The internal structure of modern office devices can seem intricate, but each element plays a specific role in ensuring smooth and efficient operation. Recognizing how these elements connect and interact helps maintain the functionality of such machines over time. This section offers a deeper look into the organization and purpose of individual modules within these systems.

From critical units responsible for motion and data processing to consumables that require regular replacement, every part serves a distinct function. Knowing how these elements align within the equipment is essential for troubleshooting, upgrades, or routine upkeep.

We will explore how different segments contribute to the overall performance, focusing on both mechanical and electronic assemblies. By understanding the interdependence of these modules, users can ensure longer service life and identify potential issues before they become critical.

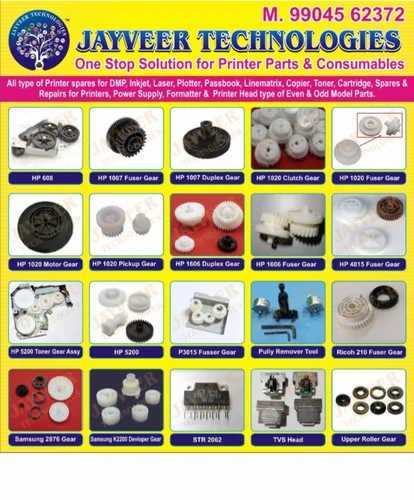

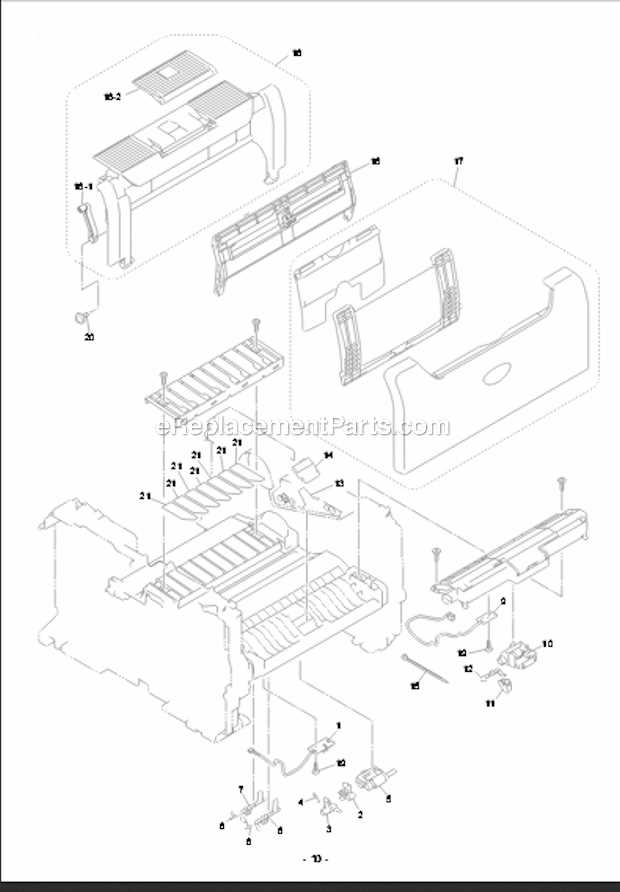

Overview of Key Printing Components

This section explores essential elements that work together to ensure seamless document production. These components contribute to smooth operation, delivering reliable output with every cycle. Understanding their functions offers insight into how the overall process maintains efficiency and consistency.

| Component | Function |

|---|---|

| Input Feeder | Handles and organizes sheets before they enter the printing mechanism, preventing misalignment and paper jams. |

| Transfer Assembly | Transfers text or images from the internal engine onto the sheet with precision. |

| Fixing Unit | Applies heat and pressure to fuse the content onto the medium, ensuring durability and resistance to smudging. |

| Control Module | Coordinates signals and monitors operations, ensuring each step follows the intended instructions. |

| Output Tray | Collects finished documents in an organized manner, ready for further use or distribution. |

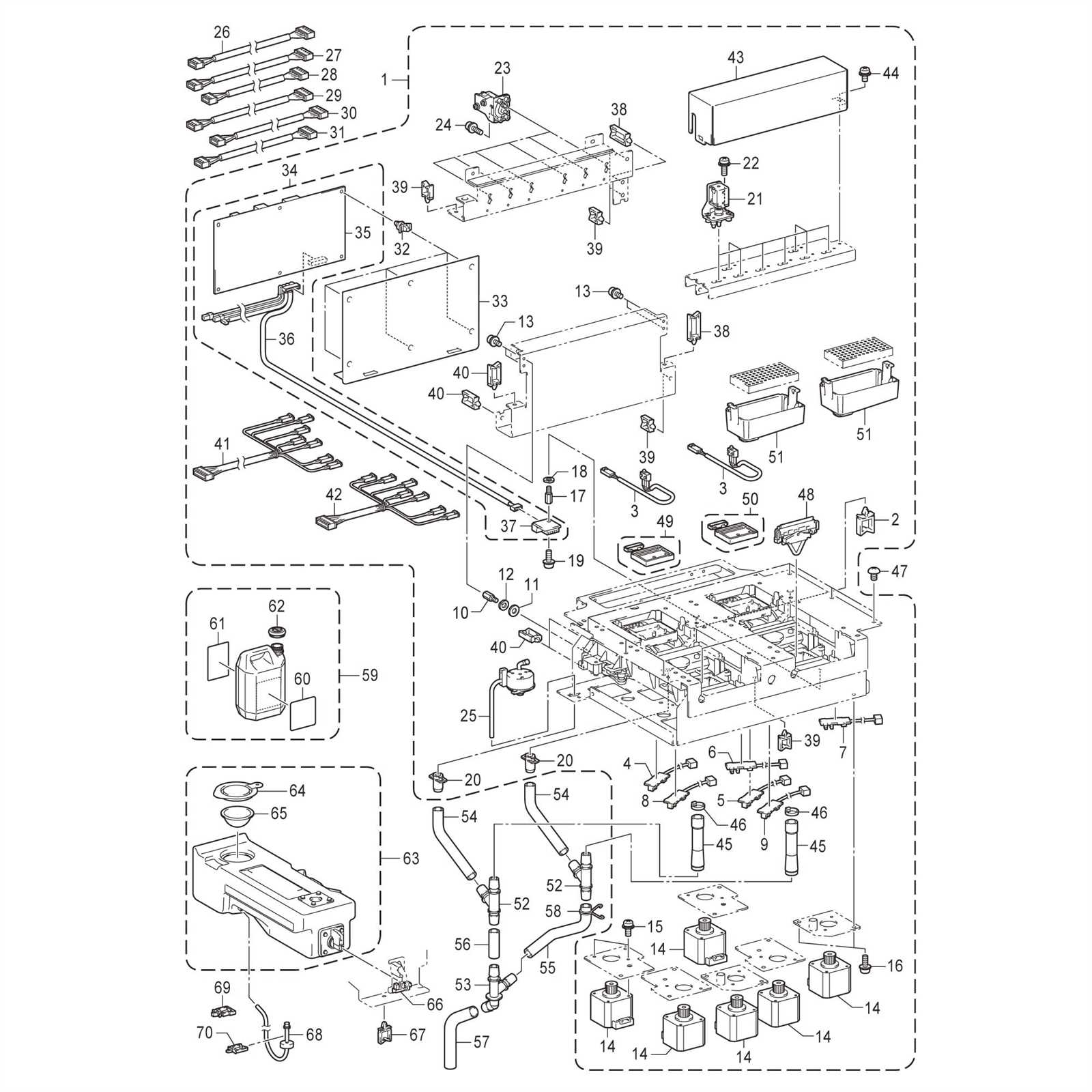

Understanding the Toner Cartridge System

The cartridge mechanism is essential for delivering precise prints by transferring pigment powder onto paper. This system relies on a well-coordinated interaction of several components that ensure the even distribution of material and smooth operation.

Within this system, the powder reservoir holds the material that gets applied to the surface. A series of rollers and blades control the flow, preventing clogs and ensuring uniform coverage. The dispensing mechanism works with an electrostatic process, drawing the powder onto designated areas.

Proper maintenance, such as refilling or replacing components, guarantees consistent results. Understanding how each part interacts helps in troubleshooting performance issues and ensures optimal use of consumables over time.

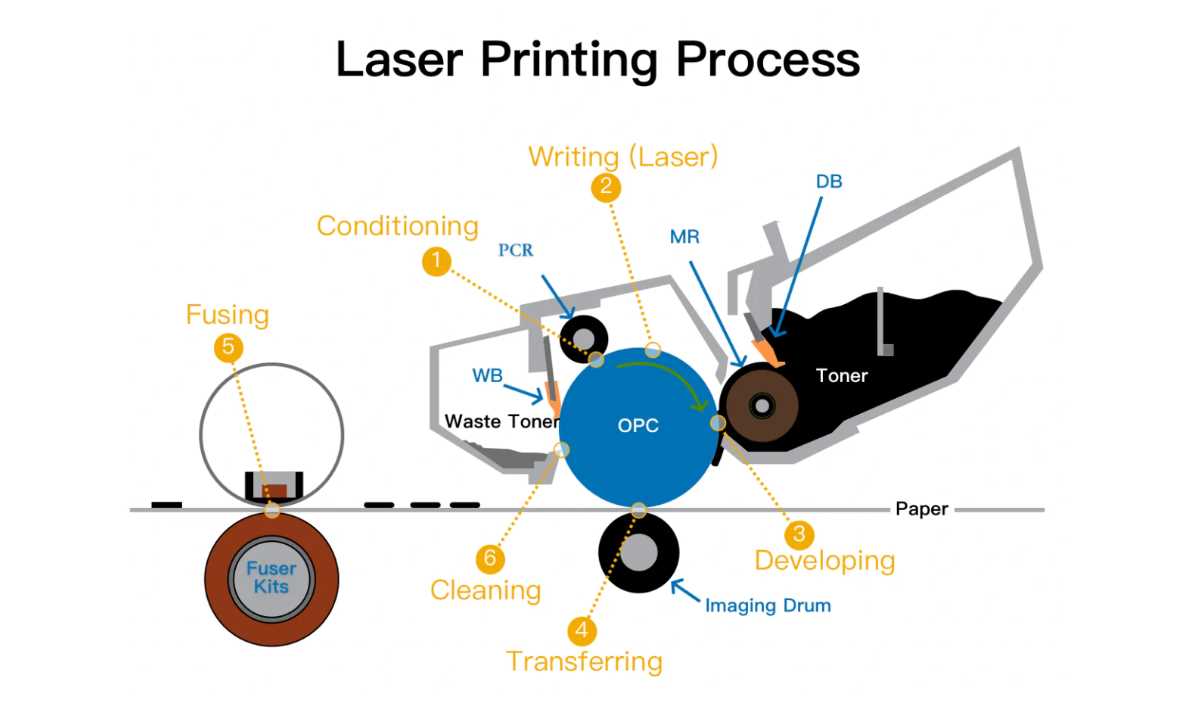

The Role of Imaging Drums in Printing

One of the core elements in modern printing systems is a rotating component responsible for transferring visual information onto the medium. This part plays a crucial role in ensuring that digital input becomes physical output with precision and clarity. Its functionality relies on synchronized movements and electrical charges that attract and release toner particles to form the desired image.

How it Works: The drum undergoes a multi-step process where it first receives an electrostatic charge. A controlled light source modifies this charge, creating patterns that correspond to the required content. As the drum rotates, it picks up pigment from the supply unit and deposits it onto the paper through contact and heat application.

Maintenance and Lifespan: Regular upkeep is essential to maintain print quality and extend the drum’s lifespan. Over time, residue buildup or wear may affect its performance, leading to faded or inconsistent output. Proper handling, cleaning routines, and timely replacement ensure smooth operation and high-quality results.

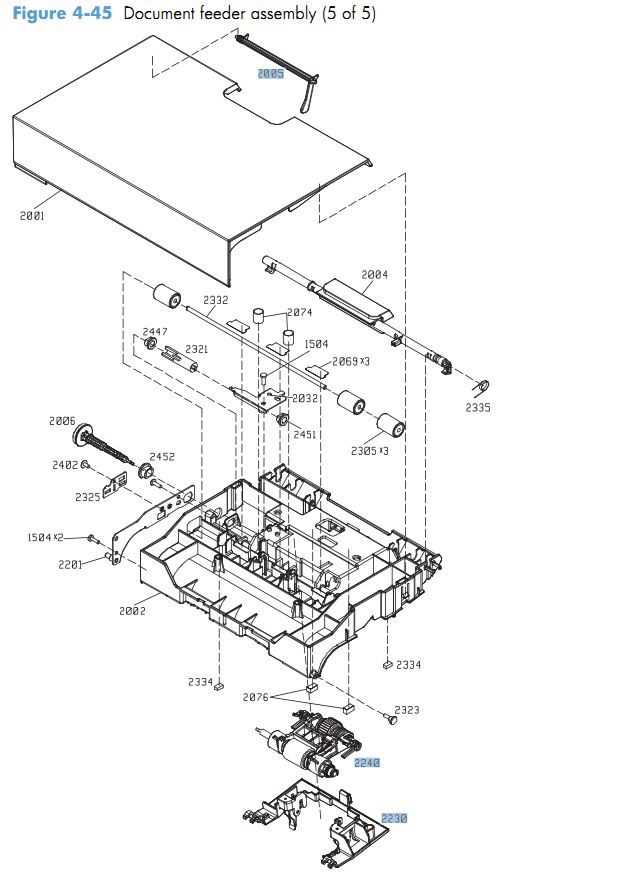

Paper Handling Mechanisms Explained

Effective management of sheets is crucial for smooth operation in any document-producing equipment. Understanding the internal process helps identify common issues and maintain reliable performance. This section explores key stages involved in the movement of sheets from loading to final output.

Sheet Feeding Process

- Input Tray System: Holds and supplies sheets for processing, ensuring proper alignment.

- Pick-Up Rollers: Grabs the top sheet from the stack and directs it into the system.

- Separation Pads: Prevent multiple sheets from entering at once by creating friction between them.

Sheet Movement and Output

- Registration Rollers: Align the sheet precisely before further processing.

- Transfer Stage: The sheet moves through mechanisms that apply content onto its surface.

- Exit Rollers: Guide the finished sheet to the output area without causing jams or misalignment.

- Output Tray: Collects the completed sheets in an orderly fashion for easy retrieval.

By maintaining the integrity of each mechanism, equipment remains dependable and minimizes disruptions during operation.

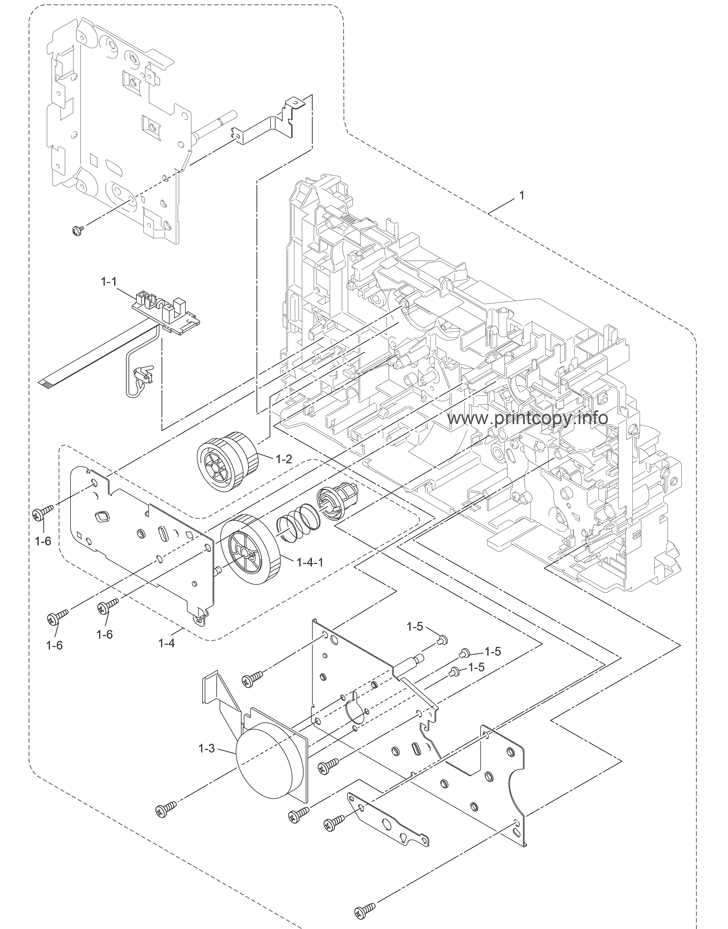

Exploring Fuser Units and Their Functions

The component responsible for finalizing image transfer plays a crucial role in ensuring the durability of printed output. By applying controlled heat and pressure, it secures pigments onto the surface, providing a smudge-resistant finish. This process guarantees that the document maintains its quality over time, even under frequent handling.

The Role of Heat and Pressure in Image Bonding

The bonding mechanism involves precision heating elements that work in tandem with pressure rollers. As the material passes through, these components activate to affix the applied medium permanently. Without this stage, the printed text or graphics would remain loose and prone to smearing, compromising usability.

Maintenance and Common Issues

Over time, wear and residue buildup can affect the efficiency of this unit. Frequent inspection and proper cleaning help prevent malfunctions such as uneven temperature distribution or jams. Inconsistent bonding often indicates the need to replace specific components, restoring optimal performance and extending the system’s lifespan.

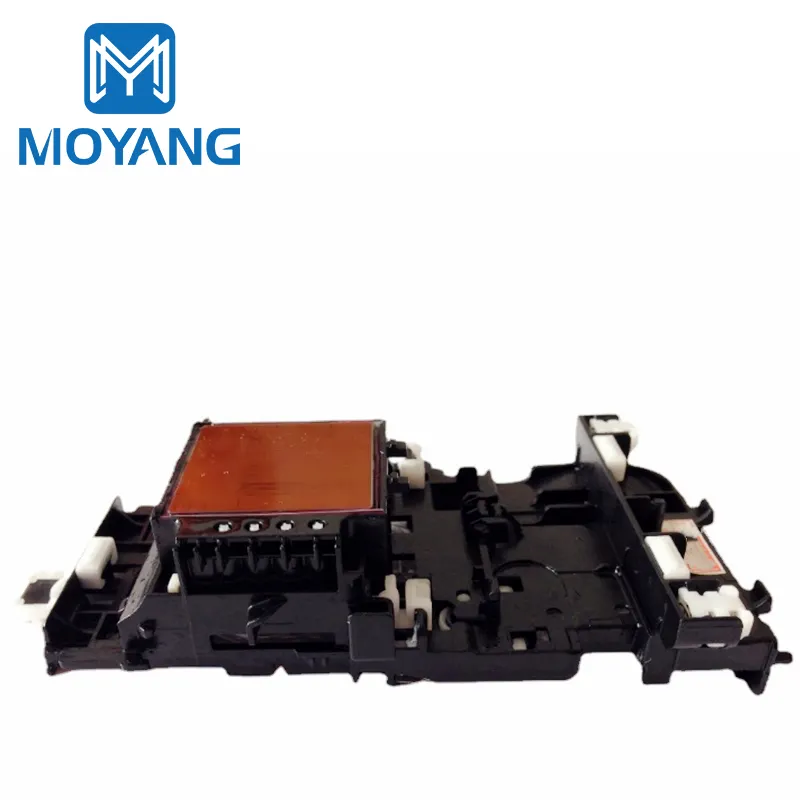

Maintenance Kits for Optimal Performance

To ensure the longevity and efficiency of your imaging device, utilizing specialized maintenance kits is essential. These kits contain various components designed to replenish and enhance functionality, contributing to uninterrupted operation and high-quality output.

Components of Maintenance Kits

Typically, these kits include items such as transfer belts, rollers, and cleaning units. Each element plays a crucial role in maintaining the overall health of the device. For instance, transfer belts facilitate the movement of media, while rollers ensure precise feeding, and cleaning units prevent debris accumulation, thereby enhancing print quality.

Benefits of Regular Maintenance

Investing in these maintenance supplies not only optimizes performance but also minimizes the risk of malfunctions. Regularly scheduled upkeep helps avoid costly repairs and extends the lifespan of your device. By adhering to a proactive maintenance schedule, users can enjoy consistent, vibrant output and maintain operational efficiency.

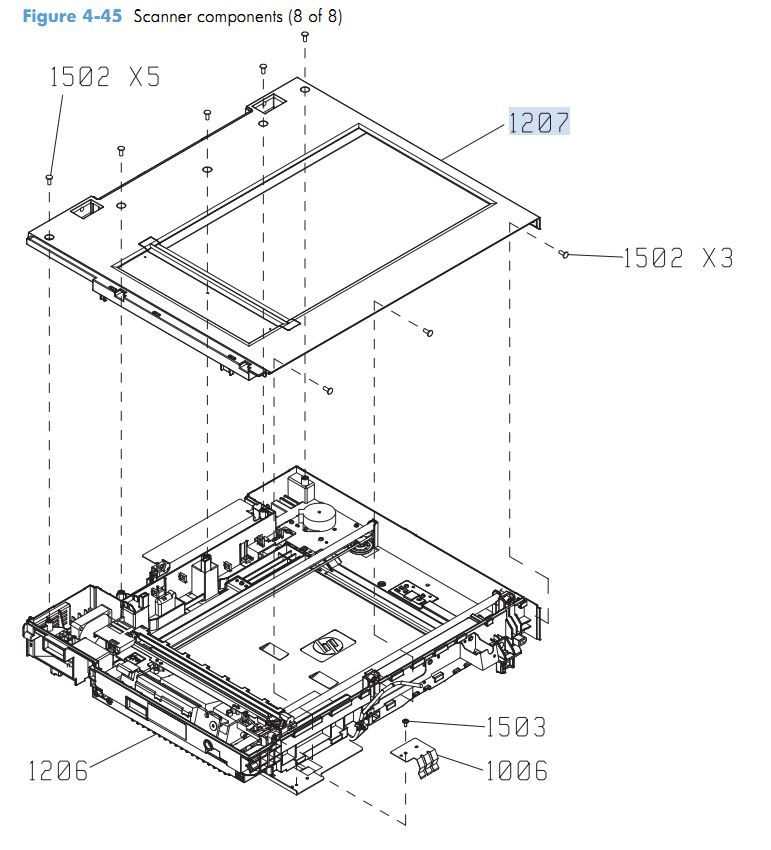

How Laser Scanners Improve Accuracy

Advanced imaging devices play a crucial role in enhancing precision across various applications. By utilizing cutting-edge technology, these tools ensure that data capture is both reliable and efficient. This section explores the mechanisms that contribute to increased accuracy in measurement and documentation processes.

Precision Measurement Techniques

One of the key advantages of using these imaging devices is their ability to perform high-resolution scans. This allows for minute details to be captured, significantly reducing errors associated with manual measurements. Moreover, the integration of automated systems further minimizes human intervention, leading to consistent and repeatable results.

Data Processing and Analysis

Another factor that enhances accuracy is the sophisticated data processing capabilities. Advanced algorithms analyze the captured information, filtering out noise and irrelevant data. This ensures that the final output reflects true measurements, which is essential for quality control and analysis in various fields.

| Feature | Benefit |

|---|---|

| High Resolution | Captures finer details |

| Automation | Reduces human error |

| Advanced Algorithms | Enhances data accuracy |

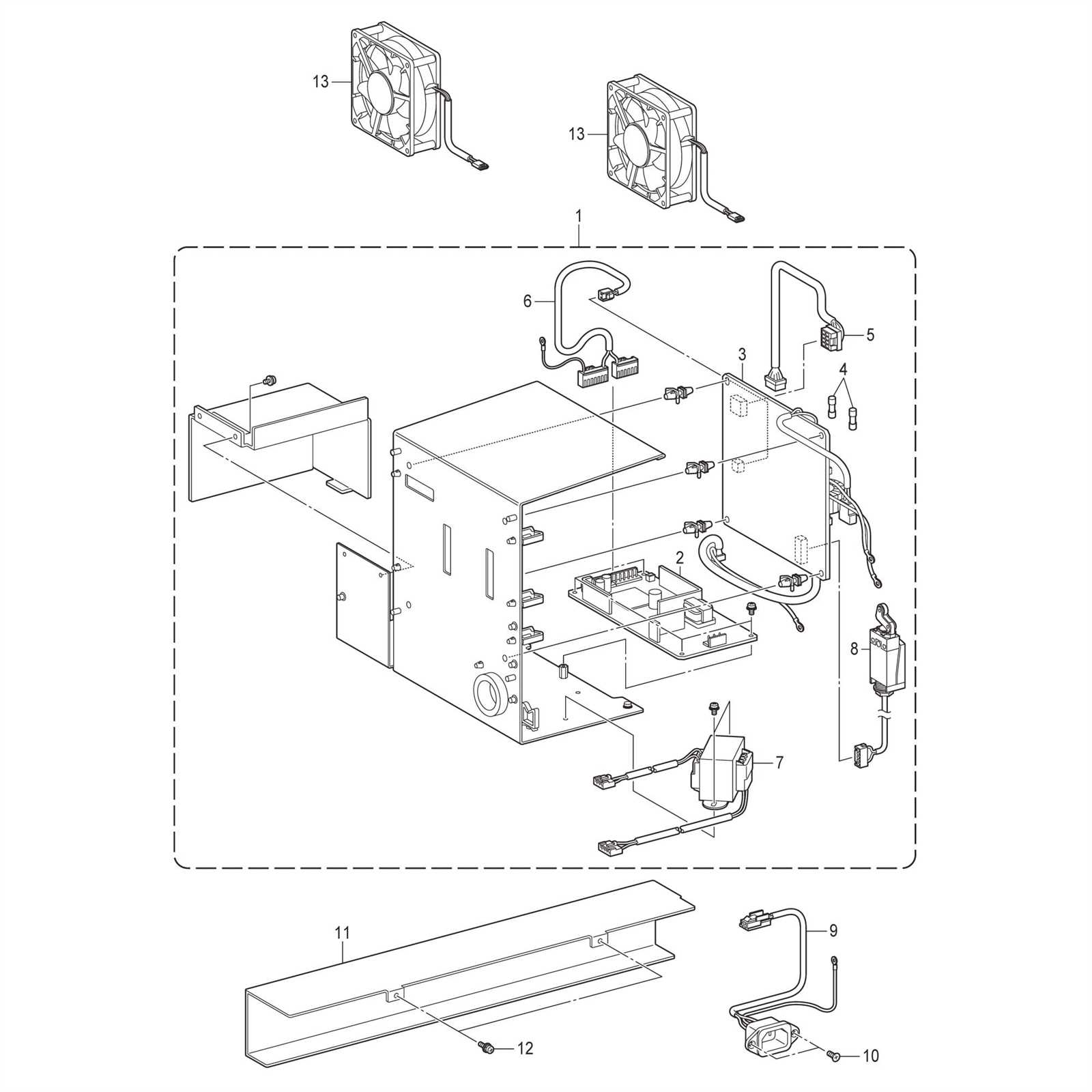

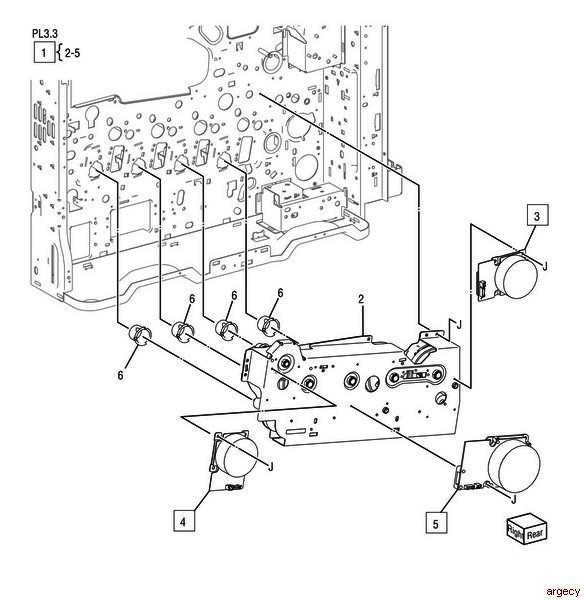

Power Supply Units and Their Importance

The functionality of various devices relies heavily on the effectiveness of their energy conversion systems. These components are crucial as they manage the distribution of electrical energy, ensuring that other elements operate smoothly and efficiently. Understanding their role can enhance the overall performance and longevity of equipment.

Role in Device Operation

Energy conversion modules are responsible for transforming high voltage electricity into usable power for internal mechanisms. This process is essential for the proper functioning of electronic circuits and prevents damage from power surges or fluctuations. Without these systems, devices would struggle to operate or could sustain irreparable harm.

Significance of Maintenance

Regular upkeep of energy management systems is vital for sustaining optimal performance. Routine inspections can identify potential issues, allowing for timely interventions that can prolong the life of the entire system. Neglecting these components may lead to increased downtime and costly repairs, emphasizing the need for proactive maintenance practices.

The Impact of Cooling Fans on Longevity

Effective thermal management is crucial for enhancing the lifespan of electronic devices. The presence of cooling mechanisms plays a significant role in regulating temperature, preventing overheating, and ensuring optimal performance. This section explores the importance of cooling systems in maintaining device integrity and reliability.

Cooling fans serve as vital components in various electronic assemblies, offering numerous benefits that contribute to overall longevity:

- Heat Dissipation: They help dissipate excess heat generated during operation, reducing the risk of thermal damage.

- Stable Performance: By maintaining an optimal temperature, these systems ensure that components operate within their designed specifications.

- Extended Lifespan: Consistent cooling can significantly prolong the life of critical components, minimizing the need for replacements.

Moreover, the design and efficiency of cooling fans can further influence their effectiveness:

- Fan Speed: Adjustable speeds can provide tailored cooling based on operational demands.

- Airflow Direction: Properly directed airflow enhances heat removal from hotspots.

- Noise Levels: Quiet operation can contribute to a more pleasant working environment.

In conclusion, the incorporation of effective cooling fans is essential in promoting device longevity. By minimizing the impact of excessive heat, these systems not only safeguard components but also enhance overall reliability and efficiency.

Connection Ports for Various Interfaces

This section delves into the different connectivity options available for peripheral devices, focusing on the essential ports utilized in modern setups. Understanding these interfaces is crucial for effective communication between devices and ensuring optimal functionality.

The most common connection ports include:

- USB Ports: Widely used for connecting various devices, offering high-speed data transfer and versatility.

- Ethernet Ports: Essential for network connections, enabling devices to communicate over local area networks (LAN).

- Parallel Ports: Historically used for connecting older peripherals, primarily for data transfer with printers and similar devices.

- Serial Ports: Commonly used for point-to-point communication with a variety of devices, including modems and sensors.

In addition to these, other specialized interfaces might be present, such as:

- HDMI: Used for high-definition video and audio transmission.

- VGA: An older standard primarily for video output to monitors and projectors.

- DisplayPort: A modern interface designed for high-resolution displays.

Each of these connection options plays a vital role in ensuring seamless integration and performance across various systems, enabling users to tailor their setups according to their specific needs.

Control Panels for User Interaction

The interface through which users engage with their devices plays a crucial role in enhancing the overall experience. Control panels serve as the primary point of interaction, allowing individuals to manage settings, initiate processes, and receive feedback from their machines. A well-designed interface not only simplifies operations but also empowers users to optimize functionality according to their specific needs.

Key Features of Control Interfaces

Effective control interfaces incorporate several essential features that contribute to user satisfaction. Intuitive layout enables quick navigation, ensuring that users can easily locate functions and settings. Additionally, visual indicators provide immediate feedback, informing users about the status of operations and any necessary actions.

Importance of User Feedback

User feedback is vital for improving interaction quality. Incorporating sound alerts and visual notifications within control panels helps to enhance communication, ensuring users are aware of important updates and potential issues. By prioritizing user-friendly designs, manufacturers can foster a more positive experience and encourage optimal usage of their devices.