In the realm of outdoor machinery, clarity in assembly and functionality is essential for optimal performance. Knowing the intricate relationship between various elements not only enhances operational efficiency but also aids in troubleshooting. This guide delves into the intricate framework that underpins effective equipment management, ensuring users are well-informed about each crucial segment.

By exploring the interconnections and specific roles of different components, users can gain valuable insights into maintenance and upgrades. Whether you are a seasoned operator or a novice, a comprehensive grasp of how each part contributes to the overall system is vital. A detailed visual representation serves as an invaluable tool, offering clarity in understanding and facilitating seamless repairs.

Equipped with this knowledge, users can confidently navigate through challenges, ensuring their machinery remains in peak condition throughout its lifespan. Mastery of these layouts empowers individuals to maximize their equipment’s potential, fostering both skill and confidence in their operational capabilities.

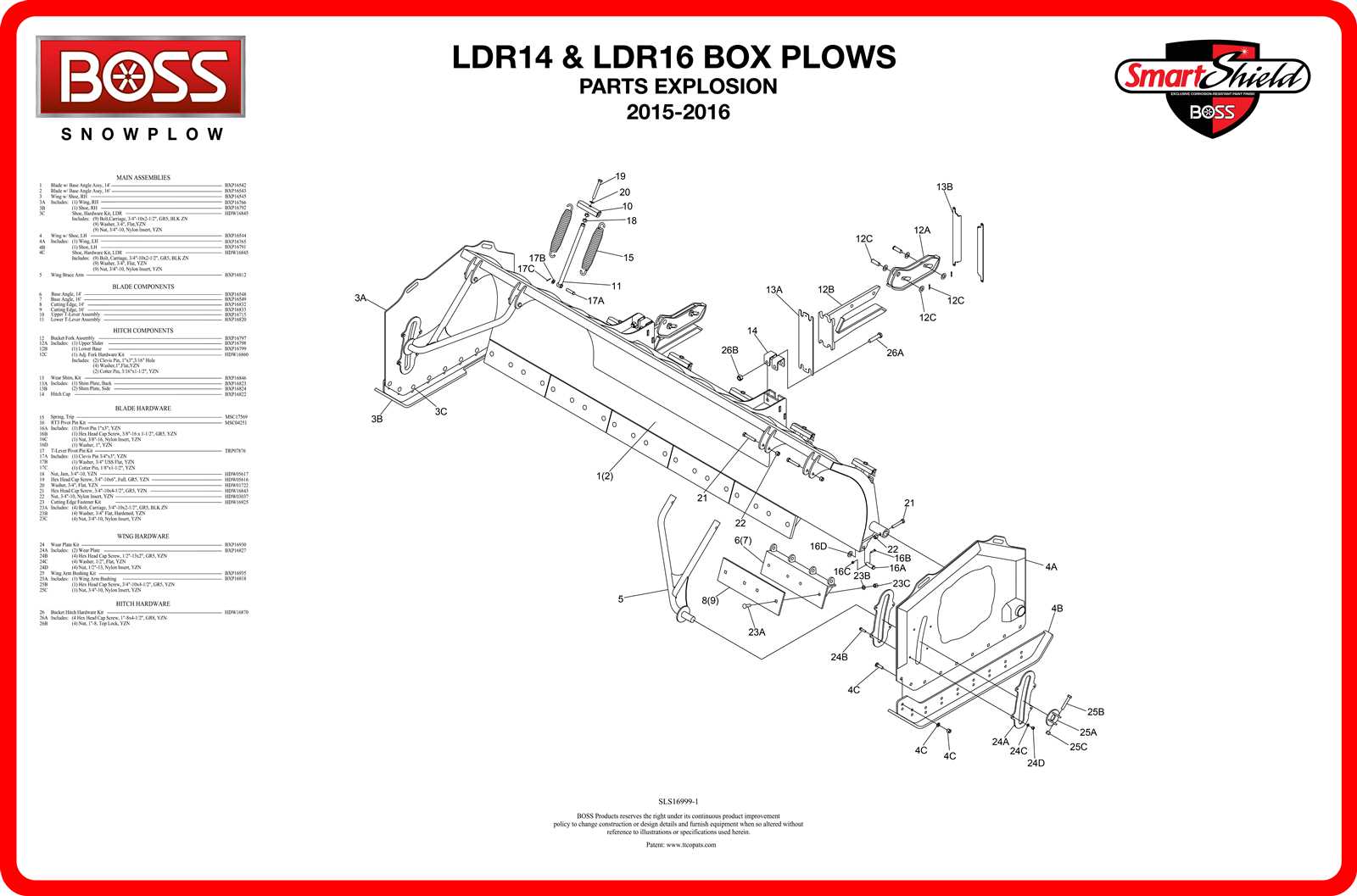

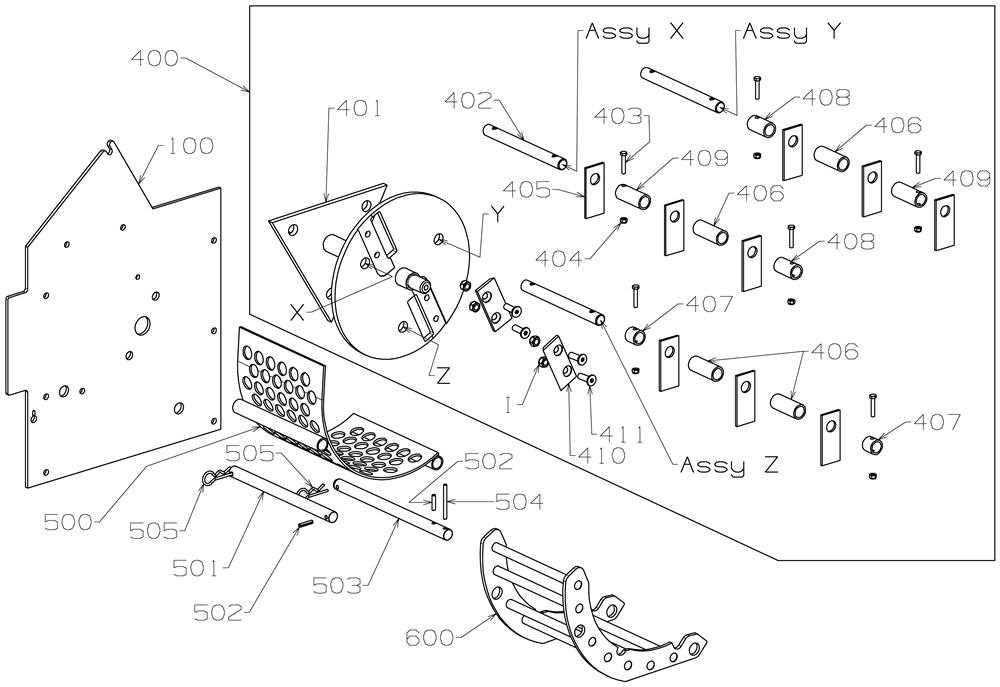

Understanding Boss V Plow Components

When tackling the challenges of snow removal or landscaping, it is crucial to have a thorough understanding of the essential elements involved in the operation. Each component plays a significant role in ensuring efficiency and reliability during use. By exploring these individual segments, one can gain insight into how they contribute to overall functionality.

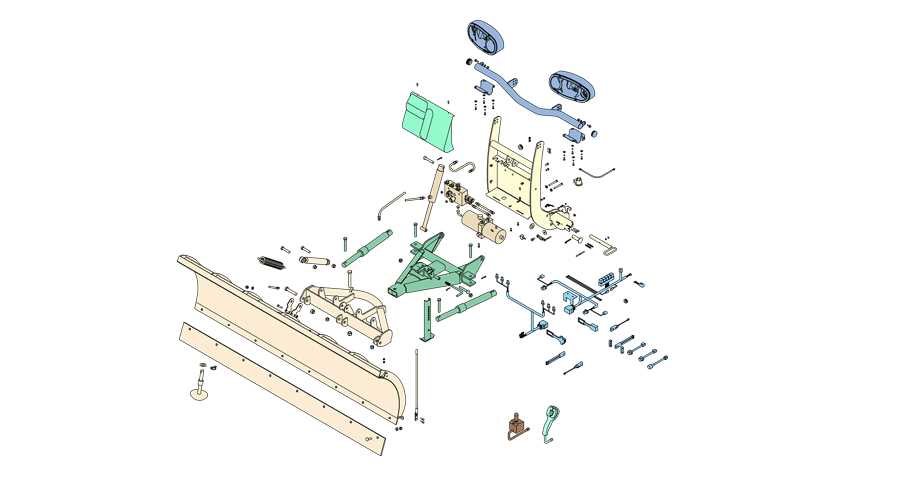

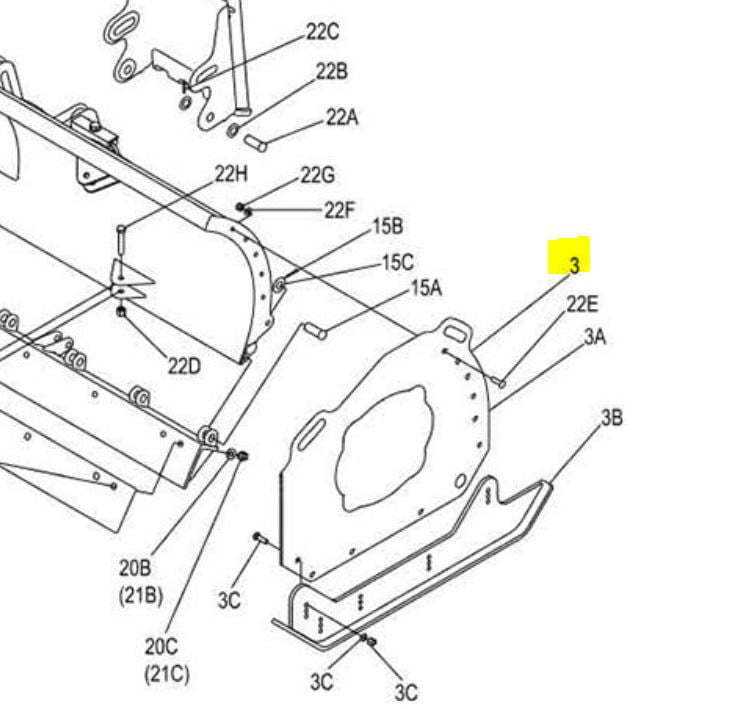

The Framework: The structural base serves as the foundation, providing stability and support. Its design is integral for withstanding various forces encountered during operation, enhancing durability and performance.

Angled Blades: The specially shaped edges are engineered to direct material effectively. Their unique configuration allows for versatile movement, adapting to different conditions and maximizing productivity.

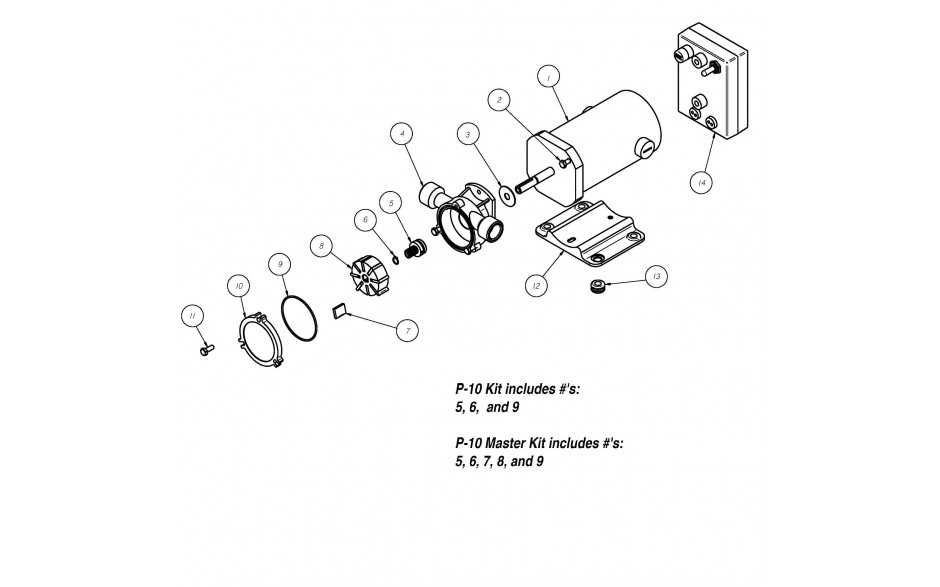

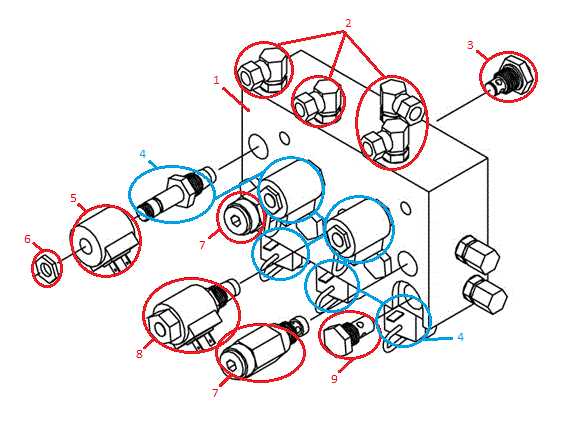

Hydraulic Mechanisms: These systems are vital for maneuverability, allowing for seamless adjustments in blade positioning. Their efficiency is paramount in ensuring quick response times and optimal handling.

Mounting Hardware: Secure attachment is essential for safety and functionality. The hardware is designed to provide a robust connection, ensuring that all elements remain firmly in place during operation.

Control Systems: The user interface is crucial for operational command. Intuitive controls allow for precise adjustments, enabling the operator to respond swiftly to changing conditions on the ground.

By understanding these critical elements, users can better appreciate the intricacies involved in effective snow management and maintenance tasks, leading to improved performance and satisfaction in their endeavors.

Essential Parts of V Plow System

The effectiveness of a versatile snow-clearing system relies on several key components that work in harmony to ensure optimal performance. Understanding these fundamental elements is crucial for anyone looking to maintain efficiency during winter operations.

Mounting Frame: This structural element serves as the foundation, providing stability and secure attachment to the vehicle. Its robust design ensures durability under harsh conditions.

Blade Assembly: The adjustable front segment is designed to tackle varying snow depths and types. Its unique shape allows for enhanced maneuverability and efficient snow displacement.

Hydraulic System: Essential for controlling the blade’s movement, this mechanism enables precise adjustments. It allows the operator to raise, lower, and angle the blade according to the specific requirements of the job.

Control Mechanism: The interface used by the operator plays a vital role in managing the entire system. An intuitive design ensures quick and effective adjustments, enhancing overall usability.

Wear Shoes: These protective elements are crucial for extending the lifespan of the blade assembly. They prevent excessive wear on the underside while also improving the efficiency of snow removal.

By understanding these integral components, operators can ensure their system functions at peak efficiency, ultimately leading to safer and more effective snow management.

Importance of Proper Maintenance

Regular upkeep of equipment is crucial for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also minimizes the risk of unexpected breakdowns. When machinery is well-maintained, it operates more smoothly, leading to better results in various applications.

Neglecting maintenance can lead to a range of issues, from minor inconveniences to major malfunctions. Components that are not regularly serviced may wear out more quickly, resulting in costly repairs or replacements. By adhering to a structured maintenance schedule, operators can identify potential problems early and address them before they escalate.

Moreover, well-maintained equipment often leads to improved safety for users. Ensuring that all elements are functioning correctly reduces the likelihood of accidents and injuries. Investing time and resources into maintenance is ultimately a wise decision that pays off in both performance and safety.

Common Issues with Plow Parts

Many users encounter a variety of challenges when utilizing their snow-clearing equipment. Understanding these prevalent difficulties can enhance performance and extend the lifespan of essential components.

Worn Components: Over time, crucial elements may experience degradation due to constant exposure to harsh conditions. This wear can lead to decreased efficiency and increased risk of malfunction.

Improper Alignment: Misalignment can occur during installation or operation, resulting in uneven distribution of stress. This issue not only affects functionality but can also lead to further damage if not addressed promptly.

Corrosion: Exposure to moisture and road salt can cause rust and deterioration. Regular maintenance is vital to prevent this, ensuring that all surfaces remain intact and operational.

Loose Connections: Bolts and fasteners can become loose over time, leading to instability. Routine checks are essential to maintain secure attachments and overall safety.

Fluid Leaks: Hydraulic systems may develop leaks, which can significantly hinder performance. Identifying and repairing these leaks is crucial for maintaining optimal operation.

How to Identify Wear and Tear

Recognizing the signs of deterioration in machinery is crucial for maintaining efficiency and safety. Regular inspection can prevent unexpected failures and prolong the lifespan of equipment. Key indicators often include unusual noises, decreased performance, and visible damage.

Examine surfaces for signs of abrasion or cracking, which may indicate excessive friction or stress. Pay attention to any abnormal vibrations during operation, as these can signal misalignment or other underlying issues. Additionally, monitor fluid leaks and residue build-up, as these can point to worn seals or gaskets.

By staying vigilant and proactive, operators can effectively manage the integrity of their machinery and address problems before they escalate.

Tools Needed for Repair

When it comes to maintaining and fixing equipment, having the right instruments on hand is crucial for ensuring efficiency and effectiveness. The selection of tools can greatly influence the success of any repair task, enabling a smooth workflow and minimizing downtime.

Below is a list of essential tools that are commonly required for conducting repairs effectively:

| Tool | Description |

|---|---|

| Socket Set | A collection of various sizes of sockets used for fastening and loosening bolts and nuts. |

| Wrenches | Hand tools designed to grip and turn fasteners, available in different types and sizes. |

| Screwdrivers | Tools used to drive screws, available in various head types such as Phillips and flathead. |

| Pliers | Handy tools for gripping, twisting, and cutting, essential for handling small components. |

| Torque Wrench | A specialized tool for applying a specific torque to fasteners, ensuring proper tension. |

| Diagnostic Equipment | Devices that help identify issues and assess the functionality of systems. |

| Safety Gear | Essential personal protective equipment such as gloves, goggles, and ear protection. |

Equipping yourself with these tools not only streamlines the repair process but also enhances safety and precision in your work.

Best Practices for Installation

When undertaking the assembly of equipment, following best practices is crucial for ensuring optimal functionality and safety. This section outlines key steps and considerations that can enhance the installation process, making it efficient and effective.

Preparation and Planning

Before starting the installation, it is essential to carefully review the guidelines and gather all necessary tools and components. Creating a checklist can help prevent any oversight and ensure that each element is accounted for. Additionally, preparing the workspace by clearing any obstacles will facilitate a smoother assembly experience.

Proper Alignment and Tightening

During the installation, maintaining proper alignment of all components is vital to prevent future issues. Gradually tightening fasteners in a specific order can help achieve an even distribution of pressure. Always refer to the manufacturer’s recommendations for torque specifications to ensure longevity and reliability.

Upgrading Your Plow for Efficiency

Enhancing your snow removal equipment can significantly improve performance and productivity during harsh winter conditions. By focusing on advanced features and innovative technology, operators can maximize their effectiveness and minimize effort.

Investing in quality components is essential. Consider improved blades that provide better cutting capabilities, as well as enhanced hydraulic systems that offer quicker response times. These upgrades can lead to a smoother operation and less wear on your machinery.

Furthermore, integrating smart controls allows for precise adjustments, ensuring that every movement is optimized for efficiency. Regular maintenance and timely upgrades will not only extend the lifespan of your equipment but also ensure that you are prepared for any winter challenge.

Comparing Boss V Plow Models

This section delves into the various models of a specific type of snow removal equipment, highlighting their unique features and benefits. Understanding these differences is crucial for making an informed decision that aligns with individual needs and preferences in handling winter weather challenges.

Key Features of Each Model

Each variation of this snow management tool offers distinct advantages that cater to different user requirements. Below is a comparison of some popular models, showcasing their specifications and unique functionalities.

| Model | Width | Weight | Adjustable Angles | Material |

|---|---|---|---|---|

| Model A | 8 ft | 600 lbs | 3 | Steel |

| Model B | 7.5 ft | 550 lbs | 4 | Polyethylene |

| Model C | 9 ft | 700 lbs | 5 | Stainless Steel |

Choosing the Right Option

Selecting the appropriate model involves considering various factors such as the size of the area to be cleared, the frequency of use, and personal handling preferences. By weighing these aspects against the specifications listed above, users can determine which option best fits their operational needs.

Safety Tips for Plow Usage

When engaging in snow removal or similar tasks, prioritizing safety is crucial. Understanding the equipment and its operation helps prevent accidents and ensures efficient work. This section outlines essential guidelines to follow for a secure and effective experience.

Before starting any work, always perform a thorough inspection of the machinery. Check for wear and tear, and ensure that all components are functioning correctly. Regular maintenance is key to preventing malfunctions that could lead to injuries.

Always wear appropriate protective gear, including gloves, boots, and eyewear. These items can significantly reduce the risk of injury from falling debris or unexpected equipment movements. Additionally, ensure that clothing fits well and does not pose a snag hazard.

Maintain a clear line of sight while operating the machinery. Avoid distractions, and keep the area around you free from obstacles. Awareness of your surroundings can help you react swiftly to any unexpected situations.

Follow the manufacturer’s instructions for operation and load limits. Overloading the machinery can lead to loss of control, making it essential to adhere to specified guidelines. Be mindful of the terrain and adjust your speed accordingly to maintain stability.

Lastly, ensure that others are at a safe distance when operating the equipment. Communicate with anyone nearby to avoid accidents. By following these safety measures, you can help create a secure working environment and effectively carry out your tasks.

Winter Preparation for Plowing

As the colder months approach, ensuring readiness for snow removal becomes essential. A proactive approach not only enhances efficiency but also guarantees safety during operations. Careful assessment and proper maintenance of equipment are key factors in achieving optimal performance throughout the winter season.

Inspecting Equipment is a critical step. All components should be thoroughly examined for wear and tear. Replacing damaged parts and ensuring everything is in good working order will prevent unexpected breakdowns when the weather turns harsh.

Fluid Checks are equally important. Engine oil, hydraulic fluid, and coolant levels must be verified to ensure they are appropriate for low temperatures. Using winter-grade fluids can make a significant difference in performance and reliability.

Testing Lighting and Electrical Systems is essential as well. Visibility is crucial during winter operations, and ensuring all lights are functional will enhance safety during low-light conditions. Consider adding additional lighting if necessary to improve visibility in challenging weather.

Preparing for Storage can also impact readiness. Cleaning and properly storing equipment when not in use will prolong its lifespan. Covering machines or storing them in a sheltered area can protect them from the elements and reduce maintenance needs.

By following these guidelines, you can delve into the ultimate preparation for winter operations, ensuring both efficiency and safety throughout the season.

Resources for Parts and Service

This section provides essential information for obtaining components and support necessary for maintenance and repairs. Accessing reliable resources is crucial for ensuring optimal performance and longevity of your equipment.

| Resource Type | Description | Contact Information |

|---|---|---|

| Authorized Dealers | Specialized retailers offering genuine components and expert advice. | Visit local directories or manufacturer websites. |

| Online Marketplaces | Websites providing a variety of components from multiple suppliers. | Check platforms like Amazon, eBay, or specific industry sites. |

| Repair Manuals | Comprehensive guides that offer step-by-step instructions for maintenance. | Available for purchase or download on official websites. |

| Service Centers | Professional facilities providing repair services and consultations. | Contact through the manufacturer’s website for local options. |