In the realm of power equipment, a comprehensive grasp of the various elements that constitute a tool is essential for optimal performance and maintenance. By examining these intricate assemblies, users can enhance their understanding and extend the lifespan of their devices. This exploration allows for a deeper appreciation of how each segment contributes to the overall functionality.

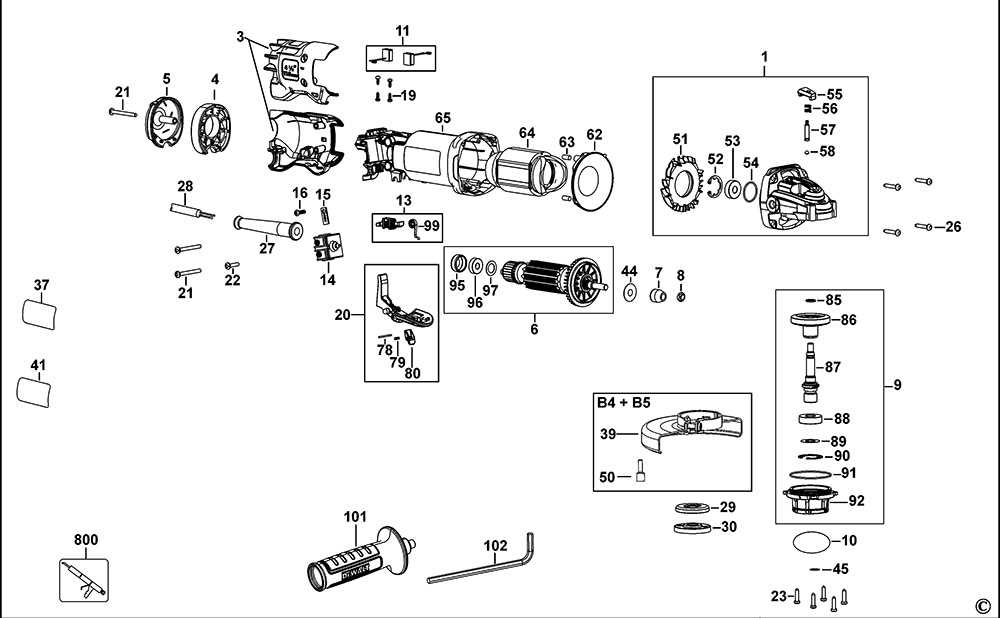

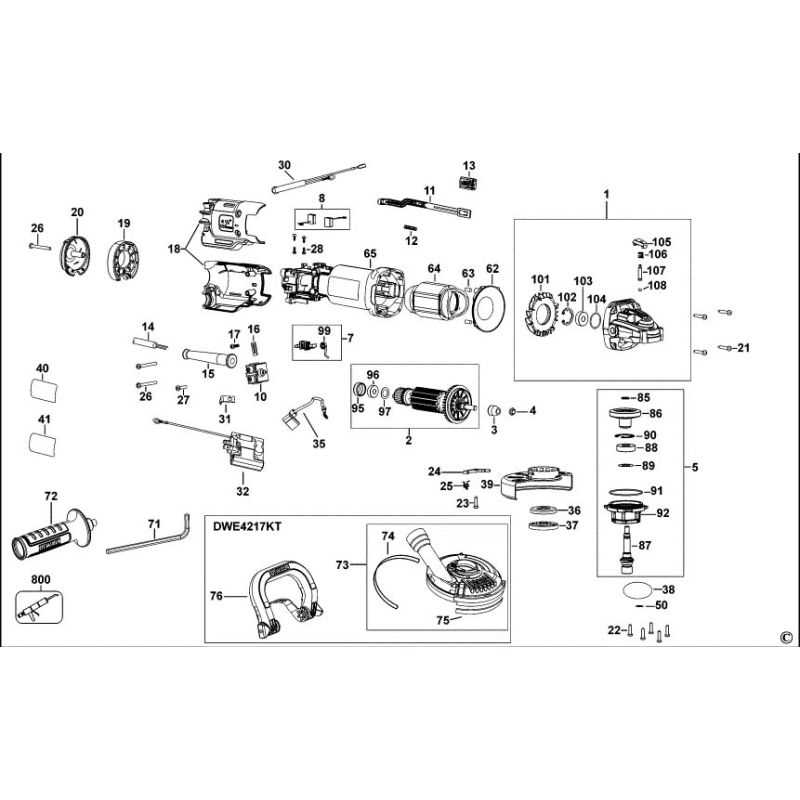

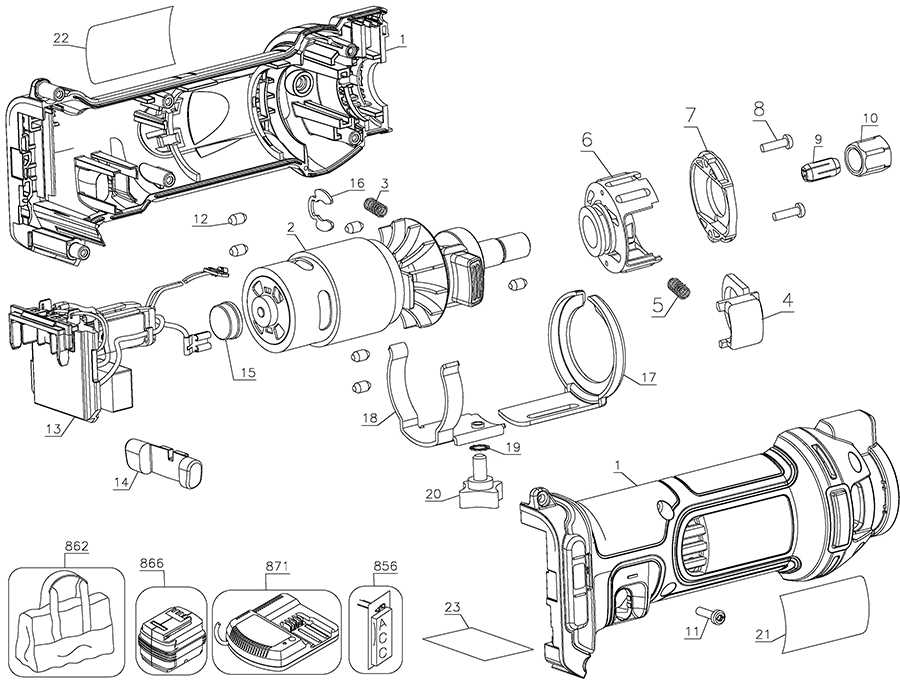

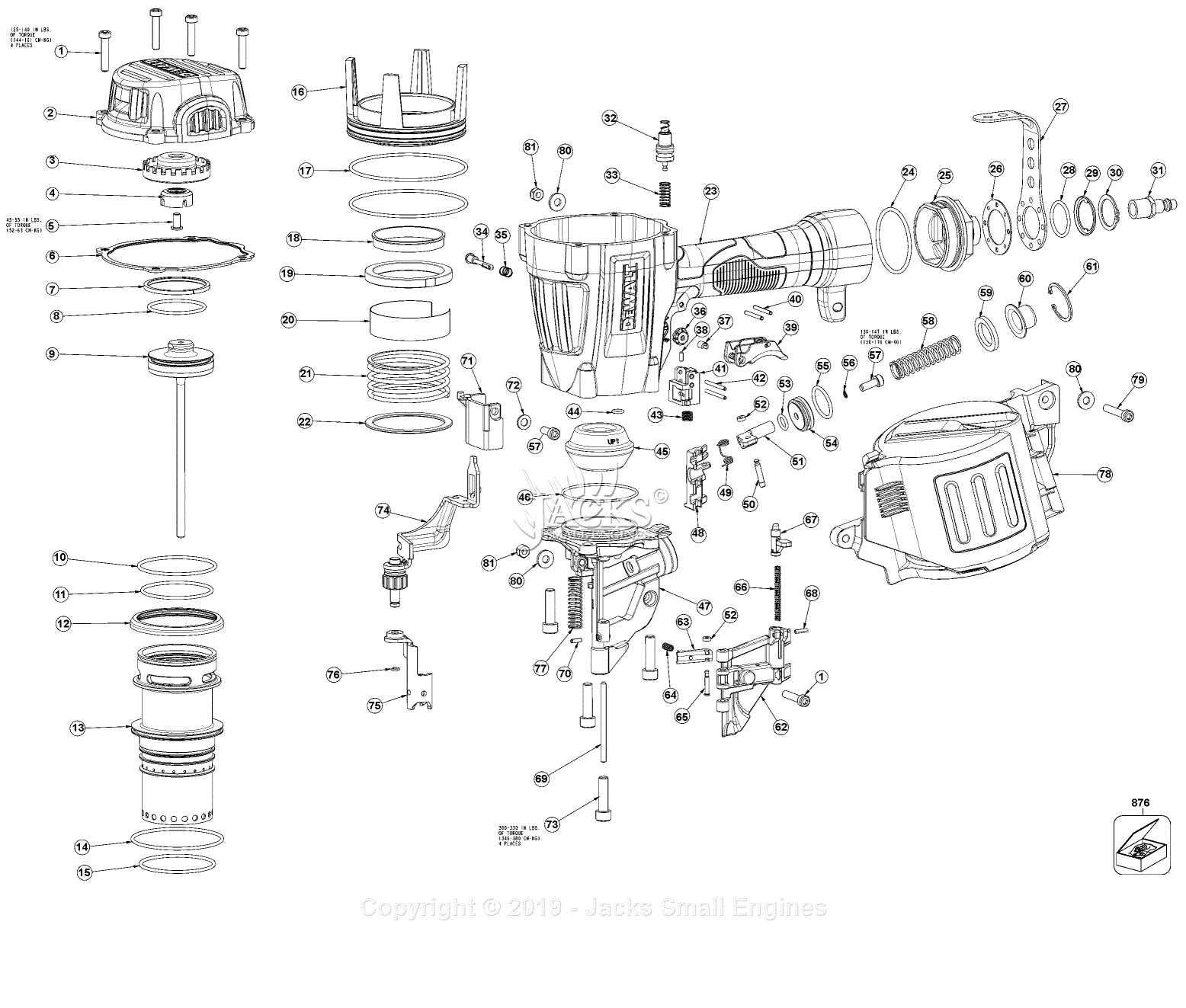

Visual representations serve as valuable resources, aiding users in identifying and locating specific elements within their machinery. These illustrations not only simplify the process of repairs but also foster a proactive approach to upkeep. With the right information, anyone can delve into the mechanics of their equipment with confidence.

Ultimately, having access to detailed layouts can be a game-changer for both novice and experienced users. Recognizing how each component interacts will empower individuals to tackle challenges head-on, ensuring their tools remain reliable and efficient throughout their use.

Dewalt DWE4012 Overview

This section provides a comprehensive look at a powerful tool designed for both professionals and DIY enthusiasts. Its robust construction and efficient performance make it an essential addition to any toolkit. With a focus on versatility, this device is well-suited for a variety of applications, ensuring reliable results and user satisfaction.

The equipment boasts a compact design that enhances maneuverability, making it ideal for tight spaces. Its high-speed capabilities allow for swift and precise cutting, contributing to improved productivity on any job site. Durability is a key feature, as this model is engineered to withstand rigorous use over time.

Incorporating advanced technology, this tool ensures optimal efficiency while maintaining user comfort. Safety features are also integrated, providing peace of mind during operation. Whether tackling home improvement tasks or professional projects, this tool stands out as a go-to option for achieving excellent results.

Understanding Power Tool Components

Power tools are essential for a variety of tasks, combining advanced engineering and precise parts to deliver exceptional performance. Understanding the individual elements that make up these devices can enhance both usability and maintenance, leading to improved efficiency and longevity.

Key Elements of Power Tools

Every power tool consists of several critical components, each serving a specific function. The motor is the heart of the machine, providing the necessary force, while gears and bearings facilitate movement and stability. Additionally, the housing protects internal parts and enhances safety during operation.

Importance of Maintenance

Regular upkeep is vital for ensuring optimal functionality. Inspecting components for wear and tear can prevent malfunctions and extend the life of the tool. By familiarizing oneself with the various elements, users can better address issues and keep their tools in top condition.

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations of individual elements play a crucial role in simplifying the identification and organization of each section, ensuring that users can efficiently manage their tools and devices.

Enhanced Clarity and Efficiency

When dealing with complex equipment, having a visual guide significantly enhances clarity. Users can quickly locate specific pieces and comprehend their functions. This leads to improved efficiency during disassembly and reassembly processes, minimizing downtime and potential errors.

Facilitating Troubleshooting

Effective troubleshooting relies heavily on the ability to pinpoint malfunctioning components. Visual aids provide a structured approach to diagnostics, allowing users to systematically identify issues. With a clear overview of each part’s relationship to others, addressing problems becomes more straightforward and less time-consuming.

Key Features of the DWE4012

This model stands out in its category, offering a blend of performance, durability, and user-friendly design. Its features are tailored to meet the demands of both professional tradespeople and DIY enthusiasts, ensuring versatility and efficiency in various applications.

Performance Specifications

With a powerful motor and high-speed capabilities, this tool ensures that tasks are completed quickly and effectively. Its design allows for seamless operation in diverse environments, making it an ideal choice for heavy-duty work.

User-Centric Design

Ergonomically crafted, this tool promotes ease of use, reducing fatigue during extended periods of operation. The intuitive controls and lightweight structure enhance maneuverability, ensuring precise handling.

| Feature | Specification |

|---|---|

| Motor Power | 7 Amp |

| Speed | 12,000 RPM |

| Weight | 4.5 lbs |

| Design | Compact and lightweight |

Common Issues and Solutions

Many users encounter a variety of challenges with their power tools over time. Understanding these common problems and their resolutions can enhance the longevity and performance of the equipment.

Frequent Problems

- Overheating during use

- Unusual noises while operating

- Inconsistent power delivery

- Physical damage to external components

Solutions

- Ensure proper ventilation and take breaks to cool the tool.

- Inspect for loose parts and tighten them as needed.

- Check the power source and replace damaged cords.

- Regularly clean and maintain external surfaces to prevent wear.

Where to Find Replacement Parts

Finding the right components for your tools can greatly enhance their performance and longevity. There are various sources available for acquiring these necessary items, ensuring you can keep your equipment in optimal working condition.

Online Retailers

Numerous online marketplaces specialize in tool components, providing an extensive selection. Websites dedicated to power tool accessories often feature detailed descriptions, user reviews, and competitive pricing, making them an excellent option for consumers.

Local Hardware Stores

Visiting nearby hardware shops can yield immediate results. Many of these establishments stock essential replacements and can offer advice on compatibility and installation, allowing for a hands-on approach to your repairs.

How to Read a Parts Diagram

Understanding the layout of a component illustration is essential for effective maintenance and repair. This visual representation serves as a guide, detailing each element and its relationship to the overall structure. By familiarizing yourself with this graphic, you can simplify the process of identifying, ordering, and replacing specific pieces.

Identifying Key Elements

Begin by examining the various sections of the illustration. Typically, components are numbered or labeled for easy reference. Pay close attention to the legend or key, as it provides crucial information regarding the identification of each item. This will help you understand how each part interacts within the assembly.

Understanding Assembly Order

In addition to identification, the illustration often indicates the sequence in which components should be assembled or disassembled. Look for arrows or sequential numbers that guide you through the process. Following this order can prevent damage and ensure that everything fits together correctly.

Utilizing the Visual Guide

Finally, keep the illustration handy during your repair or maintenance tasks. This visual guide will not only aid in identifying items but will also serve as a reference for installation procedures, making the entire process more efficient. By mastering how to interpret these graphics, you can enhance your skills and confidence in handling repairs.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your power tools. Regular attention not only ensures optimal performance but also enhances safety during use. By following a few key practices, you can maintain your equipment in excellent condition, allowing it to serve you well for years to come.

Regular Cleaning: Keep your tools free from dust and debris. After each use, wipe down surfaces and check for any buildup in crevices. Use a soft brush or compressed air to remove particles that can hinder performance.

Lubrication: Periodically apply appropriate lubricants to moving parts to reduce friction and wear. This step is crucial for maintaining smooth operation and preventing overheating.

Inspection: Regularly inspect your equipment for signs of wear or damage. Look for frayed cords, loose screws, or cracks in the housing. Address any issues promptly to prevent further damage.

Proper Storage: Store your tools in a dry, clean environment. Use protective cases or racks to avoid unnecessary impacts and exposure to moisture, which can lead to corrosion.

Battery Care: If your equipment is battery-operated, ensure that you charge the batteries correctly and store them at optimal temperatures. Avoid leaving batteries in the tool for extended periods if not in use.

Implementing these strategies can significantly enhance the reliability and lifespan of your equipment, ensuring it remains a valuable asset in your toolkit.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions can create a secure environment, allowing for efficient and effective repairs.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Disconnect the power source before starting any repair work to avoid electrical shocks.

- Keep the workspace tidy and free of clutter to minimize hazards.

Additional Considerations

- Use tools as intended and ensure they are in good condition.

- Be aware of your surroundings and ensure adequate lighting in the work area.

- If unsure about any procedure, consult the manufacturer’s guidelines or a professional.

Tools Needed for DWE4012 Repairs

When it comes to maintaining and fixing power tools, having the right equipment is essential for ensuring efficiency and safety. A well-prepared toolkit can significantly streamline the repair process, allowing for quick and effective troubleshooting. Below are the necessary implements that will aid in handling various issues that may arise.

Essential Hand Tools

- Adjustable Wrench

- Phillips and Flathead Screwdrivers

- Hex Key Set

- Pliers (needle-nose and standard)

- Rubber Mallet

Power and Measuring Tools

- Multimeter

- Voltage Tester

- Torque Wrench

- Drill/Driver

- Measuring Tape

By equipping yourself with these tools, you can tackle a variety of maintenance tasks with confidence, ensuring your equipment remains in top working condition for years to come.

Comparison with Similar Models

When exploring power tools, it’s essential to evaluate how various options stack up against one another. This section highlights key distinctions and similarities between comparable devices, allowing users to make informed decisions based on performance, features, and usability.

- Performance:

- Motor power and efficiency

- Speed settings and adjustments

- Durability under heavy use

- Features:

- Safety mechanisms

- Ease of use and ergonomics

- Compatibility with attachments

- Price Range:

- Budget-friendly options

- Mid-range choices with added features

- High-end models for professional use

By examining these criteria, users can delve into a more detailed understanding of which tool may ultimately suit their needs best.

Expert Recommendations for Users

When utilizing power tools, ensuring optimal performance and longevity is crucial. Experts recommend several practices that can enhance the user experience and maintain the functionality of these devices.

- Regular Maintenance: Schedule periodic inspections to identify any signs of wear and tear. Lubricating moving parts can prevent unnecessary friction and extend the life of the equipment.

- Follow Manufacturer Guidelines: Adhere strictly to the provided user manual. Understanding the specific requirements and limitations of the tool ensures safe and efficient operation.

- Use Quality Accessories: Invest in high-quality attachments and consumables. Inferior products can compromise performance and safety.

- Keep the Workspace Clean: A tidy environment reduces the risk of accidents and allows for better focus while working.

- Stay Informed: Participate in workshops or online forums to stay updated on best practices and new advancements in tools and technology.

By incorporating these expert recommendations, users can significantly improve their experience and the longevity of their equipment.

Customer Reviews and Feedback

Customer insights play a crucial role in understanding the performance and reliability of tools. Users often share their experiences, highlighting both strengths and areas for improvement. Analyzing this feedback can provide valuable information for prospective buyers, ensuring informed decisions.

Many users commend the durability and efficiency of the tool, noting its robust construction and consistent performance in various tasks. The positive feedback often emphasizes how well it handles demanding projects, making it a favorite among professionals and DIY enthusiasts alike.

However, some customers express concerns regarding specific features, mentioning occasional challenges with particular components. These insights help manufacturers identify potential issues and enhance future designs, ultimately leading to a better user experience.

Overall, customer feedback serves as a vital resource, guiding both users and manufacturers in their ongoing pursuit of quality and innovation in the industry.