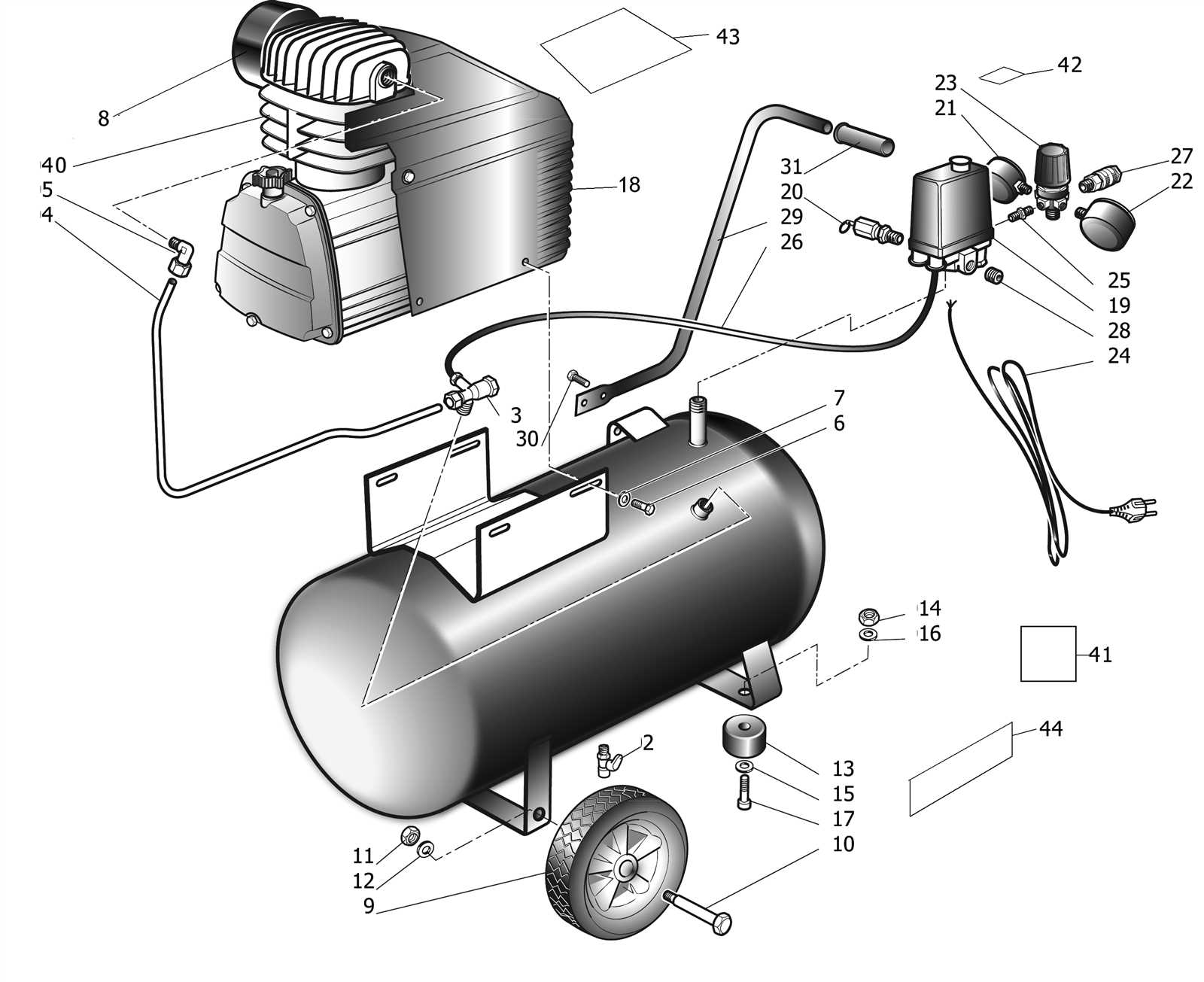

Dewalt D55168: Key Components Overview

This air compressor model is composed of several vital elements that work together to ensure optimal performance. Understanding the primary sections and their roles is crucial for both maintenance and troubleshooting. Below is a breakdown of the most significant features that contribute to its efficiency and longevity.

Main Structural Elements

- Compressor Tank: The large storage unit that holds pressurized air, designed to deliver consistent output during use.

- Regulator: Controls the pressure level by adjusting the air output according to the user’s needs.

- Pressure Switch: Automatically monitors and adjusts pressure levels to maintain stability and prevent overload.

Operational Mechanisms

- Motor: The driving force behind the entire system, responsible for powering the air compression process.

Understanding the Air Compressor Layout

An air compressor is composed of several interconnected components, each serving a vital role in converting power into compressed air. To fully grasp how these machines function, it’s important to explore the arrangement of their key elements. By understanding the layout, one can better maintain, troubleshoot, and optimize the performance of the entire system.

Main Components and Their Functions

The essential parts of an air compressor typically include the motor, pump, tank, and pressure control system. The motor drives the pump, creating the energy needed to compress the air. The pump, often located at the heart of the compressor, is responsible for drawing in and compressing the air. Once compressed, the air is stored in the tank, ready for use as needed. The pressure control

How to Identify Major Dewalt D55168 Parts

Understanding the key components of any air compressor is essential for proper maintenance and troubleshooting. Familiarizing yourself with the primary elements helps ensure that the equipment operates smoothly and efficiently. This section provides an overview of the most important mechanisms, highlighting their functions and how to recognize them within the system.

- Motor Assembly: The heart of the system, responsible for powering the compression process. Look for the unit connected to the main power source, often located near the base.

- Pressure Regulator: This device controls the air pressure delivered to tools. It typically features an adjustable knob and is positioned near the outlet where hoses attach.

- Tank: A large cylindrical container that stores compressed air. It is usually the most visible part of the machine, designed to hold high-pressure air until it is needed.

- Pressure Switch: Responsible for regulating the activation of the compressor when the pressure level changes.

- Check Valve: Prevents compressed air from flowing back into the pump, ensuring one-way air movement.

- Regulator: Helps control and adjust the output pressure, maintaining stable operation.

- Air Filter: Prevents debris and dust from entering the system, keeping internal parts clean and functional.

- Drain Valve: Allows for the release of moisture buildup, crucial for avoiding rust and water damage.

- Safety Valve: Automatically releases exc

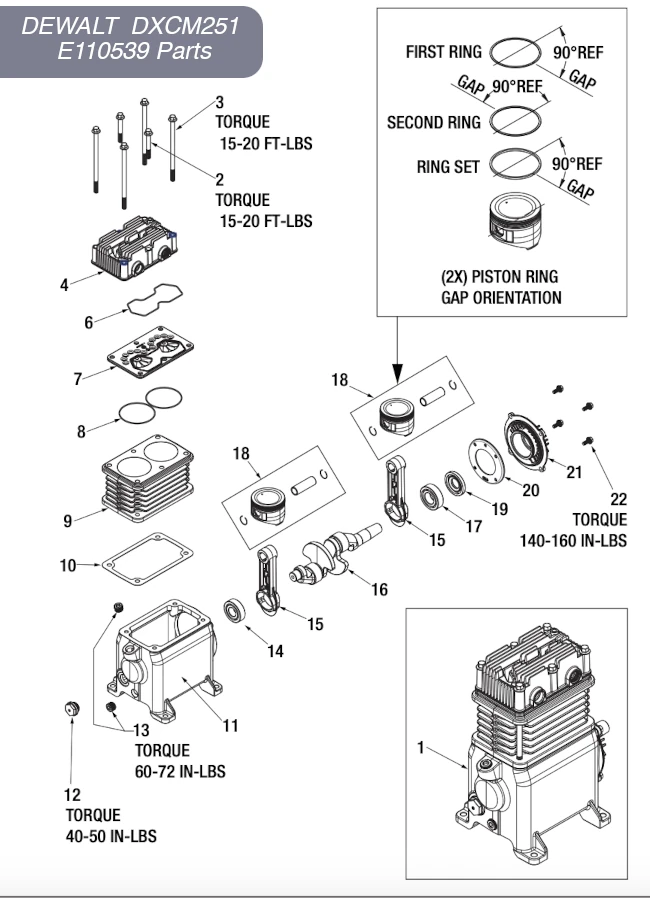

Exploring the Inner Mechanics of D55168

Understanding the intricate components of a powerful tool reveals the remarkable engineering that drives its performance. This section delves into the essential elements that contribute to the functionality and efficiency of this specific model. By examining the construction and interrelationships of its various parts, users can gain insights into its operation and maintenance.

Key Components and Their Functions

- Motor: The heart of the device, responsible for converting electrical energy into mechanical energy, facilitating optimal power output.

- Compressor: This element compresses air, creating the necessary pressure for various applications, ensuring reliable operation.

- Tank: Stores compressed air, allowing for sustained performance during use, contributing to efficiency and effectiveness.

- Regulator: Controls air pressure levels, ensuring consistent performance and preventing damage to connected tools.

- Fittings and Hoses: Enable the secure connection of accessories and facilitate the movement of compressed air to the tool.

Maintenance and Care Tips

- Regularly check and clean the air intake filter to maintain optimal airflow.

- Inspect all hoses and fittings for wear or leaks to prevent performance issues.

- Periodically drain the tank to remove moisture and prevent rust.

- Lubricate moving parts as recommended to ensure smooth operation.

By grasping the essential components and maintenance practices, users can maximize the longevity and performance of their tool. This understanding fosters a deeper appreciation for the craftsmanship involved in creating reliable and efficient equipment.

Troubleshooting Issues with Air Compressor Parts

Air compressors are essential tools that power various equipment and facilitate numerous tasks. However, like any mechanical device, they can experience issues that affect performance and efficiency. Identifying and addressing these problems promptly can save time and money while ensuring the tool operates smoothly.

Common issues may arise from factors such as inadequate airflow, unusual noises, or failure to build pressure. Understanding the underlying causes of these symptoms is crucial for effective diagnosis. For instance, clogs in the intake or discharge valves can hinder airflow, while worn components may lead to abnormal sounds. Regular maintenance, including checking for leaks and ensuring proper lubrication, can help mitigate these problems.

When troubleshooting, it’s important to approach each potential issue systematically. Start by inspecting the power source and connections, as electrical failures are a frequent cause of malfunctions. Next, examine the compressor’s settings and controls; improper adjustments can prevent optimal operation. If problems persist, disassembly of the unit may be necessary to investigate internal components such as the motor, tank, or pressure switch.

In conclusion, understanding common problems associated with air compressors and their potential causes is vital for effective troubleshooting. By adopting a methodical approach and performing regular checks, users can enhance the longevity and efficiency of their equipment.

Where to Buy Genuine D55168 Parts

Finding authentic components for your equipment is crucial for ensuring its optimal performance and longevity. Quality replacements not only enhance functionality but also provide peace of mind, knowing that your tools are fitted with reliable parts. Whether you’re looking to perform routine maintenance or undertake repairs, sourcing these items from reputable suppliers is essential.

There are several trusted avenues to explore when seeking original replacements. Below is a table summarizing the best options available, along with their key features:

Source Description Website Official Manufacturer Direct purchase ensures authenticity and warranty coverage. www.dewalt.com Authorized Dealers Retailers certified by the manufacturer, providing genuine items and customer support. www.dewalt.com/dealers Online Marketplaces Reputable e-commerce platforms can offer a variety of components, but verify seller ratings. www.amazon.com Local Hardware Stores Physical stores often carry a selection of reliable replacements; checking inventory beforehand is advisable. N/A By exploring these resources, you can confidently acquire the necessary components, ensuring your equipment continues to function at its best.

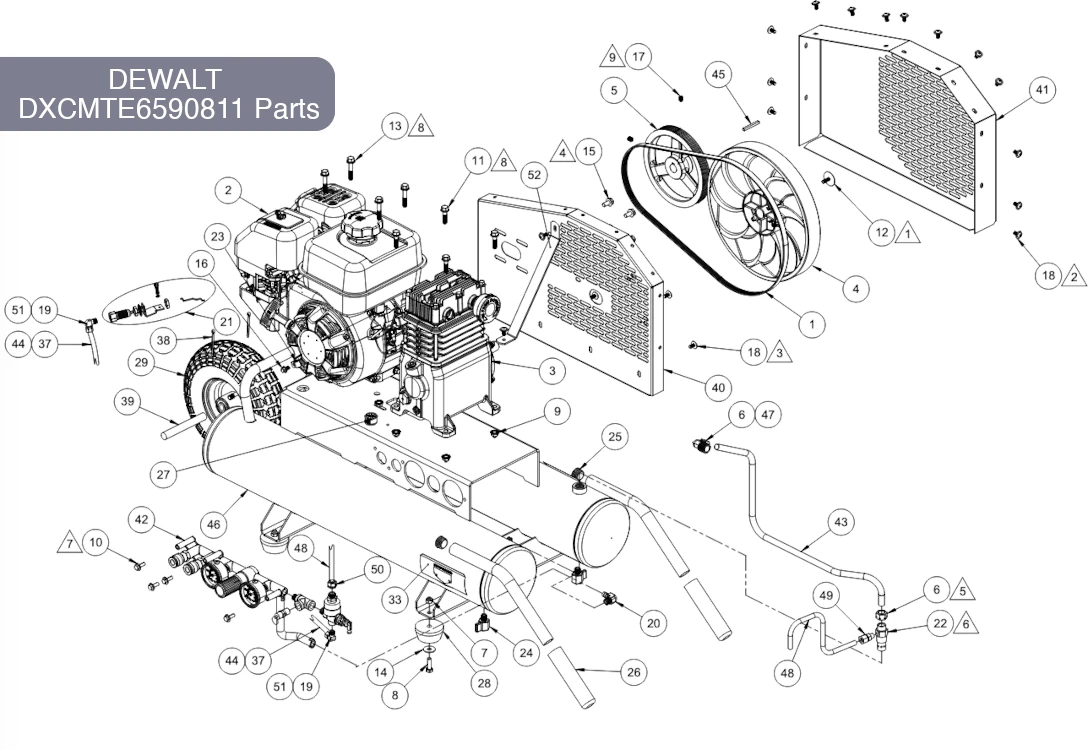

Comparing Dewalt D55168 Parts to Other Models

This section explores the distinctions and similarities among various components from a specific model and its counterparts in the market. Understanding these differences can help users make informed decisions regarding repairs, upgrades, and replacements. By analyzing the key features and designs, one can appreciate the engineering choices made for different tools and their implications for performance and usability.

Component Durability and Design

The robustness of components plays a crucial role in the overall longevity of power tools. When comparing the strength and build quality of elements from this particular model with those from its competitors, it becomes evident that variations exist in materials and construction techniques. Some brands may prioritize lightweight designs, while others focus on enhanced durability, affecting the tool’s performance in demanding conditions.

Interchangeability and Compatibility

Another significant aspect to consider is the interchangeability of components. While certain models may offer parts that can easily be swapped with other tools, others might have proprietary designs that limit compatibility. This can impact maintenance convenience and cost-effectiveness for users looking to source replacement items or perform upgrades. Evaluating compatibility not only affects repair options but also influences the overall investment in a tool ecosystem.

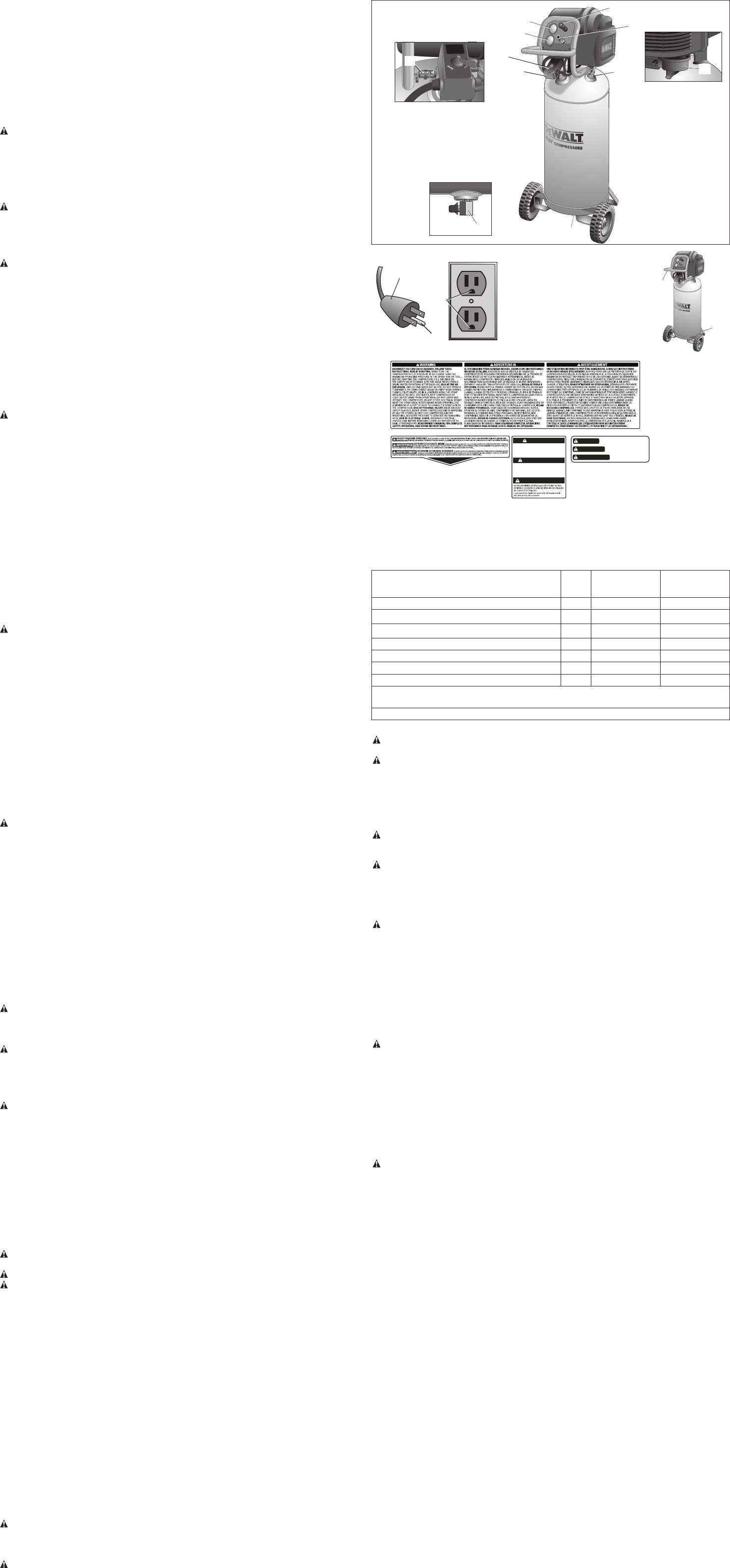

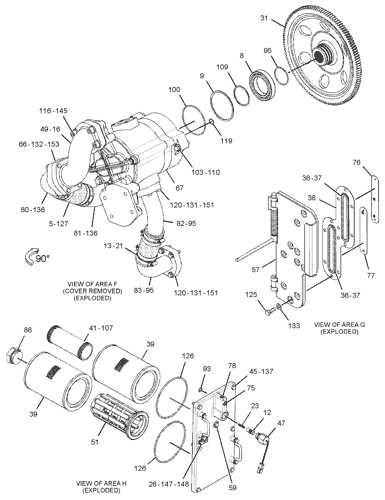

How to Read the D55168 Parts Diagram

Understanding the layout of components in machinery is essential for effective maintenance and repair. This section provides guidance on interpreting the visual representation of various elements, aiding users in identifying, sourcing, and replacing specific items as needed.

To effectively navigate the illustration, consider the following steps:

- Familiarize Yourself with the Legend: Most illustrations will include a legend or key that defines symbols and notations used throughout. Make sure to review this first to understand what each symbol represents.

- Identify Main Sections: Components are typically organized into categories or sections. Identify the major parts of the assembly, as this will help you focus on relevant areas during your inspection.

- Examine Numbering Systems: Many visual layouts utilize a numbering system to correlate with parts lists. Pay attention to these numbers as they can direct you to specific items for ordering or replacement.

- Note the Orientation: Look for indications of how components are oriented within the assembly. This can be crucial for proper installation or removal procedures.

- Refer to Supplementary Documentation: Often, additional manuals or guides are available that provide detailed descriptions of each component. Cross-reference these documents for clarity and deeper understanding.

By following these steps, users can enhance their comprehension of the mechanical layout and facilitate more efficient repairs or maintenance actions.

DIY Repairs for Dewalt D55168 Compressor

Maintaining and repairing your air compressor can extend its lifespan and enhance its performance. Whether you are experiencing minor issues or need to address significant malfunctions, knowing how to tackle common repairs can save you both time and money. This section will guide you through essential repair processes, equipping you with the knowledge to handle common problems effectively.

Identifying Common Issues

Before proceeding with any repair work, it is crucial to identify the symptoms your equipment is exhibiting. Common signs include unusual noises, leaks, or failure to start. Diagnosing these issues early can prevent further damage. Take the time to observe and listen closely; understanding the root cause will allow you to focus your efforts effectively.

Basic Repair Techniques

Once you have identified the issue, you can move on to repairing it. Simple fixes may involve tightening loose connections, replacing worn-out seals, or changing filters. Always refer to the manufacturer’s guidelines for specific components. If the problem persists after attempting these repairs, consider consulting a professional technician for a more thorough evaluation. Remember to use appropriate safety measures, such as disconnecting the power supply before starting any work.

In summary, familiarizing yourself with typical repair techniques can empower you to maintain your compressor effectively. A proactive approach to troubleshooting and fixing issues can lead to a smoother and more efficient operation.

Understanding Safety Features in D55168 Parts

Ensuring user safety is paramount when operating any power equipment. Manufacturers implement various mechanisms and components designed to minimize risks and protect the operator during use. This section delves into the critical safety features found in the assembly of the specified model, emphasizing their importance and functionality.

Key Safety Mechanisms

Several essential mechanisms are integrated to enhance the safety of the equipment. Understanding these features helps users appreciate their role in providing a secure working environment. The following are some key safety mechanisms:

- Pressure Relief Valve: This feature prevents excessive pressure buildup, reducing the risk of equipment failure and ensuring stable operation.

- Safety Lockout: A vital component that prevents accidental activation, this mechanism requires deliberate action to engage, minimizing unintentional starts.

- Guarding Shields: Protective barriers designed to shield users from flying debris and accidental contact with moving parts.

- Emergency Shut-Off: Easily accessible controls that allow for immediate power disconnection in case of emergencies, safeguarding the user from potential harm.

Importance of Regular Maintenance

Regular inspection and maintenance of these safety features are crucial for optimal performance and user protection. Consider the following maintenance tips:

- Check the functionality of the pressure relief valve regularly to ensure it operates correctly.

- Inspect the safety lockout mechanism for any wear and tear to guarantee reliable performance.

- Ensure that guarding shields are intact and securely attached to avoid accidents.

- Test the emergency shut-off function periodically to confirm it works as intended.

By prioritizing the understanding and maintenance of these safety features, users can significantly reduce the risk of accidents and enhance their overall experience with the equipment.

Essential Maintenance Tips for D55168 Components

Proper maintenance of your compressor unit ensures its longevity, optimal performance, and safety. Regular care and attention to key elements can help avoid costly repairs and downtime. Below are crucial recommendations for maintaining vital components to ensure your machine operates efficiently and reliably.

Regular Inspection and Cleaning

Ensure all external and internal parts are kept clean from dust and debris. Periodically check for any buildup around vents, hoses, and fittings. Accumulated dirt can impede airflow, causing the unit to overheat or operate inefficiently. Use a soft brush or compressed air to clear hard-to-reach areas.

Lubrication and Component Wear

Regularly lubricating moving parts, such as pistons and seals, prevents friction and prolongs the life of these elements. Follow the manufacturer’s guidelines for the appropriate lubricant and intervals. Simultaneously,

Common Replacement Parts for Dewalt D55168

When maintaining an air compressor, certain components are more prone to wear and tear, requiring periodic replacements to ensure optimal performance. Keeping an eye on these elements can extend the equipment’s lifespan and prevent unexpected breakdowns. Below is a list of the most frequently swapped out components, all essential for ensuring efficient functionality.