When working with complex machinery, having a clear understanding of its individual elements is crucial. Each component plays a vital role in the overall functionality, ensuring smooth operation and efficiency. This section aims to explore the intricate relationships between these pieces and their contributions to the performance of the equipment.

In addition to enhancing your knowledge, familiarizing yourself with the various segments can empower you to troubleshoot issues effectively. By pinpointing where a malfunction might occur, you can save time and resources in maintenance and repairs. Moreover, a comprehensive grasp of these elements allows for optimal usage, leading to longer lifespan and better outcomes.

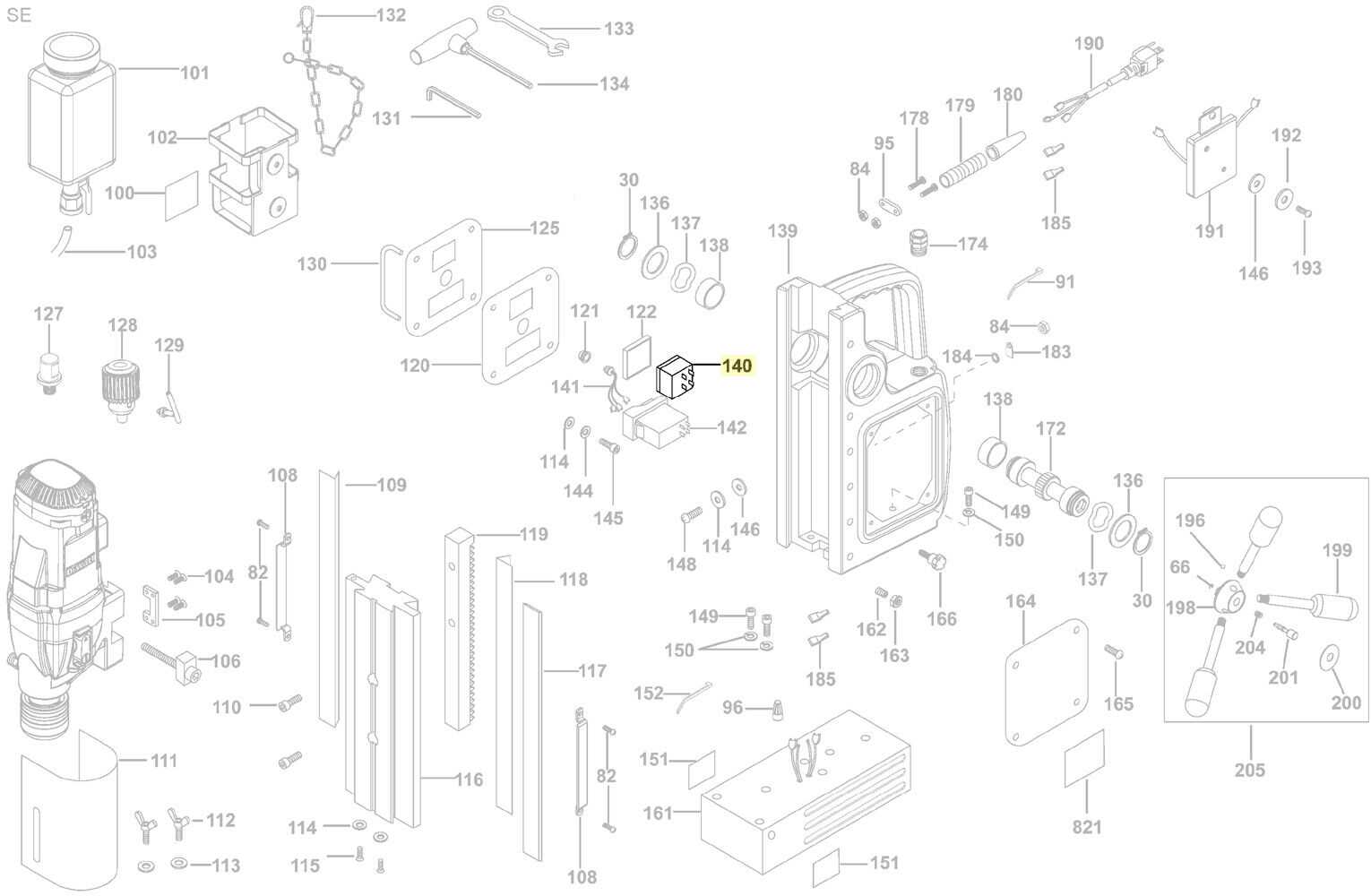

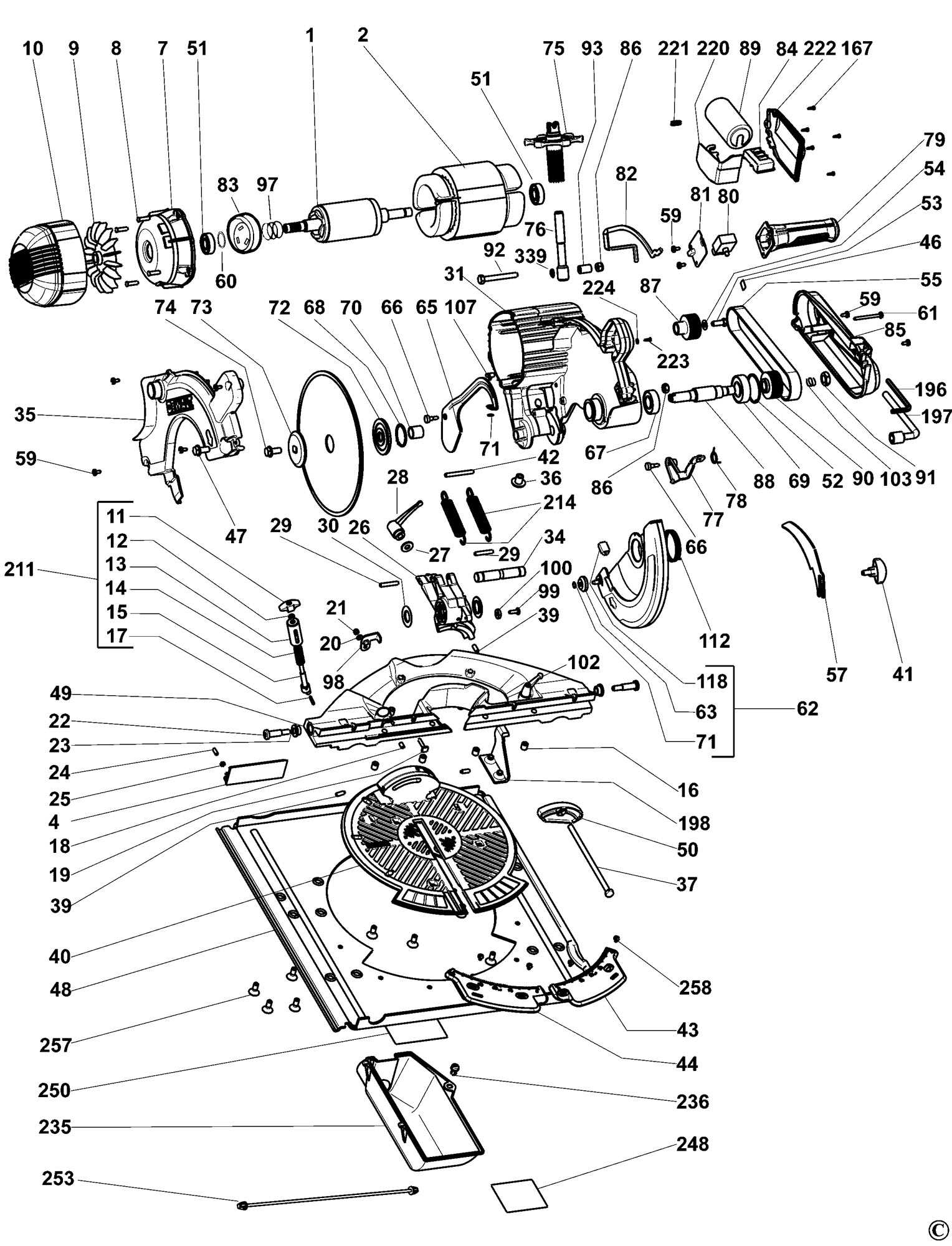

As we delve deeper into this topic, we will examine visual representations that illustrate the layout and interconnections of the components. Such diagrams serve as invaluable references, guiding users through assembly and disassembly processes while providing clarity on the arrangement of parts. Ultimately, this understanding not only aids in practical application but also enriches your overall experience with the tool.

Understanding the DW7231 Parts Diagram

Grasping the components of a complex tool is essential for effective maintenance and repair. A visual representation serves as a valuable resource, offering insight into each element’s role and interconnection within the system. This clarity aids users in troubleshooting and enhances their overall operational knowledge.

To further illustrate the key components, the following table highlights the essential elements and their corresponding functions:

| Component | Description |

|---|---|

| Base | Provides stability and support for the entire unit. |

| Fence | Guides material for precise cutting and alignment. |

| Cutter | Engages with the material to create clean cuts. |

| Motor | Powers the device, driving the cutting mechanism. |

| Control Panel | Allows users to adjust settings for optimal performance. |

Importance of Accurate Parts Diagrams

Precise representations of components play a crucial role in the effective functioning of machinery and equipment. They serve as essential guides for maintenance and assembly, ensuring that every element fits together seamlessly. Without accurate visual aids, the risk of errors increases, potentially leading to costly repairs and downtime.

Enhancing Efficiency

Clear and detailed illustrations significantly enhance operational efficiency. Technicians can quickly identify and locate necessary components, minimizing the time spent troubleshooting or reassembling. This efficiency not only saves time but also boosts overall productivity.

Reducing Errors

When users rely on well-crafted visual guides, the likelihood of mistakes decreases dramatically. Clear depictions help in understanding complex structures, making it easier to execute repairs or modifications. In turn, this accuracy promotes safer working environments, ultimately leading to improved reliability of the equipment.

Overview of DW7231 Components

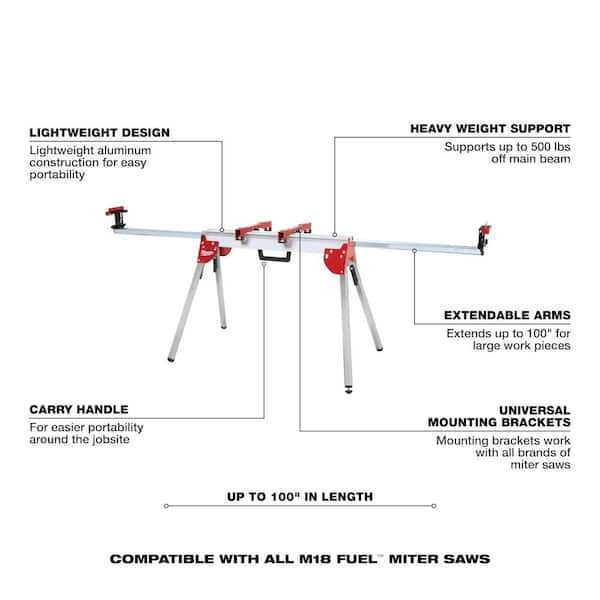

This section provides a comprehensive understanding of the various elements that comprise the tool, highlighting their functions and interactions. Each component plays a crucial role in the overall performance and efficiency of the equipment.

Main Elements

The primary parts of the tool are designed to work seamlessly together, ensuring optimal functionality. Key components include the motor, blade assembly, and support structure, each contributing to the tool’s reliability and precision.

Component Specifications

| Component | Description |

|---|---|

| Motor | Powers the tool, enabling smooth operation and high torque. |

| Blade Assembly | Responsible for cutting, offering various options for different materials. |

| Support Structure | Provides stability and durability, allowing for precise cuts. |

Common Issues with DW7231 Parts

When working with a particular model of equipment, users often encounter various challenges related to its components. Understanding these frequent problems can help in effective troubleshooting and maintenance. Issues may arise from wear and tear, improper usage, or even manufacturing defects, affecting the overall performance and safety of the machine.

One prevalent concern is the deterioration of specific elements due to extended use. Over time, some components may become less effective, leading to decreased efficiency or operational failures. Additionally, incorrect assembly or installation can result in misalignment, causing additional strain on the machinery.

Another common issue involves the accumulation of debris or dust in crucial areas, which can impede functionality. Regular cleaning and maintenance are essential to prevent such build-up. Furthermore, users may experience compatibility problems when attempting to replace components with non-original parts, which may not fit or perform as intended.

Lastly, periodic inspection is crucial. Failing to identify signs of wear early can lead to more significant issues down the line, increasing repair costs and downtime. Being proactive in recognizing and addressing these common challenges ensures longevity and reliability of the equipment.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient assembly and repair tasks. These illustrations provide a clear guide to identifying and locating individual elements within a complex system, ensuring that users can perform maintenance with confidence and accuracy.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself with Symbols:

- Each symbol represents a specific element; knowing what each one signifies is crucial.

- Look for a legend or key that explains the symbols used.

- Identify Sections:

- Break down the illustration into manageable parts to better understand the overall layout.

- Note any highlighted areas that may indicate focus points or critical components.

- Pay Attention to Numbers:

- Many visuals include reference numbers that correlate with a parts list or inventory.

- Cross-reference these numbers for clarity on specific items.

- Examine Relationships:

- Observe how different elements interact with each other within the system.

- Understand the flow of components to ensure correct assembly or troubleshooting.

By following these steps, you can navigate through complex visuals with ease, enabling you to efficiently locate, identify, and understand the elements necessary for your project.

Identifying Key Components Effectively

Understanding the essential elements of a mechanical system is crucial for successful maintenance and operation. Recognizing these parts not only enhances functionality but also aids in troubleshooting and repairs. A clear approach to identifying these components can significantly improve efficiency and reduce downtime.

Utilizing Visual Aids

One of the most effective methods to discern various elements is through visual references. Diagrams and illustrations can provide a comprehensive overview, allowing individuals to grasp the arrangement and interrelation of components. Visual aids simplify complex structures, making it easier to pinpoint specific areas of interest or concern.

Creating a Systematic Checklist

Another practical strategy is developing a detailed checklist that outlines each critical component. This method ensures that no part is overlooked during inspections or repairs. By systematically reviewing each item, one can quickly identify any discrepancies or potential issues. Consistency in this process fosters a deeper understanding and enhances overall proficiency in managing the system.

Where to Find Genuine Parts

When seeking authentic components for your equipment, it’s essential to know the right places to look. Genuine items ensure reliability and optimal performance, which is crucial for maintaining the integrity of your tools. This guide highlights the best sources to acquire original elements, providing peace of mind with every purchase.

Authorized Dealers

Visiting authorized retailers is one of the most reliable options. These dealers often have direct connections with manufacturers, ensuring you receive certified items. Additionally, they typically offer expert advice and support, enhancing your buying experience.

Manufacturer’s Website

Another effective way to secure original components is by visiting the manufacturer’s official website. Many brands provide a dedicated section for purchasing genuine parts directly. Here, you can explore the full range of available options and confirm authenticity.

Maintenance Tips for DW7231

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By adhering to a systematic maintenance routine, you can prevent unexpected breakdowns and enhance the efficiency of your tool. Below are some practical suggestions to keep your device in top condition.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean the exterior | After each use | Use a damp cloth to remove dust and debris. |

| Check for wear | Monthly | Inspect for signs of damage or excessive wear on critical components. |

| Lubricate moving parts | Every 3 months | Apply appropriate lubricant to ensure smooth operation. |

| Inspect electrical connections | Quarterly | Ensure connections are secure and free from corrosion. |

| Replace filters | Annually | Check and replace air or dust filters as needed. |

By implementing these simple yet effective maintenance practices, you can extend the life of your tool and ensure reliable performance during every use.

Comparing DW7231 with Other Models

This section aims to explore the differences and similarities among various tools in the same category. By examining features, performance, and user feedback, we can identify what sets one model apart from others in its class.

Key Features Overview

| Model | Weight | Power | Special Features |

|---|---|---|---|

| Model A | 35 lbs | 1500 W | Compact design, quick setup |

| Model B | 40 lbs | 1600 W | Advanced safety features |

| Model C | 38 lbs | 1550 W | Integrated storage solutions |

User Experience and Performance

User reviews indicate varying levels of satisfaction with different models. While some prioritize portability, others focus on power efficiency. Understanding these preferences helps in determining the ultimate choice for different tasks.

Upgrading Parts for Better Performance

Enhancing the functionality of your equipment can significantly boost efficiency and reliability. By selecting superior components, you can transform performance, ensuring that your machinery operates at its peak. Understanding which elements to improve is essential for achieving optimal results.

Key Components to Consider

- Motors: Upgrading to high-efficiency models can reduce energy consumption.

- Blades: Sharp, durable blades enhance cutting precision and reduce wear.

- Bearings: High-quality bearings minimize friction, extending the lifespan of your equipment.

Benefits of Upgrading

- Improved Speed: Enhanced components can lead to faster operation times.

- Increased Durability: Superior materials often offer better resistance to wear and tear.

- Cost Efficiency: Investing in quality components can reduce maintenance costs over time.

Common Repairs for DW7231 Users

For users of this equipment, understanding typical issues and their solutions can enhance performance and longevity. Common malfunctions may arise from wear and tear, improper use, or lack of maintenance. Familiarity with frequent repairs can help prevent downtime and ensure smooth operation.

Frequent Issues and Solutions

| Issue | Solution |

|---|---|

| Worn Bearings | Replace with high-quality bearings to ensure smooth movement. |

| Loose Components | Tighten screws and bolts regularly to maintain stability. |

| Motor Overheating | Check for dust accumulation and ensure proper ventilation. |

| Electrical Malfunctions | Inspect wiring and connections for damage, and replace as needed. |

Preventive Maintenance Tips

Regular maintenance checks can significantly reduce the frequency of these repairs. Cleaning, lubrication, and timely replacements of wear parts will contribute to optimal functionality and durability of the equipment.

Expert Recommendations for Parts Replacement

When it comes to maintaining and enhancing the performance of your equipment, timely and informed replacements are crucial. Experts emphasize the importance of recognizing wear and tear and addressing issues proactively to avoid more significant problems down the line. Understanding which components require attention and when to replace them can greatly improve functionality and extend the lifespan of your machinery.

Regular Inspections: Conduct routine assessments to identify any signs of damage or deterioration. Keeping an eye on critical elements will allow you to catch potential issues early, ensuring efficient operation.

Quality Over Cost: Invest in high-quality replacements rather than opting for the cheapest options. Quality components often offer better performance and durability, ultimately saving you money in the long run by reducing the frequency of replacements.

Consult Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for replacement intervals and specifications. Adhering to these guidelines ensures that you maintain optimal performance and safety standards.

Seek Professional Advice: When in doubt, consult with a professional technician. Their expertise can provide valuable insights into which components may need replacement and the best practices for doing so.

Staying informed and proactive about replacements will not only enhance the efficiency of your machinery but also contribute to a safer and more productive working environment.

Resources for DW7231 Owners

For those who own this particular model, accessing the right information and materials is crucial for maintenance and repairs. Whether you are looking for troubleshooting tips, user manuals, or replacement components, a wealth of resources is available to ensure optimal performance and longevity.

Online Communities: Joining forums and discussion groups can provide valuable insights from other users. These platforms often share experiences, tips, and solutions to common issues, helping you connect with fellow enthusiasts.

Manufacturer’s Website: The official site is a reliable source for product documentation. You can find detailed guides, safety information, and contact details for customer support, which can be essential for addressing any concerns you might have.

Retailers and Distributors: Many retailers offer comprehensive catalogs that include accessories and components specific to your equipment. This makes it easier to find exactly what you need for repairs or upgrades.

Instructional Videos: Platforms like YouTube feature a variety of tutorials that cover maintenance procedures, installation tips, and repair guides. These visual resources can simplify complex tasks and enhance your understanding of your equipment.

Local Repair Shops: If you’re facing significant issues, consulting with a professional can save you time and ensure that repairs are conducted correctly. Local experts can provide personalized advice tailored to your model.