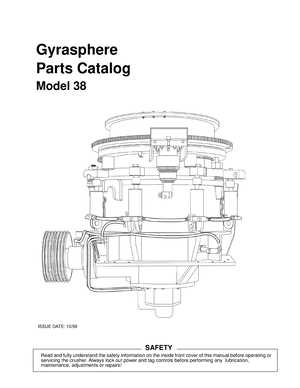

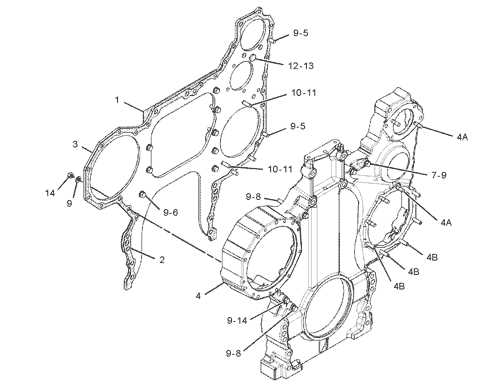

Exploring the intricate layouts of heavy machinery is essential for effective maintenance and operation. Grasping how each element interacts within an engine can significantly enhance performance and longevity. A clear representation of these components serves as a valuable resource for technicians and enthusiasts alike.

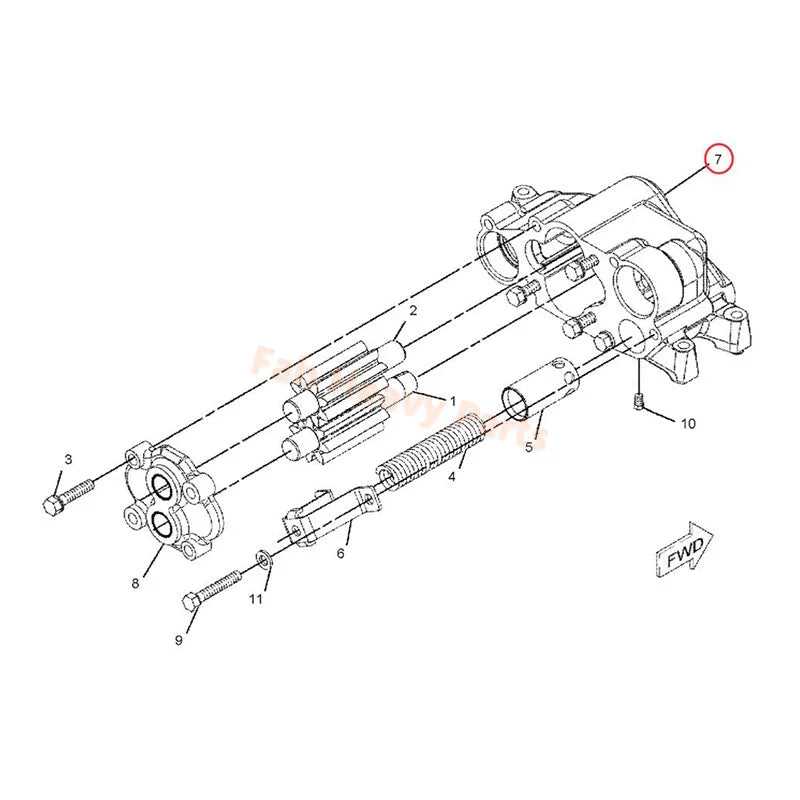

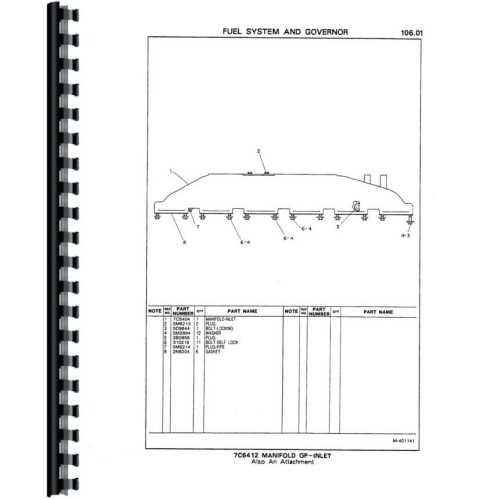

Visual aids play a crucial role in simplifying complex information. By providing a comprehensive overview of the various sections, individuals can easily identify and locate specific elements necessary for repair or inspection. This understanding not only boosts efficiency but also fosters a deeper appreciation for the engineering behind these powerful machines.

Whether you’re a seasoned professional or a newcomer, familiarity with the layout can lead to more informed decisions and better troubleshooting strategies. Engaging with these visual guides equips users with the knowledge needed to tackle challenges confidently and maintain optimal functionality.

Understanding the Cat 3406 Engine

This section explores the intricate design and functionality of a well-known diesel power unit, highlighting its significance in various applications. Gaining insights into this engine enhances the understanding of its operation and maintenance.

Key features include:

- Robust construction for durability

- High torque output for heavy-duty tasks

- Advanced fuel efficiency technologies

Understanding the internal components is crucial:

- Cylinders and pistons

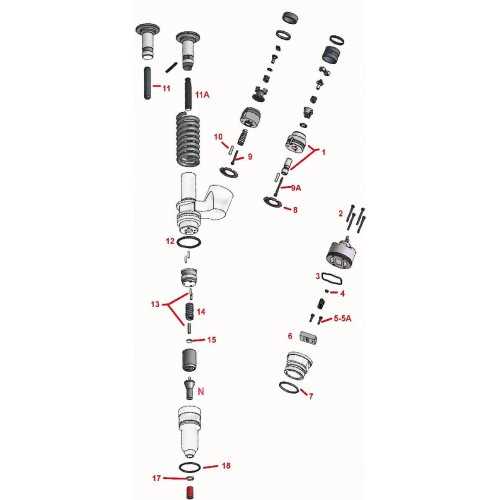

- Fuel injectors

- Cooling systems

By delving into these aspects, users can appreciate the ultimate performance and reliability this engine offers in demanding environments.

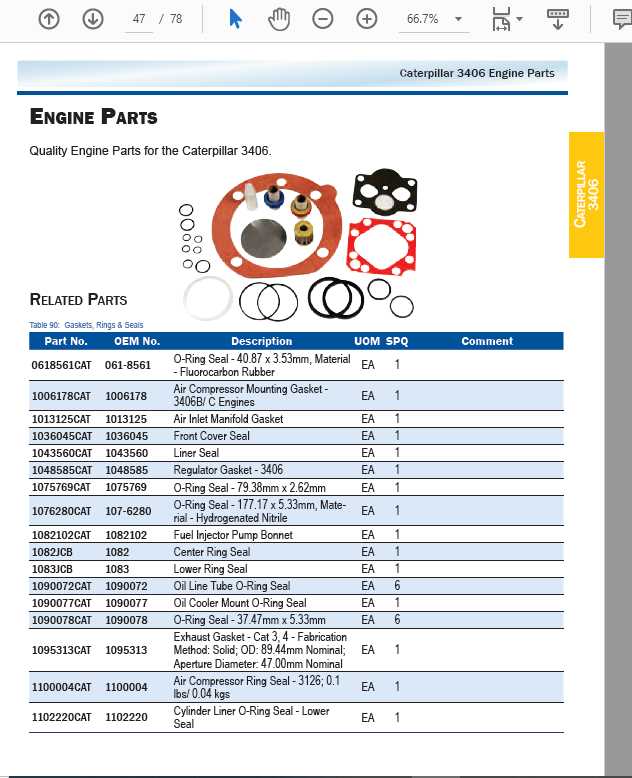

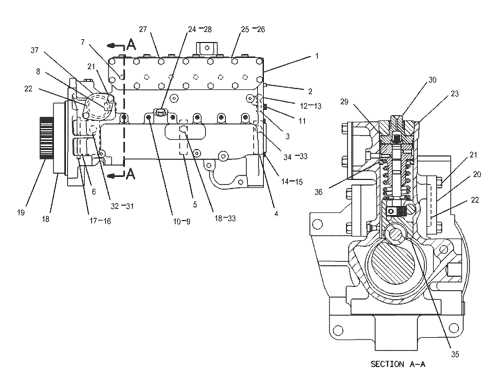

Key Components of Cat 3406

Understanding the essential elements of this heavy-duty engine is crucial for effective maintenance and performance optimization. Each component plays a significant role in the overall functionality, ensuring reliability and efficiency in various applications.

The core assembly includes the block, which serves as the foundation, housing vital internal mechanisms. Coupled with the cylinder head, these elements facilitate the combustion process. The crankshaft, a pivotal piece, converts linear motion into rotational energy, driving the engine’s power output.

Moreover, the fuel injection system is integral for precise fuel delivery, enhancing combustion efficiency. Cooling components, such as the radiator and water pump, maintain optimal operating temperatures, preventing overheating. Lastly, the exhaust system ensures the safe expulsion of gases, contributing to both performance and environmental standards.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the intricate workings of machinery. They provide clarity and enable users to identify various elements efficiently, facilitating maintenance and repairs. By illustrating how individual parts interact within a system, these visual aids enhance comprehension and promote effective troubleshooting.

Enhancing Communication

Utilizing visual schematics fosters better communication among technicians and engineers. When discussing specific elements or issues, referring to these illustrations minimizes misunderstandings and ensures everyone is on the same page. This streamlined communication is vital for teamwork and efficient problem resolution.

Facilitating Efficient Repairs

When faced with mechanical challenges, having a visual guide simplifies the repair process. Technicians can quickly locate the necessary components, making the identification of issues and replacement of faulty items more straightforward. This not only saves time but also reduces the risk of errors during maintenance tasks.

In summary, visual representations of components are indispensable tools that significantly enhance understanding, communication, and repair efficiency in machinery maintenance. Their importance cannot be overstated in ensuring smooth operations and prolonging equipment lifespan.

Common Issues with Cat 3406 Parts

When dealing with heavy machinery, certain components often present challenges that can impact performance and reliability. Understanding these frequent issues is crucial for effective maintenance and operation. Identifying common malfunctions helps in preventing costly repairs and downtime.

Wear and Tear: One of the primary concerns involves gradual degradation of components due to constant use. Components like gaskets and seals may deteriorate over time, leading to leaks and inefficiencies.

Overheating: Excessive heat can cause serious problems in the engine’s functionality. Insufficient coolant flow or faulty thermostats can result in overheating, which might damage internal parts and reduce overall efficiency.

Fuel System Problems: Issues within the fuel delivery system, such as clogged filters or failing injectors, can lead to suboptimal performance. Regular checks and replacements can mitigate these risks.

Electrical Failures: Electrical components, including wiring and sensors, are susceptible to wear and corrosion. Malfunctions in these areas can lead to starting issues and erratic behavior of the machinery.

Vibration and Noise: Unusual vibrations or sounds may indicate problems with mounts or bearings. Addressing these issues early can prevent more significant damage and ensure smoother operation.

By staying aware of these common challenges and addressing them proactively, operators can maintain the functionality and longevity of their machinery, ensuring optimal performance in demanding environments.

Finding Reliable Replacement Parts

When searching for trustworthy components for heavy machinery, it’s crucial to ensure that the products meet quality standards and compatibility requirements. The right choices can enhance performance and extend the lifespan of your equipment, preventing costly downtimes and repairs.

| Criteria | Description |

|---|---|

| Quality Assurance | Look for suppliers that offer warranties or guarantees on their products, indicating reliability. |

| Compatibility | Ensure the components are designed specifically for your machinery model to avoid performance issues. |

| Reputation | Research suppliers with positive reviews and a history of customer satisfaction in the industry. |

| Support | Select vendors that provide technical support and advice on installation and maintenance. |

Maintenance Tips for Longevity

Ensuring the durability of your machinery involves regular upkeep and attention to detail. Implementing a proactive maintenance schedule can significantly enhance performance and extend operational life. Below are essential practices to consider for optimal functioning.

Regular Inspections

- Conduct frequent visual checks for wear and tear.

- Monitor fluid levels and conditions to prevent leaks.

- Inspect belts and hoses for signs of cracking or fraying.

Routine Servicing

- Change oil and filters as per manufacturer recommendations.

- Lubricate moving parts to minimize friction and wear.

- Replace any worn components promptly to avoid further damage.

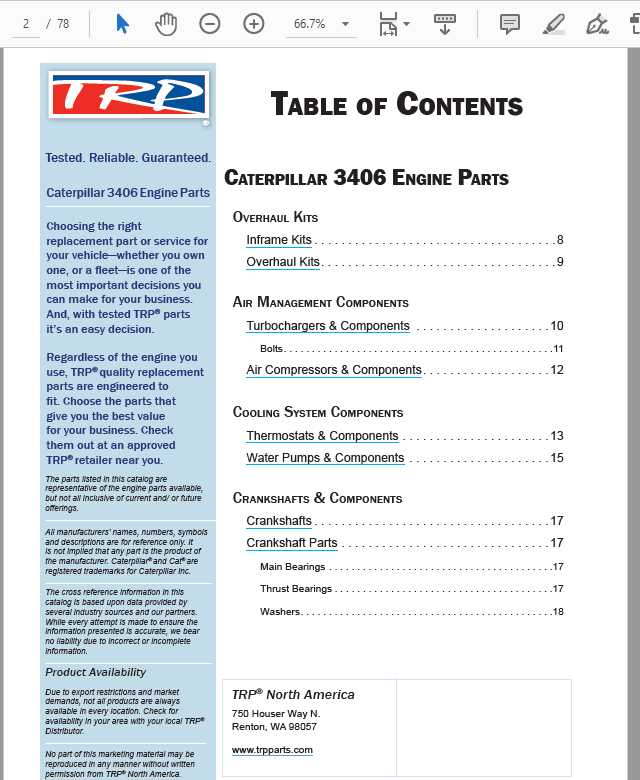

Using Diagrams for Repairs

Visual representations play a crucial role in facilitating effective maintenance and restoration tasks. They provide a clear roadmap, enabling technicians to understand complex systems and components effortlessly. Utilizing these visuals not only enhances comprehension but also boosts efficiency during repairs.

Benefits of Visual Aids

- Improved clarity in identifying parts and functions.

- Streamlined troubleshooting processes.

- Enhanced accuracy in reassembly.

- Time-saving in locating issues.

Best Practices for Effective Use

- Refer to updated visuals to ensure accuracy.

- Cross-reference with manuals for comprehensive understanding.

- Annotate as necessary to highlight critical areas.

- Maintain organization by categorizing sections logically.

Aftermarket vs. OEM Parts

When it comes to replacing components in heavy machinery, the choice often boils down to two main categories: original manufacturer offerings and alternative options. Each has its own set of advantages and drawbacks, which can significantly influence performance, cost, and longevity.

Understanding the distinctions between these two types of components is crucial for making informed decisions that align with both operational needs and budgetary constraints.

- Original Manufacturer Components:

- Typically designed to meet specific performance standards.

- Often come with warranties that guarantee quality.

- May be more expensive due to brand reputation and reliability.

- Alternative Options:

- Generally available at a lower price point.

- Variety of brands and quality levels, which can lead to inconsistency.

- May lack comprehensive warranties or support services.

Ultimately, the decision between these options should consider factors such as the specific application, the anticipated usage, and the long-term maintenance strategy. Balancing cost against quality and performance is essential to ensure optimal functionality and durability of the machinery.

Upgrading Your Cat 3406 Engine

Enhancing the performance of your heavy-duty engine can significantly improve efficiency and power. This section explores various strategies for optimization, focusing on key components that can be upgraded to achieve the ultimate results in performance and longevity.

Boosting Power and Efficiency

One effective way to increase horsepower is by upgrading the fuel delivery system. Consider replacing the injectors with high-performance alternatives, which can enhance combustion efficiency. Additionally, integrating a more efficient turbocharger can lead to better airflow, ultimately contributing to increased torque.

Improving Cooling and Lubrication

Enhanced cooling systems are crucial for maintaining optimal temperatures during operation. Upgrading to a high-capacity radiator and improved coolant can prevent overheating. Furthermore, investing in a superior oil filtration system will ensure better lubrication and prolong engine life.

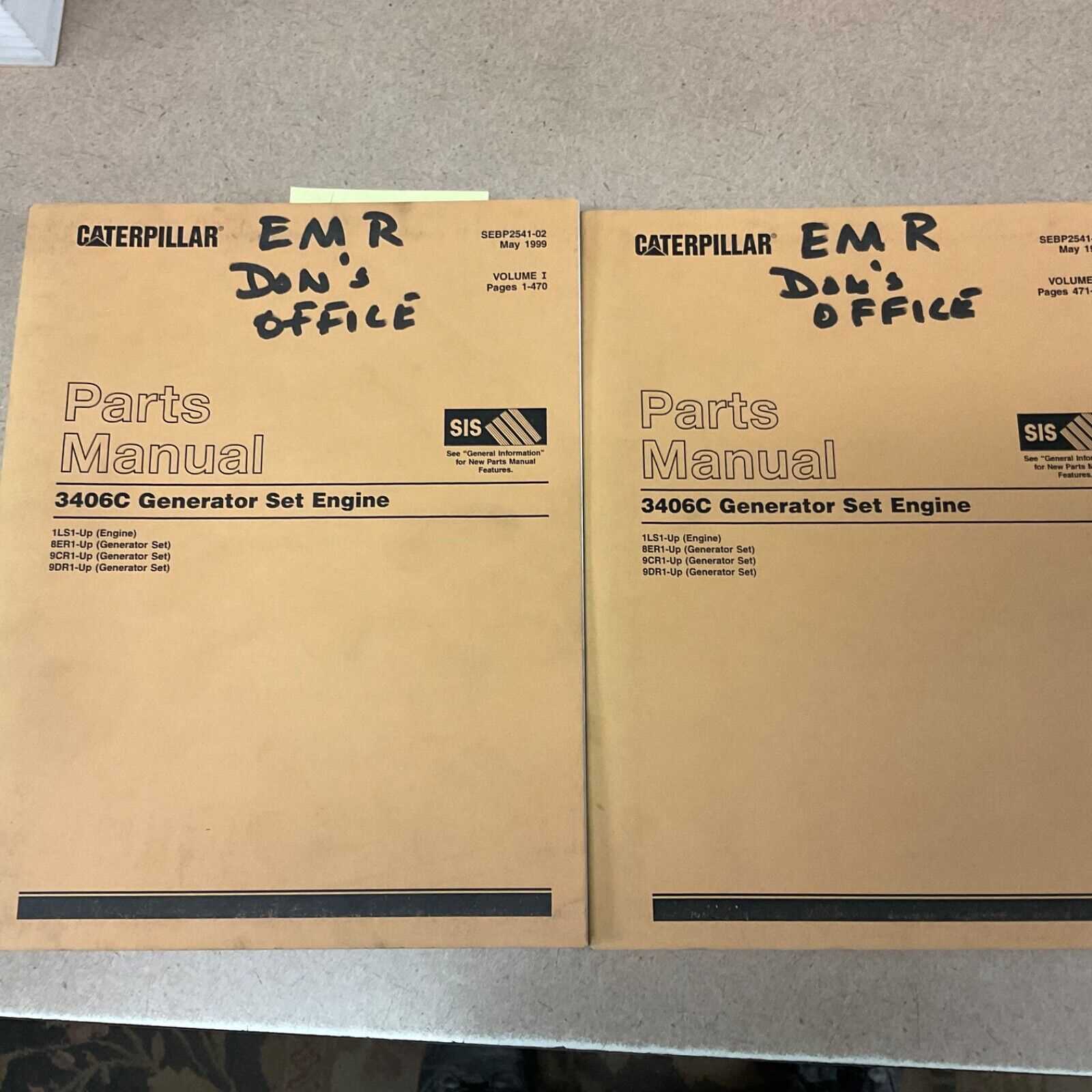

Resources for Parts Diagrams

Accessing reliable resources for understanding component layouts is essential for effective maintenance and repair. Whether you’re a professional mechanic or a DIY enthusiast, having the right tools at your disposal can make all the difference.

Online Platforms

- Manufacturer Websites: Often provide detailed visual guides and specifications.

- Forums and Community Groups: Engage with experienced users for insights and shared resources.

- Repair Manuals: Available for purchase or online download, these documents often include comprehensive illustrations.

Physical Resources

- Local Dealerships: Can offer printed materials or access to specialized databases.

- Workshops: Attend classes or sessions that cover detailed assembly and maintenance procedures.

- Library Archives: Many libraries hold technical manuals and guides that can be borrowed or accessed.

FAQs about Cat 3406 Components

This section addresses common inquiries related to the various elements of a specific heavy machinery engine. Understanding these components is essential for maintenance and optimal performance. Here, we provide concise answers to frequently asked questions, helping users navigate their needs more effectively.

What are the key components of this engine?

The primary elements include the cylinder head, fuel injectors, oil pump, and turbocharger, each playing a vital role in engine function.

How can I identify a malfunctioning part?

Signs of wear or failure can include unusual noises, decreased performance, or warning lights on the dashboard. Regular inspections are crucial for early detection.

Where can I find replacement components?

Replacement elements can be sourced from authorized dealers, aftermarket suppliers, or specialized online retailers, ensuring compatibility with your engine model.

What maintenance practices are recommended?

Routine checks on oil levels, filter cleanliness, and component integrity are essential. Following the manufacturer’s guidelines will help extend the engine’s lifespan.

Are there any common issues with these components?

Common problems may include injector clogs, gasket failures, or overheating. Being aware of these issues can aid in timely repairs.

How can I enhance the performance of my engine?

Upgrading certain elements, using high-quality lubricants, and adhering to maintenance schedules can significantly boost overall efficiency.