When it comes to thermal printing technology, having a clear understanding of the internal workings and essential components is crucial for effective maintenance and troubleshooting. This section provides an insightful overview of the various elements that constitute a thermal printing device, emphasizing the significance of each part in ensuring optimal functionality.

By familiarizing yourself with the intricate layout and roles of these components, you can enhance your ability to diagnose issues and carry out necessary repairs. From the printing mechanism to the electronic circuits, each segment plays a vital role in delivering high-quality prints and efficient operation.

As you delve into this topic, you’ll discover how the interplay between different components affects performance and reliability. Grasping this knowledge not only empowers you to maintain your device more effectively but also equips you with the insights needed to make informed decisions when it comes to replacements or upgrades.

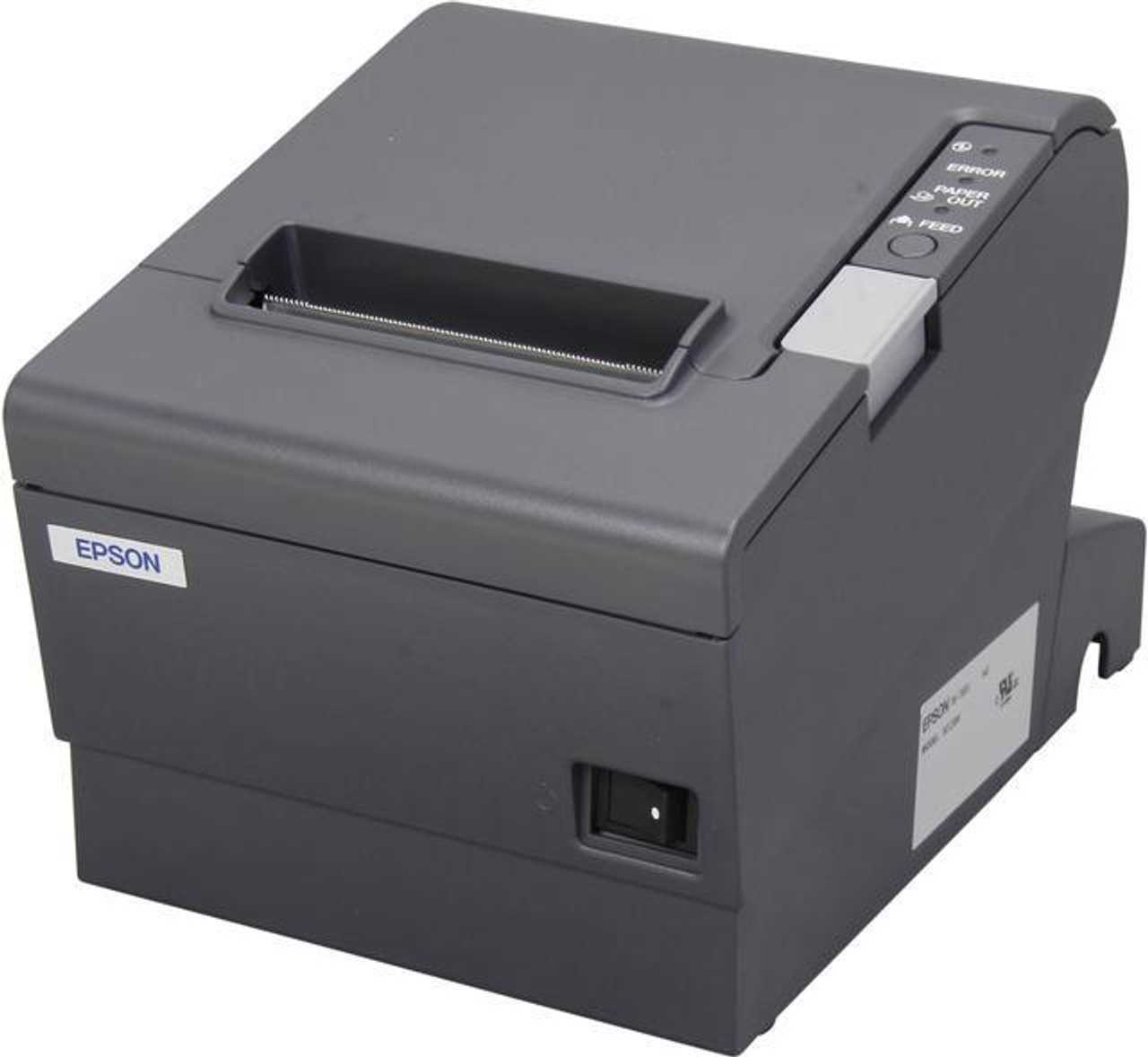

Understanding the Epson TM-T88V Printer

This section provides a comprehensive overview of a popular model of thermal printing devices widely utilized in various commercial settings. Recognized for their reliability and speed, these machines are essential tools for businesses that require efficient receipt printing solutions.

Key features of this thermal printer include:

- Compact design suitable for limited counter space

- High-speed printing capabilities to enhance customer service

- Durable construction that withstands heavy usage

- Multiple connectivity options for seamless integration

- User-friendly operation, simplifying maintenance and troubleshooting

The mechanism behind this type of printer relies on thermal technology, which utilizes heat to produce clear, high-quality printouts on special paper. Understanding its components can assist in troubleshooting and optimizing performance.

- Print Head: The core element responsible for producing the printed output.

- Paper Mechanism: Controls the feeding and cutting of the printing material.

- Interface Ports: Allow connection to various devices such as POS systems or computers.

- Power Supply: Ensures consistent energy delivery for uninterrupted operation.

Familiarity with these elements is vital for effective maintenance and can help extend the device’s lifespan while ensuring optimal functionality.

Key Features of TM-T88V Model

This model is renowned for its exceptional performance and reliability in the world of receipt printing. With cutting-edge technology and user-friendly design, it meets the diverse needs of various business environments, making it a preferred choice for retail and hospitality sectors.

High-Speed Printing

One of the standout characteristics of this device is its ability to produce receipts rapidly, enhancing customer service by minimizing wait times. Capable of printing at speeds up to 350 mm per second, it ensures efficiency even during peak hours.

Versatile Connectivity Options

Offering a wide range of connectivity solutions, this model accommodates various business systems. With options like USB, Ethernet, and Bluetooth, users can easily integrate the printer into existing setups, facilitating smooth communication and operation.

Durability is another crucial aspect, with a robust design that withstands the rigors of daily use. Additionally, the energy-efficient features contribute to lower operational costs, aligning with the sustainable practices of modern businesses.

Overall, this receipt printer combines speed, versatility, and durability, making it an ideal solution for businesses looking to enhance their transactional processes.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of devices. These illustrations provide technicians with a clear view of the internal structure and assembly of equipment, facilitating a more efficient troubleshooting process. By accurately depicting how various elements interact, they simplify complex mechanical systems.

Such representations enhance understanding by allowing users to identify specific elements quickly, reducing the time spent searching for parts. Furthermore, they aid in training new personnel, ensuring that everyone involved in repairs has a consistent reference point. With clear visuals, communication among team members becomes more effective, as they can discuss specific components without confusion.

Additionally, detailed visual guides can prevent errors during disassembly and reassembly. Misplaced components can lead to malfunction, and having a precise guide minimizes the risk of mistakes. Ultimately, these resources not only improve repair efficiency but also extend the lifespan of the equipment by promoting proper handling and maintenance practices.

Common Issues with TM-T88V Parts

Understanding the typical challenges associated with various components of thermal printers can significantly enhance troubleshooting and maintenance efforts. This section aims to highlight prevalent problems that users might encounter, along with potential solutions to ensure optimal functionality.

- Paper Jams:

- Improper loading of the printing medium.

- Dust or debris obstructing the feed mechanism.

- Worn-out rollers failing to grip the paper effectively.

- Print Quality Issues:

- Faded or inconsistent prints due to low ink levels or defective ribbon.

- Head alignment problems affecting print clarity.

- Temperature variations causing issues with thermal responsiveness.

- Connectivity Problems:

- Loose or damaged cables disrupting communication.

- Configuration errors in the device settings.

- Compatibility issues with different operating systems.

- Overheating:

- Insufficient ventilation around the unit.

- Prolonged usage leading to excessive heat build-up.

- Faulty internal components affecting temperature regulation.

Addressing these issues promptly can prevent further complications and extend the lifespan of the device. Regular maintenance and proper usage play critical roles in mitigating these common challenges.

How to Use the Parts Diagram

Understanding the layout of components in a device is essential for effective maintenance and repair. This visual representation provides a clear overview, allowing users to identify individual elements and their functions. Mastering this illustration can significantly enhance troubleshooting skills and simplify the replacement of faulty pieces.

Begin by familiarizing yourself with the illustration, noting the different sections and the labels associated with each part. This foundational knowledge will help you navigate the details more efficiently. As you study the layout, pay close attention to any accompanying notes or references that might indicate specific functions or common issues related to particular components.

Next, use the visual guide during your repair process. When a malfunction occurs, cross-reference the problematic area with the corresponding section in the visual representation. This will enable you to quickly locate the defective part and understand its relationship to other elements, ensuring a comprehensive approach to the repair.

Finally, consider keeping a record of any issues and the parts involved. This documentation will prove invaluable for future maintenance and can assist others who may encounter similar challenges. By leveraging this visual tool, users can enhance their understanding, improve efficiency, and ensure the longevity of their devices.

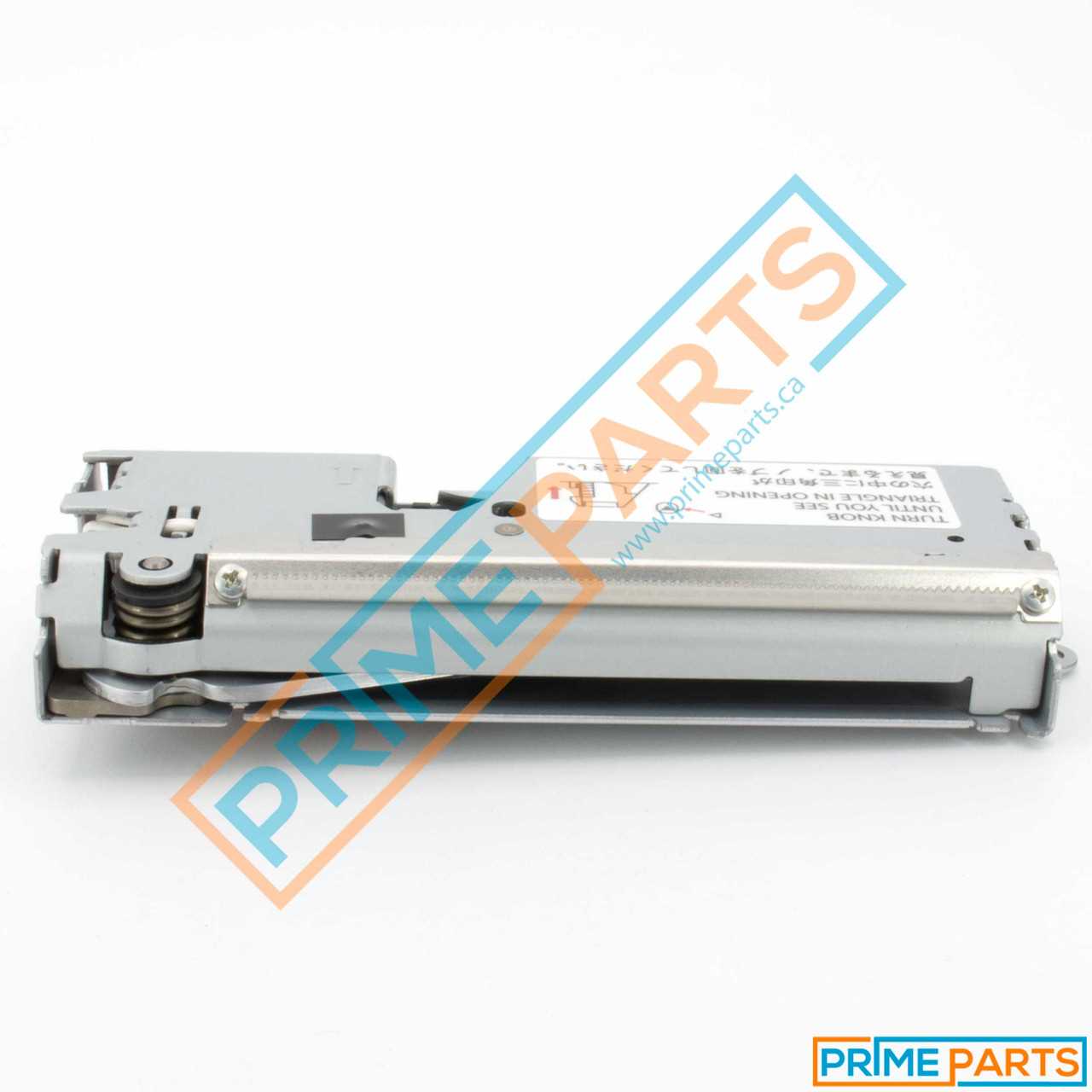

Replacement Parts for TM-T88V

When it comes to ensuring optimal functionality of your thermal receipt printer, knowing about the various components available for replacement is essential. Whether you’re dealing with wear and tear or specific malfunctions, having access to the right resources can significantly enhance performance and longevity. This section explores the crucial elements that may require attention and offers insights into their roles within the device.

Common Components Needing Replacement

- Print Head: The primary element responsible for creating text and images on receipts, often subject to wear due to prolonged usage.

- Roller: Ensures smooth movement of paper, which can become damaged over time, leading to jamming or misalignment.

- Power Supply: A vital source of energy; issues here can lead to the printer not powering on or experiencing intermittent failures.

- Mainboard: The central circuit board that controls the printer’s functions; failures can result in erratic behavior or complete shutdowns.

- Paper Cutter: An automated component that trims receipts; if malfunctioning, it can hinder the receipt output process.

Identifying When to Replace Components

Recognizing the signs that indicate the need for component replacement is critical. Look out for:

- Frequent paper jams.

- Poor print quality, such as fading or incomplete characters.

- Unusual noises during operation.

- Inconsistent power issues.

- Physical damage to any visible parts.

By staying informed about these components and their functionalities, you can maintain the efficiency of your thermal printer and avoid unnecessary downtime.

Visualizing the Printer Assembly

Understanding the structure of a thermal printing device is crucial for effective troubleshooting and maintenance. This section delves into the various components that make up the printer, providing a clear representation of its assembly. By familiarizing oneself with these elements, users can enhance their operational efficiency and prolong the lifespan of the equipment.

Key Components of the Device

- Main Body: The central unit housing essential mechanisms.

- The component responsible for transferring ink onto the paper.

- Control Board: The electronic circuit that manages the device’s functions.

- Power Supply: The source providing energy to the machine.

- Paper Feed Mechanism: The system that moves the printing medium through the device.

Understanding the Interconnections

- The main body serves as the foundation for all components.

- The control board connects to the print head and power supply, ensuring coordinated operation.

- The paper feed mechanism interacts with both the print head and main body, facilitating smooth output.

By grasping how these elements interact, users can better appreciate the functionality of the printing device, paving the way for informed decision-making during repair and upkeep tasks.

Maintenance Tips for TM-T88V

Ensuring the longevity and efficiency of your printing device is essential for maintaining smooth operations in any business environment. Regular upkeep not only enhances performance but also minimizes potential issues that could disrupt workflow. Here are several practical tips to keep your device in optimal condition.

- Keep it Clean:

Regularly remove dust and debris from the exterior and interior components. Use a soft cloth and a gentle cleaning solution to wipe down surfaces, and a small brush or compressed air to clear any buildup around the printing mechanism.

- Check Paper Quality:

Use high-quality thermal paper to prevent jams and ensure clear prints. Poor quality paper can lead to residue buildup, affecting print quality and causing mechanical problems.

- Monitor Ink and Supplies:

Always keep an eye on ink levels and replace supplies as needed. Regularly check for any signs of wear on the printing head and replace it according to the manufacturer’s recommendations.

- Conduct Regular Tests:

Perform test prints periodically to ensure the device is functioning correctly. This helps identify any issues early on, allowing for timely repairs.

- Update Firmware:

Stay updated with the latest firmware releases. These updates can improve performance and add new features, ensuring your device operates at its best.

By following these maintenance practices, you can prolong the lifespan of your printing device and ensure consistent, high-quality output for your business needs.

Finding Genuine Epson Parts

When it comes to maintaining your printing device, ensuring that you use authentic components is crucial for performance and longevity. Genuine parts not only guarantee compatibility but also uphold the manufacturer’s standards, ensuring your equipment runs smoothly. This section provides guidance on how to locate and acquire these essential elements effectively.

Here are some key considerations when searching for authentic replacements:

- Authorized Retailers: Always opt for official distributors or certified sellers. They offer a reliable source for genuine components.

- Manufacturer’s Website: Check the official site for recommended suppliers. This can help you find trustworthy vendors.

- Product Packaging: Genuine items usually come in high-quality packaging with the brand’s logo and information. Look for any signs of tampering.

- Part Numbers: Utilize the specific identification numbers associated with the components to verify authenticity. This information is often available in user manuals.

To further ensure you are making a wise purchase, consider the following:

- Research customer reviews for the seller. Feedback from other buyers can provide insight into their reliability.

- Compare prices, but be cautious of significantly lower prices, which may indicate counterfeit goods.

- Ask questions about the return policy and warranty for the components you intend to purchase.

By following these steps, you can confidently acquire the necessary components to keep your printing equipment operating at its best.

DIY Repair vs. Professional Service

When faced with the need for maintenance or fixing a malfunctioning device, users often find themselves at a crossroads: should they attempt a do-it-yourself (DIY) approach or seek the assistance of a qualified technician? This decision can significantly impact both the outcome of the repair and the user’s overall experience. Each option presents its own set of advantages and challenges, making it essential to weigh them carefully.

Advantages of DIY Repair

One of the most appealing aspects of a DIY repair is the potential cost savings. By taking matters into their own hands, individuals can avoid labor fees typically associated with professional services. Additionally, engaging in a self-repair can foster a sense of accomplishment and deepen one’s understanding of the device’s mechanics. For those with a knack for technical tasks, this option allows for flexibility in scheduling and the possibility of learning new skills.

Benefits of Professional Service

Conversely, opting for expert assistance ensures a higher likelihood of successful repairs. Professionals possess specialized knowledge and experience, allowing them to diagnose issues accurately and apply effective solutions swiftly. This approach not only saves time but also mitigates the risk of causing further damage, which can often occur during DIY attempts. Furthermore, many professionals offer warranties on their work, providing peace of mind that any issues arising post-repair will be addressed without additional costs.

Ultimately, the choice between a DIY repair and enlisting professional help depends on individual circumstances, including technical aptitude, time availability, and the complexity of the issue at hand.

Resources for Technical Support

Accessing reliable resources for technical assistance is crucial for maintaining the functionality and efficiency of printing devices. Various platforms offer detailed information, troubleshooting guides, and expert advice to help users navigate common issues. Below is a compilation of essential resources to enhance your support experience.

| Resource Type | Description | Access Link |

|---|---|---|

| Official Support Website | The primary source for product manuals, troubleshooting tips, and firmware updates. | Visit Here |

| User Forums | A community-driven platform where users can share experiences and solutions. | Join Now |

| Video Tutorials | Step-by-step visual guides that simplify installation and maintenance processes. | Watch Videos |

| Customer Support Hotline | Direct access to technical experts who can provide personalized assistance. | Call Now |

Enhancing Longevity of the Printer

Maintaining the durability of a printing device is crucial for ensuring consistent performance and minimizing operational costs. By implementing effective strategies for care and upkeep, users can significantly extend the lifespan of their equipment. This section outlines practical tips to enhance reliability and efficiency while reducing the frequency of repairs.

Regular Maintenance Practices

Consistent servicing is vital for optimal functionality. Cleaning the internal components regularly, such as the print head and rollers, prevents the buildup of debris that can lead to malfunctions. It is advisable to follow the manufacturer’s guidelines for cleaning intervals and techniques. Additionally, checking and replacing consumables, such as ribbons or ink cartridges, in a timely manner contributes to the overall health of the device.

Environmental Considerations

The surrounding environment plays a significant role in the longevity of printing devices. Keeping the machine in a dry, temperature-controlled space protects it from humidity and extreme temperatures, which can cause damage. Ensuring adequate ventilation helps prevent overheating, a common issue that can shorten the lifespan of electronic components. Furthermore, avoiding exposure to direct sunlight and dust can mitigate potential risks to the device’s performance.