The effectiveness of moisture management systems hinges on a clear understanding of their essential elements. Each component plays a crucial role in ensuring optimal performance and longevity. By dissecting these systems, users can gain insights into how they function and how to maintain them properly.

Identifying the key features of these appliances allows for better troubleshooting and enhancement of efficiency. From the collection of excess humidity to the mechanisms that regulate airflow, every aspect is designed with a specific purpose in mind. Recognizing these roles can empower users to make informed decisions regarding repairs and upgrades.

In this exploration, we will delve into the various elements that make up these devices, offering a comprehensive overview that will aid in both understanding and practical application. With a focus on clarity, this discussion aims to illuminate the inner workings that contribute to effective humidity control.

Understanding Dehumidifier Components

To effectively manage humidity levels in indoor environments, it is essential to comprehend the various elements that contribute to moisture control systems. Each component plays a crucial role in the overall functionality, ensuring optimal performance and efficiency. This knowledge not only aids in maintenance but also enhances the ability to troubleshoot issues that may arise over time.

Key Elements of Moisture Control Systems

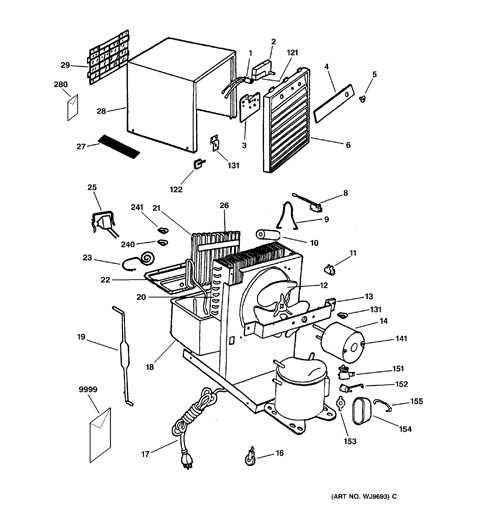

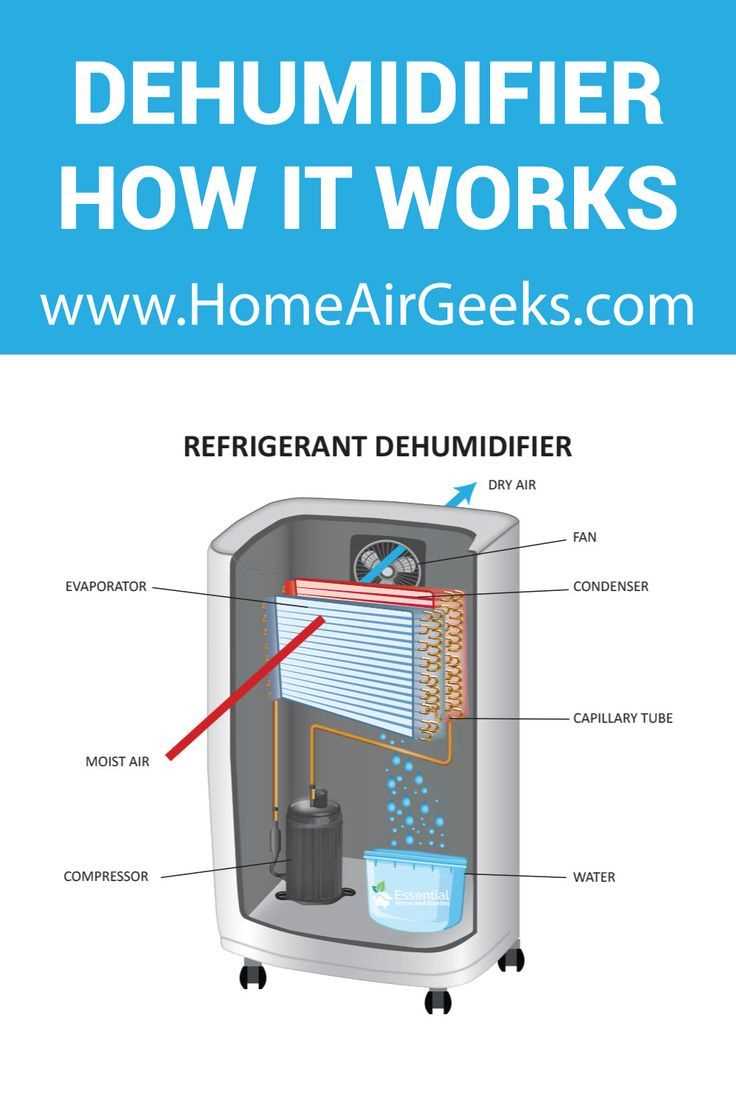

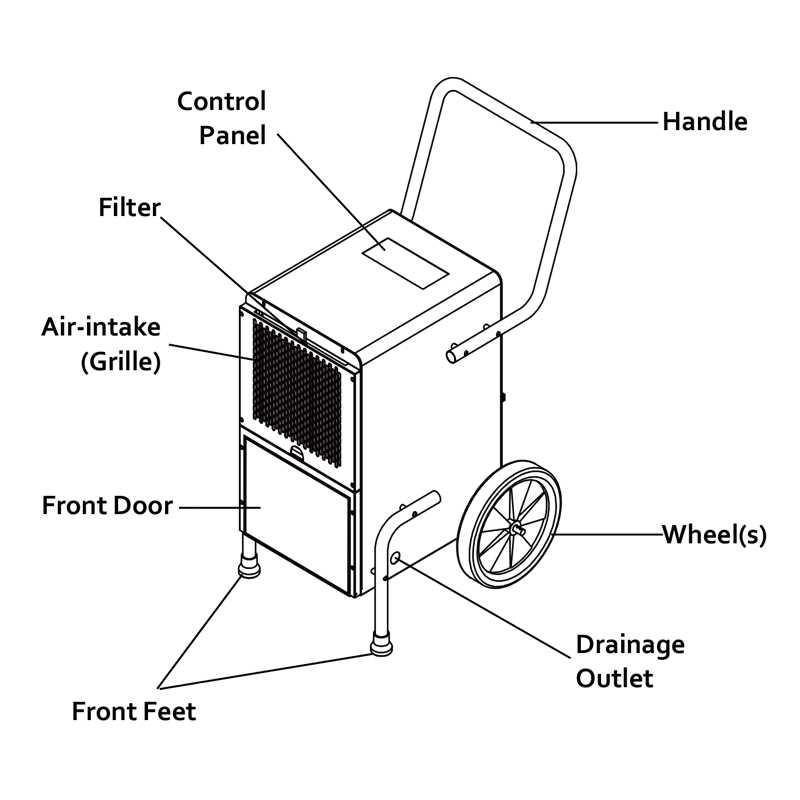

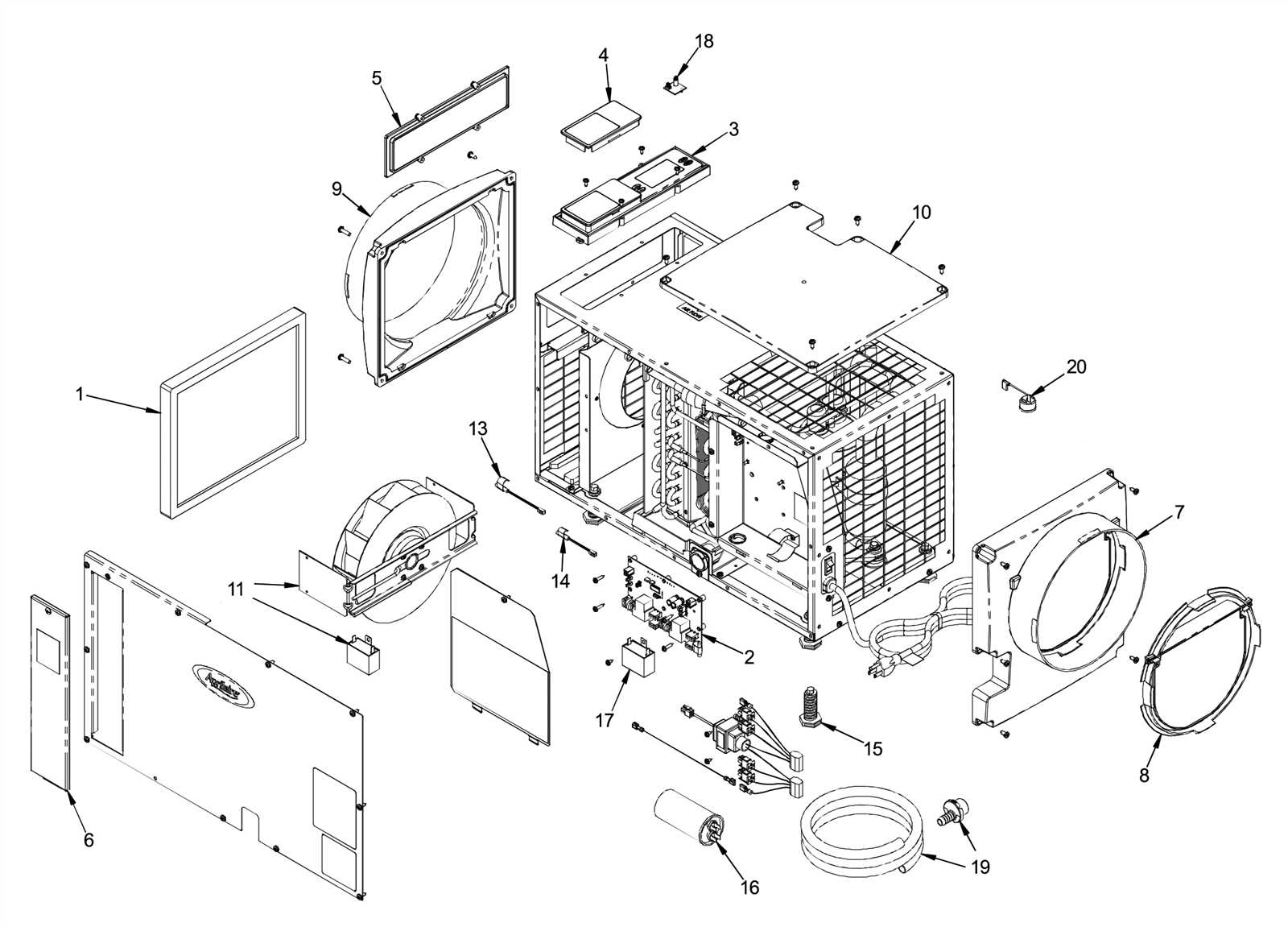

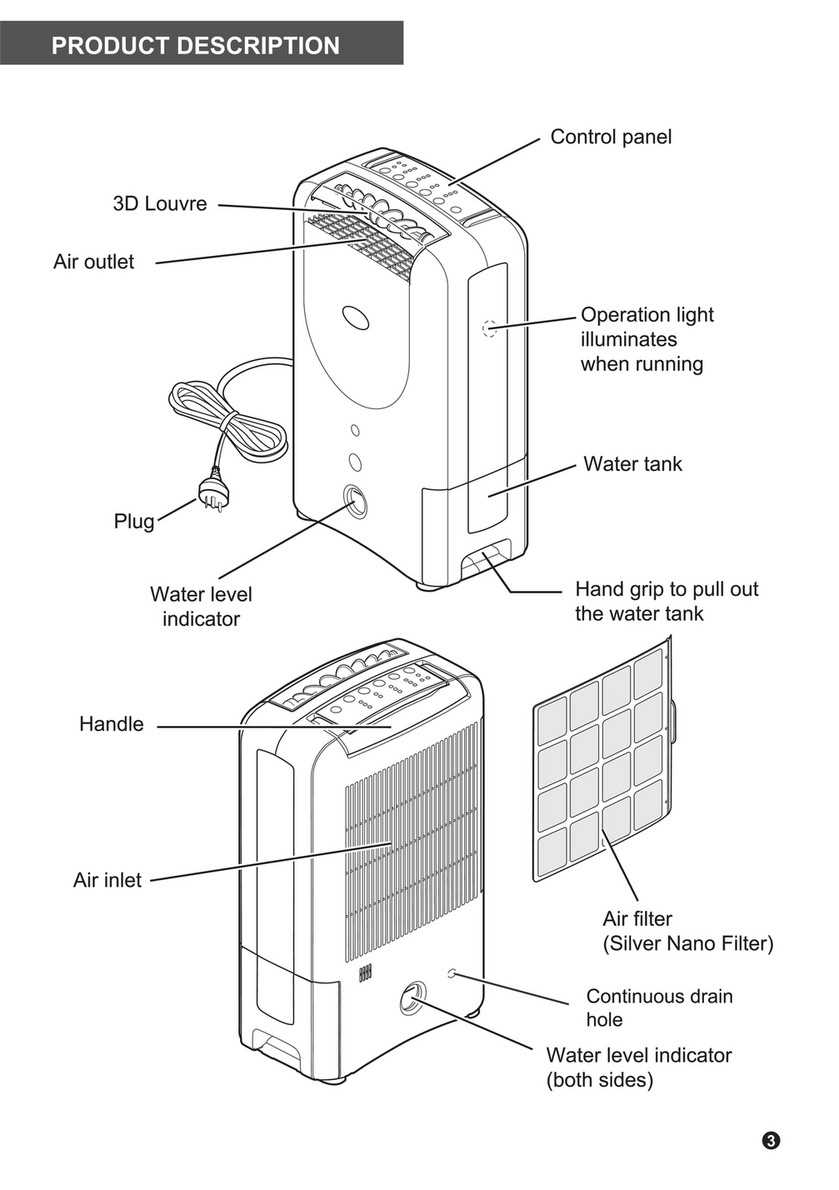

At the heart of these systems is a fan that circulates air, facilitating the process of moisture extraction. This airflow passes through a cooling coil, where the humidity in the air condenses into water droplets. A reservoir collects this moisture, which can be drained or removed as needed. Additionally, filters are employed to trap dust and allergens, improving air quality while the system operates.

Importance of Understanding Each Component

Familiarity with each element allows users to identify potential problems and understand maintenance requirements. For instance, regular cleaning of filters and ensuring proper drainage are vital for sustained efficiency. By recognizing how each part contributes to the overall process, users can ensure that their systems function effectively, creating a comfortable and healthy living space.

Key Parts of a Dehumidifier

Understanding the essential components of moisture removal devices is crucial for effective operation and maintenance. These elements work together to create a system that efficiently reduces humidity levels in indoor environments, ensuring comfort and preventing mold growth.

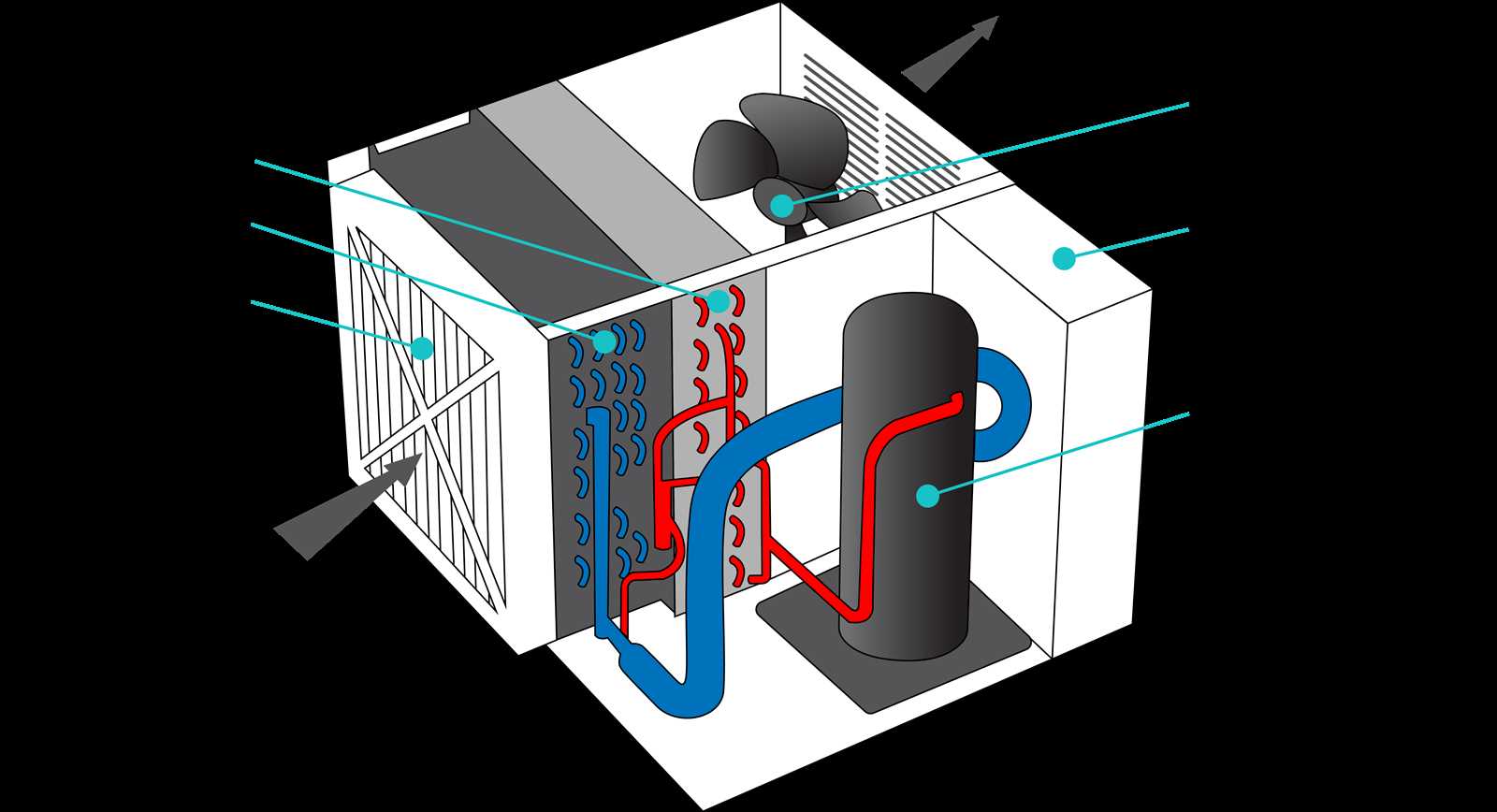

Compressor: This critical element compresses refrigerant gas, enabling it to absorb moisture from the air. Its efficiency directly impacts the unit’s performance.

Condenser: Located within the appliance, this component cools the compressed gas, allowing it to release the moisture it has gathered. The condensation process is vital for effective moisture removal.

Evaporator Coil: This coil plays a significant role by allowing the refrigerant to evaporate and absorb heat, further facilitating moisture extraction from the surrounding air.

Fan: The fan circulates air over the evaporator coil, ensuring a continuous flow of humid air into the system. This movement is essential for optimal moisture absorption.

Water Collection Tank: As moisture condenses, it collects in this reservoir. Regular monitoring and emptying of the tank are necessary to maintain efficient operation.

Humidistat: This device regulates humidity levels by controlling when the system operates. It ensures the environment remains at a comfortable moisture level.

By delving into these components, users can better understand how each functions within the system to achieve the ultimate goal of maintaining an ideal indoor climate.

Functionality of the Compressor

The compressor plays a crucial role in maintaining optimal humidity levels by facilitating the movement and transformation of refrigerant within the system. This process is essential for extracting moisture from the air, thereby ensuring a comfortable and healthy environment.

Operational Mechanism

At its core, the compressor operates by increasing the pressure of the refrigerant, allowing it to transition from a low-pressure gas to a high-pressure gas. This transformation is vital for the subsequent condensation of moisture. The compressor draws in the refrigerant and compresses it, which raises its temperature and pressure before it enters the condenser.

Key Functions

| Function | Description |

|---|---|

| Compression | Increases refrigerant pressure, facilitating heat exchange. |

| Refrigerant Circulation | Ensures continuous flow of refrigerant through the system. |

| Temperature Regulation | Maintains optimal operational temperatures by controlling heat removal. |

In summary, the compressor is essential for effectively managing humidity levels, enabling the entire system to function efficiently and providing a comfortable atmosphere indoors.

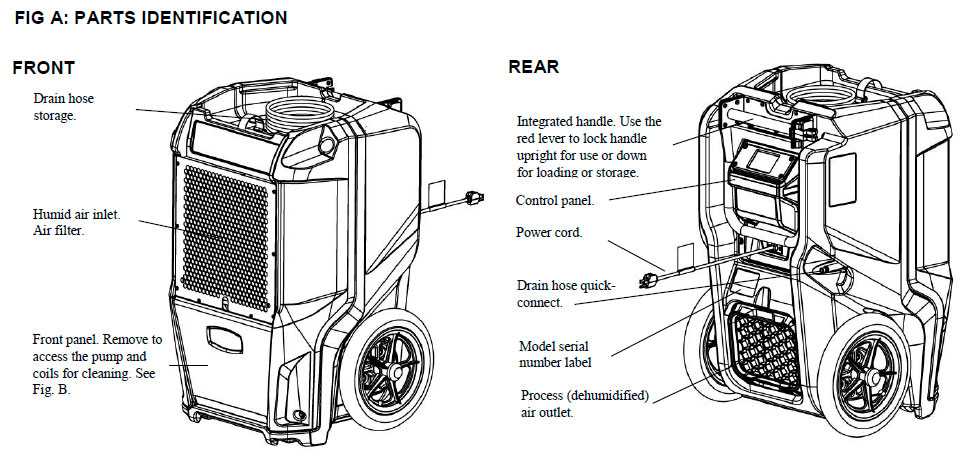

Role of the Fan Assembly

The fan assembly serves a crucial function in moisture removal systems, enhancing overall efficiency and performance. Its primary task revolves around air circulation, ensuring that the environment remains optimal for the extraction of humidity.

Key functions of the fan assembly include:

- Airflow Regulation: It facilitates the movement of air across the cooling coils, promoting effective condensation.

- Temperature Control: By circulating air, it helps maintain a balanced temperature, preventing overheating of components.

- Humidity Reduction: Continuous airflow aids in the rapid removal of moisture from the environment.

- Filtration Enhancement: The fan also assists in drawing air through filters, improving air quality by trapping dust and allergens.

In summary, the fan assembly is integral to the functioning of moisture removal systems, playing a vital role in maintaining efficiency and ensuring a comfortable atmosphere.

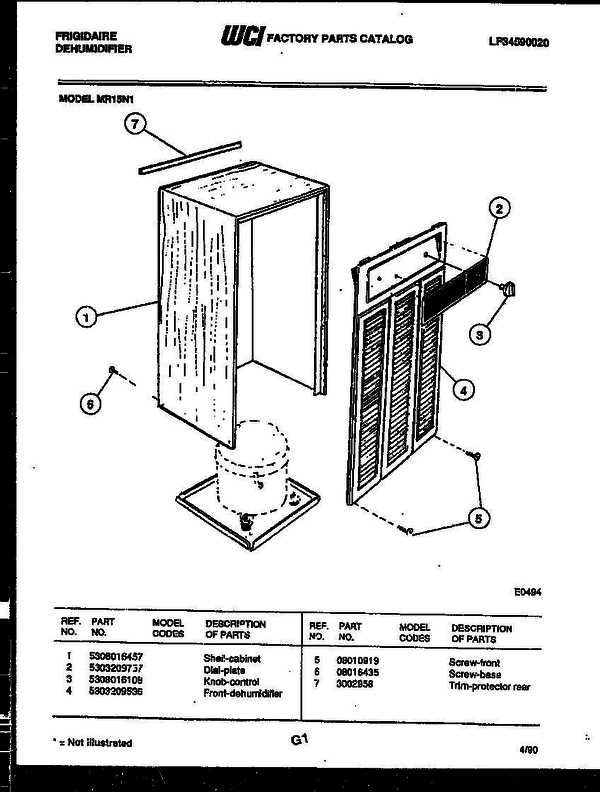

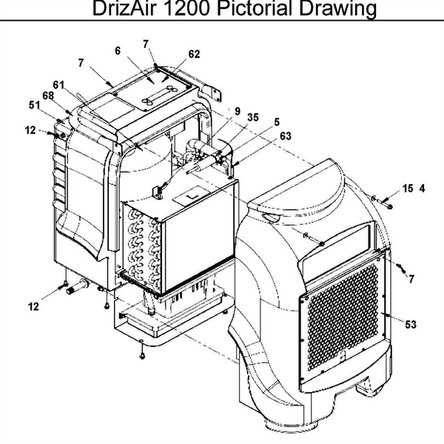

Importance of the Water Tank

The water reservoir plays a crucial role in maintaining optimal humidity levels within a space. Its primary function is to collect moisture extracted from the air, ensuring that the entire process of moisture control operates efficiently. Without this component, the effectiveness of moisture reduction would be severely compromised, leading to discomfort and potential damage to the environment.

Efficiency is significantly enhanced by the presence of this container, as it allows for the accumulation of water over time. This enables a system to work continuously without frequent interruptions for drainage. The design and capacity of the tank directly influence how well the moisture management device performs, making it an essential element in any effective moisture control system.

Moreover, the water reservoir facilitates monitoring and maintenance. Many units come equipped with indicators that alert users when the tank is full, preventing overflow and ensuring that the operation remains hassle-free. This feature not only contributes to the longevity of the system but also promotes a user-friendly experience.

In summary, the water storage unit is integral to the overall functionality and efficiency of moisture control mechanisms, directly impacting performance and user satisfaction.

How the Humidity Sensor Works

The humidity sensor plays a crucial role in regulating moisture levels within an environment. It detects the amount of water vapor present in the air, ensuring optimal conditions for comfort and preventing damage to materials.

These sensors operate using various technologies, each with its unique method of measurement. The most common types include:

- Capacitive Sensors: These measure changes in capacitance as humidity varies, allowing for precise readings.

- Resistive Sensors: These rely on changes in electrical resistance in response to humidity fluctuations.

- Thermal Conductivity Sensors: These analyze the thermal properties of the air to determine moisture content.

Each type has its advantages and specific applications, but they all aim to provide accurate humidity measurements. The sensor typically consists of:

- Sensor Element: This component detects moisture and generates a signal.

- Transmitter: Converts the sensor’s output into a readable format.

- Calibration Circuit: Ensures accuracy by adjusting the output based on known humidity levels.

Understanding the functionality of these sensors is essential for maintaining ideal humidity levels in any space.

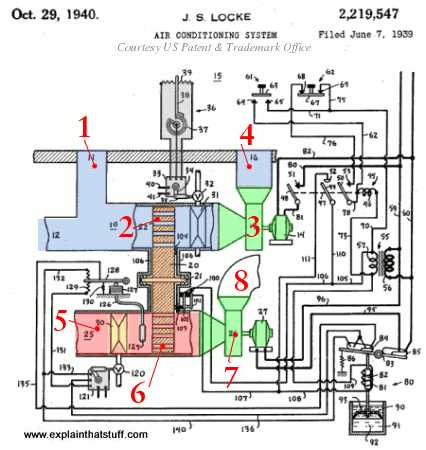

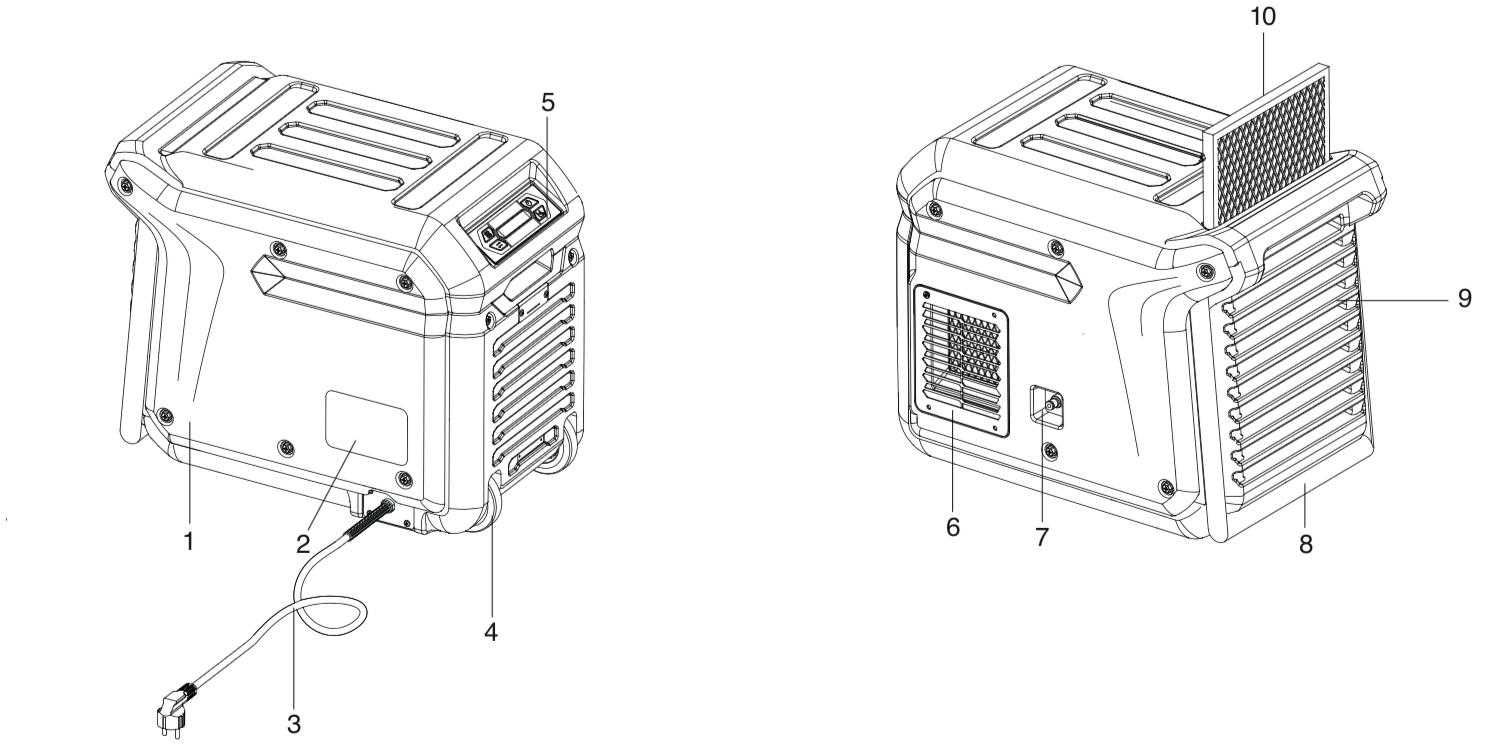

Electrical System Overview

The electrical system plays a crucial role in the functionality and efficiency of humidity control devices. It comprises various components that work in unison to ensure optimal performance, safety, and user convenience.

Key Components

- Power Supply: Provides the necessary voltage and current for operation.

- Control Circuit: Regulates the overall functioning and settings.

- Fans and Motors: Facilitate air circulation and moisture extraction.

- Sensors: Monitor humidity levels and adjust operations accordingly.

Operational Flow

- Power is supplied to the unit.

- Sensors detect environmental conditions.

- The control circuit processes this data.

- Fans and motors activate based on the settings.

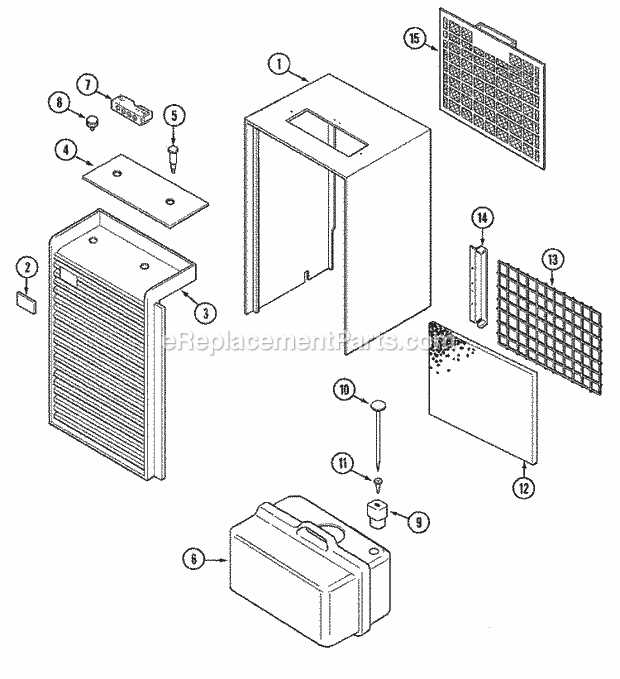

Air Filter Maintenance Tips

Proper upkeep of air filtration components is crucial for optimal performance and air quality. Regular attention ensures longevity and efficiency, reducing potential health risks associated with poor air circulation.

Regular Cleaning Schedule

Establishing a routine for cleaning filters can greatly enhance their effectiveness. Depending on usage, consider the following frequency:

| Usage Level | Cleaning Frequency |

|---|---|

| Light | Every 3 months |

| Moderate | Every month |

| Heavy | Every 2 weeks |

Replacement Considerations

In addition to cleaning, consider replacing filtration elements periodically. Signs of wear, decreased airflow, or unusual odors can indicate the need for a new filter.

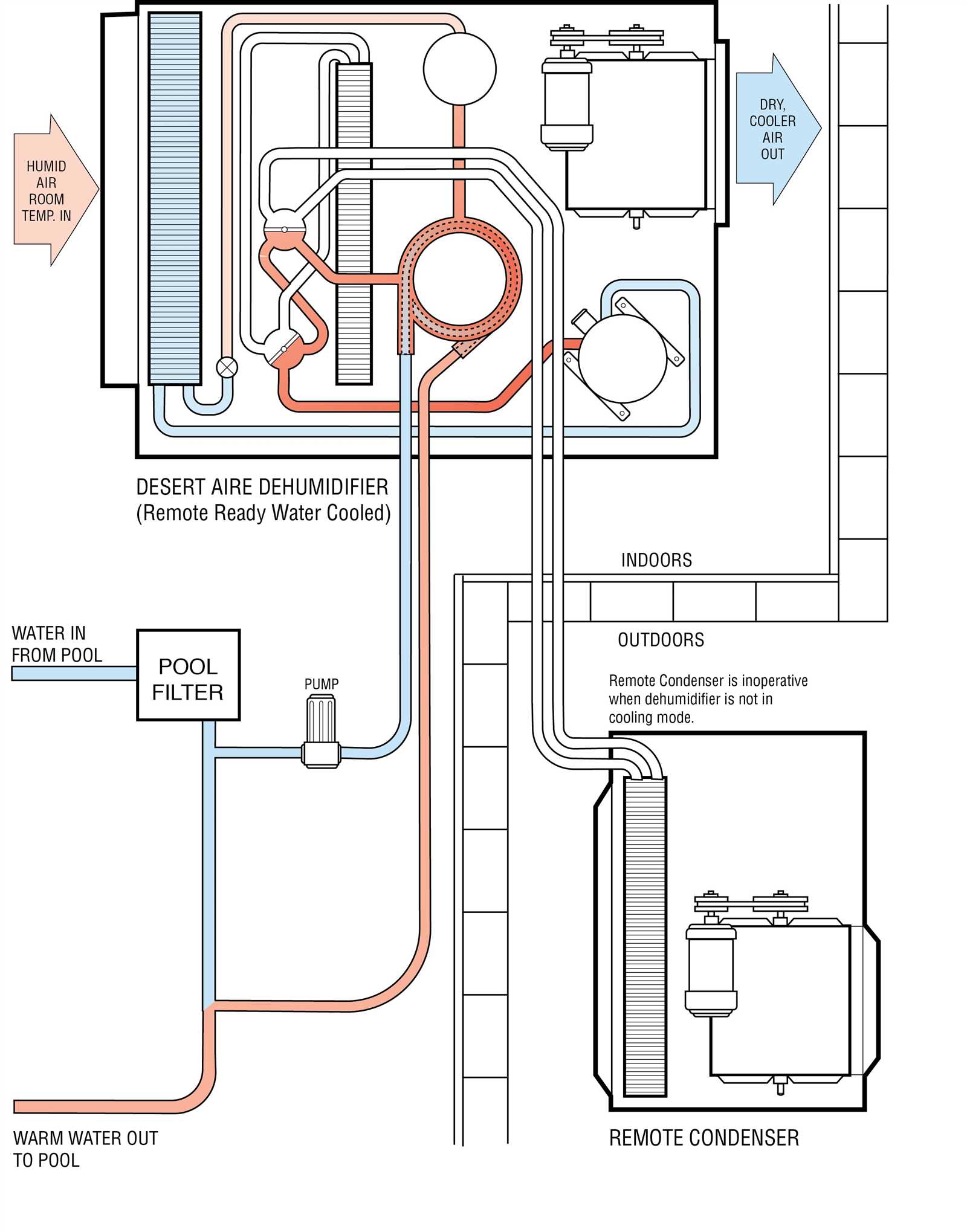

Understanding the Drainage System

The effective removal of excess moisture is crucial for maintaining optimal indoor air quality. A well-designed system ensures that water is efficiently collected and expelled, preventing issues like mold growth and structural damage.

Key Components

- Collection Tray: Captures condensation that accumulates.

- Drain Hose: Facilitates the flow of water to an external location.

- Pump: Assists in elevating water to higher drainage points.

Importance of Maintenance

- Regularly inspect hoses for clogs or leaks.

- Clean the collection tray to prevent algae growth.

- Check the pump functionality to ensure proper operation.

Impact of Coils on Efficiency

The performance of moisture removal systems heavily relies on the functionality of the metal structures within them. These components play a crucial role in heat exchange, influencing overall effectiveness and energy consumption.

- Heat Transfer: The design and material of the coils affect how efficiently heat is absorbed and released.

- Airflow: Proper coil placement ensures optimal air circulation, enhancing moisture extraction.

- Maintenance: Clean coils prevent energy loss and maintain high performance levels.

Ultimately, understanding the role of these structures can lead to improved system design and efficiency.

Heat Exchanger Explained

The heat exchanger plays a crucial role in regulating temperature and enhancing efficiency in various systems. Its primary function involves transferring thermal energy from one medium to another, facilitating processes that require heating or cooling without mixing the two fluids. This component is essential in numerous applications, ensuring optimal performance and energy conservation.

There are various types of heat exchangers, each designed for specific needs. For instance, plate and shell types offer distinct advantages in terms of space and efficiency. By maximizing surface area and optimizing flow paths, these systems enhance the transfer of heat, which is vital for maintaining desired conditions in many industrial and residential applications.

In essence, the design and functionality of a heat exchanger significantly impact the overall effectiveness of the system it serves. Understanding its mechanics allows for better maintenance and troubleshooting, ultimately leading to improved longevity and reliability.

Identifying Common Issues

Recognizing typical problems that can arise in moisture control appliances is essential for maintaining their efficiency and longevity. By understanding these challenges, users can take proactive steps to ensure optimal performance.

Frequent Challenges

- Insufficient humidity reduction

- Unusual noises during operation

- Water leakage or overflow

- Foul odors emitted

Troubleshooting Steps

- Check the settings and ensure they are correctly configured.

- Inspect for clogs or blockages in drainage systems.

- Examine the power source and connections.

- Clean filters regularly to maintain airflow.

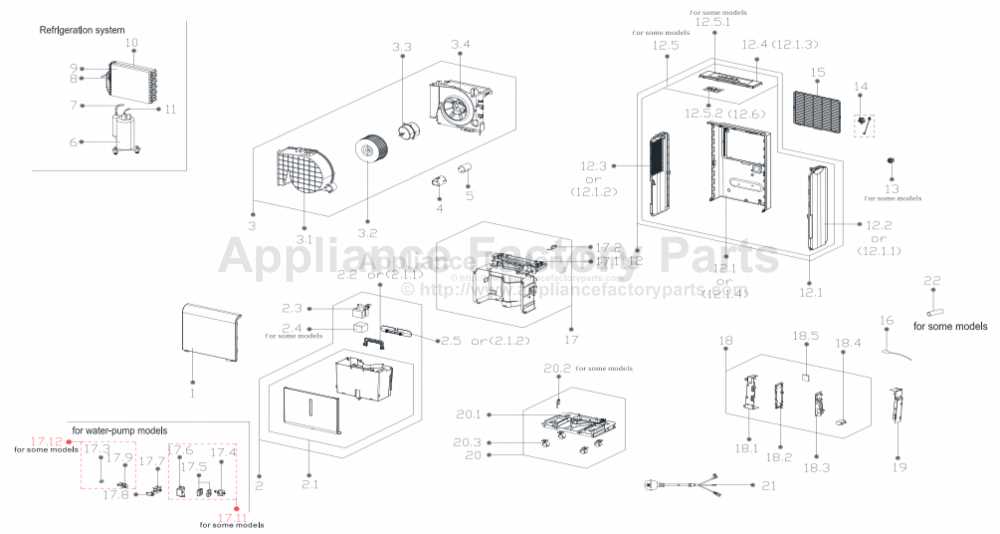

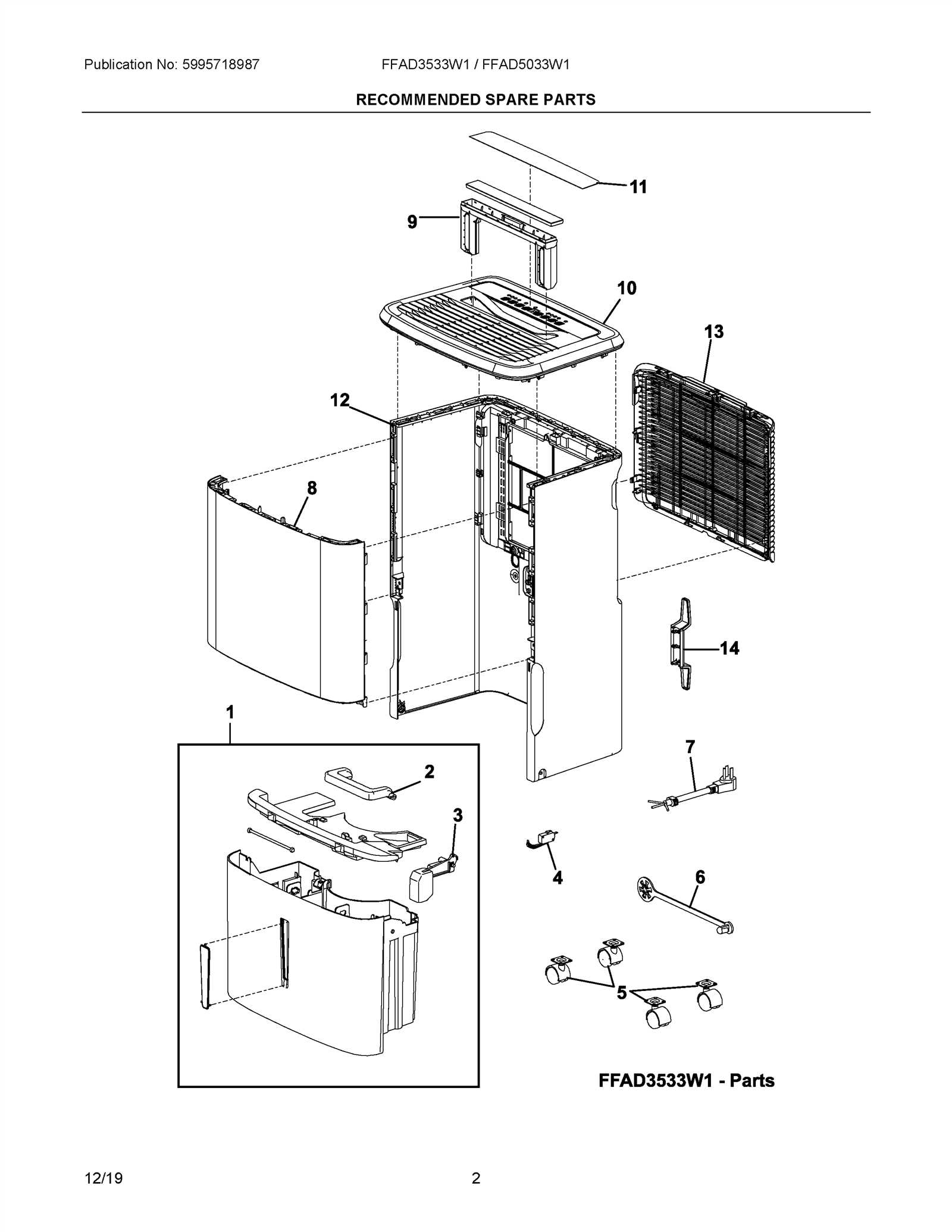

Repair and Replacement Options

Maintaining the efficiency of your moisture extraction unit is crucial for optimal performance. Over time, certain components may wear out or become less effective, necessitating repair or replacement. Understanding your options can help you extend the lifespan of the unit and enhance its functionality.

Common Issues and Solutions

- Water Leakage: Check the drainage system for clogs. Clean or replace the drainage hose as needed.

- Insufficient Moisture Removal: Inspect the filter and fan. Cleaning or replacing these elements can improve performance.

- Noisy Operation: Tighten any loose screws and check for debris in the fan area. If the noise persists, consider replacing the motor.

Replacement Components

- Filters: Regularly changing the air filter can significantly enhance air quality and efficiency.

- Drain Hoses: Replace worn or cracked hoses to ensure proper drainage.

- Fan Blades: If the blades are damaged or worn, replacing them can reduce noise and improve airflow.

Consulting the manufacturer’s guidelines for specific components and procedures will ensure that repairs are carried out correctly, promoting better longevity and efficiency of the unit.