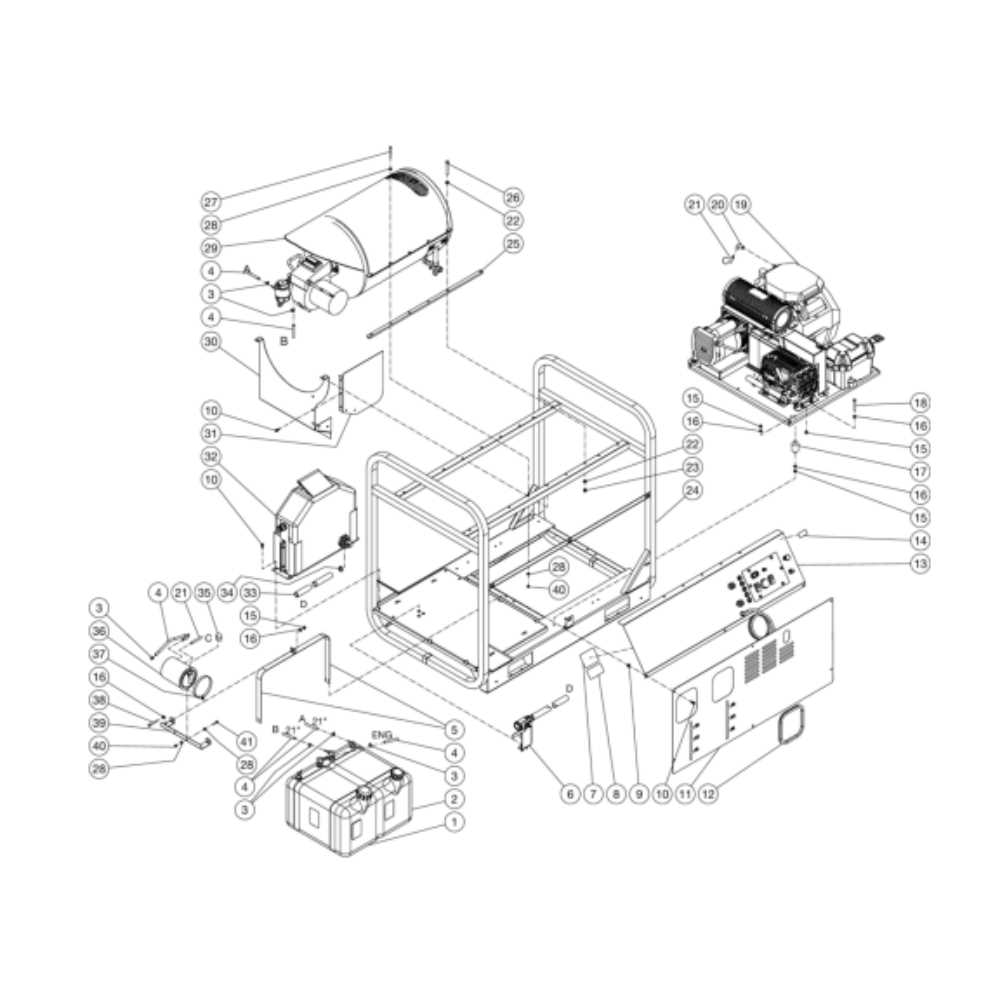

Exploring the intricate workings of a power generator can greatly enhance its functionality and lifespan. Each element plays a critical role, contributing to the overall efficiency and performance. By familiarizing yourself with the various sections and mechanisms, you can ensure that your equipment operates smoothly and reliably.

In this guide, we will delve into the specific sections of a typical generator unit, offering insights into their arrangements and functions. A clear understanding of these components will empower users to perform maintenance tasks with confidence and make informed decisions about repairs or upgrades.

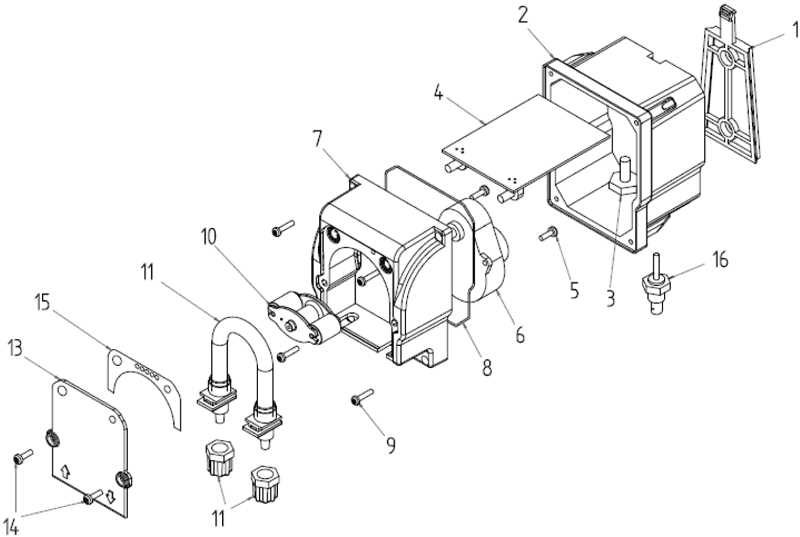

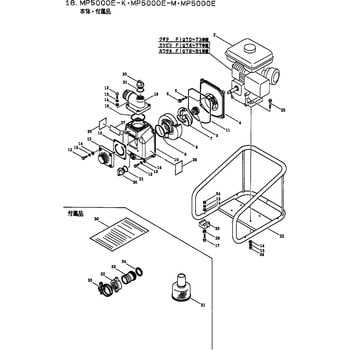

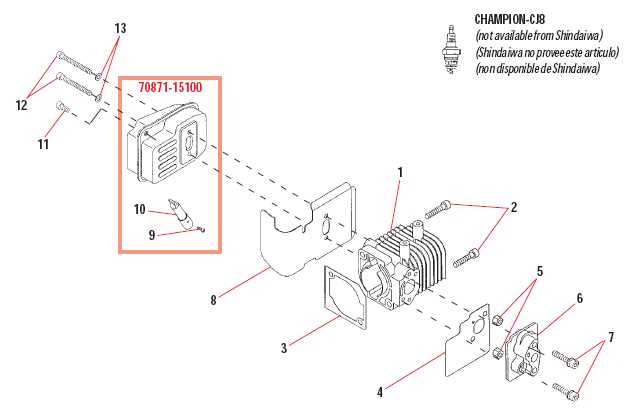

Moreover, visual representations of the layout can serve as valuable references. Whether you are a seasoned technician or a novice user, having access to detailed illustrations can facilitate troubleshooting and enhance your familiarity with the unit. This resource aims to equip you with the knowledge necessary to navigate the essential aspects of your generator efficiently.

Overview of the Generator

This section provides a comprehensive look at a specific model of portable power generator designed for reliability and efficiency. This unit is often favored for various applications, from outdoor events to emergency backup, due to its robust features and performance capabilities.

Key Features

- High wattage output for multiple appliances.

- Durable construction for long-term use.

- Portability with wheels and a convenient handle.

- Efficient fuel consumption for extended operation.

Applications

- Camping and outdoor activities.

- Construction sites requiring power tools.

- Emergency power supply during outages.

- Outdoor events and festivals.

Key Features of the Generator

This section explores the essential characteristics that define the efficiency and reliability of a portable power source. Understanding these features can significantly enhance user experience and utility in various situations, whether for home backup or outdoor activities.

Performance and Efficiency

The generator is designed for optimal performance, providing consistent power output and fuel efficiency. Its robust engine ensures that users can rely on it during critical times, while innovative technology minimizes operational costs.

Portability and Design

The lightweight and compact design makes it easy to transport, allowing for convenient use in different environments. Built-in handles and wheels facilitate mobility, making it a practical choice for camping, tailgating, or emergency use.

| Feature | Description |

|---|---|

| Power Output | Delivers sufficient wattage for various appliances. |

| Fuel Type | Compatible with multiple fuel types for versatility. |

| Noise Level | Operates quietly to minimize disruption. |

| Safety Features | Includes overload protection and circuit breakers. |

Importance of Understanding Parts

Grasping the intricacies of components is crucial for effective maintenance and optimal performance of any machinery. Knowledge of how individual elements interact can significantly enhance troubleshooting and repair processes, ensuring longevity and reliability.

Moreover, familiarizing oneself with various elements fosters confidence in handling equipment, empowering users to make informed decisions about upgrades or replacements. This understanding can ultimately lead to improved efficiency and safety, reducing the likelihood of costly repairs caused by neglect or misuse.

Common Issues and Solutions

When operating portable power generators, users may encounter several frequent challenges that can affect performance and efficiency. Understanding these common issues is crucial for ensuring smooth operation and longevity of the equipment.

1. Difficulty Starting: One prevalent issue is trouble starting the unit. This can often be resolved by checking the fuel levels, ensuring the choke is in the correct position, and inspecting the spark plug for wear or damage.

2. Inconsistent Power Output: Users might experience fluctuations in power supply. To address this, it’s essential to verify that the load is within the generator’s capacity and to inspect the wiring for any signs of wear or loose connections.

3. Excessive Noise: Unusual noise levels can indicate underlying problems. Regular maintenance, such as lubricating moving parts and tightening bolts, can help minimize sound and improve performance.

4. Fuel Leaks: Fuel leaks pose safety risks and can be addressed by examining hoses and fittings for damage, replacing any compromised parts, and ensuring all connections are secure.

5. Overheating: If the generator overheats, it may shut down automatically. Allow it to cool, and check for blockages in the airflow and clean the air filter to promote better ventilation.

Where to Find the Parts Diagram

Locating a schematic for your equipment can greatly enhance your understanding of its components and assist in any maintenance or repair tasks. Fortunately, several reliable sources are available to help you obtain this essential information.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often offers downloadable resources, including schematics and user manuals. |

| Online Retailers | Websites that sell replacement components frequently provide diagrams for reference to ensure compatibility. |

| Repair Forums | Communities dedicated to equipment repairs can be a treasure trove of shared resources and diagrams. |

| Service Centers | Authorized service locations typically have access to comprehensive schematics for the products they support. |

| Technical Manuals | Some printed manuals include detailed diagrams and can often be found at libraries or purchased from specialty bookstores. |

Utilizing these resources will facilitate your search and ensure you have the necessary information for effective repairs and maintenance.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential for optimal performance and longevity. This guide will provide a systematic approach to ensuring your device operates smoothly, enhancing efficiency and preventing potential issues.

Begin by disconnecting the power source to ensure safety. Inspect the exterior for any signs of wear or damage. Clean the surfaces with a damp cloth to remove dirt and debris.

Next, check the fuel system. Replace any old fuel and ensure that fuel lines are clear. Additionally, inspect the oil level and change it if necessary, following the manufacturer’s recommendations.

Examine filters and replace them if they appear dirty or clogged. This step is crucial for maintaining airflow and preventing overheating.

Lastly, test the functionality of all components, ensuring they operate as intended. Regular checks and timely interventions will significantly enhance the reliability of your equipment.

Identifying Replacement Components

When maintaining or restoring machinery, understanding how to pinpoint necessary components is essential for efficient operation. This process involves recognizing the specific elements that require replacement and sourcing suitable alternatives. Proper identification not only enhances functionality but also extends the lifespan of the equipment.

Understanding Component Functions

Each part of a machine serves a distinct purpose. Familiarizing yourself with these functions is crucial. For instance, some components are responsible for generating power, while others may facilitate movement or ensure safety. By comprehensively understanding these roles, you can accurately determine which parts are failing or worn out.

Sourcing Suitable Alternatives

Once you have identified the required components, the next step is to find appropriate replacements. Always consider compatibility and quality when searching for alternatives. Reputable suppliers often provide detailed specifications that can guide your selection. Additionally, online resources and community forums can be invaluable for finding recommendations and insights into the best options available.

Compatibility with Other Models

This section explores the interchangeability of components across different generator models, emphasizing the versatility and convenience for users. Understanding compatibility can significantly enhance maintenance efficiency and reduce costs.

Many generators share similar frameworks and parts, making it possible to use components from various models interchangeably. Here are some key aspects to consider:

- Shared Components: Many manufacturers design parts that fit multiple models, allowing for easier sourcing and replacement.

- Performance Specifications: It’s essential to check voltage ratings and power outputs to ensure compatibility with the desired model.

- Design Variations: While some parts may be compatible, others may require slight modifications or adjustments to fit correctly.

- Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for compatibility to avoid potential issues.

When considering components from other models, users can often find solutions that are both cost-effective and efficient, leading to improved generator performance and longevity.

DIY Repair Tips and Tricks

Repairing equipment can be a rewarding experience, offering both cost savings and a sense of accomplishment. Whether you’re tackling mechanical issues or addressing electrical faults, having the right approach can make a significant difference. This section will explore various techniques and insights to help you confidently manage your repair projects.

Start by gathering essential tools and materials before diving into the repair process. A well-organized workspace enhances efficiency and minimizes frustration. Make sure to consult user manuals or online resources for guidance on specific components and their functions.

When disassembling any unit, label each part and keep screws organized to ensure a smooth reassembly. Take photographs during the process to reference later, particularly for complex setups. Additionally, always prioritize safety by disconnecting power sources and wearing appropriate protective gear.

For troubleshooting, consider using a systematic approach. Identify symptoms and eliminate possible causes step by step. This methodical strategy can save time and help pinpoint the root of the problem.

Finally, don’t hesitate to reach out to online communities for advice or support. Many enthusiasts share their experiences and solutions, which can provide valuable insights for your own projects. Happy repairing!

Essential Tools for Repairs

When it comes to maintaining and fixing equipment, having the right tools at your disposal is crucial. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed efficiently and effectively. Below are some fundamental instruments that every DIY enthusiast should consider for their repair projects.

Basic Hand Tools

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for assembling and disassembling components.

- Wrenches: Both adjustable and fixed wrenches help in tightening or loosening bolts and nuts.

- Pliers: Needle-nose and standard pliers can grip, twist, and cut wires and other materials.

- Hammer: A reliable hammer is necessary for driving nails and making adjustments to parts.

Power Tools

- Drill: A power drill facilitates the creation of holes and the installation of fasteners with ease.

- Impact Driver: This tool provides extra torque for driving screws and is especially useful for tough materials.

- Saw: A power saw, whether circular or reciprocating, is essential for cutting through various materials with precision.

- Sander: To achieve smooth finishes, a sander is invaluable for wood and other surfaces.

Equipping yourself with these essential tools will not only enhance your repair capabilities but also boost your confidence in tackling various projects. With the right instruments at hand, you can address issues effectively and maintain the longevity of your equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure the longevity and functionality of the equipment. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks during the repair process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial when working on mechanical devices. This includes safety goggles to protect the eyes from debris, gloves to shield the hands from sharp edges and hot surfaces, and sturdy footwear to prevent foot injuries. Additionally, using hearing protection in noisy environments can safeguard against long-term auditory damage.

Workspace Safety

Maintaining a clean and organized workspace is vital for safety during repairs. Ensure that tools are easily accessible and properly stored to avoid tripping hazards. Adequate lighting is also important to clearly see the components being worked on. Furthermore, always disconnect power sources before beginning any repairs to eliminate the risk of electrical shock or unintended machine operation.

Resources for Further Assistance

When it comes to maintaining and repairing equipment, having access to reliable resources is essential. Whether you’re looking for detailed manuals, troubleshooting guides, or community forums, there are numerous avenues to explore for obtaining the support you need. This section will outline various options that can help you navigate any challenges you may encounter.

Online Forums and Communities

Engaging with fellow enthusiasts and experts can be incredibly beneficial. Online forums provide a platform for users to share experiences, tips, and solutions to common problems. Websites dedicated to machinery often host active communities where members can ask questions and receive prompt responses. Participating in these discussions can enhance your knowledge and connect you with others who share your interests.

Manufacturer Resources

Many manufacturers offer extensive resources for their products. This includes official websites where you can find user manuals, maintenance guides, and parts lists. In addition, customer support services are often available to assist with specific inquiries. Utilizing these resources ensures that you have accurate information and support tailored to your specific equipment.