Exploring the intricate design and functionality of marine propulsion systems reveals how various components work together to ensure smooth operation and efficiency. The focus here is on understanding the relationship between each part and its role in enhancing performance. A clear grasp of these elements is crucial for anyone involved in maintenance or repair tasks, offering insights into the complex interaction of gears, shafts, and other mechanical elements.

Each system’s success relies on the precision of individual elements, where even minor malfunctions can significantly impact overall functionality. By understanding the layout and connections, technicians can approach troubleshooting with confidence, addressing issues more efficiently. This section aims to break down the key components, providing clarity on their individual and collective importance.

Proper comprehension of the structure allows for more informed decisions regarding repair or upgrades. The arrangement and specification of these elements can greatly influence the longevity and performance of the entire unit, making this knowledge essential for those looking to optimize or maintain their equipment with precision.

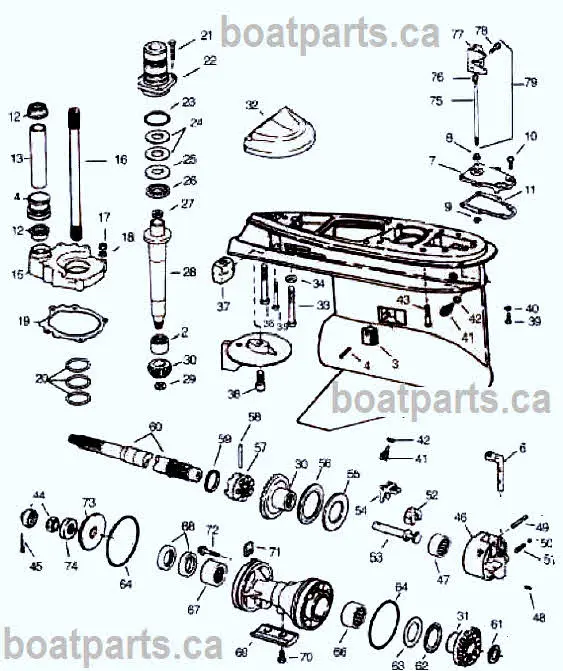

Overview of Bravo 3 Components

This section provides a detailed examination of the key elements that work together to enable optimal performance in marine propulsion systems. These components are designed to interact seamlessly, contributing to the overall efficiency and durability of the system. Understanding how each part functions is crucial for maintenance, troubleshooting, and achieving superior performance in various conditions.

Drive unit: The primary housing that contains the gearing mechanism, this part is essential for transmitting power from the engine to the propeller. It is engineered to withstand high forces and provide smooth motion through the water.

Steering mechanism: A vital component that allows for precise navigation and maneuverability. Its design ensures the vessel responds accurately to helm inputs, providing stability and control in challenging conditions.

Propeller assembly: This set of blades is responsible for converting rotational energy into thrust, propelling the vessel forward. The material and shape of the blades are optimized for efficiency and resistance to wear, ensuring long-term performance.

Transmission system: A series of interconnected gears that manage the flow of power between the engine and the propulsion unit. It is designed to handle variable loads and provide reliable performance across a range of speeds.

Each of these components plays an essential role in ensuring smooth operation, and their interaction is critical to the system’s overall success. Proper maintenance and understanding of each part’s function will help extend the lifespan and improve the reliability of the entire unit.

Understanding the Gear Mechanism

The gear system plays a crucial role in transferring power from the engine to the propulsion unit, ensuring smooth and efficient movement. It operates through a series of interlocking components that work together to adjust the torque and rotational speed as needed. The interaction of these gears enables optimal performance under varying conditions, providing stability and control for the vessel.

Gears are designed to engage with each other at precise angles, creating a mechanism that can handle varying loads and speeds. These components are built to withstand significant stresses while maintaining efficiency, which is essential for the system’s longevity and functionality. Proper alignment and maintenance are key to ensuring that these elements continue to function as intended, minimizing the risk of wear and tear over time.

The gear ratio is another critical aspect, determining how the system distributes force. It dictates the balance between speed and power, allowing for adjustments based on the required performance. Whether at idle or full throttle, the gears shift seamlessly to meet the demands of the vessel, providing smooth transitions during operation.

Key Parts in Bravo 3 Outdrive

The marine propulsion system features a variety of crucial components that contribute to the overall efficiency and performance. Each element serves a specific function, ensuring smooth operation and optimal power delivery to the vessel. Understanding these components is essential for maintaining and repairing the system effectively.

| Component | Description |

|---|---|

| Gearcase | Located at the bottom of the assembly, the gearcase houses the essential gears that transfer power from the engine to the propeller. It plays a pivotal role in speed control and torque distribution. |

| Drive Shaft | This long shaft connects the engine to the lower unit, transferring rotational power to drive the vessel’s propulsion mechanism. |

| Propeller | The propeller is responsible for converting the engine’s power into thrust, propelling the boat forward. Its design directly affects speed and fuel efficiency. |

| Trim Cylinder | This hydraulic component allows for the adjustment of the angle of the propulsion unit, optimizing performance based on water conditions and boat load. |

| Shift Mechanism | This system allows for the engagement of forward and reverse gears, enabling the vessel to move in both directions. Precision is critical for smooth transitions. |

Essential Bearings and Seals

In any mechanical system, the smooth operation of moving components relies heavily on the precision and durability of various internal elements. These components play a crucial role in reducing friction, supporting rotating parts, and preventing the intrusion of contaminants. Without these vital parts, the efficiency and lifespan of the mechanism would be compromised.

Bearings are designed to facilitate the smooth movement of rotating parts by reducing friction. They come in various types, each suited for specific load-bearing and rotational tasks. The choice of bearing type depends on the application, load capacity, and the required speed of operation. A well-selected bearing ensures minimal wear and long-term reliability.

Seals, on the other hand, act as protective barriers, preventing dirt, water, or other foreign substances from entering sensitive areas of the system. They also retain lubrication, ensuring that the internal components are properly maintained throughout their lifespan. The durability and material of seals are paramount for maintaining the integrity and functionality of the entire assembly.

Impeller Functionality and Design

The impeller plays a crucial role in water propulsion systems by converting rotational energy into the flow of water. This device is designed to create pressure differences, enabling efficient movement and circulation. The performance of an impeller greatly influences the overall efficiency of the system, ensuring optimal water delivery or exhaust under various conditions.

Design Considerations

Several factors must be taken into account when designing an impeller, including size, shape, and the material used. The geometry of the blades determines the amount of water that can be moved, with specific angles and curves maximizing flow efficiency. The materials chosen for construction need to withstand environmental factors such as corrosion and wear, especially when exposed to water elements that vary in temperature and salinity.

Impact on Performance

Efficiency and durability are the primary performance metrics influenced by impeller design. An optimally designed impeller enhances the system’s flow rate and minimizes energy loss, leading to better fuel efficiency and reduced operational costs. Regular maintenance and occasional replacements are essential to maintain peak performance, as worn-out components can lead to reduced performance or even system failure.

How the Propeller Works

The propeller is a critical component in driving a vessel through the water. By converting rotational energy into thrust, it allows the boat to move forward or backward, depending on the direction of rotation. This essential mechanism functions through the interaction of its blades with the surrounding water, creating differences in pressure that push the vessel in the desired direction.

As the blades rotate, they generate a force known as lift, which propels the vessel forward. This movement is achieved through the angle of attack, or the pitch of the blades, which determines how much water is displaced with each rotation. A properly adjusted angle is crucial for maintaining efficiency and achieving the optimal speed.

In addition to the angle, the shape of the blades plays a significant role in the overall performance. Curved blades can produce a smoother flow of water, increasing the propulsion efficiency, while flat blades might be more suited for high-speed applications. The material composition of the propeller also impacts its strength and durability, ensuring long-term functionality in varying conditions.

Maintaining the Bravo 3 Outdrive

Proper upkeep of your vessel’s propulsion system is crucial for optimal performance and longevity. Regular maintenance ensures smooth operation, prevents potential issues, and enhances the overall boating experience. To keep the unit in top condition, it is essential to follow a routine check-up schedule and address any wear and tear promptly.

Key Areas to Focus On

- Lubrication: Regularly check and replace the lubricants to prevent internal friction and rust.

- Inspection of Seals: Ensure seals are intact and functioning to avoid water entry and possible damage.

- Gear Housing: Examine the gear housing for signs of cracks or leaks that might compromise performance.

Steps for Effective Maintenance

- Check the Fluid Levels: Ensure the lubrication fluid is at the proper level and replace it if needed.

- Inspect the Props: Examine for any signs of damage or wear, and replace if necessary to maintain efficiency.

- Clean the System: Regular cleaning helps avoid buildup of debris and ensures smooth operation.

- Test for Performance: After maintenance, perform a test run to ensure everything is functioning as expected.

Lubrication and Fluid Management

Proper lubrication and fluid handling are essential for maintaining the efficiency and longevity of mechanical systems, particularly in marine environments. Ensuring the right balance of oils and fluids reduces friction, prevents corrosion, and keeps components running smoothly under high stress. Regular monitoring and timely replacements are crucial for optimal performance.

Types of Fluids Used

- Engine oil: Keeps moving parts well-lubricated and prevents wear.

- Gear oil: Protects internal gears and ensures smooth operation.

- Hydraulic fluids: Used to operate hydraulic systems, providing power and control.

Maintenance Practices

- Check fluid levels regularly to avoid overheating and potential damage.

- Replace oils and fluids as per manufacturer guidelines to maintain efficiency.

- Use the recommended fluid types to ensure compatibility with the system’s components.

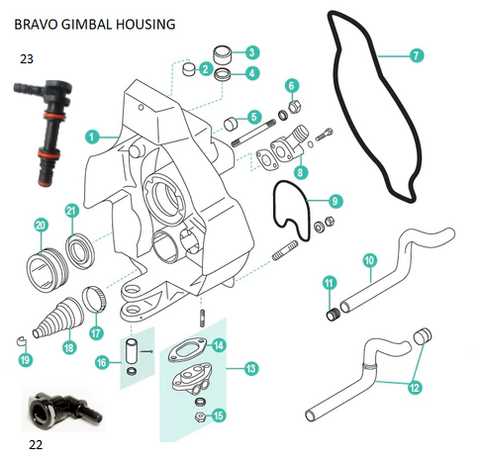

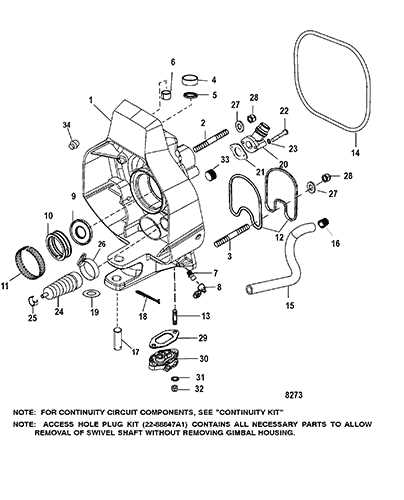

Inspecting Bravo 3 Housing

When working with marine propulsion systems, it is essential to carefully examine the external casing that houses the key mechanical components. This inspection ensures the overall integrity of the unit, helping to detect wear, corrosion, or other potential issues that may compromise performance. Regular checks contribute significantly to the longevity and smooth operation of the system, preventing costly repairs or failures during use.

Identifying Common Issues

The external casing, which shields internal components, can suffer from various types of damage. Frequent inspection focuses on detecting signs of wear, cracking, and corrosion. These issues are often caused by prolonged exposure to saltwater, debris, and operational stress. Identifying these problems early is crucial for maintaining optimal functionality.

Steps for a Thorough Inspection

Performing a detailed inspection involves several key steps to ensure the housing is in proper working order. The process includes visually checking for any physical damage, measuring wear on key surfaces, and ensuring all seals and connections are intact. Additionally, it’s important to assess the housing’s overall alignment with the rest of the system to avoid operational issues.

| Inspection Task | Method | Signs of Trouble |

|---|---|---|

| Visual Check | Examine the housing for cracks, dents, or signs of corrosion. | Visible cracks, discoloration, or bubbling. |

| Seal Condition | Inspect the seals for any gaps or wear that might cause leaks. | Loose, frayed, or hardened seals. |

| Alignment | Ensure the housing aligns properly with the other components. | Misalignment or difficulty in connecting parts. |

Corrosion Prevention Techniques

Ensuring the longevity and optimal performance of marine equipment requires addressing one of its most persistent challenges: corrosion. The presence of water, especially saltwater, accelerates the degradation of metal components, making it crucial to adopt effective prevention methods. By applying proper techniques, it is possible to significantly reduce the impact of corrosion and extend the lifespan of critical systems.

Protective Coatings

One of the most effective ways to combat corrosion is by applying protective coatings to exposed surfaces. These coatings create a barrier that prevents moisture and corrosive elements from coming into direct contact with metal parts. Epoxy-based and polyurethane coatings are commonly used for their durability and resistance to harsh marine environments.

Anode Systems

Another vital technique is the use of sacrificial anodes, typically made from metals like zinc, magnesium, or aluminum. These anodes are strategically placed to corrode in place of more valuable components. As the anodes deteriorate, they absorb the corrosive impact, thereby preserving the integrity of surrounding materials.

Bravo 3 Drive Shaft Analysis

The main rotating component in marine propulsion systems plays a critical role in transmitting torque from the engine to the propeller. Understanding its design, function, and maintenance needs ensures the efficiency and durability of the entire propulsion unit. This section delves into the key aspects of this essential shaft, highlighting its structure, performance characteristics, and potential issues to be aware of.

Design and Construction

This central shaft is engineered to handle high rotational forces while enduring the harsh marine environment. Typically made from corrosion-resistant materials, its design incorporates precision balancing to minimize vibrations and ensure smooth power transmission. Key features include:

- Corrosion-resistant materials such as stainless steel or composite alloys

- Heat treatment for enhanced strength and durability

- Precision machining for smooth operation and reliability

Performance Considerations

The efficiency of the shaft is directly tied to its ability to transfer power without excessive friction or wear. Proper alignment and periodic inspection are crucial to maintaining optimal performance. Factors such as:

- Alignment with the engine and propeller

- Lubrication for smooth operation

- Vibration control mechanisms to prevent damage

should be regularly checked to prevent mechanical failures. Keeping these elements in balance enhances longevity and overall performance.

Understanding Shaft Alignment

The correct positioning of mechanical components is essential for the smooth functioning of any system. Proper alignment ensures that moving parts work together without causing undue stress, wear, or vibration. In marine systems, this alignment plays a crucial role in maintaining operational efficiency and longevity.

Alignment is the process of adjusting two connected parts so that they move in harmony, minimizing friction and enhancing performance. Without accurate alignment, misalignment can lead to inefficiencies, vibrations, and damage to connected systems. A proper setup not only prevents wear but also optimizes power transfer and fuel efficiency.

Misalignment often results in poor performance, increased maintenance costs, and potential system failure. Regular checks and adjustments help avoid these issues and ensure optimal performance over time. For systems relying on rotational forces, like those in watercraft, alignment must be precise to prevent excessive strain on gears and bearings.

Checking for misalignment typically involves measuring the distances between key points and ensuring they meet manufacturer specifications. Fine-tuning is necessary to ensure the shaft remains centered and free from distortion, preserving the functionality of the entire system.

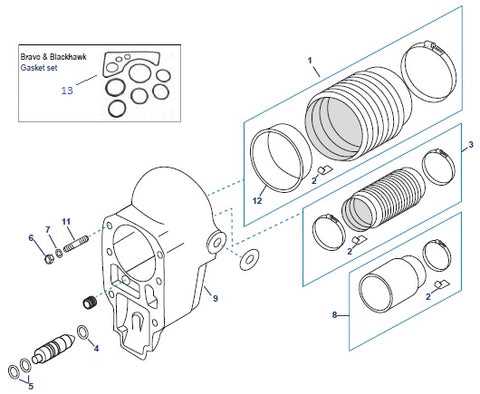

Bravo 3 Coupling Parts Breakdown

The coupling mechanism in marine propulsion systems plays a crucial role in transferring power from the engine to the drive unit. This breakdown highlights key components involved in this connection, ensuring that energy flows smoothly, providing efficient movement. Understanding each piece’s function within the coupling assembly is essential for effective maintenance and troubleshooting.

Main Components

- Drive Shaft: The core element transferring rotational power from the engine to the lower unit.

- Universal Joint: Allows flexibility in the system, absorbing vibrations and accommodating movement between the drive and engine shafts.

- Coupler: Connects the drive shaft to the engine’s output shaft, facilitating the flow of torque.

Supporting Components

- Bearings: Provide support to rotating parts, ensuring smooth motion and reducing friction.

- Seals: Protect the internal components from water and debris, maintaining the system’s integrity.

- Gaskets: Ensure a proper seal between mating parts to prevent leakage.