In the world of automotive engineering, comprehending the intricate assembly of a vehicle’s propulsion system is essential for both enthusiasts and professionals. This section delves into the intricate layout and functionality of key elements that contribute to the performance and reliability of contemporary vehicles. By examining these components, we can gain insights into their roles and interconnections within the overall system.

Visual representation serves as a powerful tool for grasping complex relationships among various elements. A detailed illustration can illuminate how each part interacts, offering clarity on their individual functions and contributions to the overall operation. Understanding these connections is vital for diagnosing issues and performing maintenance effectively.

Furthermore, recognizing the design and arrangement of these crucial components enables a deeper appreciation of the engineering prowess involved in modern automotive technology. As we explore the specifics, we will uncover the significance of each element and its impact on vehicle performance and efficiency.

Understanding the 3.6 Pentastar Engine

This section explores the intricacies of a high-performance power unit, renowned for its efficiency and reliability. By examining its essential components, enthusiasts can gain valuable insights into its functionality and design principles.

Key Features

One of the remarkable aspects of this power unit is its balance of power and fuel efficiency. With advanced engineering, it achieves optimal performance while minimizing environmental impact. The use of lightweight materials and innovative technologies enhances its overall effectiveness.

Common Components

Critical elements include the combustion chamber, intake and exhaust systems, and the lubrication mechanism. Understanding how these components interact provides a clearer picture of the unit’s performance capabilities. Each element plays a vital role in ensuring smooth operation and longevity.

Key Components of the Pentastar Engine

This section delves into the essential elements that constitute a high-performance power unit. Understanding these components is crucial for anyone interested in automotive engineering, as each part plays a significant role in the overall functionality and efficiency of the system.

| Component | Description |

|---|---|

| Cylinder Block | The core structure that houses the cylinders and supports various components. |

| Pistons | Moving parts within the cylinders that convert fuel into mechanical energy. |

| Cylinder Head | Covers the top of the cylinders, containing intake and exhaust valves. |

| Camshaft | Controls the timing of the valve openings and closings for optimal airflow. |

| Crankshaft | Transforms the linear motion of the pistons into rotational motion. |

| Oil Pump | Circulates lubricant to reduce friction and wear on moving parts. |

| Intake Manifold | Distributes the air-fuel mixture to the cylinders for combustion. |

| Exhaust Manifold | Collects and directs exhaust gases away from the cylinders. |

Each of these elements is intricately designed to work in harmony, ensuring optimal performance and reliability in various driving conditions. A thorough understanding of these components allows for better maintenance and enhancement of vehicular performance.

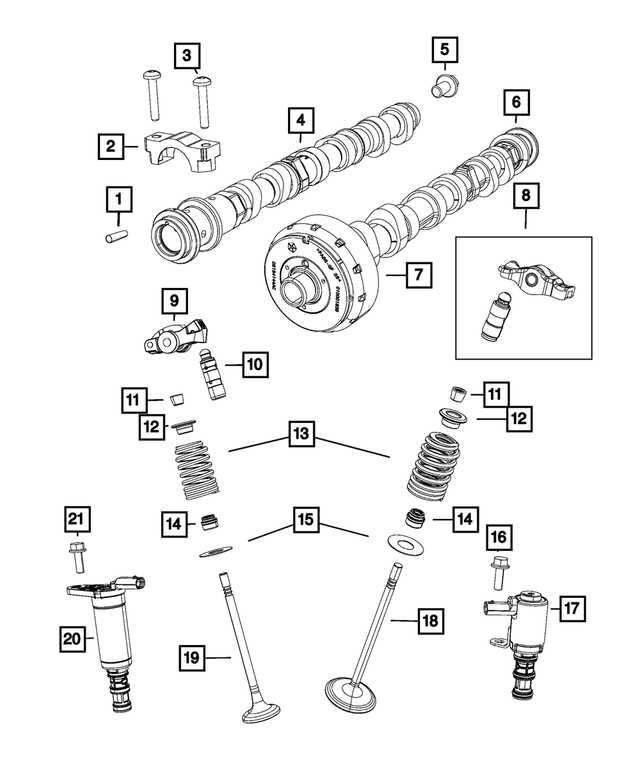

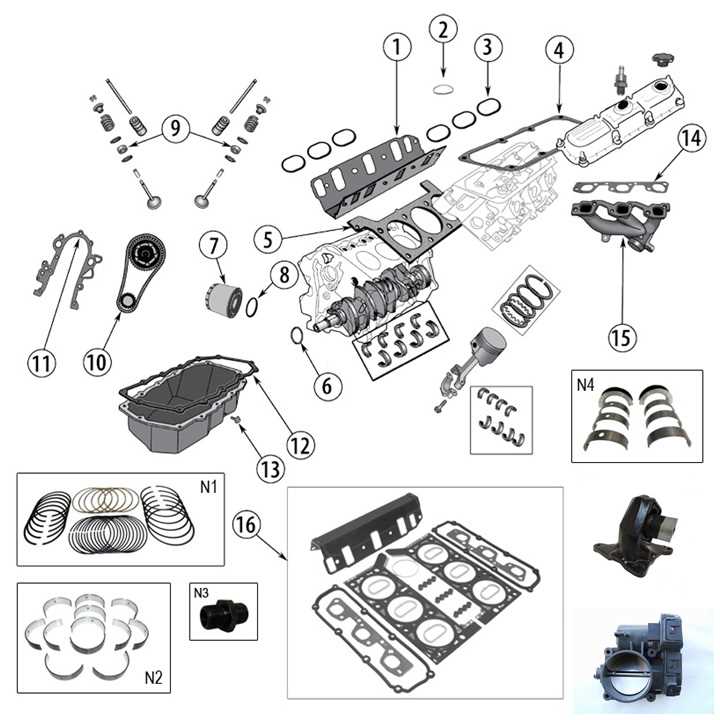

Visual Diagram of Engine Parts

This section aims to provide a comprehensive visual representation of the various components that contribute to the functionality of a motor. Understanding the layout and interaction of these elements can greatly enhance one’s knowledge of how power is generated and utilized within a vehicle. Below, we explore key features and their significance.

Main Components

- Combustion Chamber

- Crankshaft

- Pistons

- Valves

- Camshaft

Supporting Elements

- Cooling System

- Fuel Delivery Mechanism

- Exhaust System

- Electrical Components

- Lubrication System

These items work in harmony to ensure optimal performance, efficiency, and longevity. A clear understanding of each component’s role can help in diagnosing issues and performing maintenance effectively.

Common Issues with Pentastar Engine Parts

Automotive enthusiasts and mechanics often encounter several challenges associated with the components of a specific power unit. Understanding these prevalent issues is essential for effective maintenance and longevity of the system. Identifying symptoms early can save time and reduce repair costs.

Frequent Overheating Problems

One of the primary concerns is overheating, which can stem from inadequate coolant flow or thermostat malfunctions. Symptoms may include warning lights and steam emanating from the hood. Regular checks of the cooling system are crucial to mitigate this risk.

Oil Leakage and Consumption

Another significant issue involves leaks and excessive oil consumption. These can result from worn seals or gaskets, leading to diminished performance. Monitoring oil levels and addressing leaks promptly can enhance reliability.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s core components requires consistent care and attention. Regular maintenance not only enhances performance but also prolongs the lifespan of essential systems. Here are some key practices to keep in mind.

Regular Checks

- Inspect fluid levels monthly, including oil, coolant, and transmission fluid.

- Examine belts and hoses for wear or damage regularly.

- Monitor tire pressure and tread depth to ensure optimal traction.

Scheduled Services

- Follow the manufacturer’s recommended service intervals for oil changes.

- Replace air and fuel filters as needed to maintain efficiency.

- Check and adjust the alignment periodically to avoid uneven tire wear.

Adhering to these practices will significantly contribute to the performance and reliability of your vehicle over time.

Comparative Analysis of Engine Variants

This section aims to explore the distinctions and similarities among various powertrain configurations, focusing on their performance, efficiency, and technological advancements.

Key aspects to consider include:

- Power Output: Evaluating horsepower and torque metrics.

- Fuel Efficiency: Comparing miles per gallon across different setups.

- Emissions: Analyzing environmental impact and compliance with regulations.

- Maintenance Requirements: Assessing the long-term upkeep of each variant.

Understanding these factors can provide insights into which configuration may best suit specific driving needs.

- Performance Characteristics

- Cost of Ownership

- Technological Features

Ultimately, this analysis will guide consumers in making informed choices when selecting a suitable configuration for their vehicles.

Aftermarket Parts for Pentastar Engines

Exploring enhancements for your vehicle can lead to significant improvements in performance and efficiency. Various alternatives exist for those seeking to upgrade components, providing options that cater to different driving styles and needs. Quality substitutes can enhance durability and overall functionality, ensuring a more robust experience on the road.

Benefits of Upgrading Components

Investing in high-quality substitutes often results in improved horsepower, better fuel economy, and increased reliability. Many enthusiasts appreciate the customization these alternatives offer, allowing for tailored modifications that align with personal preferences and driving requirements.

Choosing the Right Alternatives

Selecting the appropriate substitutes requires careful consideration of compatibility and performance specifications. It’s essential to research reputable brands and read reviews to ensure that the chosen enhancements meet high standards of quality and effectiveness.

Assembly Process of the Pentastar Engine

The assembly procedure of this advanced power unit involves a meticulous sequence of steps designed to ensure optimal performance and reliability. Each component is integrated with precision, contributing to the overall functionality and efficiency of the system.

Key Stages in Assembly

Initially, the foundation is laid with the primary block, followed by the installation of crucial components such as the crankshaft and pistons. Attention to detail is vital during this phase to guarantee proper alignment and functionality.

Final Integration and Testing

Once the core components are secured, additional elements like the intake and exhaust systems are added. The final stage includes rigorous testing to verify performance standards, ensuring that the entire structure operates seamlessly under various conditions.

Engine Performance and Efficiency Insights

Understanding the dynamics of a vehicle’s power unit is essential for optimizing both its capabilities and fuel consumption. Various components interact to influence overall functionality, ensuring that the system operates smoothly under different conditions. By exploring these interactions, one can gain valuable insights into enhancing performance while maximizing efficiency.

Power Output and Responsiveness play crucial roles in determining how well a vehicle accelerates and handles various terrains. Factors such as air intake, combustion quality, and exhaust flow directly affect the responsiveness of the system. A well-tuned setup can significantly improve throttle response, providing a more exhilarating driving experience.

Fuel Economy is another vital aspect that often requires balancing with performance. Innovations in technology have led to designs that allow for reduced fuel consumption without sacrificing power. Techniques such as variable valve timing and advanced fuel injection systems can lead to substantial gains in efficiency, enabling drivers to travel longer distances on less fuel.

Maintenance practices also influence how effectively a vehicle operates. Regular checks and timely replacements of essential components ensure optimal functioning, which in turn supports both performance metrics and fuel economy. Neglecting these elements can result in diminished returns and potential mechanical failures.

In summary, a holistic understanding of a vehicle’s core elements allows for improved performance and efficiency. By focusing on the intricate relationships between various components and their upkeep, one can achieve a harmonious balance that enhances the driving experience while being mindful of resource consumption.

Fuel Types and Their Effects

Understanding the various types of fuel available is crucial for optimizing performance and longevity. Different fuel compositions can significantly influence overall functionality, efficiency, and environmental impact. This section explores the characteristics of common fuel types and their respective outcomes.

- Gasoline:

- Widely used due to its availability and cost-effectiveness.

- Provides quick ignition and smooth operation.

- Can lead to carbon buildup over time if not regularly maintained.

- Diesel:

- Offers better fuel efficiency and torque for heavy-duty applications.

- Generally produces higher emissions of nitrogen oxides and particulates.

- Requires more robust components to handle the higher compression ratios.

- Ethanol:

- Often blended with gasoline to enhance octane ratings.

- Renewable and can reduce greenhouse gas emissions.

- May attract moisture, leading to potential fuel system issues.

- Biodiesel:

- Derived from renewable resources such as vegetable oils or animal fats.

- Reduces dependence on fossil fuels and lowers overall emissions.

- Can sometimes cause compatibility issues with older fuel systems.

- Natural Gas:

- Known for its cleaner combustion properties.

- Generally results in lower greenhouse gas emissions.

- Requires specific modifications to the fuel delivery system.

In conclusion, selecting the appropriate fuel type is essential for maximizing performance and minimizing negative impacts. Awareness of each option’s advantages and drawbacks allows users to make informed choices for their specific needs.

Upgrades for Enhanced Engine Performance

Improving the efficiency and power output of your vehicle can significantly enhance your driving experience. A variety of modifications are available that can optimize performance, increase responsiveness, and ultimately contribute to a smoother ride. These enhancements range from simple adjustments to more complex upgrades, all aimed at achieving a more dynamic and efficient system.

Airflow Enhancements

One of the most effective ways to boost performance is by improving airflow. Upgrading the intake system allows for better air circulation, leading to increased combustion efficiency. Additionally, high-performance filters can replace standard options to trap more debris while allowing greater airflow. This combination results in a noticeable improvement in throttle response and overall power delivery.

Exhaust System Upgrades

Another crucial area for enhancement lies in the exhaust system. By installing a performance exhaust, you can reduce back pressure and improve exhaust flow. This upgrade not only enhances horsepower but also contributes to a more aggressive sound profile. Furthermore, options like headers and catalytic converters can further optimize exhaust efficiency, leading to a significant boost in overall performance.

Investing in these enhancements not only elevates your vehicle’s performance but can also contribute to its longevity and reliability on the road.