In the world of compact machinery, a comprehensive grasp of the essential elements that contribute to performance is crucial for both operators and technicians. A well-structured overview can enhance maintenance practices and streamline repairs, ensuring optimal functionality and longevity of the equipment.

Visual representation of these components serves as a valuable tool for identifying each piece’s role within the machine’s overall operation. By examining the intricate relationships among various elements, users can gain insights into troubleshooting and enhancing efficiency.

Moreover, familiarity with these components enables effective communication between operators and service personnel. This understanding fosters a collaborative approach to addressing issues and implementing upgrades, ultimately leading to improved productivity on the job site.

Understanding Bobcat Skid Steer Components

In the realm of compact machinery, comprehending the various elements that contribute to the overall functionality is crucial for efficient operation and maintenance. Each component plays a vital role, working in harmony to ensure optimal performance and reliability. Familiarity with these parts not only aids in troubleshooting but also enhances the user’s ability to make informed decisions regarding repairs and upgrades.

| Component | Description | Function |

|---|---|---|

| Engine | Power unit that drives the entire system | Generates the necessary power for movement and operation |

| Hydraulic System | Network of components that use fluid pressure | Controls lifting and lowering of attachments |

| Chassis | Frame that supports the entire machine | Provides stability and strength during operation |

| Attachments | Various tools that can be connected | Enhances versatility for different tasks |

| Tracks/Wheels | Mobility components that provide traction | Facilitates movement across various terrains |

Importance of Proper Parts Identification

Accurate identification of components is crucial for maintaining machinery efficiency and longevity. Ensuring that the right elements are selected not only enhances performance but also minimizes the risk of operational failures.

Understanding the correct specifications helps in selecting the appropriate replacements, thereby avoiding costly mistakes. An in-depth knowledge of the various components can lead to improved safety and functionality.

Furthermore, incorrect identification may result in unnecessary downtime and increased repair expenses. Streamlining the maintenance process through precise recognition ultimately supports a more productive working environment.

Common Parts in Bobcat Models

This section explores essential components found in various models of compact machinery. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Key Components

Among the vital elements are the hydraulic system, which plays a significant role in lifting and maneuvering, and the engine assembly, providing the necessary power for operation. Additionally, the undercarriage is critical for stability and traction, allowing the machine to navigate diverse terrains.

Additional Features

Other notable components include the control system that allows operators to manage functions smoothly, as well as the attachment interface, which facilitates the connection of various tools. Familiarity with these components enhances the user’s ability to perform maintenance effectively and address any operational issues that may arise.

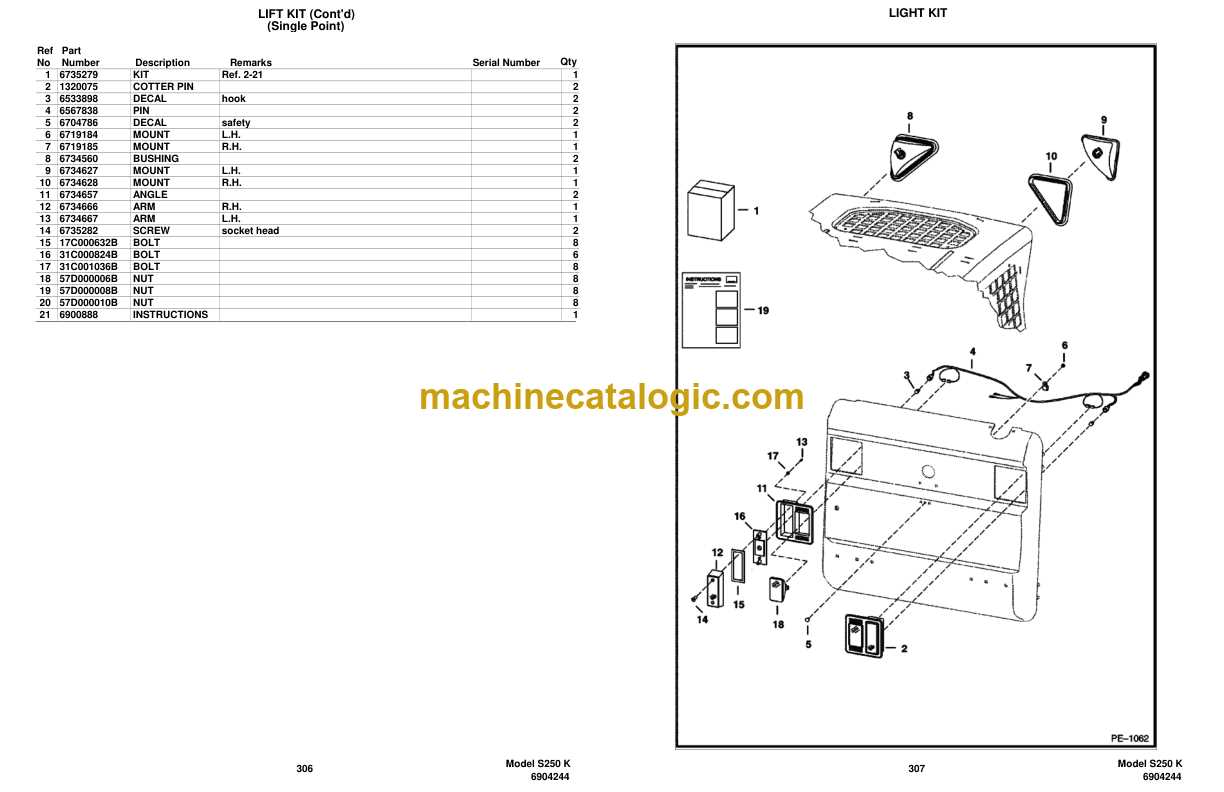

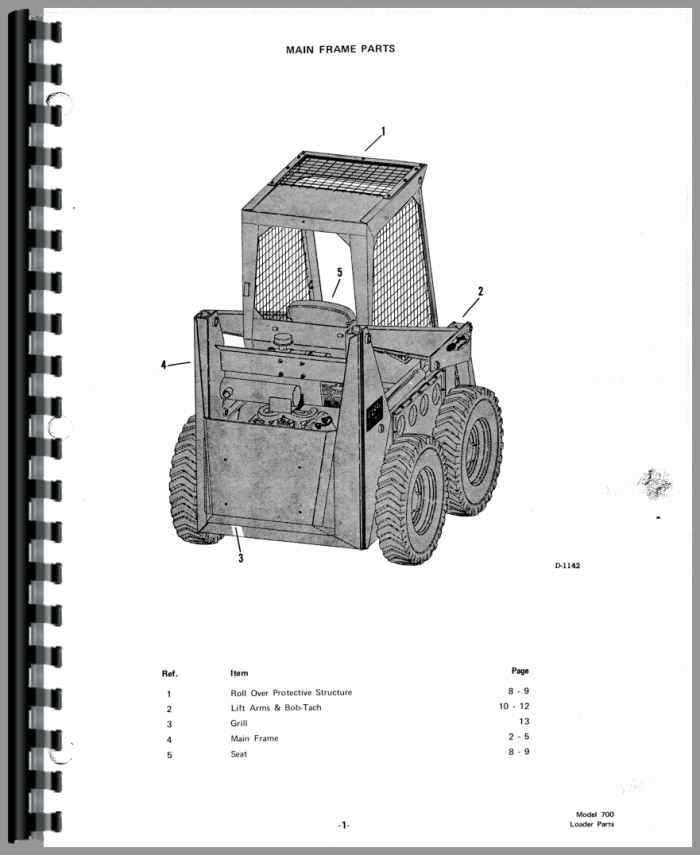

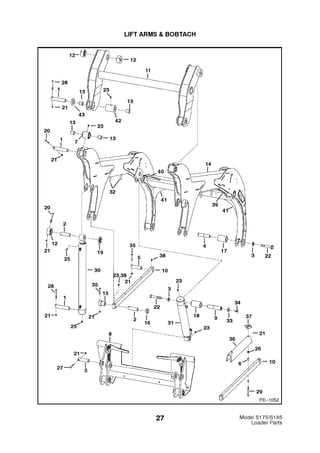

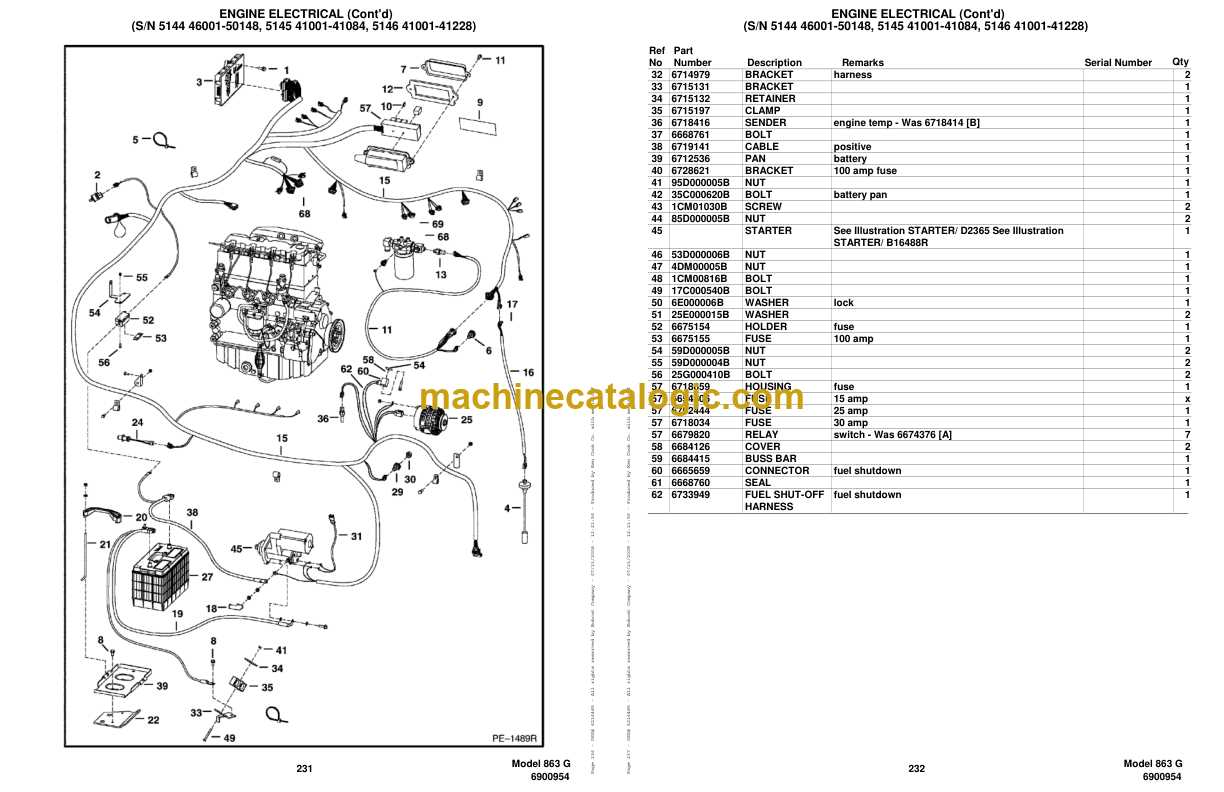

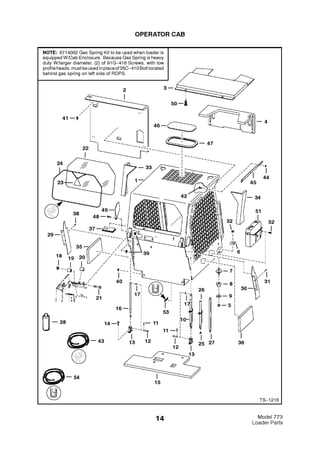

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your maintenance and repair capabilities. These illustrations serve as invaluable tools, allowing users to identify and locate individual elements within a complex assembly. Familiarizing yourself with these visuals will streamline the repair process and reduce downtime.

Identifying Key Elements

Each illustration typically includes labeled sections that correspond to specific items. Start by examining the legend or key, which provides definitions for various symbols and numbers used throughout the visual. Pay attention to the orientation of the components, as this can influence their installation and functionality. Recognizing common symbols is essential for navigating these visuals effectively.

Understanding Groupings and Relationships

Components are often grouped based on their functionality or position within the assembly. Look for connection points and how different parts interact with each other. This knowledge helps in diagnosing issues and planning repairs. Analyzing the relationships between elements can provide insights into the overall operation of the equipment.

Types of Attachments for Skid Steers

Attachments play a crucial role in enhancing the versatility and functionality of compact machinery. By utilizing various implements, operators can tackle a wide range of tasks, making these machines indispensable in construction, landscaping, and agricultural settings. Understanding the types of available accessories is essential for optimizing performance and efficiency.

| Attachment Type | Primary Use |

|---|---|

| Bucket | Material handling, digging, and moving earth |

| Forks | Lifting and transporting pallets and heavy objects |

| Auger | Drilling holes for posts, trees, or foundations |

| Blade | Grading and leveling surfaces |

| Grapple | Handling bulky or irregularly shaped materials |

| Sweeper | Cleaning debris from surfaces |

| Tiller | Preparing soil for planting |

| Snow Plow | Removing snow from roads and driveways |

Maintenance Tips for Skid Steer Parts

Ensuring the longevity and efficiency of your machinery requires regular attention to its components. Proper upkeep not only enhances performance but also prevents costly repairs. Here are some essential recommendations for maintaining your equipment’s essential elements.

Regular Inspections

Conduct frequent evaluations to identify wear and tear. Look for signs of damage such as cracks or rust. Timely detection can save you from more extensive issues down the line.

Lubrication and Cleaning

Keep moving components well-lubricated to minimize friction. Clean all areas to remove debris, which can hinder functionality. A clean machine operates more effectively and lasts longer.

Where to Find Replacement Parts

Finding high-quality components for your machinery is essential for maintaining optimal performance and longevity. Various sources offer a range of options, from original manufacturers to third-party suppliers. Each avenue presents unique benefits, allowing you to select the most suitable for your needs.

Official dealers often provide genuine components that ensure compatibility and reliability. These establishments may also offer expert advice on installation and maintenance, enhancing your overall experience. Additionally, authorized websites can be valuable resources for accessing detailed specifications and current inventories.

For those seeking cost-effective alternatives, aftermarket suppliers present a plethora of choices. Many of these vendors specialize in providing durable components that can match or exceed the quality of originals, often at a lower price point. Online marketplaces also facilitate easy comparisons and access to customer reviews, helping you make informed decisions.

Local equipment repair shops can be a convenient option as well. They frequently stock commonly needed items and can offer personalized service, assisting in selecting the right components for your machinery. Networking with fellow operators can yield recommendations for reliable sources, ensuring that you find what you need efficiently.

Ultimately, exploring a combination of these resources can help you locate the best components tailored to your specific machinery requirements. Whether prioritizing quality, cost, or convenience, a thorough search will lead to the right choices for your equipment.

Benefits of Using OEM Components

Choosing original equipment manufacturer components ensures optimal performance and longevity for machinery. These elements are specifically designed to fit and function seamlessly, providing reliability and efficiency.

Quality Assurance

Utilizing OEM components guarantees superior quality standards. The benefits include:

- Manufactured to precise specifications

- Thorough testing for durability

- Consistent performance over time

Enhanced Compatibility

Original components offer unmatched compatibility with your equipment. Key advantages are:

- Perfect fit reduces maintenance issues

- Minimized risk of equipment failure

- Streamlined installation process

Safety Considerations for Part Replacement

When replacing components in heavy machinery, prioritizing safety is essential to prevent accidents and ensure optimal functionality. Understanding potential risks and adhering to safety protocols can greatly minimize hazards associated with maintenance tasks.

Before initiating any replacement procedures, consider the following guidelines:

| Safety Tip | Description |

|---|---|

| Wear Personal Protective Equipment (PPE) | Always use appropriate gear, such as gloves, goggles, and helmets, to protect against injuries. |

| Ensure Stability | Make sure the machinery is securely positioned and not at risk of rolling or shifting during work. |

| Disconnect Power Sources | Always disconnect power before performing any maintenance to avoid accidental starts. |

| Consult Manuals | Refer to operational guidelines to understand the correct procedures and specifications for replacement. |

| Work with a Partner | Having a colleague assist can provide an extra layer of safety and help handle heavy components. |

Upgrading Parts for Enhanced Performance

Improving machinery efficiency can significantly boost productivity and longevity. By focusing on the right components, operators can enhance capabilities and achieve optimal functionality.

Consider these key upgrades:

- Engine enhancements for increased power output

- Hydraulic systems for superior lifting capacity

- Track or tire improvements for better traction

- Cab modifications for enhanced comfort and visibility

Each of these upgrades contributes to an ultimate performance increase, ensuring that your equipment operates at its best in demanding conditions.

Before proceeding with modifications, assess compatibility and installation requirements to ensure seamless integration. Regular maintenance is also crucial to maximize the benefits of these enhancements.

Diagnosing Common Issues with Components

Identifying problems within machinery can often be a challenging task. Understanding how various elements function together is essential for effective troubleshooting. By examining symptoms and correlating them with specific components, one can efficiently address malfunctions and enhance overall performance.

Common issues may manifest as unusual noises, reduced efficiency, or inconsistent operation. A systematic approach to diagnosis involves checking fluid levels, inspecting filters, and assessing the integrity of connections. Regular maintenance and vigilant observation play a critical role in preventing minor issues from escalating into significant failures.

Utilizing a component reference guide can facilitate the identification of particular parts, making it easier to locate and address issues. Moreover, keeping records of past problems and resolutions can aid in recognizing patterns and predicting potential malfunctions in the future.

Resources for Bobcat Parts Manuals

Accessing accurate documentation is essential for anyone involved in machinery maintenance and repairs. Various resources provide comprehensive manuals, aiding in understanding components and their assembly. These references are invaluable for ensuring efficient operations and prolonging equipment lifespan.

Online Platforms

Numerous websites offer downloadable manuals and diagrams. These platforms often feature user-friendly navigation, enabling quick access to specific models and parts. Community forums on these sites also provide insights and shared experiences from fellow operators.

Manufacturer Support

Direct support from the manufacturer can be a reliable source for official documentation. Many manufacturers maintain dedicated sections on their websites where users can request or access detailed manuals. Additionally, contacting customer service can yield further assistance and guidance.