The functionality and efficiency of a cutting apparatus heavily rely on its individual elements. Each component plays a critical role in the overall performance, contributing to precision and durability during operation. A comprehensive overview of these components can greatly enhance the user’s ability to maintain and troubleshoot the device effectively.

Familiarity with each element is essential for anyone looking to optimize their experience with the equipment. By understanding how the various parts interact, users can ensure their tool remains in peak condition. This knowledge not only aids in the selection of replacement elements but also assists in identifying potential issues before they escalate.

In the subsequent sections, a detailed exploration of these integral components will be provided. This will serve as a valuable resource for users seeking to enhance their understanding and proficiency with the cutting apparatus.

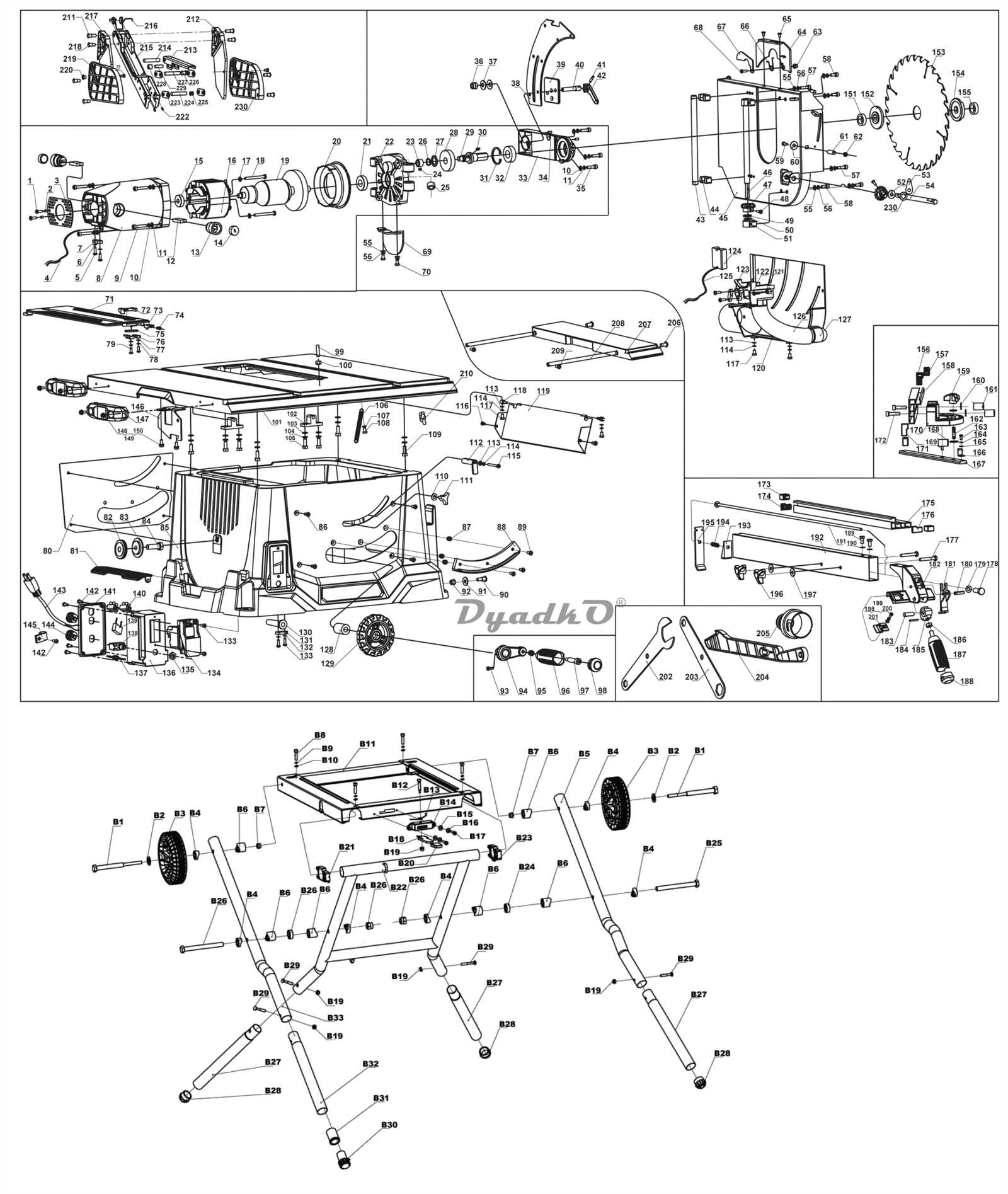

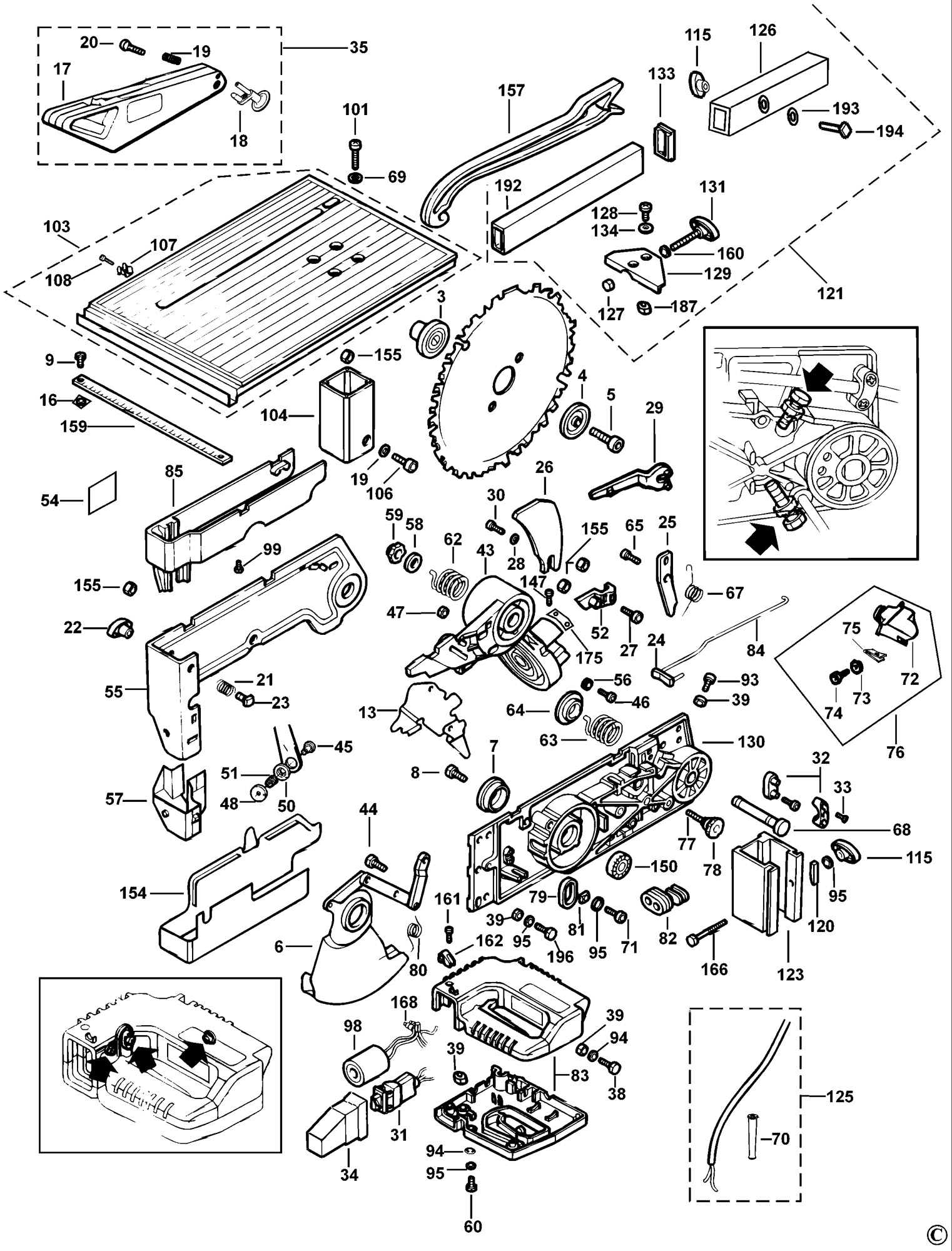

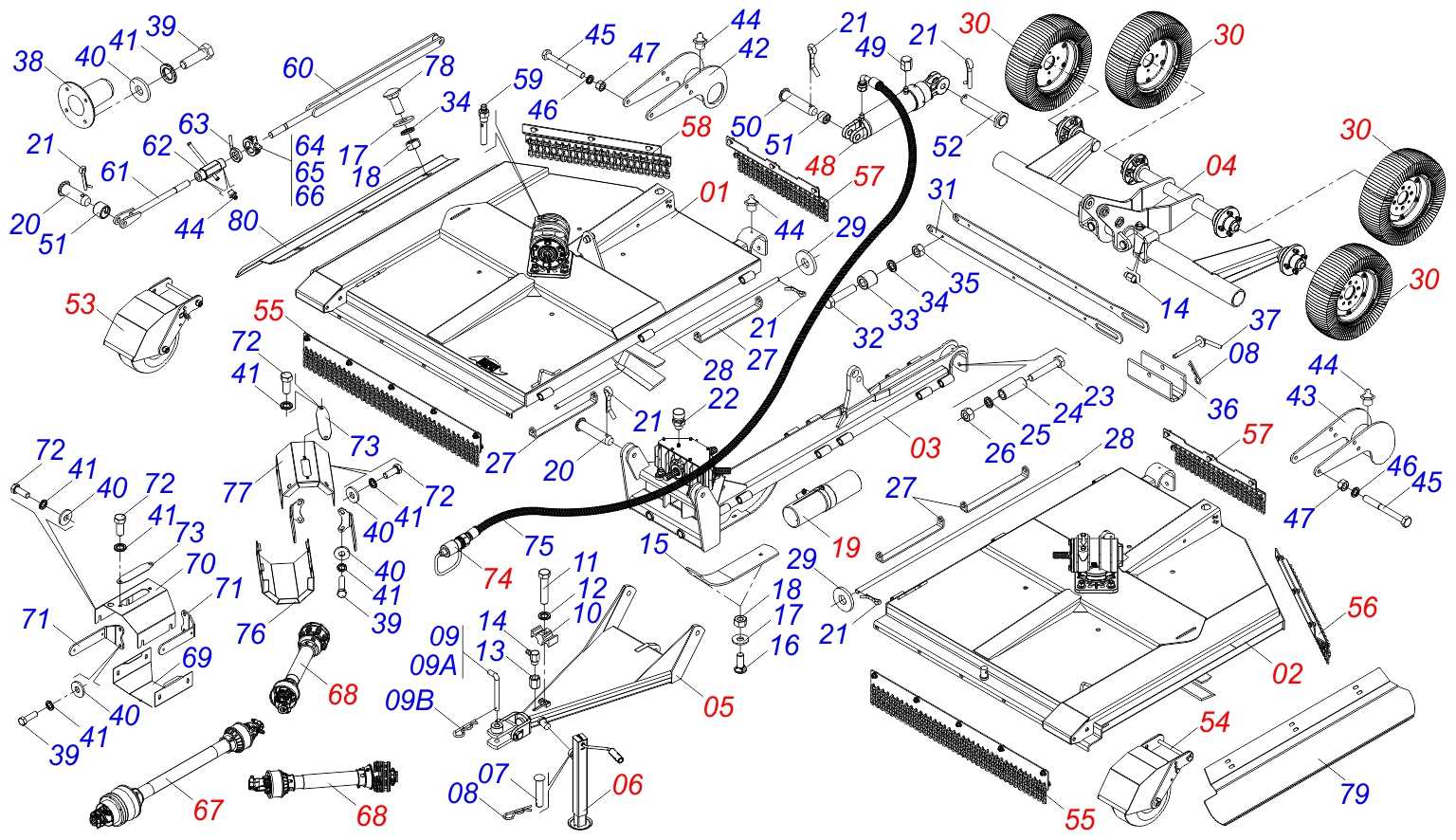

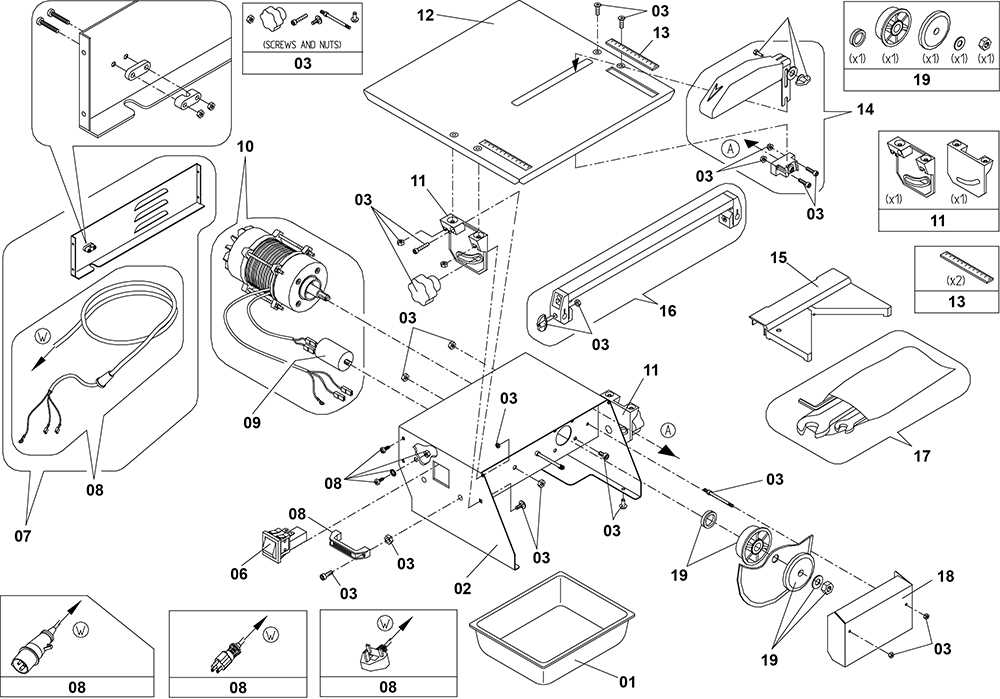

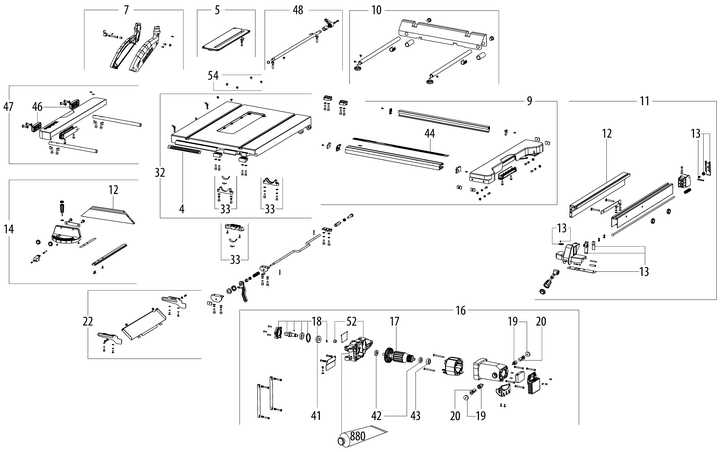

This section provides an overview of the essential components of a specific cutting tool, helping users to familiarize themselves with its construction and functionality. By examining the visual representation of the various elements, individuals can gain insights into how these parts interact, ensuring optimal operation and maintenance.

Key Components Explained

Each segment within the representation serves a distinct purpose, contributing to the overall efficiency of the equipment. Understanding these roles is crucial for troubleshooting and repair, enabling users to identify issues and execute appropriate solutions.

Interrelationships of Components

Recognizing how different parts work together enhances comprehension of the tool’s performance. Each element not only fulfills its task but also influences the operation of others, highlighting the importance of each segment in achieving effective results.

| Component | Description |

|---|---|

| Base | The foundation providing stability and support. |

| Motor | Powers the device, facilitating movement and cutting. |

| Blade | The primary tool for executing cuts through materials. |

| Fence | Ensures precision and safety during operation. |

Common Issues and Solutions

In the realm of cutting equipment, users often encounter various challenges that can hinder performance. Identifying these common complications and implementing effective solutions is essential for maintaining efficiency and ensuring optimal operation.

Here are some frequent problems and their corresponding fixes:

- Unstable Cutting:

This issue may arise from uneven surfaces or improper setup.

- Ensure the equipment is positioned on a level surface.

- Check and adjust the stabilizing components for balance.

- Inconsistent Performance:

Users may notice fluctuations in cutting speed or quality.

- Inspect the power source for reliability.

- Examine the blades for dullness and replace if necessary.

- Excessive Vibration:

Vibration can lead to reduced accuracy and potential hazards.

- Check for loose connections or components.

- Ensure that all fittings are securely tightened.

- Overheating:

Excessive heat may indicate strain or improper usage.

- Allow the equipment to cool down during extended use.

- Verify that ventilation pathways are clear.

By addressing these common concerns, users can enhance the performance and longevity of their cutting equipment.

Replacing Worn-Out Parts

Maintaining optimal performance in your cutting tool often requires timely updates to its components. Over time, certain elements may become less effective, leading to decreased efficiency and potential safety hazards. Recognizing when to replace these elements is crucial for ensuring smooth operation and extending the lifespan of your equipment.

Identifying Signs of Wear is the first step in the replacement process. Common indicators include unusual noises, vibrations, or reduced cutting accuracy. Pay close attention to any irregularities during operation, as these may signal that specific components need to be evaluated for potential replacement.

Gathering Replacement Components is essential once you’ve identified which elements require attention. It is advisable to source high-quality replacements that match the specifications of your device to ensure compatibility and reliability. Checking the manufacturer’s guidelines can provide valuable insights into the correct components needed for a successful swap.

Installation Process should be approached with care. Always follow the recommended procedures to avoid damaging your equipment. Begin by disconnecting power to ensure safety. Use appropriate tools for removing the worn-out components and carefully install the new ones, ensuring a secure fit. After installation, perform a thorough check to confirm everything is functioning correctly.

Regular maintenance, including replacing worn-out elements, is key to maintaining the efficiency and safety of your cutting equipment. By being proactive, you can ensure that your device operates at peak performance for years to come.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of your equipment. Regular maintenance not only enhances efficiency but also prevents potential issues that may arise from neglect. Implementing a routine care schedule will help you achieve the best results.

1. Clean Regularly: Keeping the machinery clean is fundamental. Dust and debris can accumulate and interfere with functionality. Use a soft brush or a vacuum to remove particles from all accessible areas.

2. Lubricate Moving Parts: Ensure that all movable components are well-lubricated to reduce friction and wear. Use the appropriate lubricant as recommended in the manual, applying it sparingly to avoid attracting more dust.

3. Check for Wear and Tear: Regularly inspect components for signs of damage or excessive wear. Address any issues promptly to prevent further deterioration. This proactive approach will save you time and money in the long run.

4. Store Properly: When not in use, keep your equipment in a dry and secure location. Protect it from extreme temperatures and humidity, which can lead to corrosion or other forms of damage.

5. Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for maintenance and care. These guidelines are designed to ensure safe and efficient operation over time.

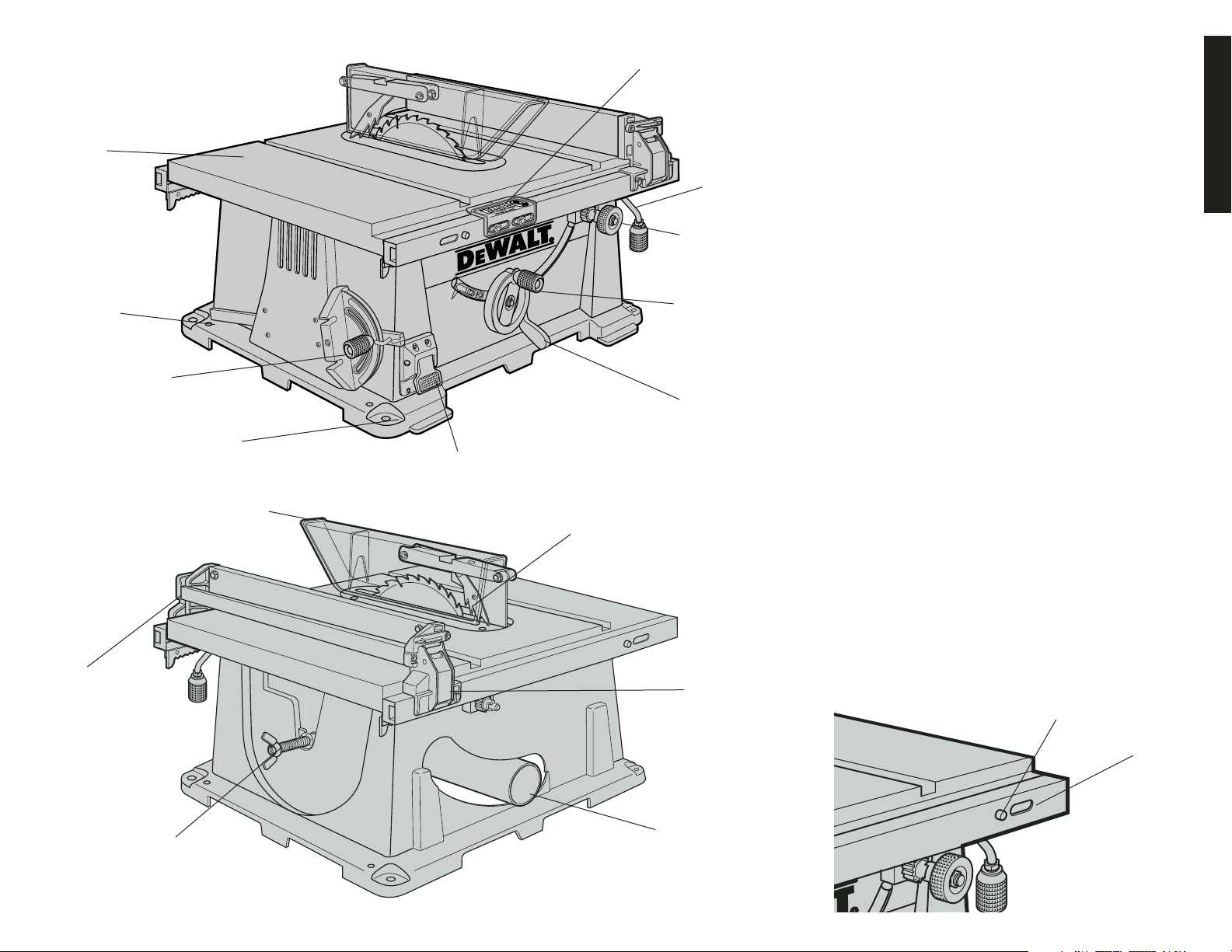

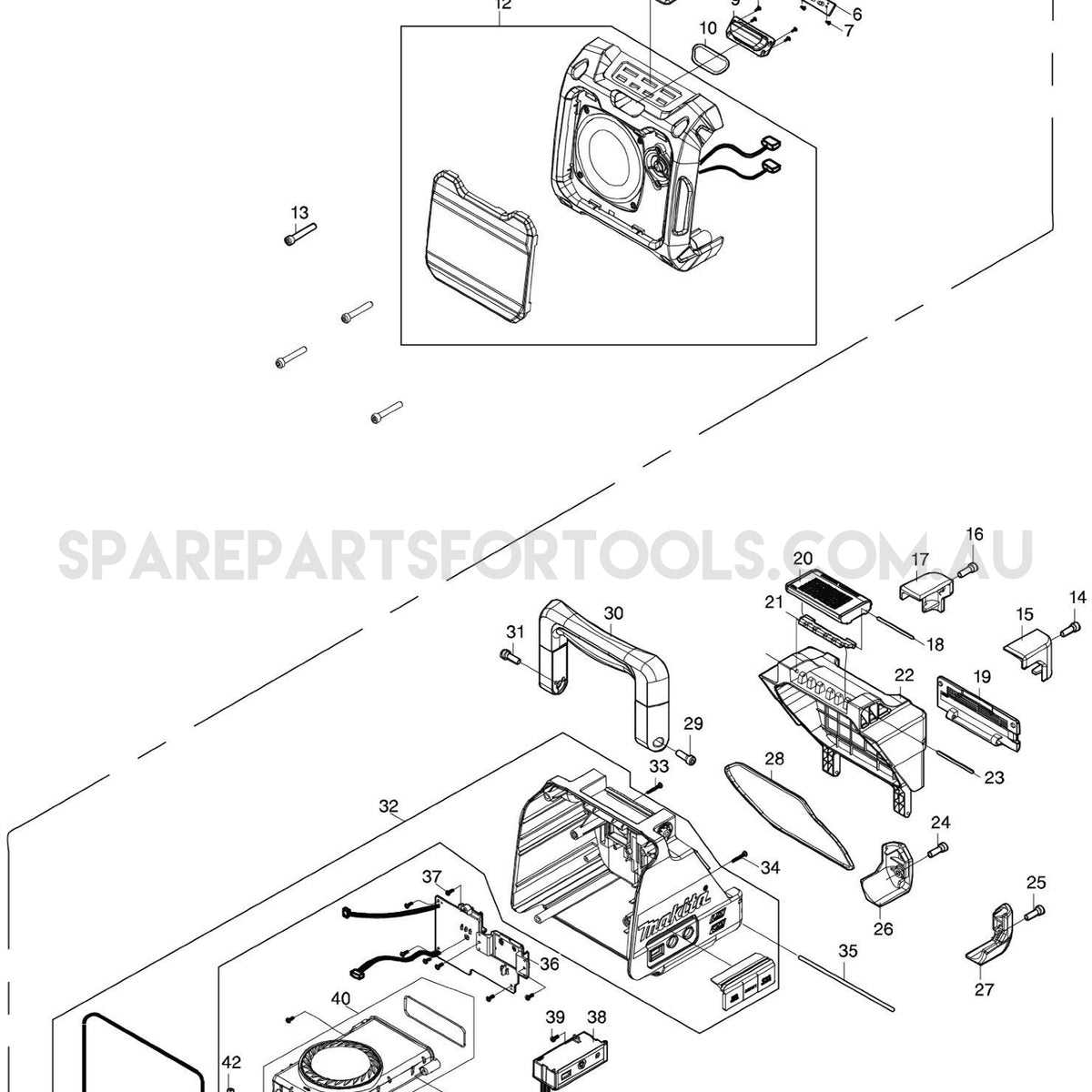

Safety Features Explained

Ensuring user protection is paramount in any woodworking apparatus. Various mechanisms are incorporated into the design to prevent accidents and enhance safe operation. Understanding these safety attributes is crucial for both novice and experienced users to minimize risks while working with cutting equipment.

Emergency Stop Mechanism

One of the most critical safety features is the emergency stop mechanism, which allows users to halt the operation instantly in case of an unexpected situation. This feature is vital for quickly responding to emergencies, ensuring that the equipment can be shut down without delay.

Blade Guard System

The blade guard system serves as a protective barrier, covering the cutting element when not in use. This feature is essential in preventing accidental contact with the blade, significantly reducing the likelihood of injuries during operation. Regular checks to ensure the guard is functioning correctly are recommended for optimal safety.

| Safety Feature | Description |

|---|---|

| Emergency Stop | Allows for immediate cessation of operation in emergencies. |

| Blade Guard | Protects users from accidental blade contact when not in use. |

| Anti-Kickback Device | Prevents the workpiece from being forcibly ejected back toward the operator. |

| Power Switch Lock | Prevents accidental start-up of the equipment. |

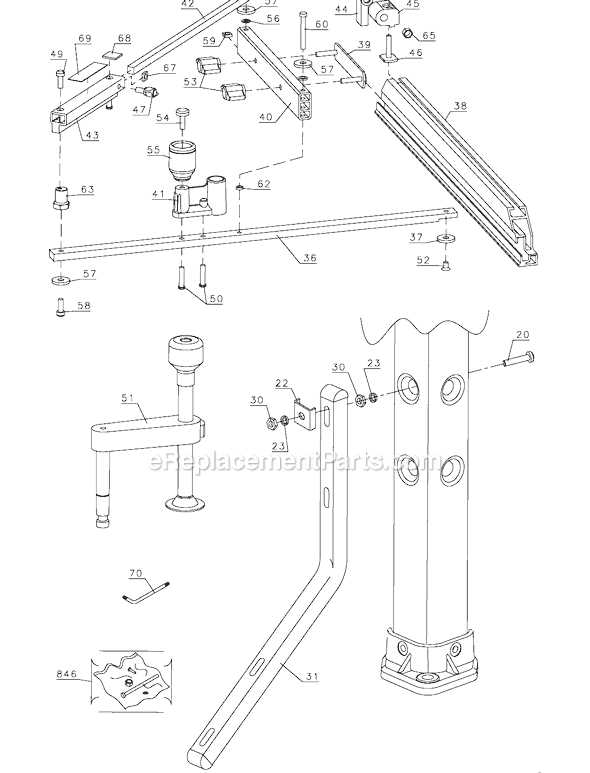

Choosing the Right Accessories

Selecting the appropriate add-ons for your cutting equipment can significantly enhance its performance and versatility. The right components not only improve efficiency but also ensure safety during operations. Understanding various options available in the market is essential for maximizing the capabilities of your machinery.

When considering which accessories to acquire, keep in mind the specific tasks you intend to accomplish. Certain attachments cater to particular functions, and matching them with your requirements can lead to improved results. Here are some common accessories to consider:

| Accessory Type | Purpose | Benefits |

|---|---|---|

| Blades | Cutting various materials | Precision and efficiency |

| Fences | Guiding cuts for accuracy | Improved safety and consistency |

| Push Sticks | Protecting hands while cutting | Enhanced safety during operation |

| Dust Collectors | Minimizing debris | Cleaner workspace and healthier environment |

Investing in high-quality accessories can lead to a more productive and safer experience. Evaluate your specific needs and explore various options to find the best fit for your projects.

Upgrading Your Table Saw

Enhancing your woodworking apparatus can significantly improve its functionality and precision. By investing in the right components, you can elevate performance, streamline operations, and ensure a smoother experience while working on your projects.

Start by evaluating the current features of your machine. Identify areas that could benefit from enhancements, such as blade quality, fence accuracy, or dust collection efficiency. Upgrading these elements not only improves the overall capability but also extends the lifespan of the equipment.

Consider adding advanced accessories like a digital readout for improved measurements or a more robust support system for larger workpieces. These modifications can enhance safety and accuracy, making your tasks more efficient and enjoyable.

Research compatible options that fit your model, ensuring seamless integration. Consulting forums or communities dedicated to woodworking can provide insights and recommendations for trusted upgrades. Remember, a well-optimized machine can make a world of difference in your craftsmanship.

Where to Find Replacement Parts

Locating components for your equipment can be a straightforward process with the right resources. Various avenues exist to ensure you have access to the necessary replacements to keep your machine operating efficiently.

Authorized Retailers and Distributors

One of the most reliable options is to consult authorized retailers and distributors. These establishments typically offer genuine replacements that are compatible with your device. Their knowledgeable staff can assist in identifying the correct components you require.

Online Marketplaces

Another excellent resource for sourcing replacements is online marketplaces. Numerous websites specialize in offering a wide selection of components, often at competitive prices. Be sure to verify the credibility of the seller and check customer reviews to ensure quality and service reliability.