In any technical context, grasping the configuration of various elements is essential for effective maintenance and repair. A clear representation of these elements helps users comprehend how each part interacts within the system, ensuring optimal functionality and efficiency. This section will delve into the intricacies of these layouts, providing a valuable resource for enthusiasts and professionals alike.

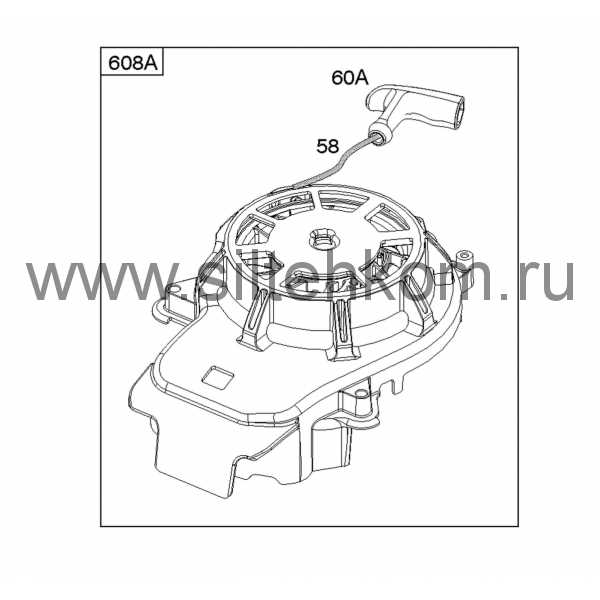

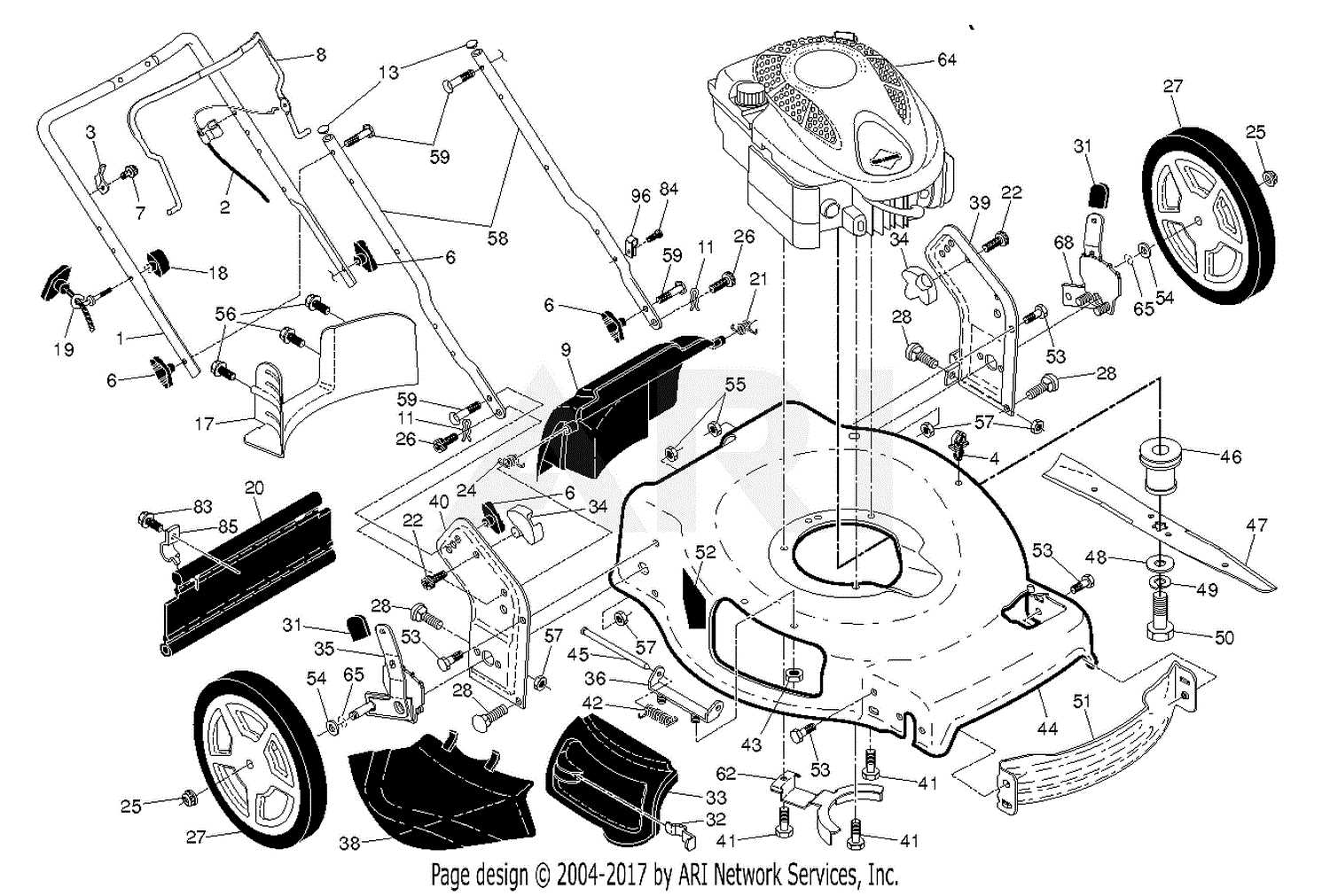

Illustrating the Arrangement allows users to visualize the positioning and connectivity of different components. By examining these representations, one can gain insights into the assembly and disassembly processes, which are crucial for troubleshooting and routine checks. Such knowledge not only enhances the understanding of the equipment but also empowers users to carry out their tasks with confidence.

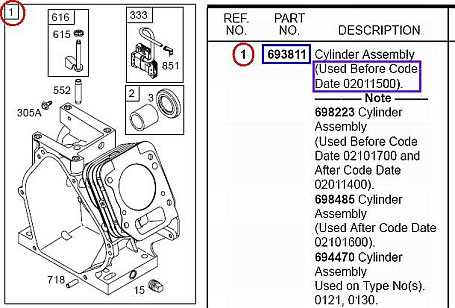

Additionally, having access to detailed representations aids in the identification of individual elements, facilitating easier procurement of replacements when necessary. This section aims to equip readers with the foundational knowledge needed to navigate and interpret these essential resources effectively.

Key Components and Their Functions

This section explores the essential elements of a mechanical system, focusing on their roles and significance. Understanding these components is vital for effective maintenance and operation, ensuring that the machinery functions smoothly and efficiently.

Core Elements

The core elements of any mechanical assembly are designed to work together harmoniously. Each part has a specific purpose, contributing to the overall functionality. For instance, the drive unit is responsible for converting energy into motion, while the control system manages the operational parameters to enhance performance.

Supporting Mechanisms

In addition to the core elements, supporting mechanisms play a crucial role in enhancing efficiency. The transmission system facilitates the transfer of energy between components, while the cooling system helps maintain optimal temperature levels, preventing overheating and ensuring durability. These supporting mechanisms are essential for the reliable operation of the entire system.

Importance of Accurate Diagrams

Clear and precise representations are essential for understanding complex systems and components. They serve as visual guides, enabling users to identify individual elements and their functions effectively. This clarity helps prevent misunderstandings and errors during assembly, maintenance, or repair processes.

Enhanced Understanding

Well-structured illustrations can significantly enhance comprehension, allowing individuals to visualize relationships between various elements. By depicting how different parts interact, these visuals simplify complex concepts and make it easier for users to grasp the overall functionality.

Efficiency in Troubleshooting

Accurate visual aids play a crucial role in diagnosing issues within systems. When users can refer to reliable representations, they can quickly pinpoint malfunctions and determine the necessary actions to resolve them. This efficiency not only saves time but also minimizes the risk of further complications during the troubleshooting process.

Understanding Parts Placement

Proper arrangement of components is essential for optimal performance and functionality. A well-organized layout not only enhances the efficiency of operation but also simplifies maintenance and repairs. Each element should be strategically positioned to facilitate easy access and ensure effective interaction with other elements.

Identifying the location of each component is crucial for users to understand how the entire system functions. Recognizing where individual elements reside allows for quicker troubleshooting and repairs, as well as a better grasp of the overall assembly. This understanding leads to improved handling and ensures that every part can be utilized to its fullest potential.

By familiarizing oneself with the arrangement, users can enhance their knowledge and skills related to the system. This knowledge empowers individuals to perform tasks with confidence, reducing the likelihood of errors and increasing overall satisfaction with the product.

Common Issues with Parts Misalignment

Misalignment among components can lead to various operational challenges, affecting overall performance and efficiency. Understanding the typical problems that arise from this issue is crucial for maintaining optimal functionality.

Identifying Misalignment Problems

Several indicators suggest that misalignment may be occurring. Here are some common signs to look for:

- Uneven wear on components

- Increased vibration during operation

- Unusual noises or sounds

- Difficulty in operation or handling

Consequences of Misalignment

The implications of misalignment can be significant, leading to both short-term and long-term issues:

- Reduced efficiency and productivity

- Higher energy consumption

- Increased risk of component failure

- Costly repairs or replacements

Addressing these alignment issues promptly can enhance performance and extend the lifespan of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of any mechanical equipment requires regular upkeep and attention. By following a few essential guidelines, users can significantly enhance the lifespan of their devices and ensure optimal performance over time. These practices not only prevent potential issues but also promote smooth operation, ultimately saving time and costs associated with repairs.

Regular Cleaning

Routine cleaning is crucial for maintaining the functionality of equipment. Dirt and debris can cause wear and tear, affecting performance. Ensure to clean the exterior and accessible internal components regularly to prevent buildup.

Scheduled Inspections

Periodic assessments of your machinery help identify wear before it leads to serious problems. Regular checks can include examining essential systems and components, ensuring everything is in good working order.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning External Surfaces | Weekly | Use a soft cloth and suitable cleaning solution. |

| Inspect Internal Components | Monthly | Look for signs of wear and ensure lubrication is adequate. |

| Full System Check | Quarterly | Evaluate all functionalities and perform necessary adjustments. |

| Replace Worn Parts | As Needed | Use manufacturer-approved replacements to ensure compatibility. |

Upgrading 675exi Components

Enhancing the functionality of machinery can significantly improve performance and efficiency. This section will explore the various enhancements that can be implemented, focusing on key components that contribute to overall effectiveness. Upgrading these elements not only extends the lifespan of the equipment but also ensures it operates at its best.

Key Areas for Enhancement

- Engine Performance

- Electrical System

- Hydraulic Components

- Transmission Efficiency

Benefits of Component Upgrades

- Improved Efficiency: Upgrading components can lead to better fuel economy and reduced operational costs.

- Enhanced Durability: Newer parts often provide greater reliability and resilience against wear and tear.

- Better Performance: Modern components can significantly boost the operational capacity of machinery.

- Increased Resale Value: Well-maintained and upgraded equipment tends to attract higher market prices.

Choosing Quality Replacement Parts

When it comes to maintaining equipment, selecting high-quality components is crucial for ensuring optimal performance and longevity. The right choices can prevent future issues, enhance functionality, and ultimately save costs. Understanding the factors that influence the selection of suitable components can help users make informed decisions.

Factors to Consider

- Material Quality: Look for components made from durable materials that can withstand wear and tear.

- Compatibility: Ensure that the replacements fit well with existing equipment specifications.

- Brand Reputation: Opt for well-known manufacturers with positive reviews and reliable products.

- Warranty and Support: Check if the parts come with a warranty or customer support for added security.

Where to Source Quality Components

- Authorized Dealers: Purchasing from authorized retailers can guarantee the authenticity of the products.

- Reputable Online Stores: Explore trusted online platforms that specialize in industrial supplies.

- Local Suppliers: Visit local shops that have a good track record for quality and customer service.

By taking these factors into account, users can confidently select high-quality replacements, ensuring that their equipment operates smoothly and efficiently.

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to grasp complex information. These illustrations serve as valuable tools for conveying intricate details in a simplified manner, making it easier for users to follow instructions or troubleshoot issues. Mastering the interpretation of these visuals is crucial for efficient analysis and application.

Key Elements to Focus On

- Symbols: Familiarize yourself with common symbols used in visuals. Each symbol often represents a specific function or component.

- Labels: Pay attention to labels that provide important information about each part of the visual representation.

- Connections: Note how different elements are connected. Arrows or lines typically indicate relationships or flow between components.

Steps for Effective Interpretation

- Begin by scanning the entire visual to get an overview of its structure.

- Identify and study each symbol, looking up their meanings if necessary.

- Follow the connections to understand the relationships and workflows.

- Refer to any accompanying legends or notes that provide additional context.

- Practice by interpreting various visuals to build confidence and proficiency.

Visualizing the Assembly Process

Understanding the process of putting components together is essential for achieving optimal functionality in any machinery. By effectively illustrating the assembly sequence, one can ensure that each element fits harmoniously into the overall structure. This visualization not only enhances comprehension but also streamlines the assembly process, minimizing errors and maximizing efficiency.

Importance of Clear Representation

Having a clear representation of the assembly sequence aids technicians in grasping how various elements interact. It emphasizes the relationship between different sections and highlights critical steps that must be followed to achieve successful integration. A detailed illustration can serve as a valuable reference, reducing the likelihood of mistakes during assembly.

Steps to Create Effective Visuals

To create effective visuals, begin by outlining the main components and their respective positions. Use distinct markings to indicate connections and sequences, ensuring clarity. Incorporate labels that guide the assembler through each step, enabling a smoother workflow. Utilizing color coding can also enhance understanding, allowing for quick identification of various parts involved in the process.

Resources for Further Research

For individuals seeking to enhance their understanding and knowledge of specific components and their arrangements, a variety of materials and platforms are available. These resources can provide valuable insights into the construction and functionality of various systems, helping enthusiasts and professionals alike deepen their comprehension.

Books on mechanical engineering and technical manuals often contain detailed explanations and illustrations that clarify complex concepts. Online forums and communities dedicated to machinery and engineering topics can also serve as excellent venues for discussion, offering firsthand experiences and solutions from fellow users. Additionally, educational websites and videos can provide interactive learning opportunities, showcasing practical applications and maintenance tips.

Lastly, manufacturer’s websites frequently host extensive documentation, including user guides and technical specifications, that can be instrumental in researching specific systems. By utilizing these diverse resources, individuals can greatly expand their knowledge base and practical skills.

Where to Find Detailed Diagrams

Locating comprehensive illustrations of mechanical components is essential for anyone involved in maintenance or repair tasks. Such visual guides can significantly enhance understanding and facilitate efficient troubleshooting. Fortunately, various resources are available to assist in obtaining these valuable references.

Online Resources

The internet offers a plethora of platforms where one can access extensive collections of technical visuals. Websites dedicated to machinery or equipment often feature downloadable manuals and reference materials. Additionally, online forums and communities can provide insights and shared resources from experienced users.

Manufacturer Support

Another reliable avenue for obtaining detailed illustrations is through the manufacturer’s official website. Most manufacturers provide product documentation that includes clear schematics and breakdowns of components. Reaching out to customer support can also yield specific information or direct you to appropriate resources.