When it comes to maintaining a high-performing cordless vacuum cleaner, it’s essential to have a clear understanding of its internal structure. Knowing the various elements that make up the cleaning head allows you to ensure optimal performance and longevity. This knowledge helps with repairs, replacements, and even simple troubleshooting, ensuring that your cleaning device remains in top condition.

Breakdown of Key Elements within the vacuum system provides insights into how each component interacts with others, creating a seamless and efficient cleaning experience. Whether you’re focused on the motor, filter, or attachment mechanisms, understanding their roles will improve your ability to maintain and repair the vacuum cleaner over time.

For those who rely on their cordless cleaner for everyday use, grasping the construction of essential parts is crucial. Regular upkeep and part replacement not only extend the life of the machine but also ensure that it continues to deliver exceptional cleaning results.

Dyson V10 Motorhead Overview

The cleaning unit is known for its advanced functionality and efficient performance, making it a popular choice for household tasks. Its lightweight design and powerful suction ensure thorough cleaning across different surfaces. Equipped with cutting-edge technology, this model provides a smooth experience, reducing the time and effort needed to maintain cleanliness.

Key Features of the Cleaning Unit

One of the standout aspects of this model is its versatility. The multi-surface capabilities allow it to adapt to both carpets and hard floors with ease. It also comes with a compact and user-friendly build, ensuring that it can easily reach tight spaces. Furthermore, the high-efficiency filtration system traps dust and allergens, making it an excellent option for allergy sufferers.

Performance and Usability

This cleaning tool delivers a combination of power and ease of use, allowing users to switch between cleaning modes depending on the surface and dirt level. Its ergonomic design offers comfortable handling, while the long-lasting battery ensures uninterrupted use for extended cleaning sessions. Moreover, the accessory options enhance its ability to tackle various tasks effectively.

Key Components Inside the Motorhead

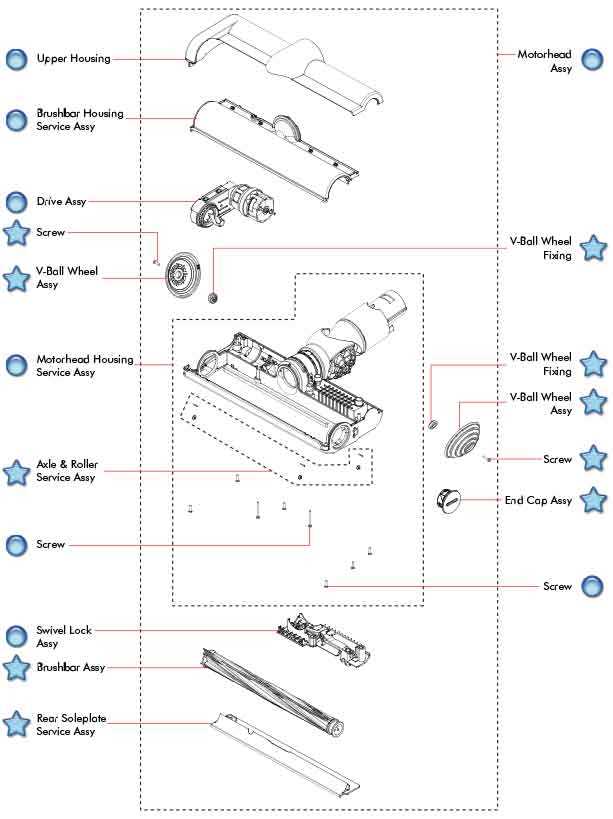

The internal structure of the cleaning attachment consists of several vital elements that work together to ensure optimal performance. Each of these components plays a crucial role in efficiently removing dirt and debris from a variety of surfaces. Understanding the core mechanisms within this system helps in identifying potential issues or improving overall maintenance routines.

At the heart of the unit is the high-speed rotating brush, designed to agitate fibers and loosen embedded particles. This rotating element is powered by a compact, energy-efficient motor, which drives the cleaning process with consistent force. Surrounding this are the support components that help guide airflow, ensuring that suction power is effectively distributed across the surface.

Additional features, such as small bearings and gears, ensure smooth movement and reduced friction. These help extend the lifespan of the brush and maintain steady performance over time. A series of flexible joints and attachments allow for effortless maneuverability, adapting to various angles and surface textures, while the motorized components seamlessly integrate to offer high cleaning efficiency.

Understanding the Dyson V10 Brush System

The brush mechanism in modern cleaning appliances plays a critical role in ensuring optimal performance. Its primary function revolves around efficiently lifting dirt, dust, and debris from a variety of surfaces. This system is specifically designed to adapt to different flooring types, making it highly versatile for both carpets and hard floors.

How the Brush Works

At the core of the system is a rotating brush that agitates the surface, loosening dirt particles so they can be easily sucked into the vacuum. The bristles are engineered to handle everything from fine dust to larger debris, while maintaining gentle contact with delicate surfaces. This design enables deep cleaning without causing damage.

Maintenance and Care

To ensure continued efficiency, regular maintenance of the brush is necessary. This includes removing tangled hair, fibers, and any obstructive materials that can affect the rotation. Routine checks not only extend the lifespan of the unit but also maintain peak cleaning performance. A well-maintained brush guarantees that the cleaning process remains smooth and effective.

How to Identify the Power Switch

Recognizing the location of the power switch is essential for efficient operation of your vacuum cleaner. It allows users to easily control the device, ensuring smooth transitions between cleaning tasks. Locating this switch can sometimes be confusing due to the compact design and placement of various controls on modern cleaners.

Key Features to Look For

The power switch typically has a distinct size and shape, making it easy to differentiate from other buttons. It is often located near the handle or on the main body, designed for easy access during use. Look for a prominent button or lever that controls the main power functions, often featuring a simple on/off mechanism.

Additional Indicators

In many cases, the power switch may be labeled or color-coded for clarity. Check for symbols or markings that indicate its function. Additionally, it may have a textured surface to help identify it by touch, providing a more intuitive user experience.

Dyson V10 Motorhead Housing Structure

The outer shell of this vacuum cleaner’s cleaning head plays a crucial role in protecting internal mechanisms and ensuring durability. Designed for both efficiency and resilience, it encases essential components that drive the cleaning process while offering robust protection from daily wear and tear.

The structural integrity of the housing is crucial for the following reasons:

- Protection of internal components: The outer layer acts as a shield against dust, dirt, and physical impacts, preventing potential damage.

- Streamlined airflow: The design ensures that air moves smoothly through the unit, improving suction power and cleaning efficiency.

- Durability: The casing is built from high-quality materials that can withstand frequent use, drops, and abrasions, contributing to the long lifespan of the device.

- Easy assembly and maintenance: The shell is designed for quick disassembly, making it easy to access the internal parts for cleaning or repairs.

Every element of the outer frame is thoughtfully engineered to balance performance and user convenience. It allows users to maintain peak functionality of the device while protecting its most sensitive components.

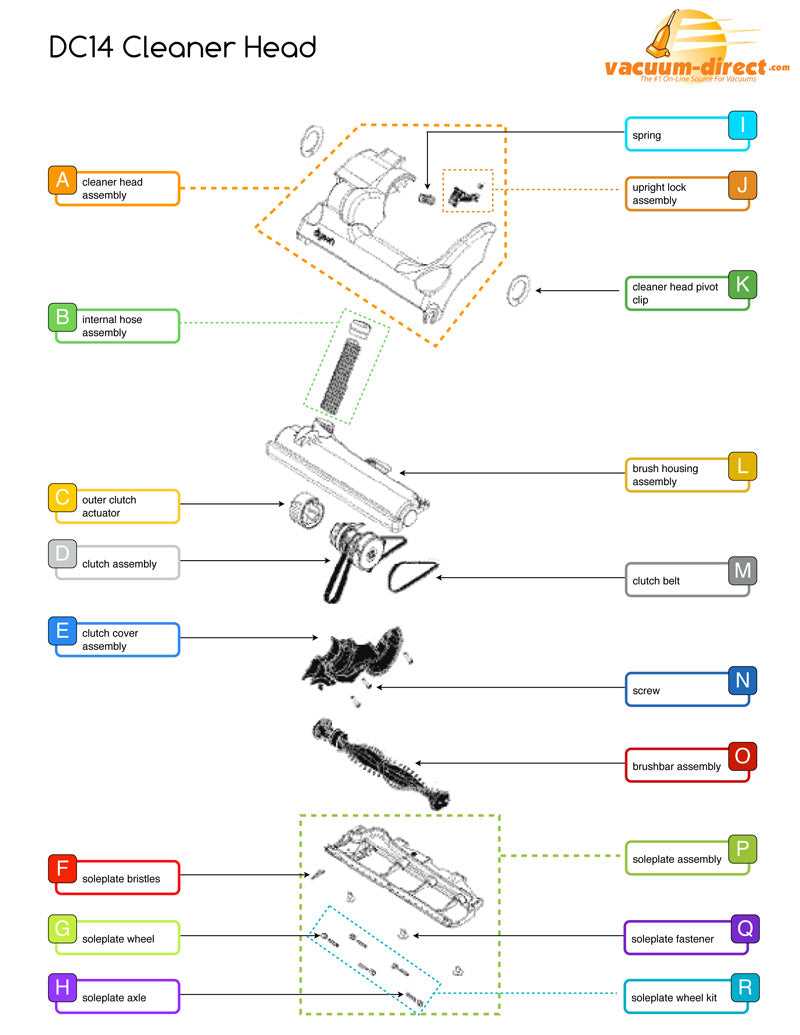

Roller and Belt Configuration Explained

The functionality of a vacuum cleaner heavily relies on the interaction between its roller brush and the drive belt. Understanding how these components work together is essential for optimal performance and maintenance. The roller, typically covered in bristles, is designed to agitate the carpet fibers, allowing for effective dirt and debris removal. Meanwhile, the belt transfers power from the motor to the roller, ensuring it spins at the required speed. Proper alignment and tension between these elements are crucial for efficient operation.

In this section, we will delve into the specifics of the roller and belt configuration, highlighting their roles, common issues, and maintenance tips to ensure long-lasting performance.

| Component | Description | Common Issues |

|---|---|---|

| Roller Brush | The rotating brush that collects dirt from surfaces. | Worn bristles, tangles from hair or debris. |

| Drive Belt | Transfers motor power to the roller brush. | Slippage, breakage, or improper tension. |

| Brush Housing | Encases the roller brush for protection and support. | Cracks or damage affecting roller performance. |

Regular inspection and maintenance of the roller and belt configuration can prevent many common issues. It is advisable to check the condition of the belt and roller brush periodically, replacing them as needed to maintain optimal cleaning efficiency.

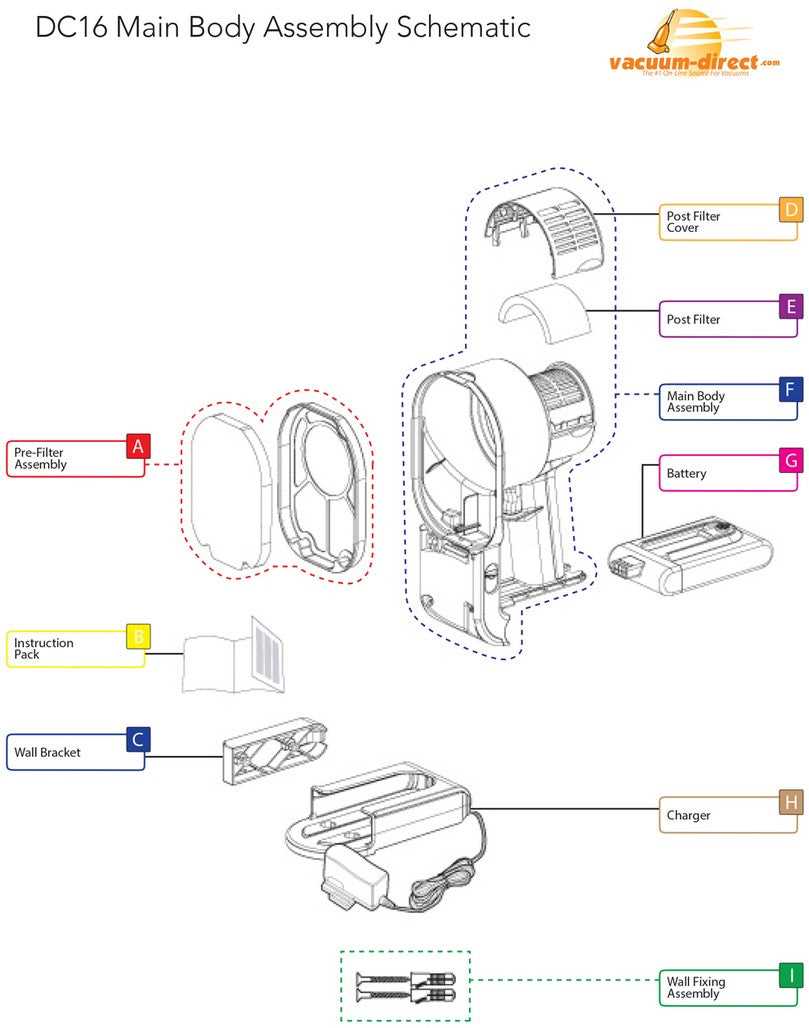

Internal Filters and Maintenance Tips

Proper maintenance of internal filtration systems is crucial for ensuring optimal performance and longevity of your cleaning device. Regularly checking and cleaning these components can prevent clogs and enhance airflow, leading to more efficient operation. This section will provide valuable insights into the internal filters and offer maintenance tips to keep your appliance functioning at its best.

The filtration system generally consists of multiple components designed to capture dust, allergens, and other particles from the air. Here’s a breakdown of the essential filters and their maintenance requirements:

| Filter Type | Location | Maintenance Frequency | Cleaning Method |

|---|---|---|---|

| Pre-Motor Filter | Near the motor assembly | Every 1-3 months | Rinse under cold water, let dry for 24 hours |

| Post-Motor Filter | At the exhaust port | Every 6-12 months | Check for wear; replace if necessary |

| HEPA Filter | Integrated into the exhaust system | Every 12 months | Replace as needed; do not wash |

In addition to regular maintenance of the filters, it is essential to ensure that the entire appliance is kept clean. Empty the dust container frequently, and wipe down the exterior surfaces to prevent dirt buildup. By following these simple tips, you can maintain the efficiency and effectiveness of your cleaning tool for years to come.

Dyson V10 Motor Assembly Breakdown

This section delves into the intricate components of a vacuum cleaner’s propulsion system, offering insights into its construction and functionality. Understanding each element’s role can enhance maintenance and troubleshooting efforts, ensuring optimal performance and longevity.

Key Components

The primary elements that make up the propulsion system include the motor, the fan assembly, and various housing structures. The motor serves as the heart of the device, converting electrical energy into mechanical energy, which drives the fan. The fan assembly, consisting of blades and a casing, efficiently moves air through the unit, creating suction to lift debris and dirt. Each of these parts works in harmony to deliver powerful cleaning performance.

Assembly Insights

Assembling these components requires precision and care. The housing must be securely fastened to prevent vibrations during operation, while ensuring proper alignment of the motor and fan. Regular maintenance checks can help identify wear or damage in any of these parts, allowing users to address issues before they impact functionality. Familiarity with this assembly can significantly aid in performing repairs or upgrades.

Commonly Replaced Motorhead Parts

In any high-performance cleaning device, certain components tend to wear out or become less effective over time. Recognizing and addressing these frequently replaced elements can significantly enhance the appliance’s efficiency and prolong its lifespan. Understanding which parts are most commonly replaced allows users to maintain optimal functionality and achieve better cleaning results.

Brush Bar: The brush bar is crucial for effective debris removal from various surfaces. Over time, bristles can become worn or tangled with hair, reducing their effectiveness. Regular inspection and timely replacement can restore the device’s cleaning power.

Filter: A clean filter is essential for maintaining strong suction and preventing allergens from circulating in the air. Filters can become clogged with dust and dirt, impacting performance. Replacing the filter regularly ensures that the unit operates at peak efficiency.

Battery: As rechargeable batteries age, their ability to hold a charge diminishes. Users may notice reduced runtime, indicating that a new battery may be needed. Investing in a high-quality replacement can enhance the overall performance of the appliance.

Hose: The flexible hose can become damaged or clogged, affecting airflow. Regularly checking for obstructions and replacing a worn hose can significantly improve suction and maneuverability.

Wheel Assembly: The wheels enable smooth movement across different floor types. Worn or damaged wheels can hinder mobility, making it challenging to navigate around furniture. Replacing them can restore the ease of movement.

Wiring and Electrical Connections Guide

This section provides a comprehensive overview of the electrical system and wiring layout essential for the optimal performance of your cleaning device. Understanding the connections and components involved is crucial for troubleshooting issues and ensuring efficient operation.

Electrical Components Overview

Each cleaning appliance contains various electrical parts, including motors, switches, and batteries, which work together to provide power and functionality. Identifying these components and their connections is vital for maintenance and repair.

Wiring Connections

Proper wiring is essential for the safe operation of your device. Each connection must be secure and correctly aligned to prevent electrical faults. Regularly check for any signs of wear or damage in the wiring, and replace any compromised sections promptly.

Troubleshooting Electrical Issues

If you experience any performance issues, begin by inspecting the electrical connections. Look for loose wires, burnt connectors, or signs of corrosion. Addressing these issues can often restore functionality without the need for extensive repairs.

Safety Precautions

Always ensure the device is unplugged before performing any electrical maintenance. Use insulated tools to prevent electrical shock, and follow all safety guidelines to avoid potential hazards during the inspection or repair process.

Cleaning the Motorhead for Optimal Performance

Maintaining the cleanliness of your vacuum’s cleaning head is crucial for ensuring its efficiency and longevity. Regularly removing dust, hair, and debris not only enhances suction power but also prevents potential malfunctions. This guide will outline effective cleaning techniques to keep your appliance functioning at its best.

Here are the steps to effectively clean the cleaning head:

- Gather Necessary Tools:

- Soft brush

- Microfiber cloth

- Warm soapy water

- Screwdriver (if needed)

- Detach the Cleaning Head:

Start by removing the cleaning attachment from the main body of the appliance. This step allows for a thorough cleaning without hindrance.

- Remove Hair and Debris:

Using the soft brush, gently scrub the bristles to dislodge hair and dust particles. Ensure you get into the crevices where dirt tends to accumulate.

- Wash the Bristle Brush:

If applicable, clean the brush bar with warm soapy water. Rinse thoroughly and allow it to dry completely before reattaching.

- Wipe Down the Surface:

Using a microfiber cloth, wipe the exterior of the cleaning head to remove any remaining dust. This step helps maintain a polished appearance.

- Reassemble:

Once all components are clean and dry, carefully reattach the cleaning head to the main unit, ensuring everything is securely fastened.

By following these steps regularly, you can ensure that your cleaning equipment operates at peak efficiency, providing you with optimal performance and maintaining the cleanliness of your home.

Replacing Damaged Parts in the Dyson V10

Maintaining the efficiency of your cleaning device often requires the replacement of worn or damaged components. Timely action can restore functionality and extend the life of your appliance. Understanding how to identify and replace these elements is essential for optimal performance.

Identifying Worn Components: Regular inspection is crucial to detect issues before they escalate. Look for signs of wear, such as reduced suction power, strange noises, or visible damage. These indicators can help pinpoint which elements need attention.

Gathering Necessary Tools: Before starting the replacement process, ensure you have the right tools on hand. Commonly required items include screwdrivers, pliers, and a soft cloth for cleaning. Having everything ready will streamline the procedure.

Step-by-Step Replacement: Begin by carefully disassembling the affected area. Follow the user manual or reliable online resources for guidance. Replace the damaged part with a compatible replacement, ensuring a secure fit. Reassemble the unit, making sure all components are correctly positioned.

Testing the Device: After the replacement, it is vital to test the appliance to ensure it operates correctly. Check for any unusual sounds or functionality issues. If everything is in order, your unit should be back to its optimal state.

Regular Maintenance: To prevent future issues, establish a routine maintenance schedule. Cleaning filters, checking for blockages, and inspecting parts can help maintain efficiency and prolong the lifespan of your device.

Where to Find Genuine Dyson Parts

When it comes to maintaining your cleaning device, sourcing authentic components is crucial for ensuring optimal performance and longevity. The market is flooded with options, but understanding where to find reliable and original elements can make a significant difference in your appliance’s efficiency.

One of the best places to look for authentic replacements is the official website of the manufacturer. They often have a dedicated section for accessories and components, ensuring that what you purchase meets the required standards for quality and compatibility. Additionally, certified retailers and authorized service centers provide peace of mind as they sell genuine items that come with warranties.

Online marketplaces can also be a resource, but caution is advised. Always verify the seller’s reputation and read reviews before making a purchase. Look for sellers that guarantee authenticity and offer easy returns in case the item does not meet your expectations. Forums and communities dedicated to cleaning devices can be valuable sources of information, often sharing recommendations for reputable vendors.

In summary, whether you choose to shop online or in-store, prioritize purchasing from trusted sources to ensure that your device remains in excellent working condition. This approach will help you avoid potential pitfalls associated with counterfeit or subpar components.