For anyone who relies on high-performance cutting equipment, understanding the intricate components that make up your tool is essential. Each element plays a crucial role in the overall functionality and longevity of the machinery. Whether you are a seasoned professional or a DIY enthusiast, familiarizing yourself with the assembly can enhance your operational efficiency and maintenance practices.

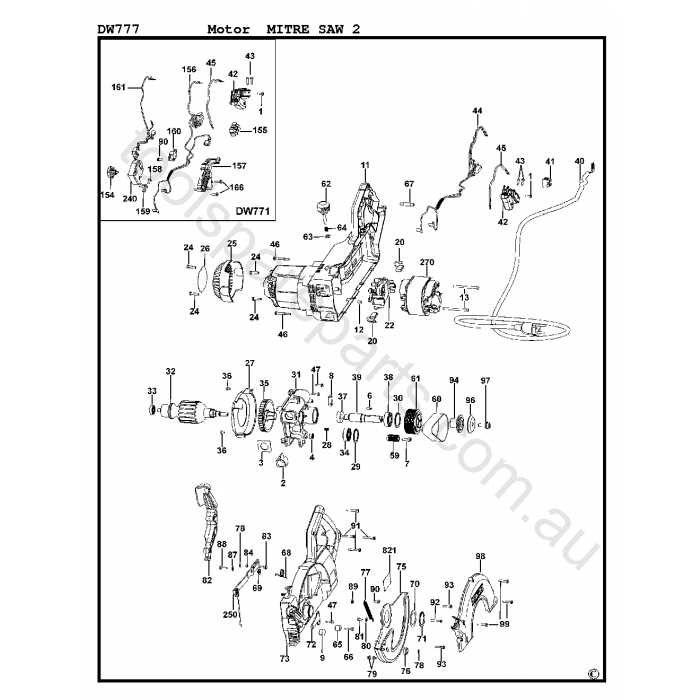

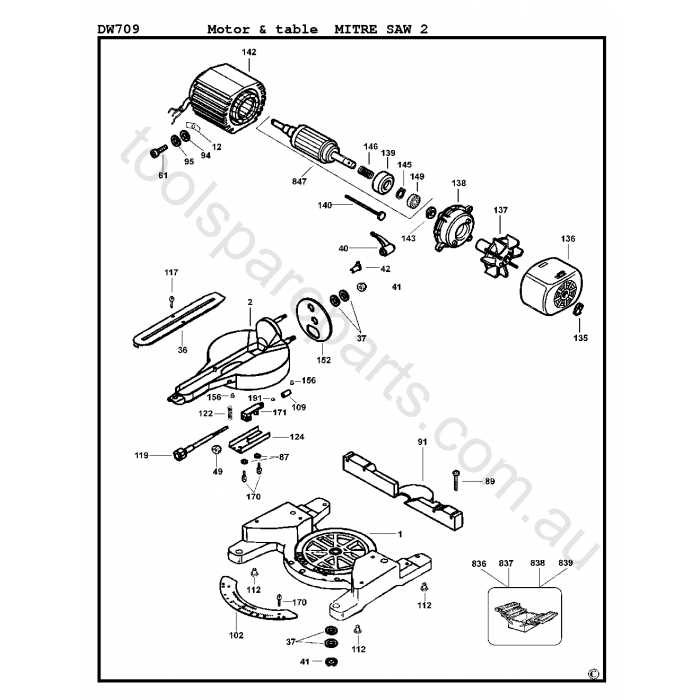

Detailed visual representations can significantly aid in the identification and organization of each component. These illustrations serve not only as a guide for troubleshooting but also as a valuable resource when seeking replacements or performing upgrades. By comprehending the structure of your equipment, you empower yourself to make informed decisions that will ensure optimal performance.

In this article, we will explore a comprehensive overview of a popular cutting tool’s assembly, breaking down its parts and their respective functions. Understanding these intricacies will allow you to navigate repairs with confidence and maintain the high standards required for precision work. Let’s delve into the essential elements that contribute to the excellence of your equipment.

Dewalt DW708 Overview and Features

This section provides a comprehensive look at a powerful and versatile cutting tool designed for precision and efficiency. It offers a combination of features that make it suitable for both professional and DIY projects, ensuring high-quality results in various applications.

Key Characteristics

- Robust motor that delivers exceptional performance.

- Adjustable settings for various cutting angles.

- Lightweight design for enhanced portability.

- Durable construction to withstand heavy use.

- Integrated safety features for user protection.

Benefits of Using This Tool

- Increased accuracy in cutting tasks.

- Time-saving capabilities with quick adjustments.

- Enhanced versatility for different materials.

- Reduced operator fatigue due to ergonomic design.

- Long-lasting performance with minimal maintenance.

This cutting tool is an essential addition to any workshop, providing reliability and excellence for all your cutting needs.

Importance of Parts Diagrams

Visual representations of components are crucial for understanding the intricate workings of machinery. They serve as invaluable tools for both professionals and enthusiasts, enabling efficient identification and replacement of individual elements.

Enhanced Understanding

Such illustrations provide clarity, making it easier to comprehend how various pieces fit together. This ultimately leads to more effective repairs and maintenance, reducing the risk of errors.

Efficient Troubleshooting

When issues arise, having a visual reference allows users to quickly pinpoint problems. This expedites the repair process and ensures that the correct components are addressed, saving time and resources.

Common Issues with Dewalt DW708

Power tools often encounter a range of problems that can affect their performance and longevity. Understanding these common challenges can help users maintain their equipment effectively and ensure smooth operation.

Mechanical Failures

Mechanical issues can arise due to wear and tear, improper use, or lack of maintenance. Users may experience difficulties such as misalignment or failure of moving parts, leading to decreased efficiency.

Electrical Problems

Electrical malfunctions can also pose significant challenges. Issues like faulty wiring, blown fuses, or problems with the motor can cause the tool to operate intermittently or not at all.

| Issue | Possible Cause | Solution |

|---|---|---|

| Misalignment | Wear and tear | Adjust or replace components |

| Motor not starting | Electrical failure | Check wiring and fuses |

| Overheating | Lack of lubrication | Apply appropriate lubricant |

Understanding the Parts Breakdown

Grasping the intricacies of a tool’s components is essential for effective maintenance and troubleshooting. Each section of a device is meticulously designed to contribute to its overall functionality. By analyzing these elements, users can enhance their understanding and ensure optimal performance.

Components Overview

A thorough examination of individual elements reveals how they interact to create a cohesive unit. Familiarity with each part’s role can significantly improve repair efficiency and extend the lifespan of the equipment.

Importance of Diagrams

Visual representations serve as an invaluable resource, offering clarity and guidance. They enable users to quickly identify specific components, facilitating repairs and replacements with ease. Ultimately, understanding these visuals allows for a deeper appreciation of the equipment’s engineering.

How to Read a Parts Diagram

Understanding how to interpret a schematic can greatly enhance your ability to maintain and repair equipment. These visual aids provide detailed information about the components and how they are assembled, helping to ensure that each element is correctly identified and placed.

Step-by-Step Guide

- Familiarize Yourself with Symbols: Every schematic uses a variety of symbols to represent different components. Make sure to understand these before proceeding.

- Identify the Key Areas: Look for sections that show the main assemblies or specific systems. These areas help you navigate through the illustration quickly.

- Match Components to Labels: The illustration will often include labels or numbers that correspond to specific items. Use these references to locate individual elements in the chart.

Common Tips for Efficient Reading

- Check for legends or explanations that clarify what each symbol or label means.

- Take note of any numbered sequences, as they typically indicate the order in which items should be assembled or disassembled.

- Ensure that you understand the orientation of the illustration to avoid any confusion when comparing it to real-world items.

Finding Replacement Parts Easily

When dealing with repairs or maintenance, one of the most common challenges is sourcing the right components. Identifying what needs to be replaced and knowing where to look can make the process smoother and quicker. By following a few simple strategies, you can avoid unnecessary delays and ensure your equipment is back up and running in no time.

Know What You Need

The first step in the search for the right components is understanding exactly what you’re looking for. This includes recognizing the specific item that needs replacing and any unique features it might have. Having a clear idea of what to search for will help streamline your efforts.

Where to Search

Once you know what you need, finding a reliable source becomes the next priority. Various platforms provide access to a wide range of items, whether you prefer physical stores or online catalogs. Ensuring you choose trusted suppliers will improve the chances of receiving quality products and minimize any issues during installation.

Maintenance Tips for Your Saw

Regular upkeep is essential to ensure that your cutting tool performs efficiently and lasts for years. Paying attention to key areas can prevent common issues and enhance its longevity.

Clean Regularly: Dust and debris can accumulate in various sections, affecting performance. After each use, it’s important to clear away any buildup, especially around the moving parts and base. This simple routine can prevent wear and help maintain precision.

Check for Wear: Over time, certain elements may start to show signs of deterioration. It’s vital to inspect them periodically to avoid malfunction or unexpected breakdowns. Look for any obvious damage and consider replacing worn-out components when necessary.

Lubricate Moving Parts: Friction can wear down components if left unchecked. Applying lubrication to the pivot points and other key areas will ensure smoother operation and reduce strain on the motor.

Align the Blade: Ensuring the cutting blade remains aligned is crucial for accurate cuts. Regularly check the alignment and make necessary adjustments to maintain the precision of your work.

By following these simple maintenance practices, you’ll be able to keep your tool in top shape, ensuring both safety and reliability for the long term.

Upgrades and Accessories for DW708

Enhancing your equipment with the right add-ons can greatly improve functionality and efficiency. Whether you aim to expand its capabilities or simply maintain performance over time, a variety of modifications are available to suit different needs. From increased precision to extended durability, these enhancements can make a significant impact on your overall experience.

| Accessory | Benefit |

|---|---|

| Laser Guide | Improves cutting accuracy by providing a clear line of sight. |

| Dust Collection System | Reduces debris and keeps the workspace clean for safer operation. |

| Extended Support Wings | Helps in managing larger materials by providing extra support. |

| Upgraded Blades | Enhances cutting speed and precision, especially on tougher materials. |

Choosing the right enhancements not only extends the lifespan of your equipment but also ensures that it performs optimally in different working conditions. The combination of accessories allows for customization, catering to specific tasks and preferences.

Customer Reviews and Feedback

Understanding the opinions and experiences of buyers is crucial for making informed decisions. Reviews often reflect both positive impressions and areas where improvements could be made. This section compiles a variety of comments from users, offering a well-rounded perspective on the product’s performance and reliability.

| User | Rating | Comment |

|---|---|---|

| John D. | 4/5 | Reliable and efficient. Some minor adjustments needed over time, but overall very satisfied. |

| Sarah M. | 5/5 | Exceeded my expectations! Smooth operation and durable components. |

| Mike T. | 3/5 | Good quality, but it required frequent maintenance after heavy use. |

| Emily R. | 4.5/5 | Works great for most tasks, but can be tricky to handle for more complex jobs. |

Comparing DW708 with Other Models

When choosing a tool, it’s important to weigh its key features and capabilities against other similar options. Different models may offer various benefits, such as improved accuracy, better portability, or enhanced power. Understanding how these differences impact performance helps users make informed decisions based on their specific needs.

| Model | Key Features | Strengths | Drawbacks |

|---|---|---|---|

| Model A | High precision, adjustable angles | Perfect for detailed work | Heavier than alternatives |

| Model B | Compact design, easy to transport | Great for mobile tasks | Less power for tougher materials |

| Model C | Strong motor, robust build |