The world of marine engines is intricate, encompassing a variety of crucial elements that work together to ensure optimal performance. Understanding the layout and function of these components is vital for any enthusiast or owner looking to maintain or repair their vessel.

In this section, we will explore a detailed representation of the various elements that make up a compact marine propulsion system. By delving into this visual guide, readers will gain insights into the ultimate efficiency and functionality of each part, enhancing their knowledge and confidence in handling their equipment.

Familiarity with these components not only aids in troubleshooting common issues but also empowers users to make informed decisions regarding maintenance and upgrades. Join us as we uncover the interconnected nature of these essential pieces and their roles in achieving a smooth sailing experience.

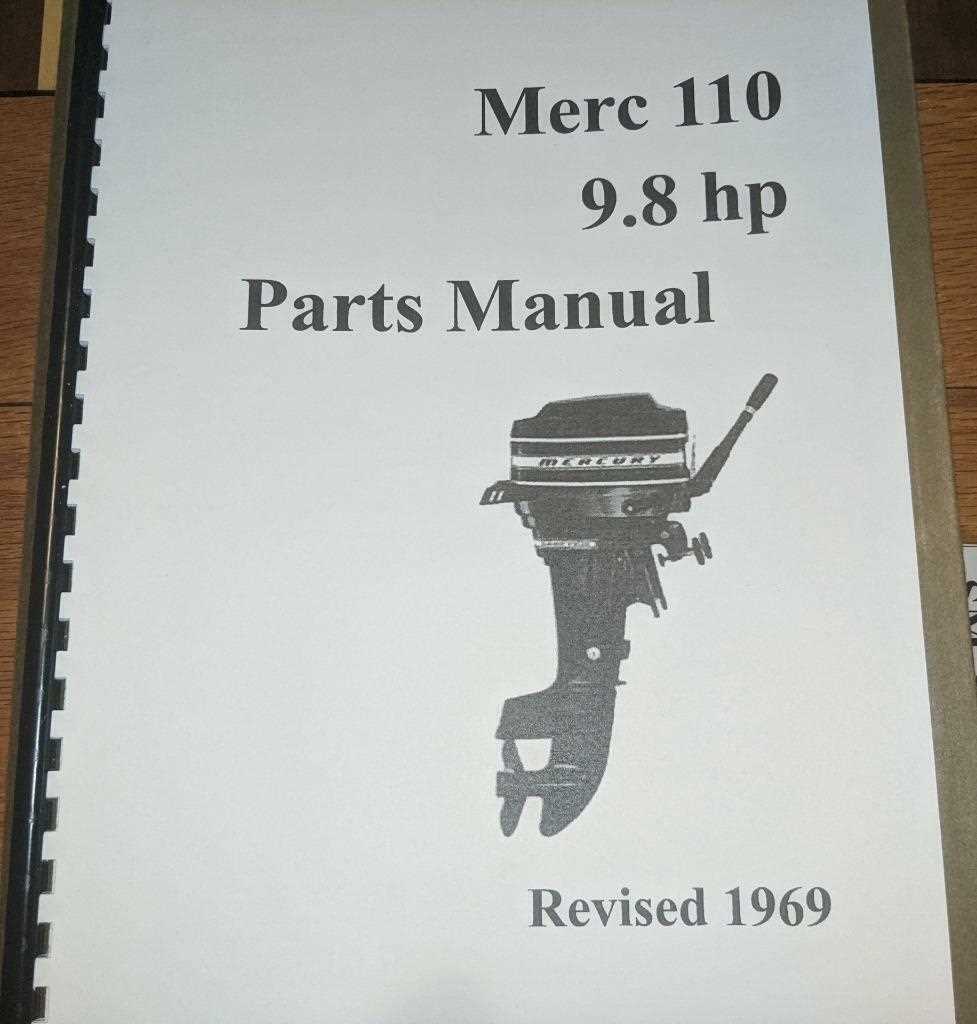

Understanding 9.8 HP Mercury Outboards

This section explores the fundamentals of small marine engines, highlighting their functionality, components, and maintenance. Grasping these aspects is essential for both novice and experienced users who rely on such engines for recreational activities.

Key Features

- Compact design for easy handling

- Reliable power output for various watercraft

- Efficient fuel consumption for extended usage

Maintenance Tips

- Regularly check oil levels and quality

- Inspect propellers for damage or wear

- Clean air filters to ensure optimal performance

Components of Mercury Outboard Motors

The functionality of marine engines relies on a variety of essential elements that work in harmony to ensure optimal performance. Each component plays a crucial role in delivering power and efficiency, making it vital for users to understand their purpose and maintenance requirements.

The powerhead serves as the engine’s core, housing the combustion process. Fuel delivery systems are responsible for supplying the necessary mixture, while the ignition system ignites this blend. Cooling mechanisms, including water pumps, prevent overheating, ensuring longevity.

The gear case contains the transmission components that facilitate movement through water, while the steering system allows for precise navigation. Additional features, such as electrical systems and control mechanisms, enhance usability, making them integral to the overall experience.

Common Issues with 9.8 HP Models

This section explores frequent challenges encountered with smaller marine engines. Understanding these issues can enhance maintenance and improve overall performance.

Performance Problems

- Inconsistent power delivery

- Difficulty starting

- Overheating

Mechanical Failures

- Fuel system clogs

- Worn components leading to leaks

- Electrical system malfunctions

Importance of Regular Maintenance

Regular inspections and timely replacements of key components can significantly reduce the risk of severe issues. This proactive approach not only saves money in the long run but also helps in maintaining the value of your equipment. Below is a table outlining some essential maintenance tasks and their benefits:

| Maintenance Task | Benefit |

|---|---|

| Oil Changes | Improves engine performance and longevity |

| Fuel System Cleaning | Enhances fuel efficiency and prevents clogging |

| Propeller Inspection | Ensures smooth operation and reduces vibration |

| Battery Maintenance | Prevents power failures and extends battery life |

| Electrical System Check | Ensures safety and reliability in navigation |

In summary, committing to regular maintenance is vital for maximizing performance and ensuring a seamless experience on the water. By addressing minor issues before they escalate, users can maintain their equipment in peak condition and enjoy countless memorable outings.

How to Identify Genuine Parts

Ensuring that you are using authentic components for your equipment is crucial for maintaining its longevity and performance. Recognizing original elements can be challenging, but with the right approach, it becomes easier to differentiate them from imitations.

- Check for manufacturer’s markings or logos that are often present on authentic items. These details are typically precise and well-crafted.

- Compare the packaging. Genuine components usually come in high-quality boxes with clear labeling and serial numbers.

- Inspect the quality of the materials. Original components are built with durable and robust materials, often distinguishing them from counterfeit versions.

- Verify the product’s weight. Sometimes, non-authentic alternatives might feel lighter or heavier due to subpar materials.

- Purchase from trusted suppliers or authorized dealers. They are more likely to provide legitimate items, reducing the risk of receiving counterfeit products.

By following these steps, you can ensure that the elements you use are not only genuine but also capable of supporting optimal functionality and performance over time.

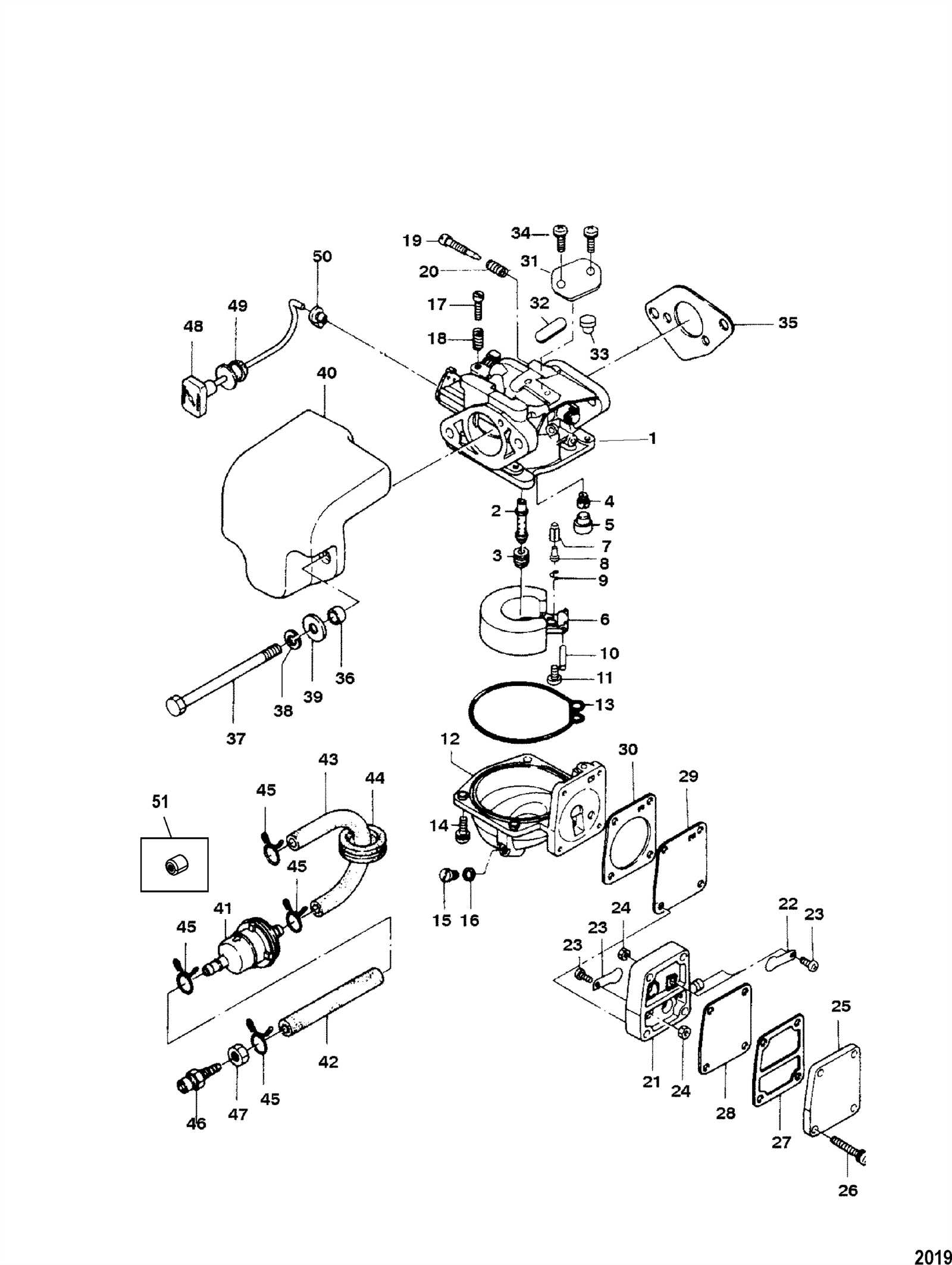

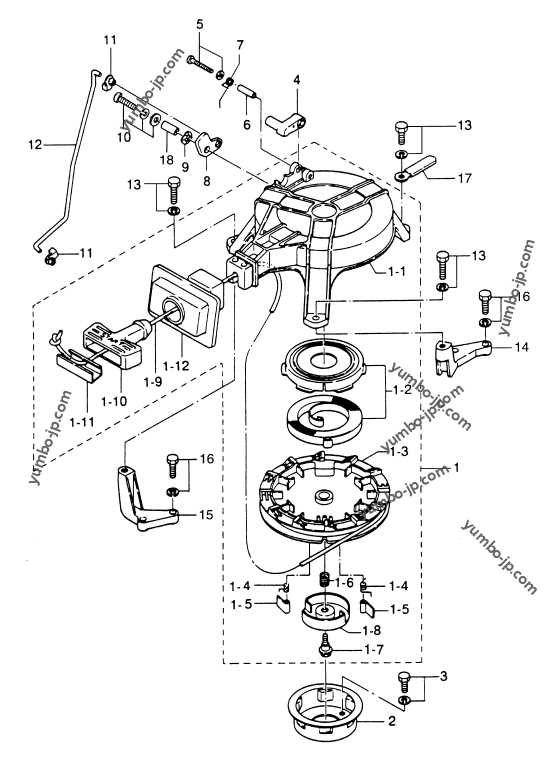

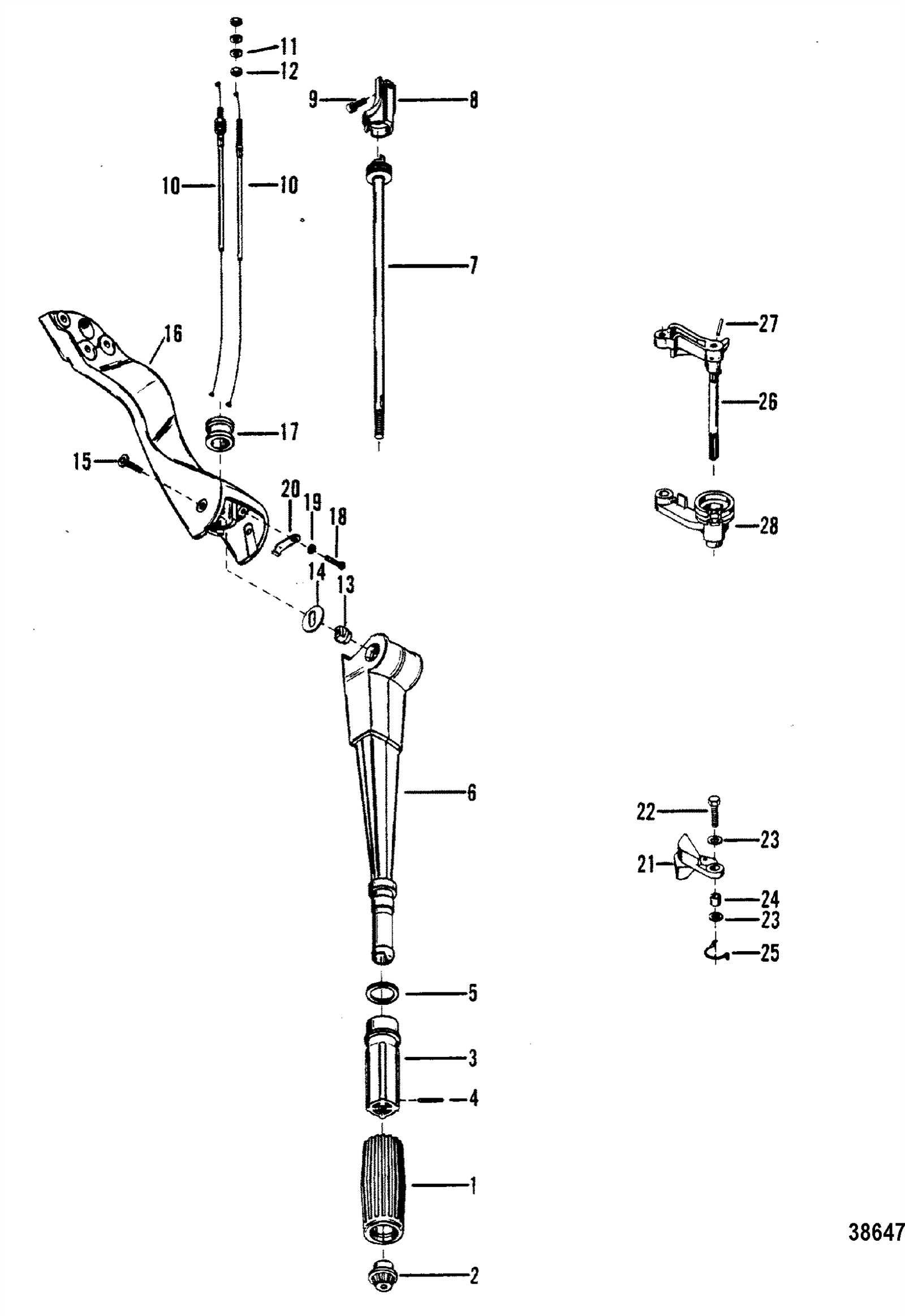

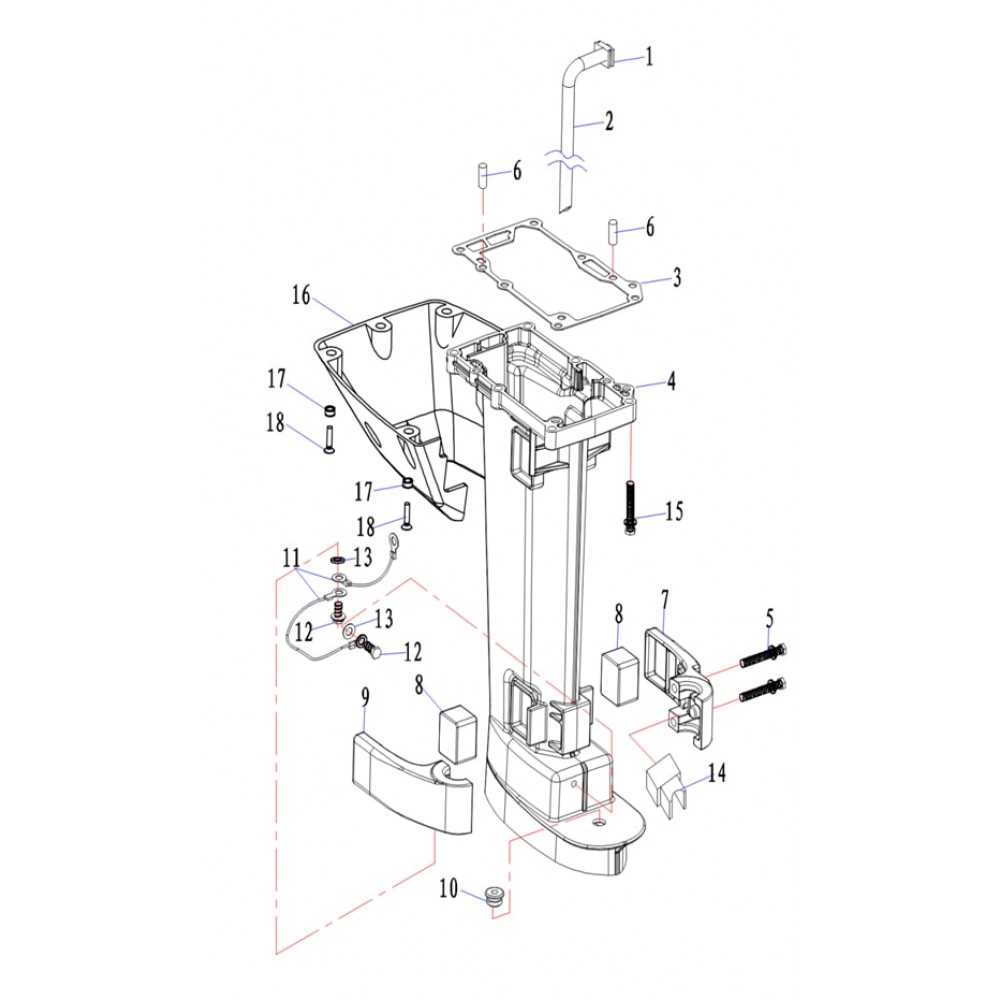

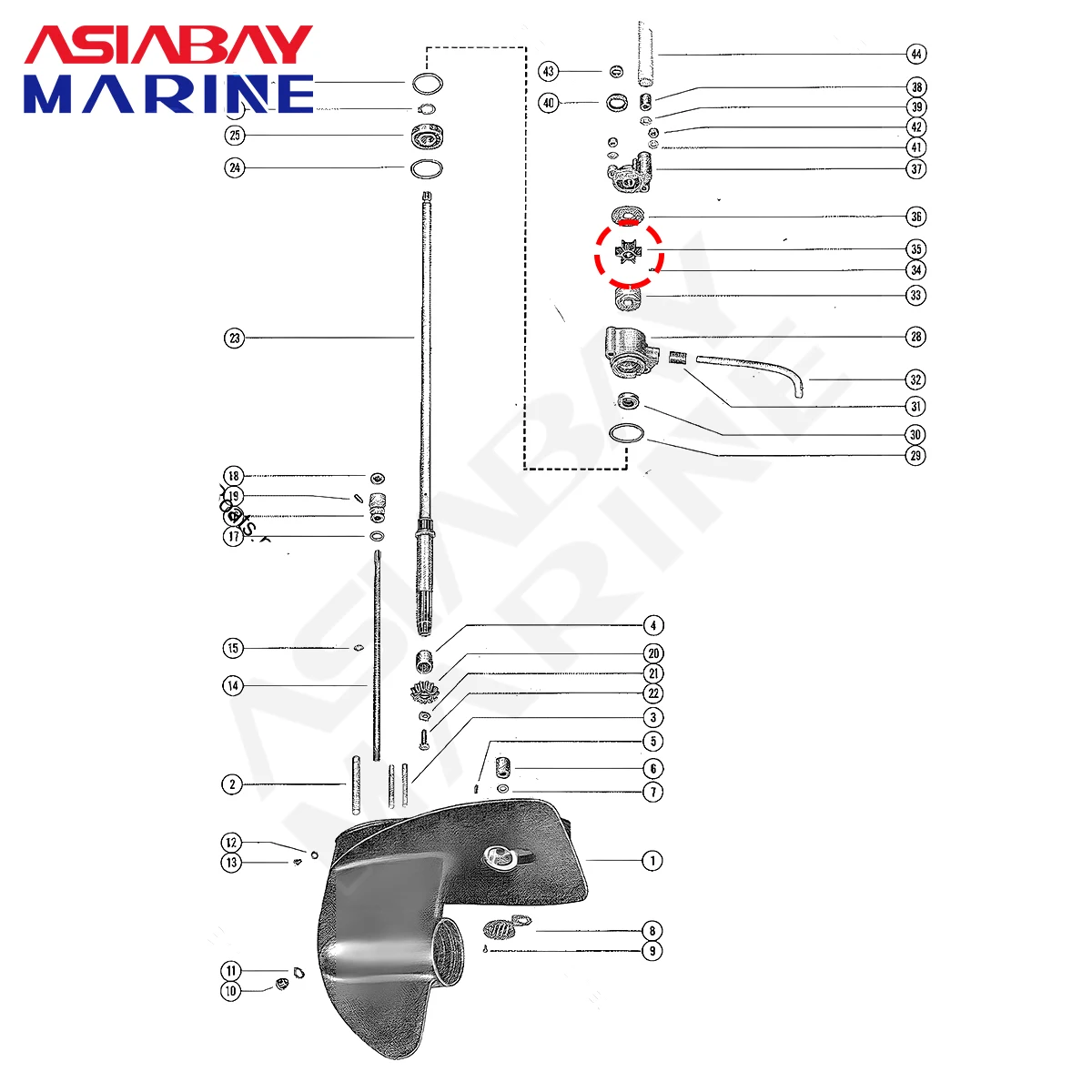

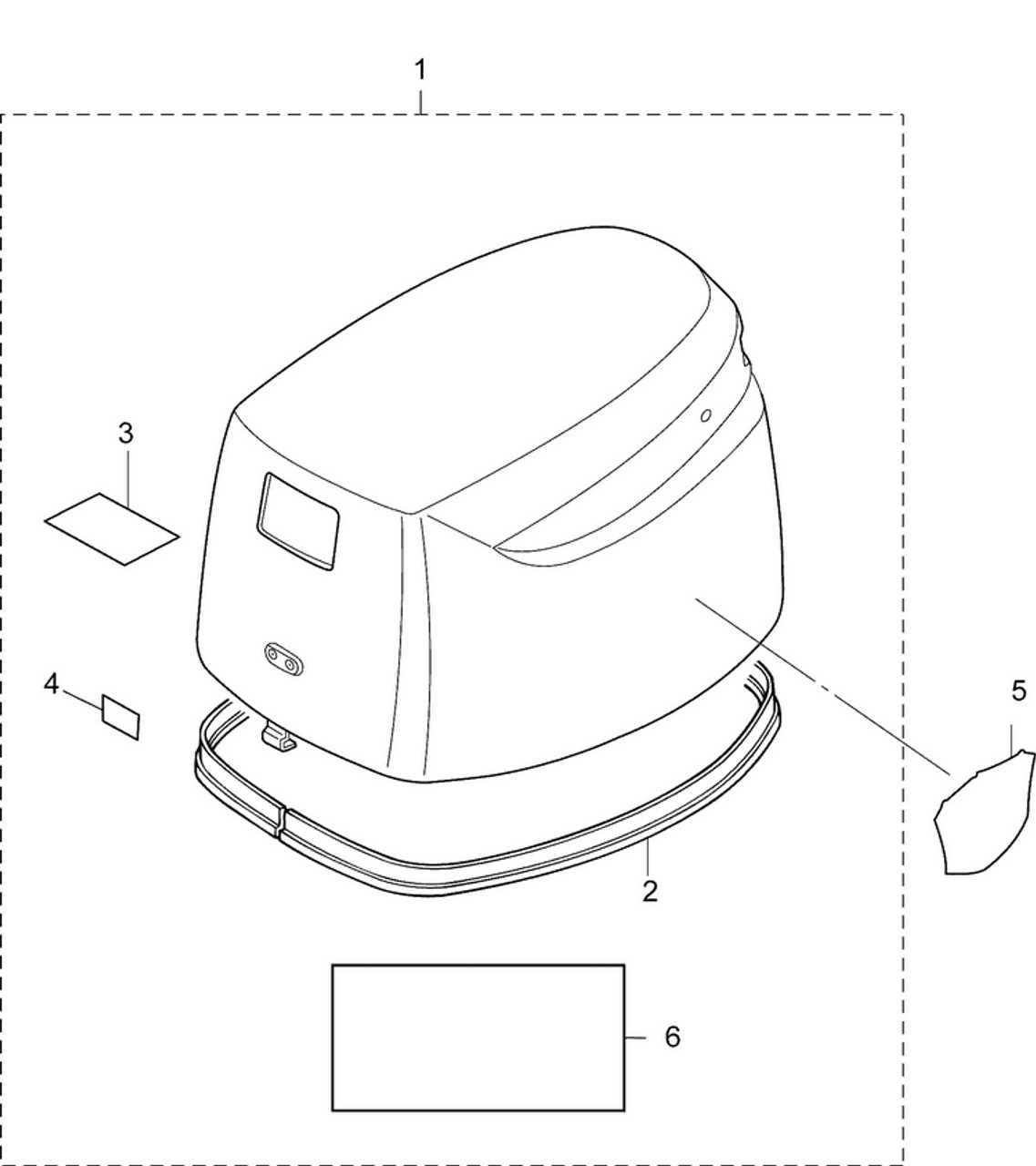

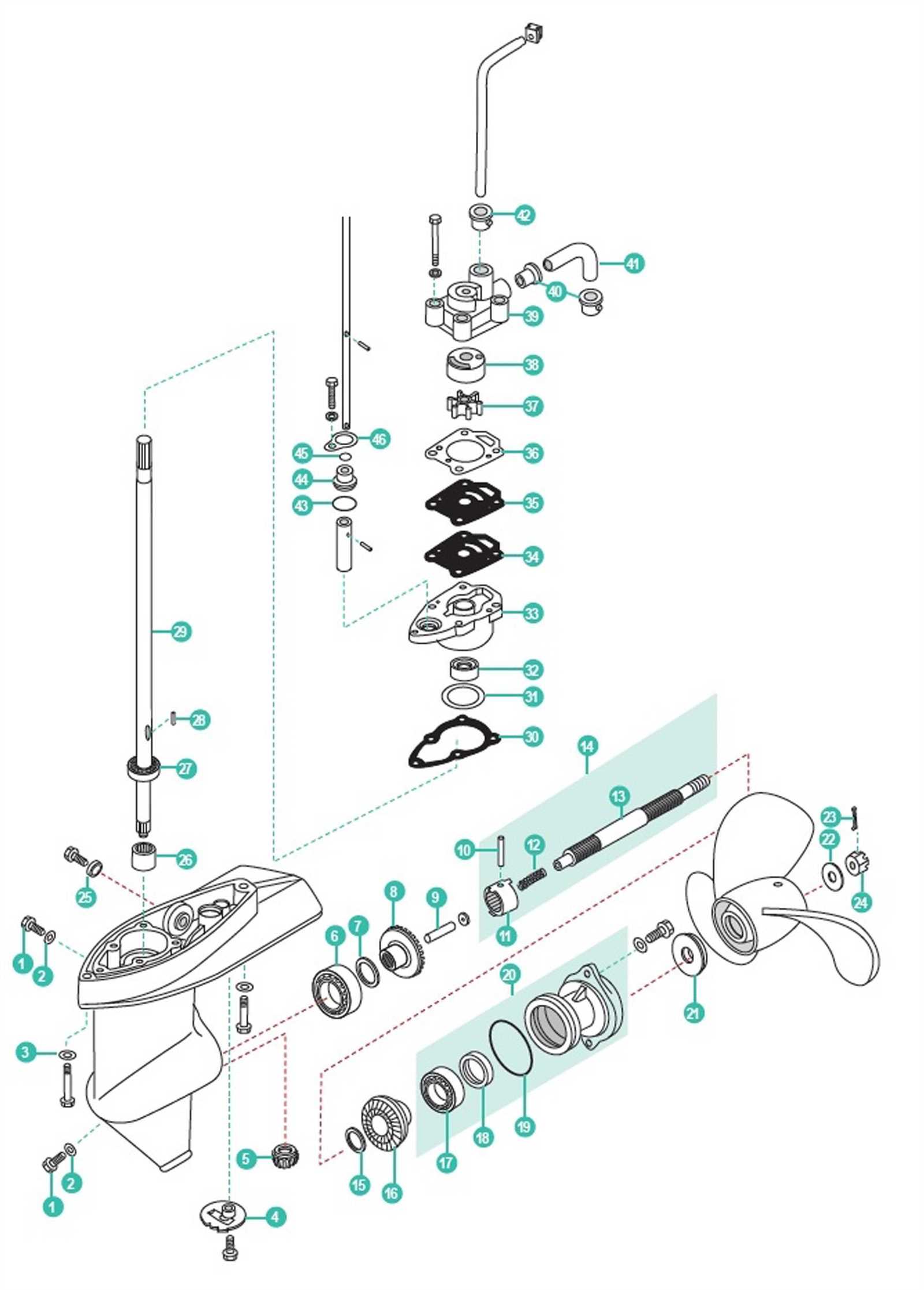

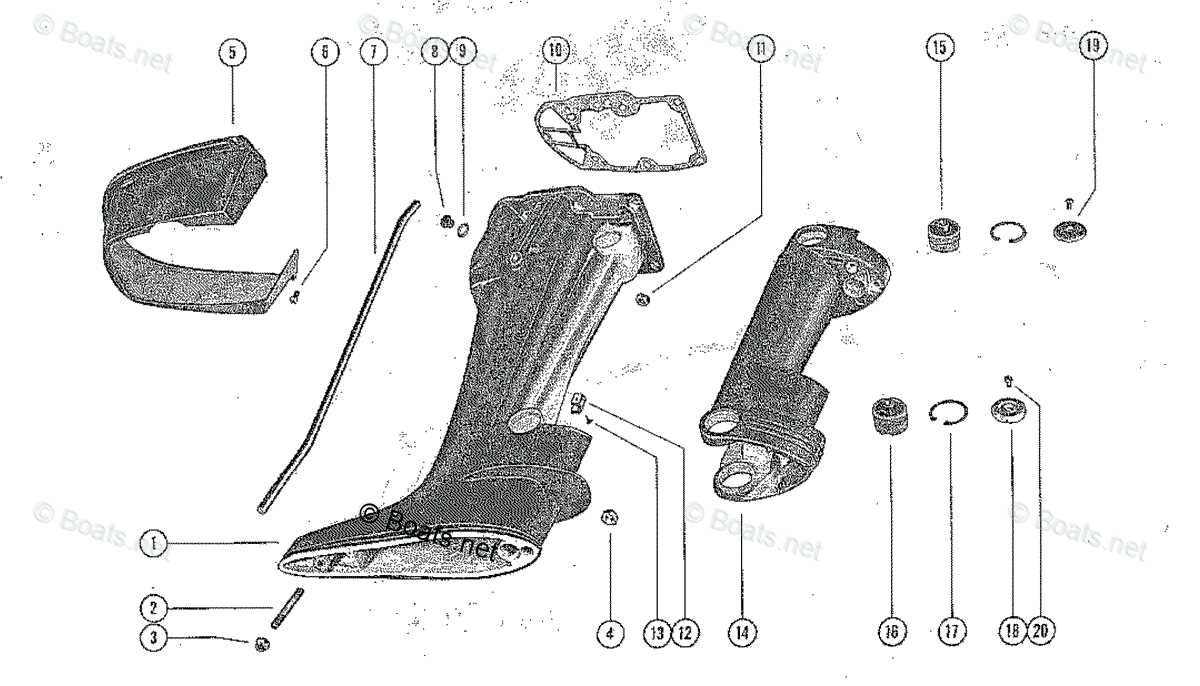

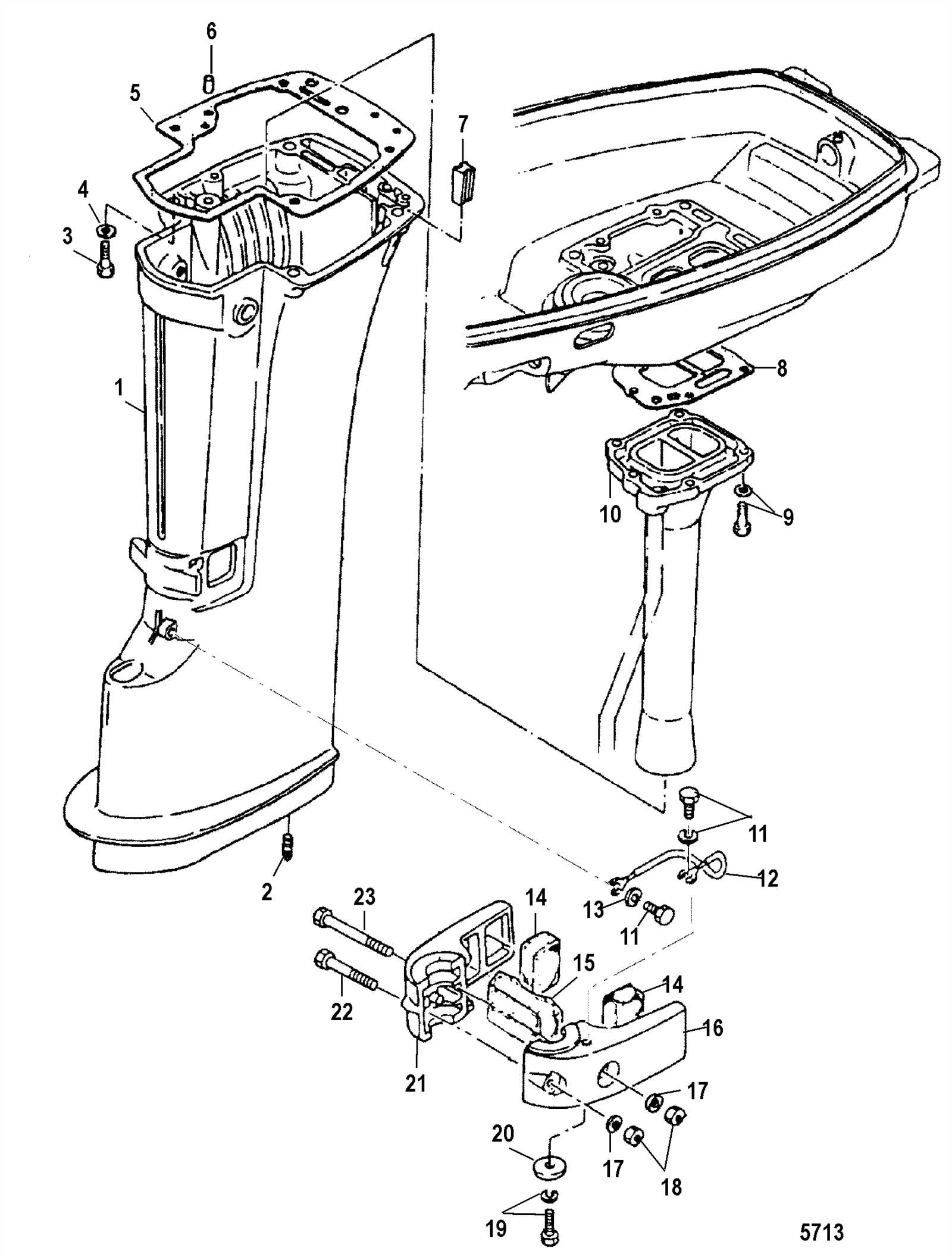

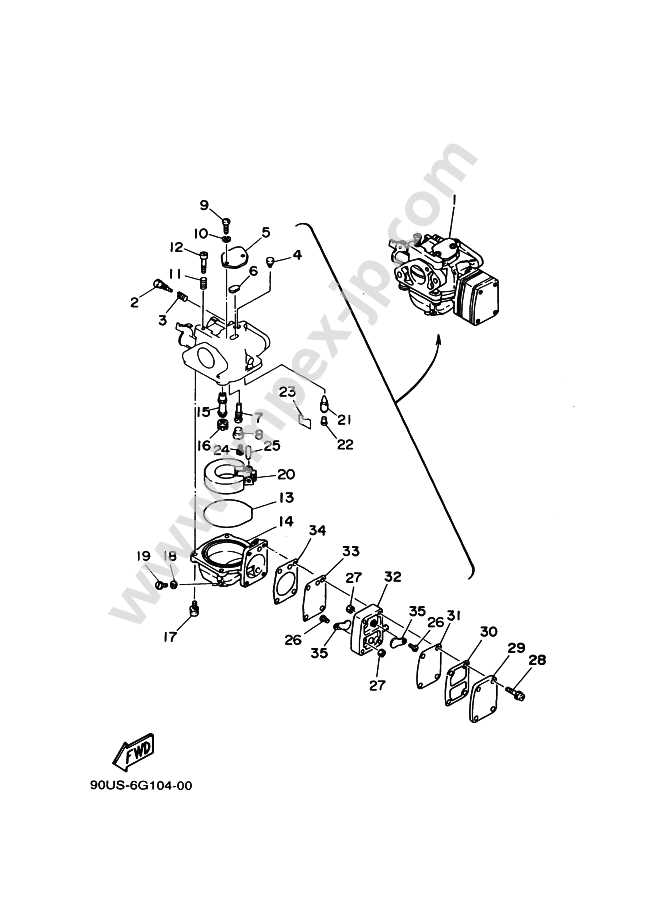

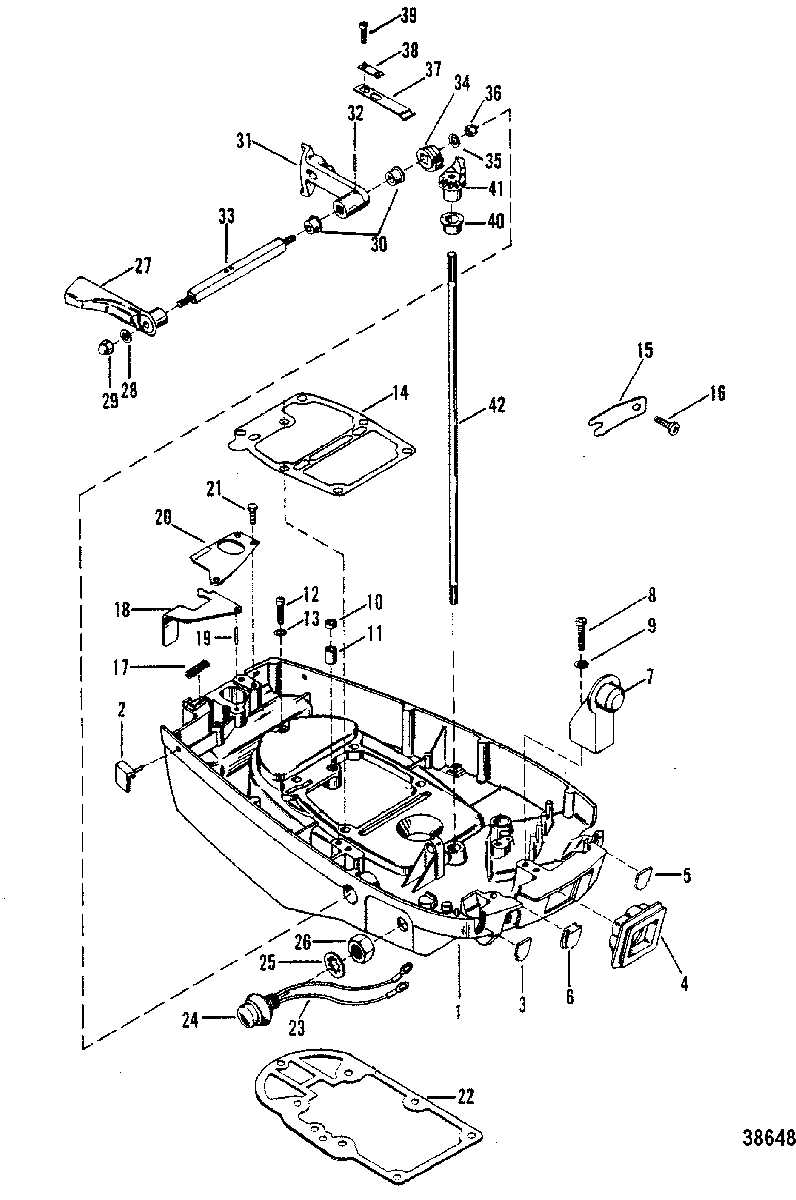

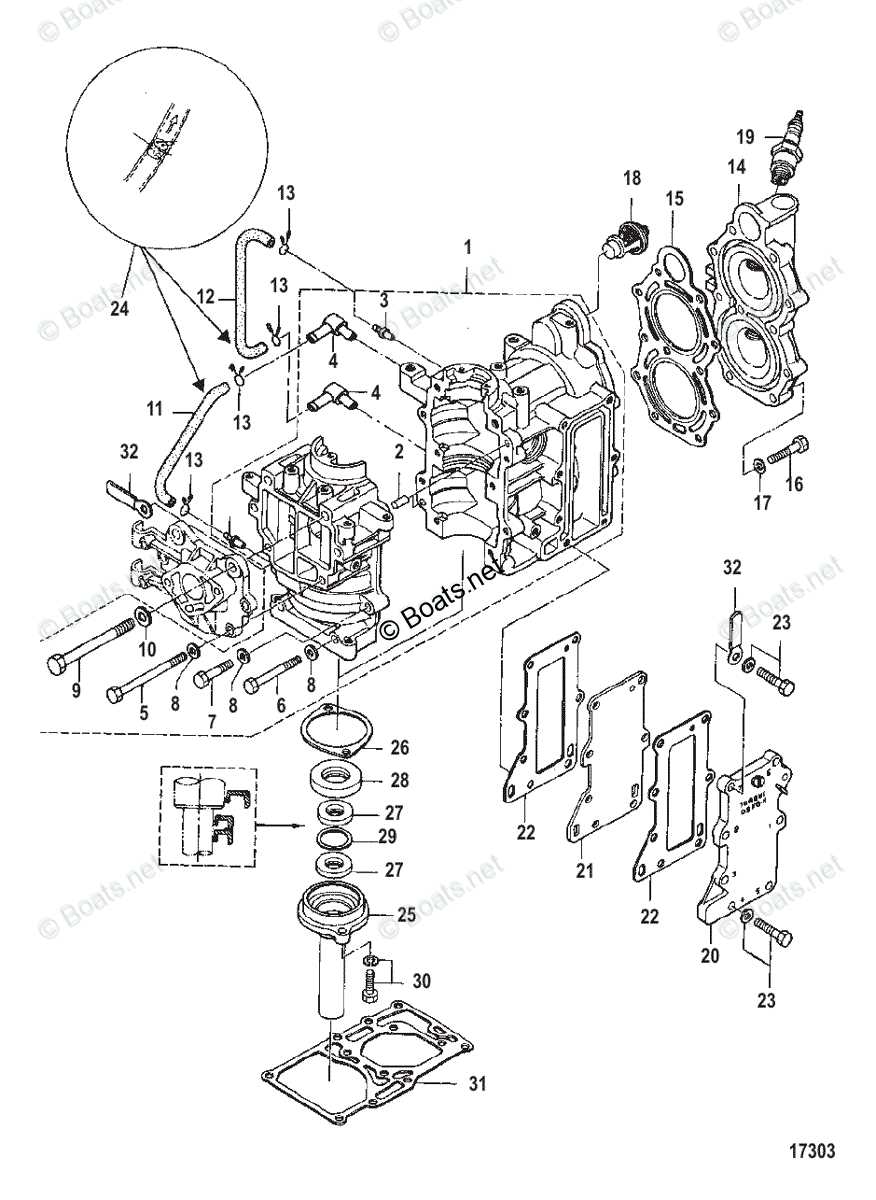

Visual Guide to Outboard Diagrams

Understanding the internal layout of various engine components can be challenging, but a clear visual representation simplifies the process. This guide offers an intuitive breakdown, helping you quickly identify key sections and their connections.

Engine Structure Overview: A well-designed illustration can reveal the intricate design of the engine’s core, showing how each mechanism is interconnected. Whether it’s fuel delivery or propulsion, you can trace each element’s role in the system.

Component Breakdown: Diagrams often include sections that highlight specific assemblies, from mechanical to electrical parts. By following these visual cues, maintenance and troubleshooting become more manageable, allowing for efficient repairs or upgrades.

Detailed depictions of critical systems enhance your understanding and ensure accuracy when working on intricate tasks. Familiarizing yourself with these illustrations enables you to make informed decisions during every step of the process.

Tools Needed for Repair Tasks

When tackling mechanical repairs, having the right set of instruments is essential to ensure both efficiency and accuracy. Proper tools not only streamline the process but also help to prevent damage to delicate components, making maintenance smoother and more reliable.

Basic Essentials

For most routine adjustments, common hand tools such as wrenches, screwdrivers, and pliers are indispensable. These instruments allow for quick fixes and fine-tuning without requiring specialized knowledge, ensuring that tasks can be handled with ease.

Advanced Equipment

In certain situations, more specialized tools such as torque wrenches, diagnostic devices, or electrical testers may be required. These ensure precision in more complex tasks, offering better control over adjustments and enhancing overall performance.

Step-by-Step Replacement Process

In this section, we’ll walk through the essential procedures for swapping out specific components in your system. This guide ensures that each step is clear and easy to follow, helping you achieve a successful replacement while maintaining optimal performance and durability.

Gathering the Necessary Tools

Before beginning, ensure you have all the required tools and equipment on hand. This will streamline the process and prevent delays. Typical tools include wrenches, screwdrivers, and safety gear to protect yourself during the task.

- Wrench set

- Screwdrivers (Phillips and flathead)

- Lubricants or sealants

- Protective gloves

Replacement Procedure

- Begin by disconnecting the power source to avoid any accidental start-ups.

- Carefully remove any external covers or shields that obstruct access to the component you’re replacing.

- Loosen and remove the fasteners holding the part in place, noting the arrangement for reassembly.

- Gently detach the old part, ensuring no damage to adjacent connections or surfaces.

- Install the new component, securing it with the original fasteners and applying lubricant if necessary.

- Double-check all connections and tighten any loose fasteners before reattaching the covers.

- Reconnect the power source and perform a test to confirm everything functions correctly.

Aftermarket vs. OEM Parts Comparison

When it comes to replacing components, one is often faced with a choice between original manufacturer pieces and those produced by third-party suppliers. Both options have their distinct advantages and challenges, making it crucial to understand how each can impact the performance and longevity of equipment.

Original manufacturer products are designed specifically for the machinery they are meant to support, ensuring a high level of compatibility and reliability. These parts undergo rigorous testing and are crafted to meet stringent quality standards. However, they can come at a premium cost.

Aftermarket alternatives, on the other hand, are typically more affordable and often offer a wider range of choices. While some third-party options match or even exceed the quality of original components, others may not meet the same durability or performance expectations. It’s essential to carefully evaluate the reputation of the supplier and the specifications of the replacement before making a decision.

Ultimately, choosing between these two categories depends on balancing cost, quality, and the specific requirements of the task at hand.

Wiring and Electrical Components Overview

The electrical system is a crucial aspect of ensuring the smooth operation of any small engine. This section delves into the key connections and circuits, providing an understanding of how various components interact to maintain functionality. With the correct configuration, the entire system works seamlessly to support ignition, power delivery, and other essential functions.

| Component | Function |

|---|---|

| Ignition Coil | Transforms low voltage into the high voltage needed to ignite the fuel-air mixture. |

| Voltage Regulator | Maintains a stable voltage output, preventing damage to other electrical components. |

| Starter Solenoid | Acts as a switch, allowing the starter motor to engage when the key is turned. |

| Battery Cables | Carry the necessary electrical current to power the engine’s various components. |

Tips for Troubleshooting Performance Issues

When dealing with reduced efficiency or inconsistent functioning, identifying the root cause can be challenging. However, with systematic observation and a methodical approach, you can often resolve the issue without extensive repairs. This section outlines key areas to inspect and test, allowing you to quickly pinpoint possible faults and maintain optimal operation.

Start by examining the most common causes of disruptions, such as fuel system irregularities. Check for blockages, leaks, or air bubbles, as they can lead to erratic performance. Additionally, ensure the flow of fuel is steady and that there is no contamination in the system.

Electrical components are another area prone to malfunctions. A weak connection or corroded wiring can result in unstable functionality. Inspect all connections for cleanliness and firmness, paying special attention to the battery terminals. A simple cleaning or tightening of wires can often restore proper performance.

Lastly, mechanical issues may arise from improper alignment or wear and tear. Bearings, seals, and moving parts should be routinely inspected for signs of damage or degradation. Lubricate parts as necessary and replace any that show significant wear to ensure smooth operation.

Where to Buy Replacement Parts

When it comes to maintaining your marine engine, finding suitable components is essential for keeping everything in optimal working condition. Whether you’re looking for new items or aftermarket alternatives, there are various sources to consider that offer a range of choices for different needs and budgets.

Authorized Dealers

One of the most reliable options is purchasing from official distributors. These providers often have a comprehensive inventory, ensuring compatibility with your specific model. Additionally, they usually offer warranties and professional support, which can be crucial for ensuring long-term performance.

Online Marketplaces

For those who prefer the convenience of shopping from home, online platforms can be an excellent resource. From specialized marine equipment websites to well-known general retailers, the variety available online allows for price comparisons and customer reviews, making it easier to make informed decisions.

- Official supplier websites

- Large e-commerce platforms

- Specialized marine stores

No matter where you choose to shop, it’s important to verify the authenticity and quality of the items to ensure a smooth and efficient repair process.