Maintaining optimal performance of your machinery requires a clear grasp of its essential elements. A comprehensive overview of the various components plays a crucial role in troubleshooting and ensuring longevity. By familiarizing yourself with these individual sections, you can enhance your operational efficiency and reduce downtime.

In this guide, we will explore the intricate network of mechanisms that contribute to the functionality of your device. Each element, from the core engine to auxiliary systems, works in harmony to deliver peak performance. Recognizing how these pieces interconnect will empower you to make informed decisions regarding maintenance and repairs.

Furthermore, understanding the layout and relationship between the different components allows for a more streamlined approach to diagnosing issues. Whether you are a seasoned technician or a novice user, this knowledge is invaluable for effective equipment management. Dive into the specifics of each part and discover how they collectively enhance the overall operation of your machinery.

Understanding Br800x Components

Gaining insight into the various elements of a complex machine is essential for effective operation and maintenance. Each component plays a crucial role in ensuring the overall functionality and efficiency of the equipment. By examining these individual parts, users can better appreciate how they contribute to the system as a whole.

Key Elements

Among the most significant aspects to consider are the core functionalities that drive performance. Motors, valves, and other integral pieces work in harmony to facilitate seamless operation. Recognizing how these components interact can lead to enhanced troubleshooting and repair processes.

Maintenance and Care

Understanding the roles of each component not only aids in operation but also in maintenance. Regular checks on critical parts such as filters and belts can prevent costly breakdowns and prolong the lifespan of the equipment. Ultimately, informed users can make better decisions regarding care and upgrades.

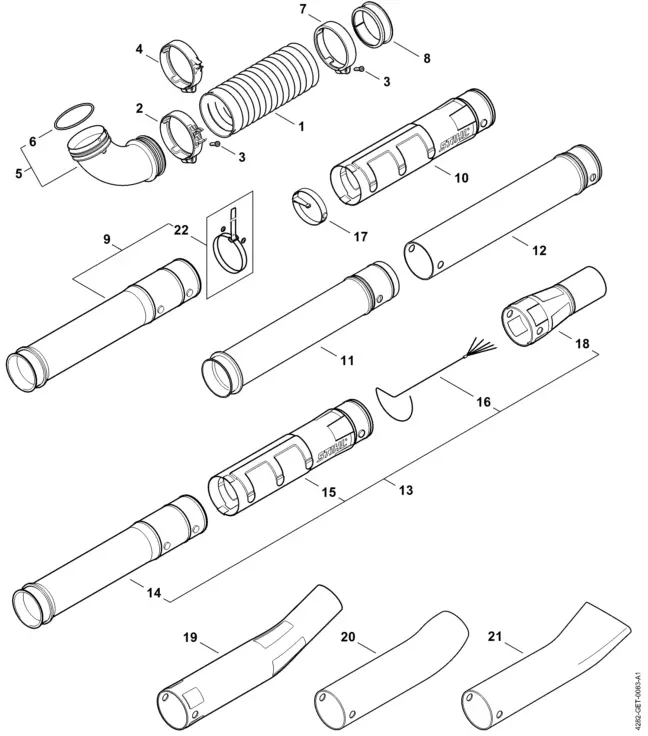

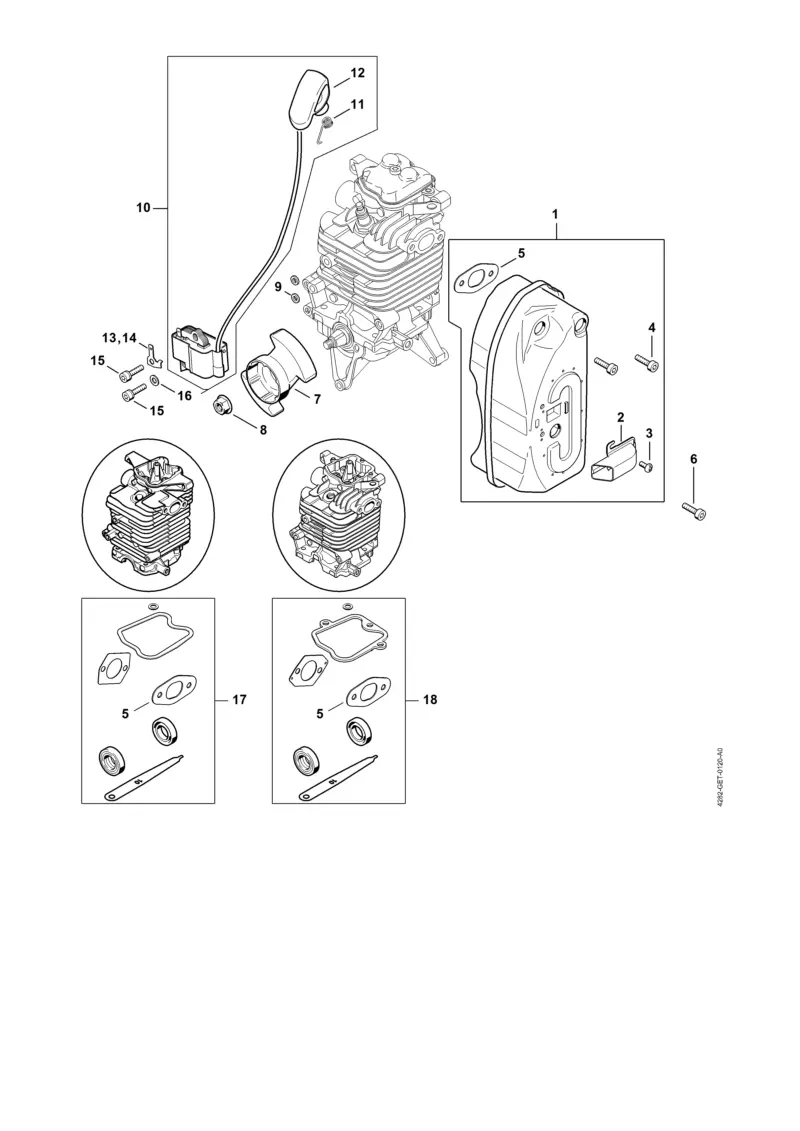

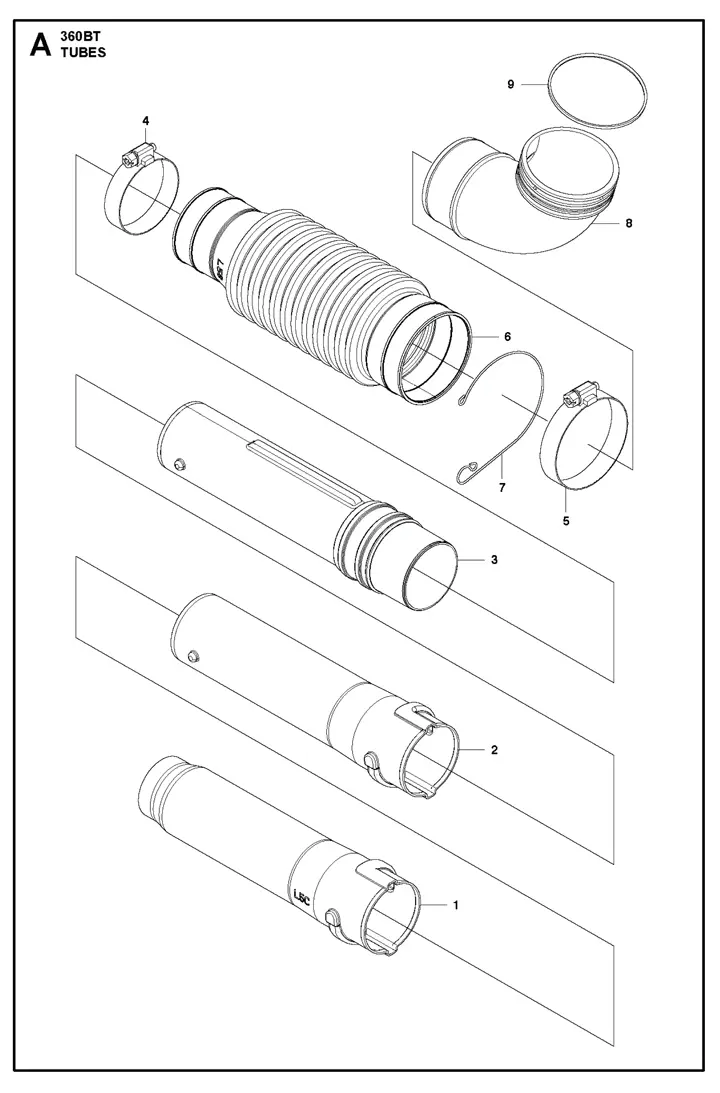

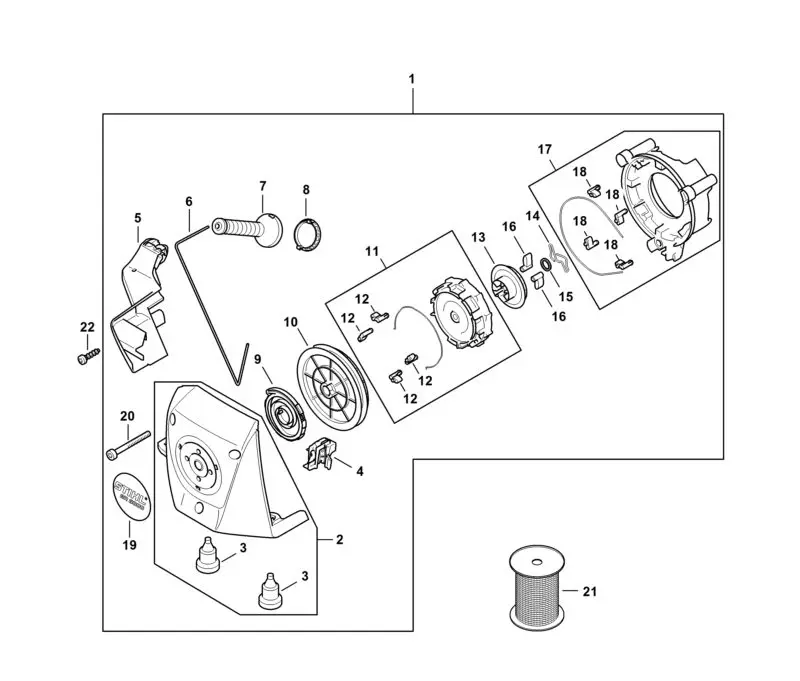

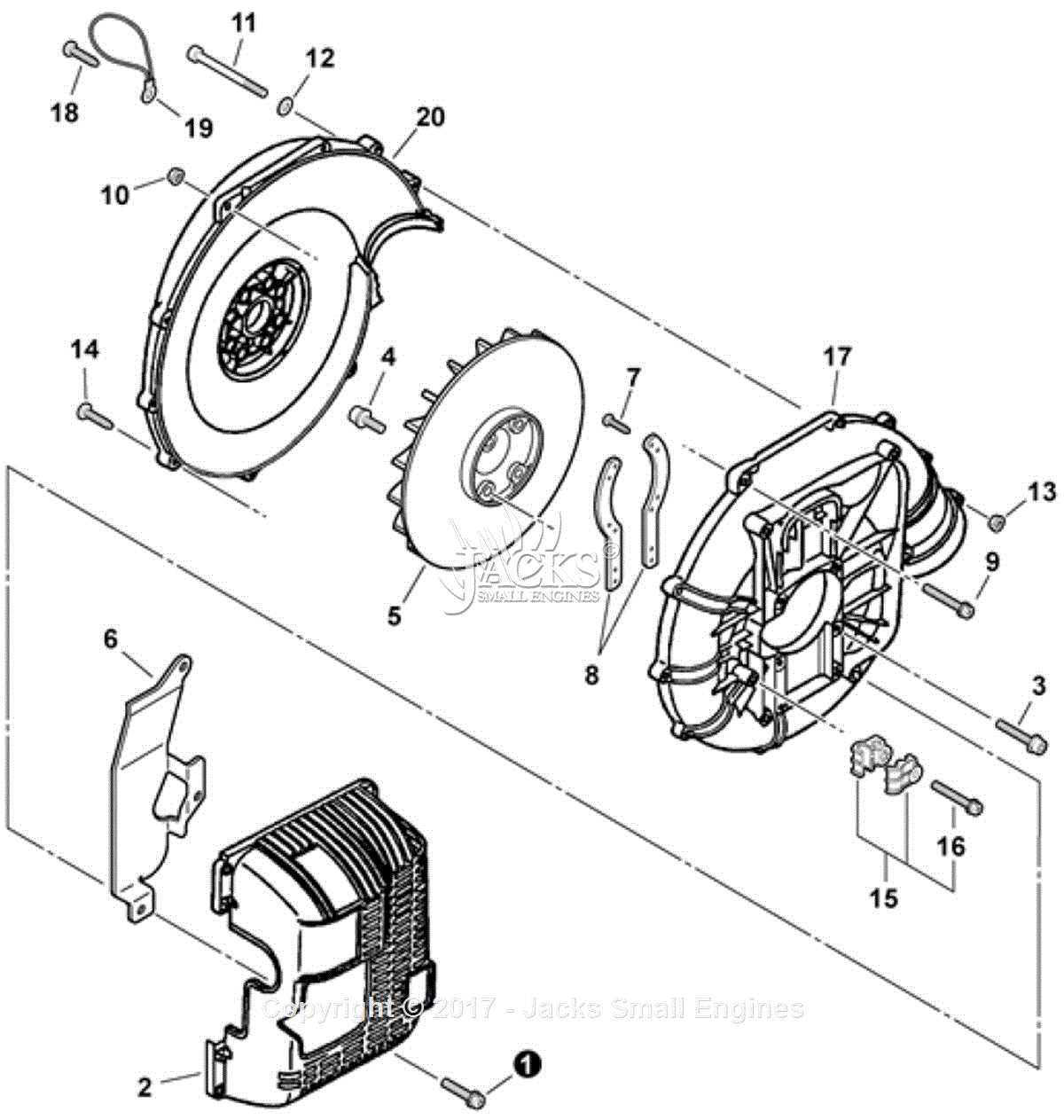

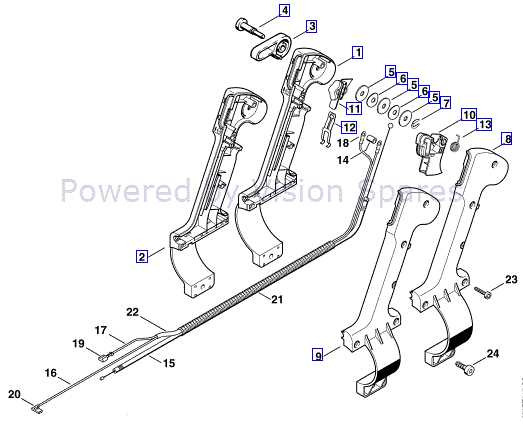

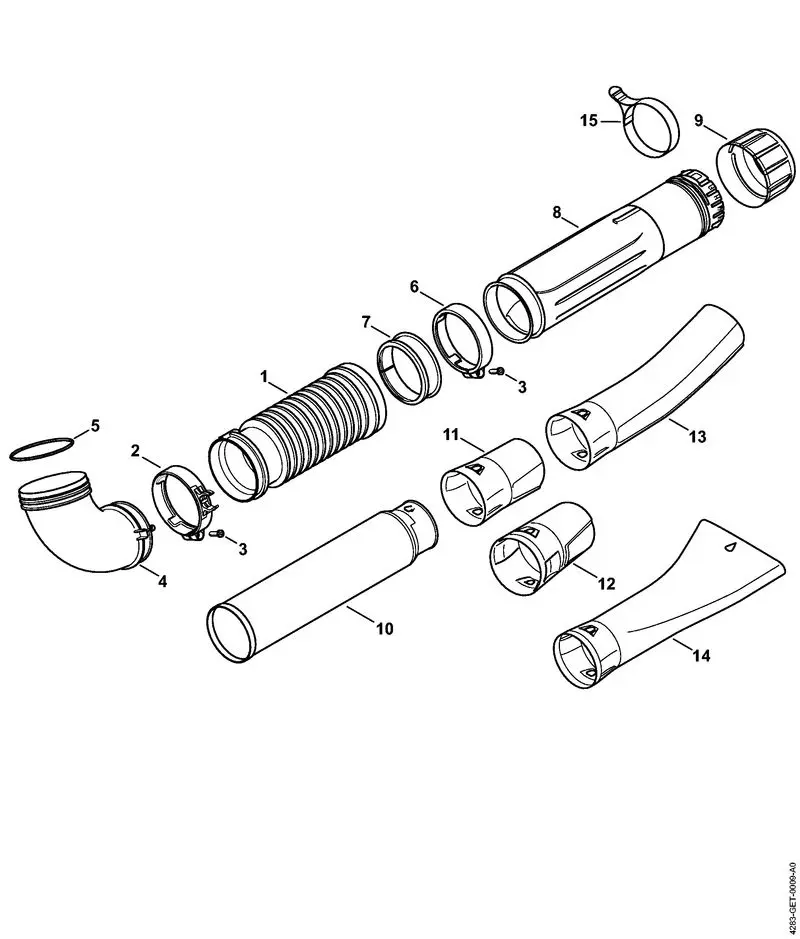

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and function of complex machinery. They provide a clear and organized way to identify each element, facilitating easier repairs and maintenance. This clarity helps users quickly locate necessary parts, reducing downtime and enhancing efficiency.

Moreover, these visual aids serve as valuable references during the assembly process, ensuring that everything fits together correctly. They can also be instrumental in troubleshooting, allowing users to pinpoint issues effectively. By fostering a deeper comprehension of mechanical systems, such representations ultimately contribute to improved performance and longevity.

Additionally, having access to such resources can empower users to undertake their own repairs with confidence, fostering a sense of independence. This not only saves time but can also lead to significant cost savings, making the ability to consult these visual tools essential for anyone involved in machinery maintenance.

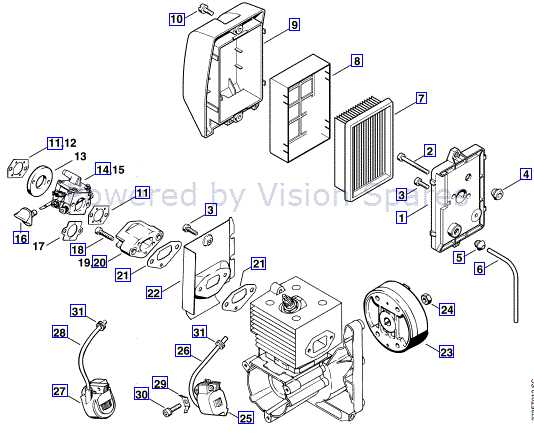

Overview of Br800x Structure

This section provides a comprehensive look at the configuration and components of a specific mechanical system, emphasizing its design and functionality. Understanding the structure is essential for effective maintenance and operation.

- Frame: The foundational element that supports all other components.

- Engine: Powers the unit and drives its primary functions.

- Transmission: Transfers power from the engine to the operational parts.

- Control Systems: Interfaces that allow user interaction and adjustments.

Each component plays a crucial role in ensuring the overall efficiency and reliability of the system. Knowledge of their interrelationships enhances operational effectiveness.

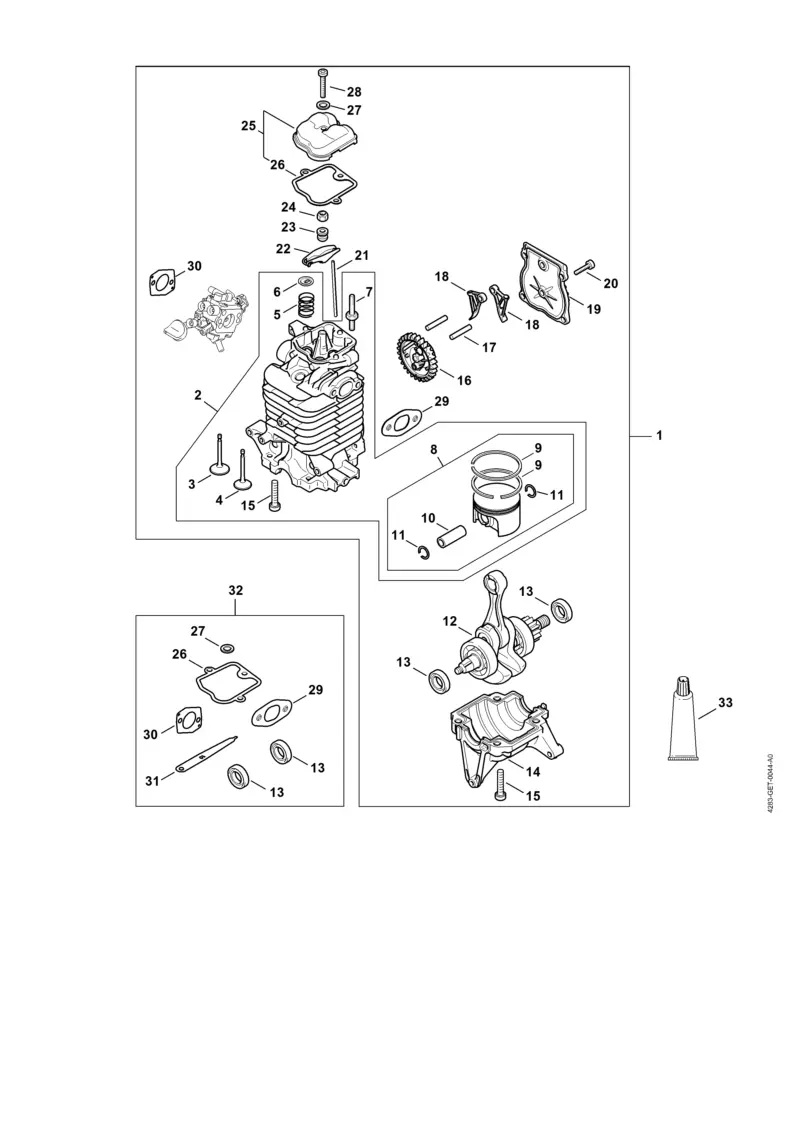

Key Parts and Their Functions

This section delves into the essential components of the equipment, highlighting their roles and significance in ensuring optimal performance. Understanding these elements can enhance user interaction and maintenance strategies, ultimately leading to improved efficiency and longevity.

Main Components

Each element of the device serves a specific purpose, contributing to the overall functionality. Below is a table summarizing the crucial elements along with their respective roles:

| Component | Function |

|---|---|

| Engine | Powers the unit, providing the necessary energy for operation. |

| Fuel Tank | Holds the fuel required for the engine to function. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean airflow. |

| Exhaust System | Channels out exhaust gases, maintaining optimal engine performance. |

| Control Panel | Allows users to manage settings and monitor operational status. |

Additional Features

Beyond the main elements, there are various auxiliary components that enhance functionality and user experience. These features may include safety mechanisms, ergonomic handles, and adjustable settings that cater to diverse operational needs, ensuring that the equipment remains versatile and user-friendly.

How to Read a Diagram

Understanding visual representations is crucial for effective assembly and troubleshooting. Familiarity with symbols and connections allows users to navigate complex structures with ease. This guide provides key insights into interpreting these visual aids accurately.

Key Elements to Consider

When examining a visual representation, pay attention to the following components:

| Element | Description |

|---|---|

| Symbols | Each icon represents a specific component or function. |

| Lines | Connective paths indicate relationships and flows between elements. |

| Labels | Annotations provide clarity and further detail about the components. |

Steps for Effective Interpretation

Follow these steps to enhance your understanding:

- Identify symbols and their meanings.

- Trace connections to comprehend relationships.

- Refer to a legend for clarification on unfamiliar elements.

Common Issues with Br800x Parts

When dealing with mechanical components, it’s common to encounter various challenges that can impact functionality and performance. Understanding these frequent issues can help in effective troubleshooting and maintenance.

Frequent Problems

Several recurring complications can arise, often due to wear and tear, improper installation, or lack of maintenance. Identifying these can lead to quicker resolutions and prolonged lifespan.

Summary of Issues

| Issue | Description |

|---|---|

| Wear and Tear | Components may degrade over time, affecting performance. |

| Improper Installation | Incorrect assembly can lead to malfunctions. |

| Lack of Maintenance | Neglecting routine checks can result in unexpected failures. |

Where to Find Replacement Parts

Finding suitable components for your equipment can be a daunting task, but several resources can simplify the process. Whether you’re looking for original manufacturers’ items or quality alternatives, knowing where to search is key to maintaining your machinery’s efficiency and longevity.

Online Retailers offer a vast selection of components, often at competitive prices. Websites specializing in equipment supplies provide detailed catalogs and customer reviews, helping you make informed choices.

Local Dealers are another excellent source. Visiting them allows you to physically inspect the items and consult with knowledgeable staff who can offer recommendations tailored to your specific needs.

Manufacturer Websites often have dedicated sections for accessories, ensuring you get authentic and compatible components. Additionally, many manufacturers provide support and guidance, making it easier to locate what you need.

Online Marketplaces can also be useful. Platforms that connect buyers and sellers may have both new and used options, allowing for budget-friendly choices. Always check seller ratings and return policies to ensure a smooth transaction.

Lastly, forums and community groups focused on your equipment type can be invaluable. Enthusiasts often share tips on where to find reliable supplies and may even offer spare items for sale or trade.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged functionality and performance of your equipment. Implementing a systematic maintenance routine not only extends the life of your tools but also enhances their efficiency, preventing costly repairs and replacements.

Routine Inspections

Conducting frequent examinations of your machinery allows you to identify wear and tear before it escalates into significant issues. Look for signs of corrosion, loose components, or unusual noises. Addressing minor problems early can save you from extensive downtime.

Proper Cleaning Techniques

Cleanliness plays a vital role in the longevity of your devices. Regularly remove debris, dirt, and grime to prevent build-up that could hinder performance. Use appropriate cleaning agents and tools that won’t damage surfaces, and ensure everything is dry before reassembling.

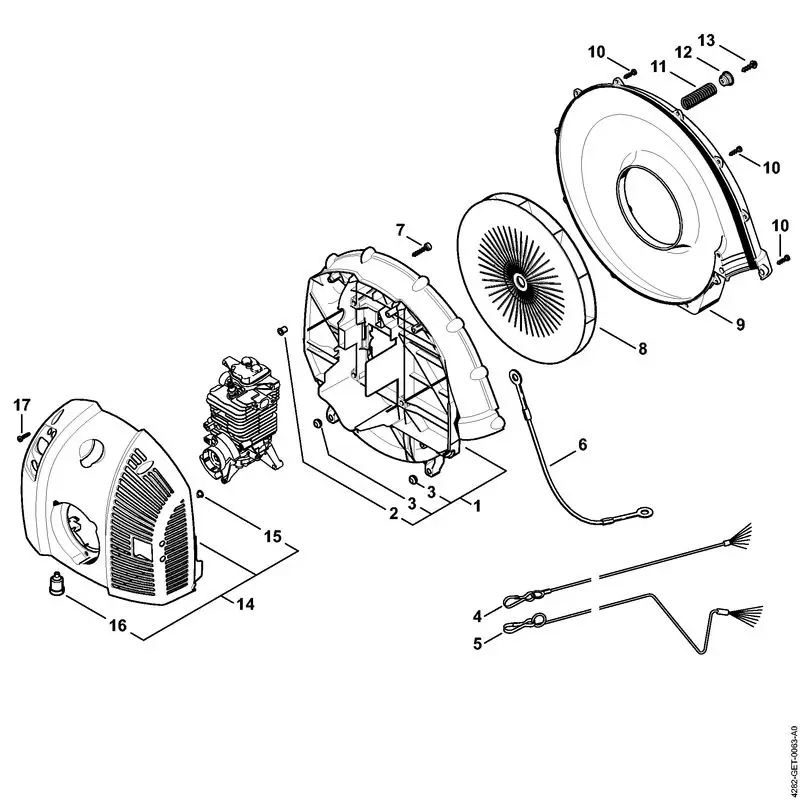

Assembly Instructions for Br800x

This section provides a comprehensive guide for the successful assembly of your equipment. Following these instructions carefully will ensure optimal performance and longevity. Each step is crucial for achieving a seamless integration of components, allowing you to maximize the functionality of your device.

Preparation Steps

Before beginning the assembly process, gather all necessary tools and components. Ensure you have a clean, organized workspace to facilitate the task. Read through the entire set of instructions to familiarize yourself with the assembly sequence and any specific requirements for each part.

Assembly Process

Start by securing the primary framework, making sure all connections are tight. Proceed to attach the secondary elements, verifying that each piece fits snugly and aligns properly. Pay special attention to the orientation of each part, as improper placement can lead to functionality issues. After completing the assembly, conduct a thorough inspection to ensure everything is in order before using the unit.

For troubleshooting, refer back to this guide as needed, and always keep safety in mind during assembly. A methodical approach will yield the best results and enhance the overall performance of your equipment.

Safety Precautions When Handling Parts

Ensuring safety during the manipulation of mechanical components is essential for preventing accidents and maintaining a secure work environment. Proper precautions can significantly reduce the risk of injury and damage to equipment.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Keep the work area clean and organized to avoid tripping hazards and facilitate efficient handling.

- Ensure proper lighting is available to clearly see the components being managed.

- Use tools that are specifically designed for the task to avoid damaging parts or causing injury.

Handling Techniques

- Lift components using your legs, not your back, to prevent strain or injury.

- When moving large items, seek assistance to ensure stability and control.

- Always secure items before disassembling or working on them to prevent unintended movement.

- Be aware of sharp edges or fragile components, handling them with care to avoid cuts or breakage.

By adhering to these guidelines, individuals can significantly enhance their safety while managing mechanical elements, fostering a more productive and secure workspace.

Upgrading Br800x Components

Enhancing the performance and functionality of your equipment can lead to significant improvements in efficiency and usability. By focusing on key elements that can be upgraded, users can achieve a more tailored experience, ensuring the device meets their evolving needs.

Key Areas for Improvement

When considering upgrades, it’s crucial to evaluate components that impact performance, such as the power supply, interface modules, and connectivity options. Each of these elements plays a vital role in maximizing overall effectiveness and can lead to a smoother operation.

Choosing the Right Enhancements

Investing in high-quality upgrades not only enhances functionality but also extends the lifespan of the device. Prioritize components that are compatible and well-reviewed, ensuring that the ultimate goal of improved performance is achieved with minimal hassle.

Comparison with Other Models

Understanding the distinctions among various machinery options can significantly influence the decision-making process for users. By examining the unique features and specifications of different models, one can determine which is best suited for specific tasks and requirements.

Performance Metrics

When comparing different units, performance metrics such as efficiency, power output, and operational speed are critical. Here are some key aspects to consider:

- Engine power: Assess the horsepower ratings across models.

- Fuel efficiency: Evaluate how much energy each machine consumes relative to its output.

- Operating speed: Compare the maximum speeds achievable by each variant.

Features and Usability

Different designs may come equipped with varying functionalities, which can enhance user experience. Notable features include:

- Control systems: Analyze the intuitiveness of the interface in each version.

- Maintenance access: Review how easily users can perform routine checks and repairs.

- Durability: Consider the materials used in construction and their impact on longevity.

By carefully evaluating these aspects, users can make informed choices that align with their specific needs and operational goals.

Resources for Further Learning

Exploring advanced machinery requires a solid foundation of knowledge. A variety of resources can enhance understanding and provide insights into the intricacies of components and their functionalities.

Books and Manuals

Comprehensive guides and technical manuals are invaluable for anyone seeking to deepen their expertise. They often include detailed explanations and illustrations.

Online Courses and Tutorials

Interactive platforms offer courses that cover fundamental concepts and practical applications, making learning more accessible and engaging.

| Resource Type | Recommended Sources |

|---|---|

| Books | Technical Guides, Industry Publications |

| Online Courses | eLearning Platforms, YouTube Channels |

| Forums | Online Communities, Discussion Boards |