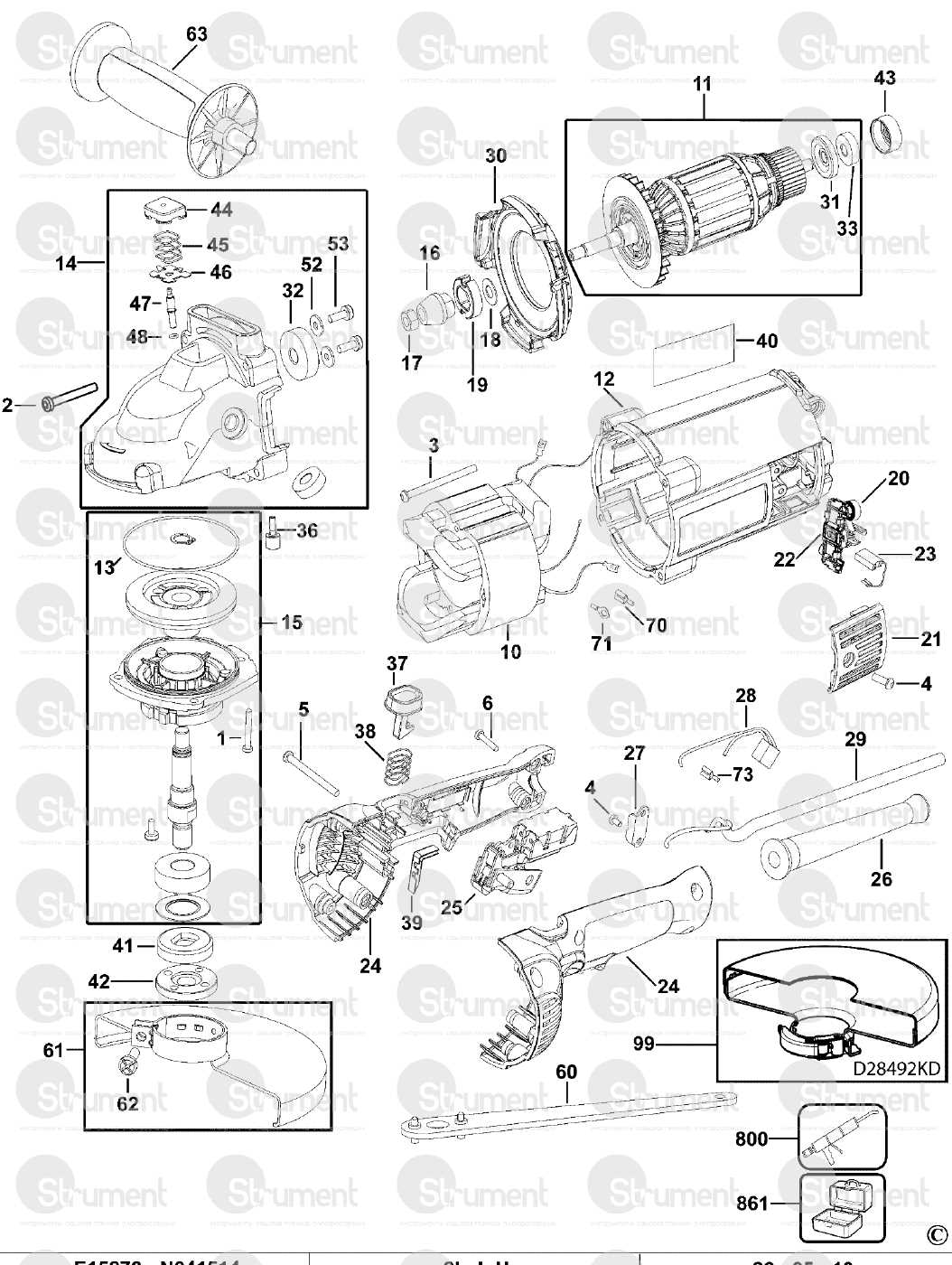

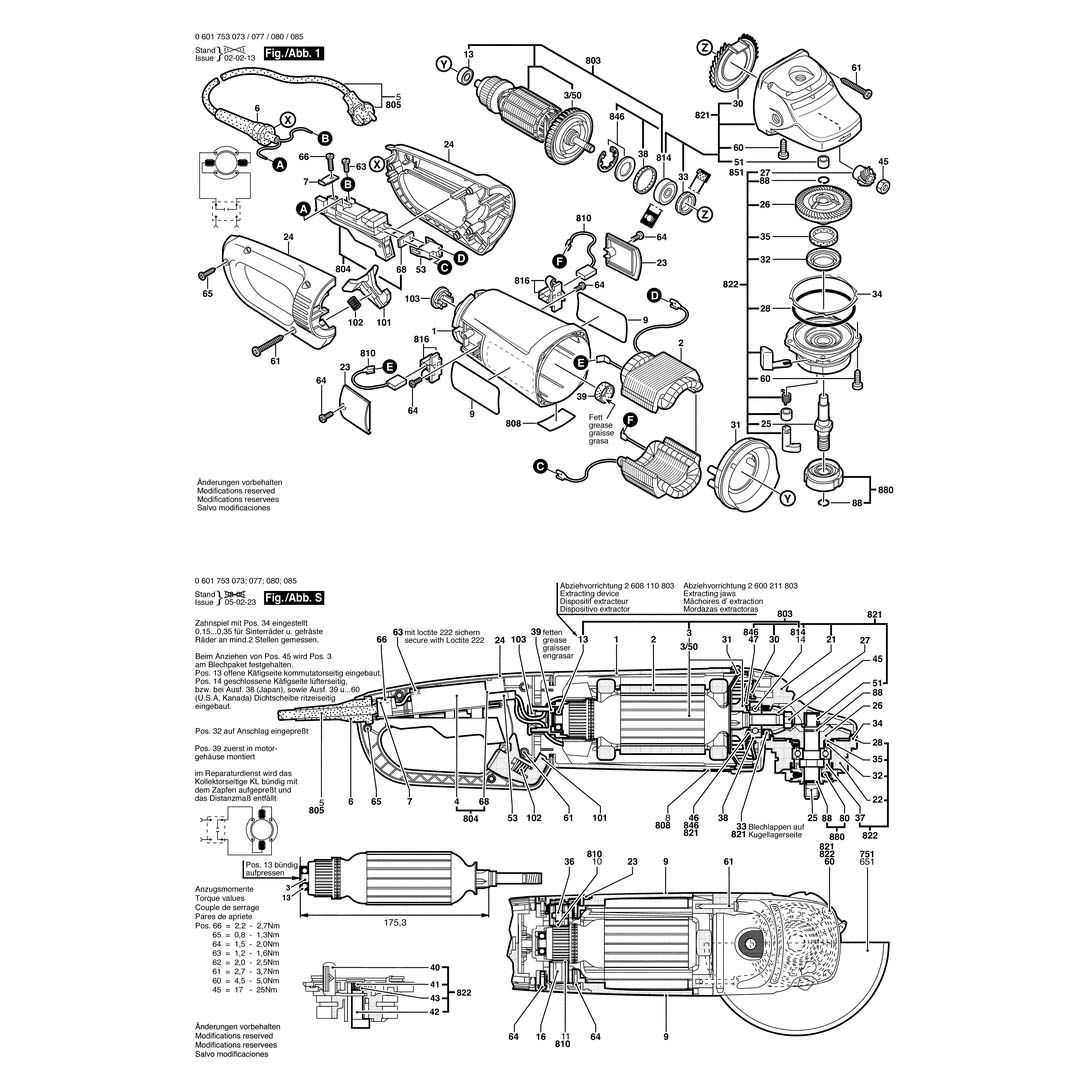

In the realm of power equipment, comprehending the arrangement of individual elements is crucial for both maintenance and repair. Having a clear visual representation of each component allows users to navigate the intricacies of their tools more efficiently. This knowledge not only enhances the lifespan of the machinery but also empowers operators to address issues swiftly and effectively.

Visual guides that depict the assembly of various parts serve as invaluable resources for technicians and hobbyists alike. These schematics highlight the relationships between components, illustrating how they work together to achieve optimal performance. With such information at hand, users can identify potential wear and tear, ensuring that their devices remain in peak condition.

For anyone looking to delve deeper into their equipment’s structure, a thorough exploration of these layouts can be transformative. By understanding how each piece fits into the larger system, operators can make informed decisions regarding repairs, upgrades, or replacements, ultimately enhancing their overall experience with the tool.

Dewalt DW402 Overview

This section provides a comprehensive examination of a well-regarded power tool known for its durability and efficiency. Ideal for professionals and DIY enthusiasts alike, this equipment excels in various applications, making it a versatile addition to any toolkit. Understanding its features, specifications, and components can greatly enhance the user experience and ensure optimal performance.

Key Features

Among the notable attributes are its robust construction, ergonomic design, and powerful motor, which collectively contribute to its reliability and effectiveness in heavy-duty tasks. The tool is designed to handle a range of materials, making it suitable for both cutting and grinding purposes.

Specifications

| Specification | Details |

|---|---|

| Power Rating | Various options available |

| Weight | Lightweight for ease of handling |

| Speed Settings | Multiple settings for versatile applications |

| Safety Features | Includes protective mechanisms |

By familiarizing yourself with the essential aspects of this tool, users can maximize their efficiency and safety during operation, ensuring high-quality results across projects.

Understanding Parts and Components

In any mechanical system, the interplay of various elements is crucial for optimal functionality. Each component plays a specific role, contributing to the overall efficiency and performance. Grasping the significance of these individual pieces can lead to better maintenance and enhanced operation.

Here are some key elements to consider when examining a tool’s structure:

- Motor: The driving force behind the operation, providing the necessary power.

- Housing: The outer shell that protects internal components and offers stability.

- Switch: A critical control element that initiates operation and ensures user safety.

- Brushes: Essential for conducting electricity to the motor, affecting performance over time.

- Spindle: The rotating axis that connects to various attachments, crucial for functionality.

Understanding these elements is vital for troubleshooting and repairs. Regular inspection can prevent wear and tear, ultimately extending the life of the equipment.

To ensure efficient performance, consider the following steps:

- Regularly check each component for signs of damage or wear.

- Keep all parts clean and free from debris.

- Replace any worn or damaged elements promptly to maintain optimal function.

By familiarizing yourself with these components, you can enhance both the longevity and efficiency of your tools, ensuring they remain reliable in various applications.

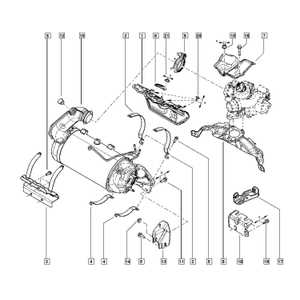

Importance of a Parts Diagram

A detailed visual representation of components plays a crucial role in the maintenance and repair of equipment. Such illustrations not only aid in identifying individual elements but also facilitate a deeper understanding of how they interact within the overall system. This clarity is essential for efficient troubleshooting and effective restoration of functionality.

Having access to a comprehensive visual guide enhances the ability to locate specific pieces quickly, reducing downtime during repairs. Users can easily reference the layout, ensuring that they have all necessary parts on hand before beginning any work. This preparedness streamlines the repair process and minimizes the risk of errors.

Furthermore, an accurate visual reference supports both novice and experienced technicians in following the assembly and disassembly procedures with confidence. Clarity in these processes promotes safety and efficiency, as it allows for a systematic approach to repairs. Ultimately, a well-illustrated reference is invaluable in maintaining the longevity and performance of the machinery.

Common Issues with Dewalt DW402

Power tools, like any machinery, can encounter various challenges over time. Understanding these common problems can help users maintain their equipment effectively and ensure optimal performance.

- Overheating: Excessive use can lead to overheating, affecting the motor and overall functionality.

- Power Loss: Inconsistent power delivery may occur, often due to faulty connections or worn-out components.

- Vibration Issues: Excessive vibration can indicate imbalance or worn parts, impacting user comfort and precision.

Regular maintenance and timely repairs can mitigate these concerns and extend the tool’s lifespan.

Where to Find Replacement Parts

When your power tool requires specific components, locating the right replacements can be crucial for optimal performance. Here are some effective avenues to explore for acquiring what you need:

- Official Manufacturer Website: Often the most reliable source for genuine components.

- Local Hardware Stores: Many carry a selection of compatible pieces for various brands.

- Online Retailers: Websites like Amazon or specialized tool sites can offer a vast inventory.

- Repair Shops: Local services may have spare parts or can order them for you.

- Forums and Communities: Engaging with fellow enthusiasts can lead to valuable recommendations.

Ultimately, ensuring your tool is equipped with the right elements will enhance its longevity and functionality.

DIY Repair Tips for Users

Engaging in self-repair can be a rewarding experience, empowering users to save money and gain hands-on skills. Understanding the essential components and their functions is crucial for effective maintenance and troubleshooting. With a bit of knowledge and the right approach, anyone can tackle repairs confidently.

| Tip | Description |

|---|---|

| Research | Gather information about the device to understand common issues and solutions. |

| Safety First | Always prioritize safety by wearing protective gear and disconnecting power sources. |

| Gather Tools | Ensure you have all necessary tools ready before starting any repair work. |

| Document Progress | Take notes or photos during disassembly to aid in reassembly later. |

| Test Thoroughly | After repairs, run tests to ensure everything functions as intended before putting the device back to use. |

Maintenance Guidelines for Longevity

To ensure the extended lifespan of your power tools, adhering to a regular maintenance routine is essential. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. Following specific guidelines can significantly contribute to the tool’s durability and efficiency.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean the exterior | After each use | Remove dust and debris to prevent buildup. |

| Lubricate moving parts | Monthly | Use appropriate lubricant to ensure smooth operation. |

| Inspect electrical components | Every 3 months | Check for wear or damage; replace if necessary. |

| Check and replace filters | Every 6 months | Keep airflow clear to prevent overheating. |

| Store in a dry place | Always | Avoid moisture exposure to prevent corrosion. |

Comparing DW402 to Other Models

This section explores the distinctions between a specific power tool and its contemporaries, highlighting key features and performance metrics. Understanding these differences can guide users in selecting the most suitable equipment for their needs.

Key Features

- Power output comparison

- Weight and portability

- Durability and build quality

- Ease of use and ergonomics

Performance Metrics

- Speed settings and control

- Noise levels during operation

- Vibration feedback

- Versatility with attachments

Customer Reviews and Feedback

Customer insights play a crucial role in understanding the performance and reliability of tools. Reviews from users not only highlight the strengths but also pinpoint potential weaknesses, helping others make informed decisions. Gathering feedback creates a community of shared experiences that enhances product transparency and trust.

Many users appreciate the durability and ease of use of these tools, often mentioning how they withstand heavy workloads without compromising performance. Positive reviews frequently emphasize the efficiency and effectiveness in various applications, showcasing their versatility across different tasks.

However, some feedback points to areas for improvement, such as the need for clearer assembly instructions or better customer support. Addressing these concerns can significantly enhance user satisfaction and overall experience. Constructive criticism is invaluable for manufacturers aiming to refine their offerings and better serve their customers.

Overall, the blend of positive and critical reviews provides a comprehensive view of product performance, assisting potential buyers in making educated choices and fostering a community of informed consumers.

Expert Recommendations for Upgrades

Enhancing the performance and longevity of your power tools can significantly improve your work efficiency. Upgrading specific components not only boosts functionality but also ensures safety and reliability during use. Experts suggest focusing on critical areas that impact overall performance.

Consider investing in high-quality blades and bits designed for your specific tasks. These can drastically improve cutting efficiency and precision. Additionally, explore advanced battery options that offer longer run times and quicker charge cycles, enhancing your overall productivity.

Don’t overlook ergonomic enhancements, such as better grips or padded handles, which can make prolonged usage more comfortable. Furthermore, regular maintenance and periodic upgrades of internal components will help maintain optimal performance and extend the tool’s lifespan.