In the world of off-road utility vehicles, a comprehensive grasp of the individual elements is essential for both enthusiasts and owners. Knowledge of these components not only facilitates effective maintenance but also enhances the overall performance of the machine. Exploring the intricate web of parts empowers users to make informed decisions, ensuring longevity and reliability.

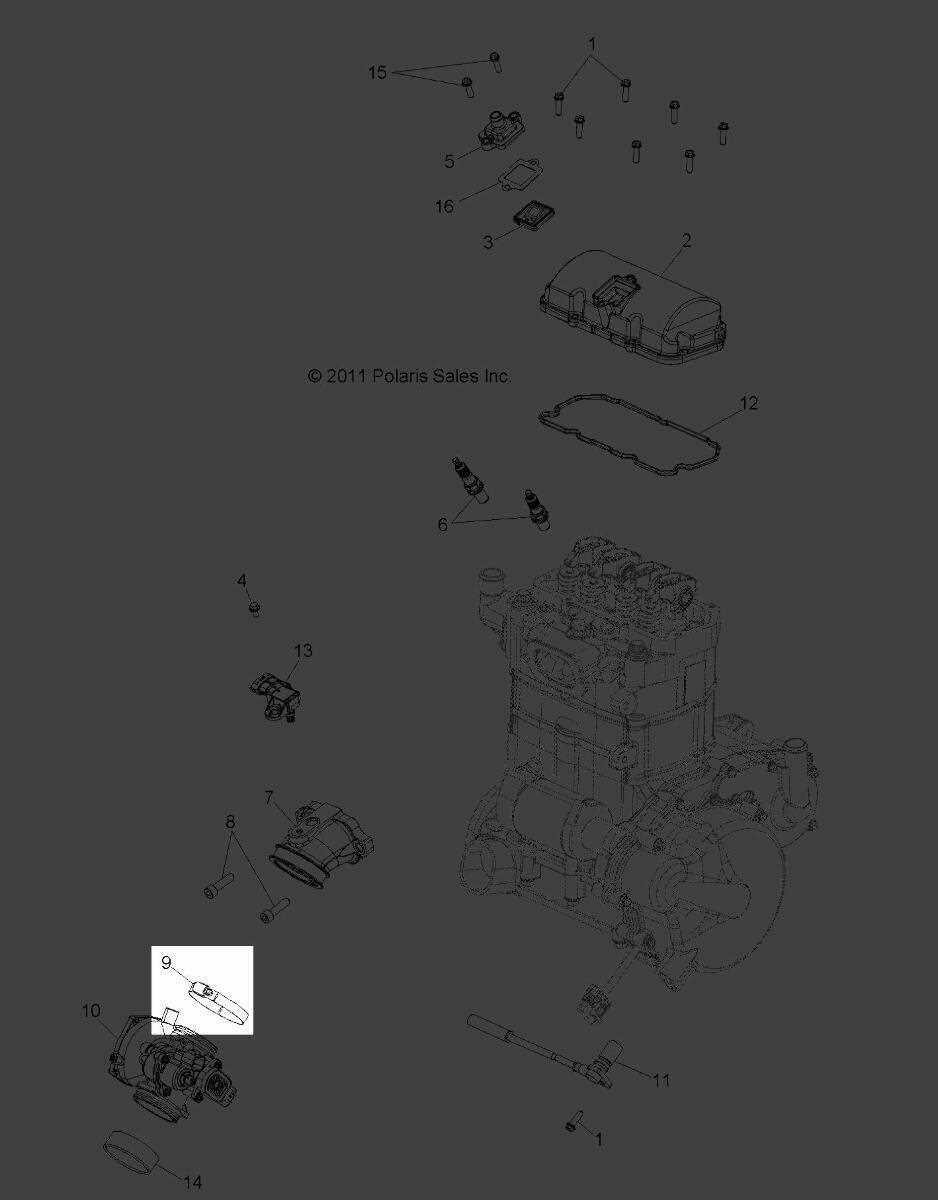

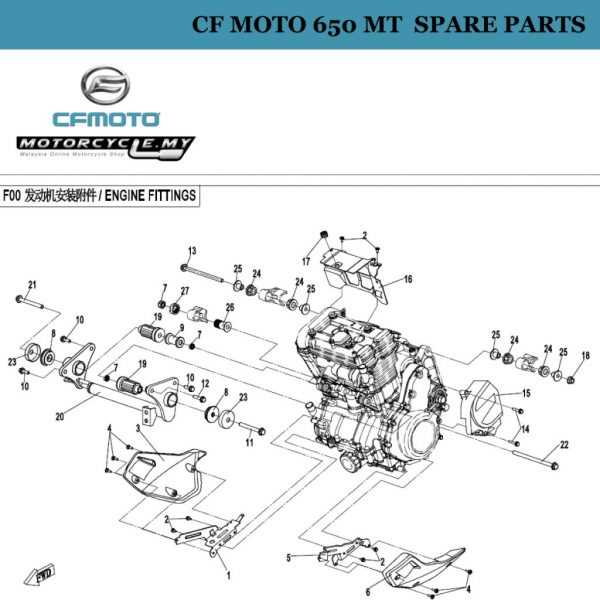

Visual representations of the assembly are invaluable for anyone looking to delve deeper into the mechanics of their vehicle. By examining detailed illustrations, one can easily identify each section and its corresponding functions. This understanding simplifies troubleshooting and repair processes, making it a vital resource for both amateur mechanics and seasoned professionals alike.

As we delve into the specifics, we’ll uncover the various assemblies and how they interact within the broader framework. This exploration will provide clarity and insight, transforming the often daunting task of maintenance into a manageable and even rewarding endeavor. Equip yourself with this knowledge to optimize your vehicle’s capabilities and enjoy your outdoor adventures to the fullest.

Understanding the Polaris Ranger 800

This section delves into the intricacies of a versatile off-road vehicle that has garnered a reputation for reliability and performance. Its design caters to both recreational enthusiasts and those needing practical utility in various terrains. By exploring its key components, users can enhance their experience and ensure longevity through proper maintenance.

Key Features

The vehicle is equipped with a powerful engine that offers robust performance, making it suitable for a wide range of applications. Durability is a hallmark of its construction, allowing it to withstand challenging environments while providing a comfortable ride. Features such as cargo space and towing capabilities further emphasize its practicality.

Maintenance and Upkeep

Regular maintenance is crucial for optimal functioning. Understanding the layout of essential elements helps in identifying potential issues before they escalate. Routine checks on the engine, suspension, and other critical systems ensure that the vehicle remains in peak condition, allowing users to tackle any adventure with confidence.

Overview of the 2013 Model

This section provides an in-depth look at a versatile all-terrain vehicle that has garnered attention for its durability and functionality. The model is designed to tackle various outdoor challenges, making it a popular choice among enthusiasts and professionals alike.

Equipped with a robust engine and an efficient transmission, this vehicle ensures a smooth ride over diverse terrains. Its design focuses on user comfort and ease of operation, appealing to both experienced riders and newcomers. Key features include enhanced cargo capacity, advanced suspension systems, and thoughtful ergonomics, all contributing to a superior driving experience.

| Feature | Description |

|---|---|

| Engine Performance | Powerful engine for reliable acceleration and towing capacity. |

| Suspension System | Advanced system providing stability and comfort on uneven surfaces. |

| Cab Design | Ergonomically designed for comfort, featuring adjustable seating. |

| Cargo Capacity | Ample space for transporting equipment and gear, enhancing utility. |

| Safety Features | Integrated safety systems ensuring a secure driving experience. |

Overall, this model represents a balanced blend of performance, comfort, and practicality, making it a reliable companion for various outdoor adventures.

Key Features of Ranger 800

This versatile utility vehicle is designed to meet a wide range of needs, from recreational activities to heavy-duty work tasks. Its robust construction and innovative design make it a reliable choice for both outdoor enthusiasts and professionals alike.

Performance is a standout characteristic, with a powerful engine that delivers impressive torque and acceleration. This allows for swift maneuvering over various terrains, whether navigating through rugged landscapes or smooth trails.

The durability of this vehicle is evident in its rugged chassis and high-quality components. Built to withstand the rigors of demanding environments, it ensures long-lasting service and minimal maintenance requirements.

Another key attribute is its versatility. With ample storage options and the ability to customize with various accessories, it adapts effortlessly to different activities, from farming tasks to off-road adventures.

Additionally, the comfort level is noteworthy, featuring an ergonomic seating arrangement and an intuitive control layout. This enhances the overall driving experience, allowing users to focus on their tasks without unnecessary distractions.

Finally, safety features are integrated throughout, providing peace of mind during operation. With advanced braking systems and protective design elements, users can navigate confidently in a variety of conditions.

Importance of Parts Diagrams

Understanding the intricate relationships between components in machinery is crucial for effective maintenance and repair. Visual representations provide a clear guide to the assembly and functionality of various elements, making it easier for technicians and enthusiasts to identify issues and execute repairs.

Benefits of Visual Representations

- Enhanced comprehension of component layout

- Streamlined troubleshooting processes

- Reduced risk of errors during assembly

- Improved efficiency in sourcing replacements

Facilitating Effective Repairs

- Allows for accurate identification of parts that need attention.

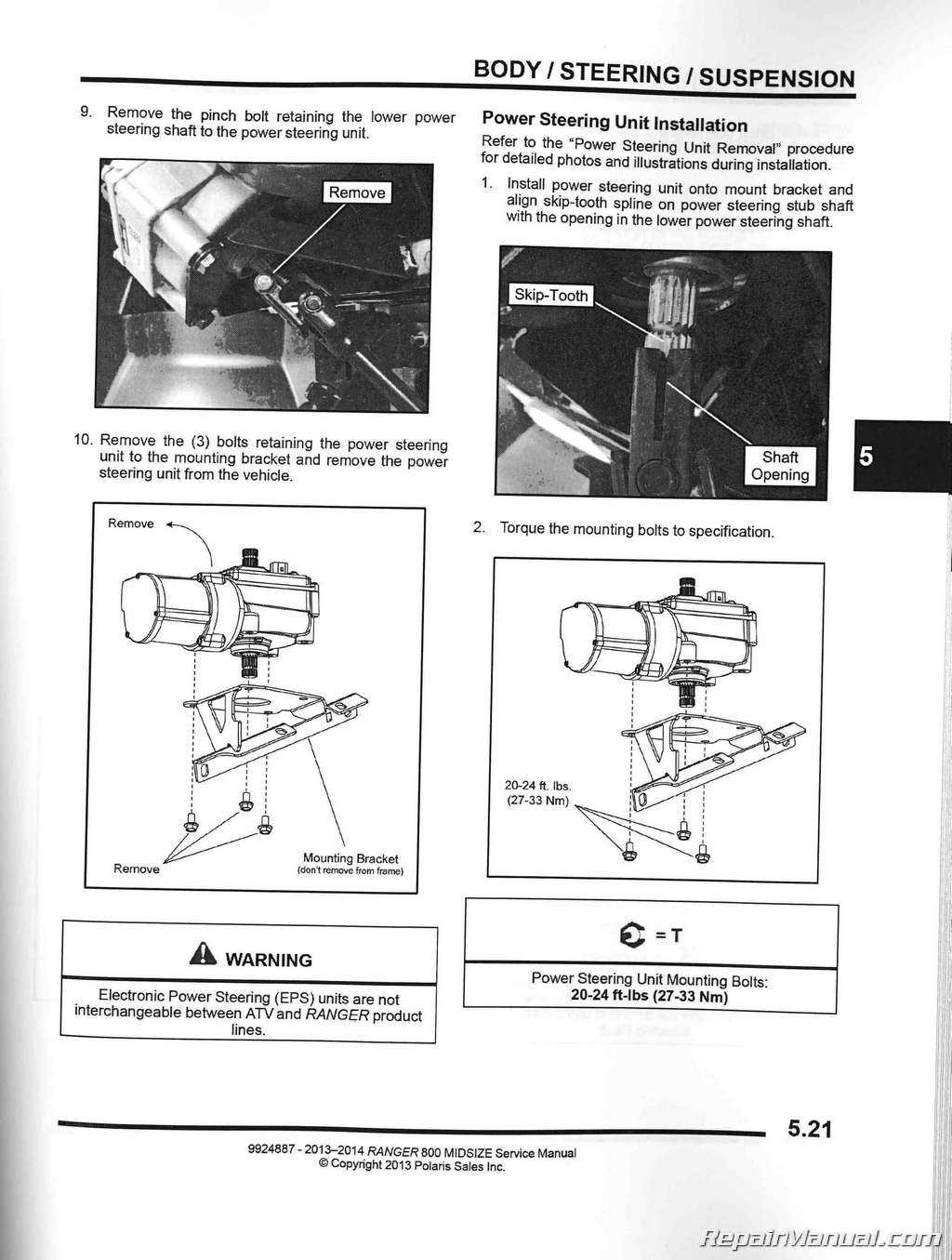

- Provides step-by-step guidance for disassembly and reassembly.

- Serves as a reference for both novice and experienced mechanics.

In summary, visual representations play a vital role in ensuring that maintenance tasks are completed efficiently and accurately, ultimately prolonging the lifespan of equipment.

Commonly Replaced Components

Regular maintenance of any vehicle involves the inspection and replacement of specific elements that tend to wear out over time. Ensuring that these components are in optimal condition is crucial for the overall functionality and performance of the machine. Understanding which parts are most likely to need replacement can help owners stay ahead of potential issues and keep their vehicle running smoothly.

Braking System: One of the most essential areas to monitor is the braking system. Over time, pads, rotors, and fluid lines may experience wear due to frequent use, requiring timely attention to maintain safe operation.

Suspension Components: The suspension system is often subject to strain from rugged terrains, leading to the need for replacements such as shocks, bushings, and control arms to preserve handling and comfort.

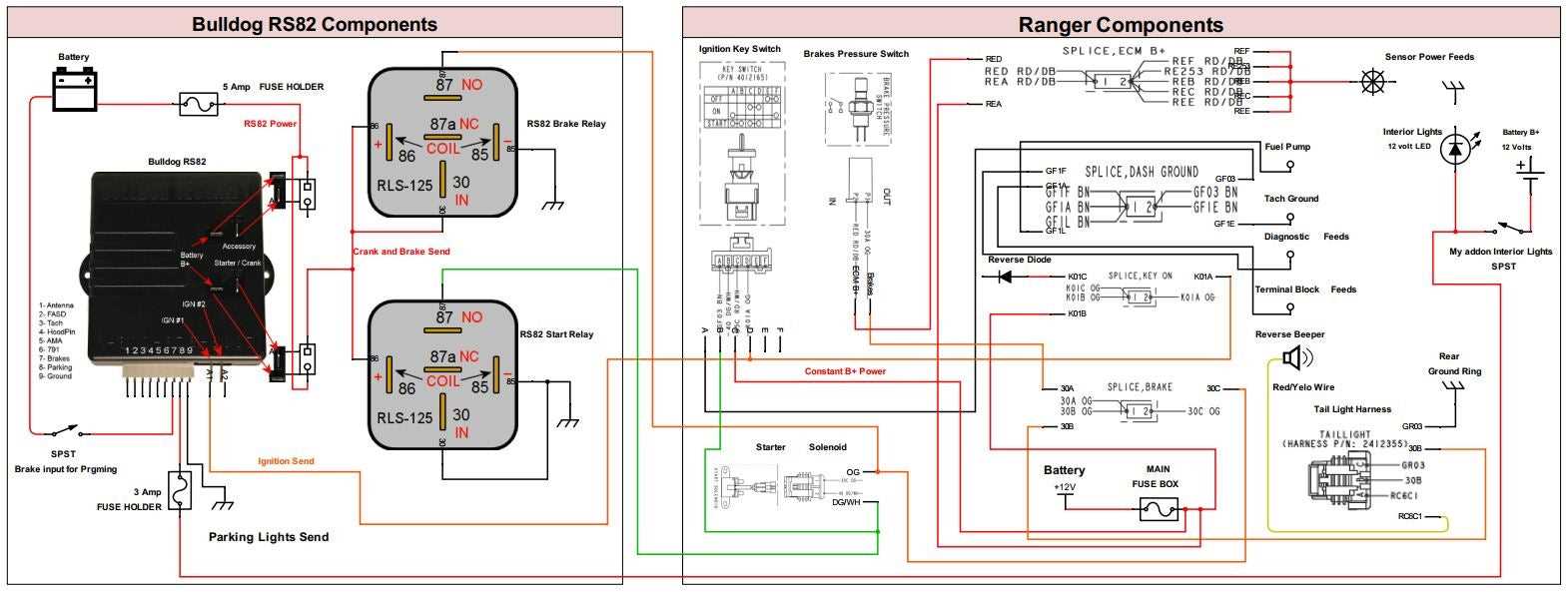

Electrical Parts: Electrical elements like wiring, batteries, and connectors may degrade with exposure to the elements or regular use, causing malfunctions that can affect the overall functionality of the vehicle. Replacing these as needed ensures continued reliability.

By staying aware of these commonly replaced components, vehicle owners can prevent more serious issues and extend the lifespan of their machine.

Accessing the Parts Diagram Online

Finding detailed visual guides for your vehicle’s components can significantly simplify maintenance and repairs. By exploring available online resources, you can quickly access information tailored to your specific model, ensuring efficient identification of required elements.

Steps to Locate Component Visuals

To begin, you’ll want to visit reliable platforms that specialize in vehicle breakdowns and visual representations of their inner workings. These steps will guide you:

- Search for a trusted website offering vehicle model breakdowns.

- Input the necessary specifications, such as engine type and model year.

- Select the relevant section for the system or area you’re working on.

Benefits of Online Visual Guides

Using online resources for viewing detailed component visuals provides several advantages:

- Immediate access to up-to-date and accurate information.

- The ability to zoom in on specific areas for clearer understanding.

- Easy sharing with service centers or other mechanics for further assistance.

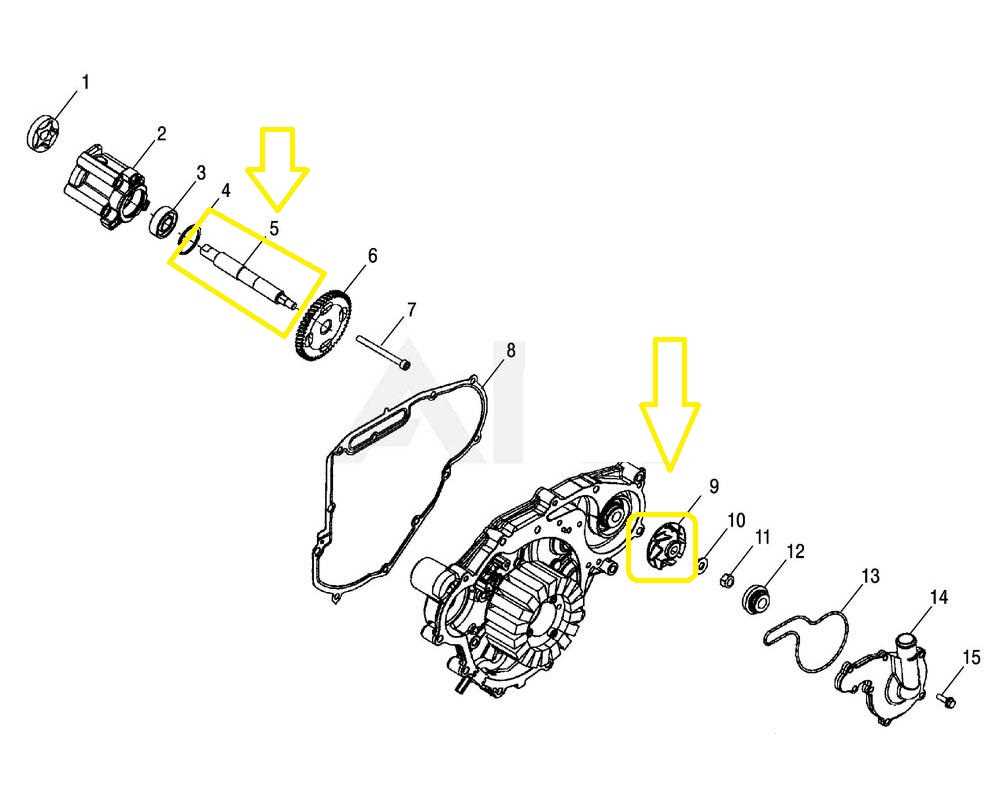

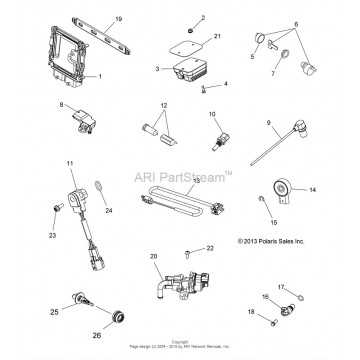

How to Read Parts Diagrams

Understanding visual guides for mechanical components is essential for anyone looking to perform maintenance or repairs. These guides provide a clear, organized view of how various elements fit together, offering valuable insights into the structure and function of a machine. By learning to interpret these visual tools, you can enhance your ability to identify specific components, see how they connect, and ensure proper reassembly.

Breaking Down the Structure

Every schematic is divided into sections that correspond to different systems or areas of the machine. These sections typically represent individual assemblies or parts that work together. Learning to focus on one section at a time allows for better understanding and makes it easier to locate the necessary components.

- Numbers: Every component is usually assigned a number that corresponds to a list of item descriptions.

- Lines and arrows: These indicate how different elements interact or are connected.

- Labels: Key areas or parts may be labeled to make identification easier.

Step-by-Step Navigation

When you begin analyzing a guide, it’s important to follow a logical sequence. Start by identifying the main areas or larger assemblies, then move towards individual elements. This approach prevents confusion and helps ensure nothing is overlooked.

- Identify the major assemblies or groups of components.

- Cross-reference the numbered elements with the provided list for details.

- Examine the lines connecting parts to understand how they interact.

With practice, interpreting these visual resources will become second nature, enabling smoother repair and maintenance processes.

Identifying Compatible Parts

When maintaining or upgrading a vehicle, it is crucial to ensure that the components you select are suitable for the specific model. Compatibility plays a key role in achieving optimal performance, safety, and longevity. Understanding which elements fit correctly can prevent issues and enhance the overall experience of your machine.

Understanding Component Specifications

Each component is designed with certain specifications in mind, including size, material, and functionality. To identify the right match, it is essential to review the details of the replacement item, making sure it aligns with the original setup of your vehicle. Checking the dimensions, connection points, and operational parameters ensures a smooth installation.

Consulting Technical Resources

In order to accurately determine compatibility, leveraging technical manuals, online resources, or expert advice is highly recommended. These references provide crucial information such as serial numbers, model variations, and manufacturing changes, which can greatly assist in finding suitable replacements. Always verify these factors to avoid mismatches.

Tools Needed for Repairs

When it comes to maintenance or restoration work, having the correct tools on hand is essential. Utilizing the right equipment not only ensures a smoother process but also prevents potential damage to the components you are working on. Whether you’re tackling minor fixes or larger overhauls, a well-prepared toolkit is the first step toward a successful outcome.

Basic Equipment

A set of fundamental tools is indispensable for most repair tasks. This includes screwdrivers, wrenches, and pliers, which are suitable for handling general hardware. Additionally, having a socket set in various sizes will help deal with bolts and nuts efficiently.

Specialized Instruments

In some cases, specific instruments are required to access or adjust particular elements. Torque wrenches ensure precision when tightening bolts, while multimeters are useful for diagnosing electrical issues. Also, prying tools and mallets can assist in safely removing or aligning components without causing harm.

| Tool | Purpose | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screwdriver Set | Fastening or loosening screws of various types | |||||||||||||||||

| Socket Wrench Set | Tightening or loosening nuts and bolts | |||||||||||||||||

| Source | Advantages | Considerations |

|---|---|---|

| Online Marketplaces | Wide variety, competitive prices, customer reviews | Potential for counterfeit or low-quality products |

| Authorized Dealers | Genuine parts, expert recommendations, warranty support | Higher prices, limited availability for older models |

DIY Repair vs. Professional Service

When it comes to maintaining your vehicle, you may face a common dilemma: should you take on the task yourself, or is it better to trust a skilled technician? Both approaches offer distinct advantages, depending on the complexity of the problem and your comfort level with tools and mechanical systems. In this section, we’ll explore the differences between self-repair and expert maintenance, helping you decide which path suits your situation.

Benefits of DIY Repair

For those who enjoy hands-on work, handling repairs on your own can save money and provide a deeper understanding of how your machine operates. With access to detailed guides and the right tools, many common fixes can be performed at home. However, it’s important to know your limitations, as tackling more complex issues without proper knowledge can lead to further damage.

Why Choose Professional Service?

Hiring a professional technician guarantees expertise and experience. Certified experts have access to specialized equipment and can quickly diagnose problems that may not be obvious to the untrained eye. Although it may cost more, professional service ensures the job is done right the first time, often with warranties for parts and labor.

| Aspect | DIY Repair | Professional Service |

|---|---|---|

| Cost | Lower upfront, potential savings on labor | Higher cost but includes expertise and warranty |

| Time | Depends on your skill level and availability | Faster with access to tools and diagnostic equipment |

| Complexity |