In the realm of office equipment, the efficient dismantling of sensitive information is paramount. A comprehensive exploration of the elements that contribute to the functionality of these devices reveals not only their intricate design but also their importance in maintaining security and confidentiality. By grasping the layout and roles of various components, users can enhance their experience and prolong the lifespan of their machinery.

The internal structure of these machines is crucial for optimal performance. Each segment plays a distinct role, from the motor that powers the device to the cutting mechanisms that ensure thorough destruction. Understanding how these parts interact allows for better maintenance and troubleshooting, ensuring that your equipment operates at its peak.

As we delve deeper into this topic, we will uncover the ultimate insights necessary for anyone looking to maximize their investment in document destruction technology. This knowledge not only aids in identifying issues but also empowers users to take proactive measures in their upkeep.

Understanding Fellowes Shredder Components

Every device designed for document destruction consists of various essential elements that work together to ensure efficiency and reliability. A thorough comprehension of these components not only aids in maintenance but also enhances the user experience. By exploring the inner workings, one can appreciate the intricacies involved in achieving effective performance.

The core mechanism is fundamental to the functioning of such machines. It includes sharp blades that slice through paper and other materials, transforming them into manageable pieces. This process is vital for safeguarding sensitive information while ensuring smooth operation.

Another crucial aspect is the waste collection system. This feature ensures that shredded material is stored properly, allowing for easy disposal. Understanding its capacity and design can help users avoid overflow and maintain optimal performance.

Additionally, control panels play a significant role in user interaction. They offer various settings and indicators, providing essential feedback about the device’s status and functionality. Familiarity with these controls can lead to more effective usage.

Lastly, maintenance components such as lubrication points and cleaning features are integral to prolonging the lifespan of the equipment. Regular upkeep is necessary to prevent malfunctions and ensure consistent results, making knowledge of these areas essential for all users.

Common Parts of Fellowes Shredders

Understanding the components of document destruction devices can enhance their longevity and efficiency. Each element plays a vital role in ensuring the machine operates smoothly, providing users with reliable performance. This section outlines key elements that contribute to the overall functionality of these devices.

Main Components

| Component | Description |

|---|---|

| Cutting Blades | Essential for slicing documents into small pieces, ensuring security and confidentiality. |

| Motor | Powers the operation, driving the blades and enabling the shredding process. |

| Feed Slot | The entry point for materials, designed for user convenience and safety. |

Additional Elements

| Component | Description |

|---|---|

| Waste Bin | Collects shredded materials, typically designed for easy removal and disposal. |

| Control Panel | Offers user interface for operation, including power and reverse functions. |

| Safety Features | Includes sensors and automatic shut-off systems to prevent accidents and ensure safety. |

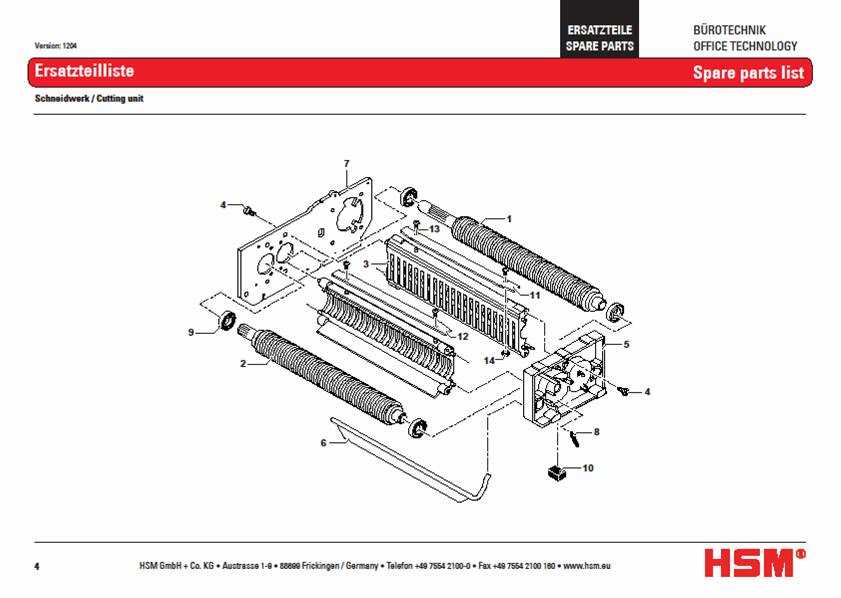

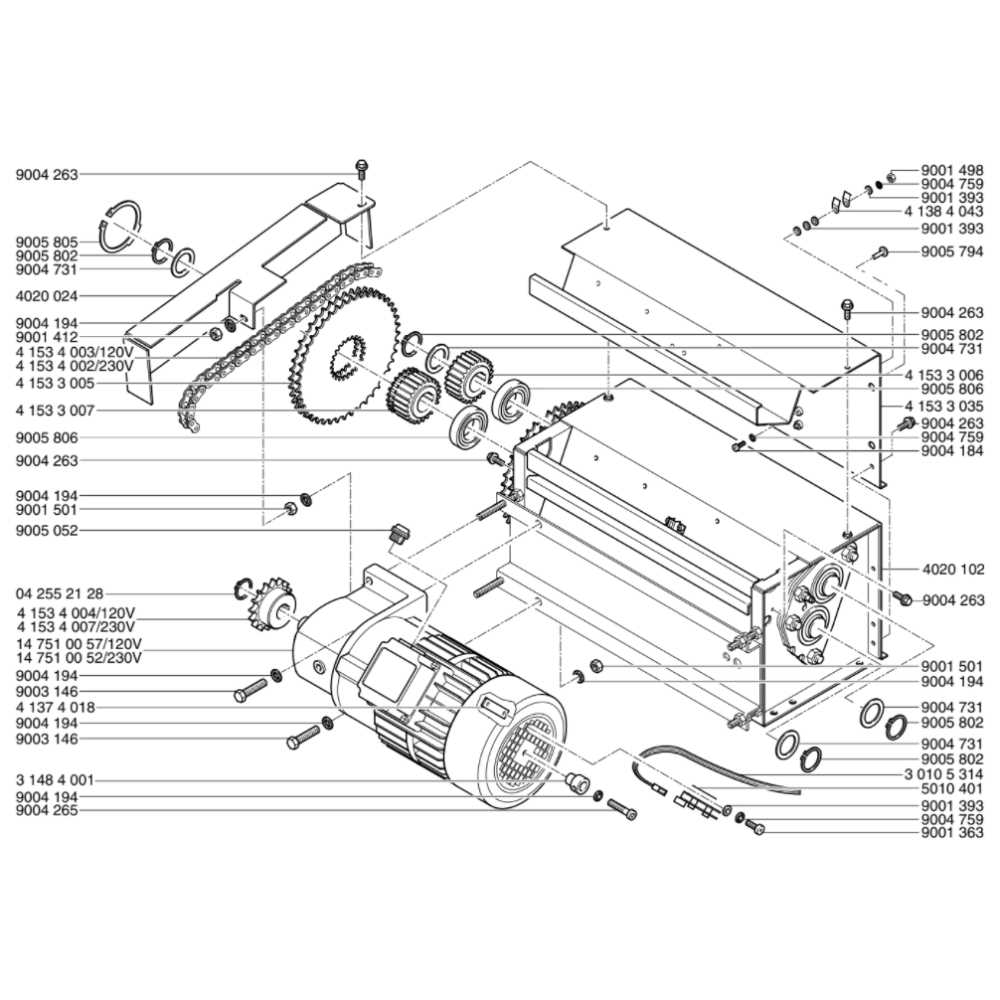

Importance of Parts Diagrams

Understanding the layout and functionality of individual components is crucial for efficient maintenance and repair of machinery. Visual representations allow users to identify specific elements, making troubleshooting and replacement more straightforward. By having a clear view of how parts interconnect, users can enhance their operational efficiency and longevity of their equipment.

Additionally, these visual guides serve as educational tools, aiding users in familiarizing themselves with various mechanisms. This knowledge empowers individuals to tackle issues proactively, minimizing downtime and potential costs associated with professional repairs. Ultimately, clear illustrations contribute to a more knowledgeable and self-sufficient user base.

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair. This visual guide provides valuable insights into the various components, illustrating their arrangement and interconnections. By familiarizing yourself with the symbols and notations, you can enhance your troubleshooting skills and ensure optimal performance.

Begin by identifying the main sections of the visual representation. Each area typically corresponds to a specific functional grouping. Familiarize yourself with the legend, which explains the symbols used throughout the schematic. This will help you understand the roles of each element.

| Symbol | Description |

|---|---|

| ⚙️ | Gear mechanism |

| Electrical connection | |

| Adjustable component | |

| Fastening element |

Pay attention to any annotations or notes that provide additional information on assembly or disassembly. These instructions are invaluable for avoiding mistakes during the maintenance process. Once you grasp the layout and purpose of each element, you will be well-equipped to navigate any related tasks efficiently.

Identifying Wear and Tear

Understanding the signs of degradation in office equipment is crucial for maintaining optimal performance. Regular inspections can help detect issues before they escalate, ensuring that devices function smoothly.

Common Indicators of wear include unusual noises, decreased efficiency, and visible damage to components. Look for frayed edges, cracks, or rust, as these can significantly impact functionality.

Moreover, periodic maintenance can extend the lifespan of your device. Always refer to the manufacturer’s guidelines for care routines and recommended check-ups.

Replacing Blades and Cutters

Maintaining the efficiency of your device often involves the timely replacement of cutting elements. Over time, these components can wear down, affecting performance and the quality of operation. Understanding the process of changing these crucial parts is essential for ensuring optimal functionality.

Tools Required

- Screwdriver

- Replacement blades

- Safety gloves

- Protective eyewear

Step-by-Step Process

- Ensure the device is unplugged to avoid any accidents.

- Carefully remove the outer casing to access the internal components.

- Identify the worn blades and assess the condition of other nearby parts.

- Unscrew and detach the damaged blades, taking care not to damage surrounding components.

- Install the new cutting elements, ensuring they are securely fastened.

- Reassemble the outer casing and double-check for any loose screws.

- Plug in the device and conduct a test run to confirm proper functionality.

Regularly inspecting and replacing cutting components not only prolongs the lifespan of your equipment but also enhances its overall performance. Adhering to these guidelines will ensure you maintain the highest standards of operation.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your device requires consistent care and attention. Regular maintenance not only enhances functionality but also extends the lifespan of the equipment. Below are some essential tips to help you maintain optimal performance.

- Regular Cleaning: Keep the exterior and interior free from dust and debris. Use a soft cloth for the outside and a gentle brush for any accessible areas inside.

- Lubrication: Apply the appropriate lubricant to moving parts as recommended by the manufacturer. This reduces friction and prevents wear.

- Proper Usage: Always follow the manufacturer’s guidelines regarding capacity and type of material to be processed. Overloading can lead to mechanical failure.

- Heat Management: Allow the device to cool down between uses, especially after heavy workloads. This prevents overheating and potential damage.

- Storage Conditions: Store the equipment in a dry, cool place to avoid humidity and temperature extremes that could affect performance.

By implementing these maintenance practices, you can ensure your equipment remains reliable and efficient for years to come.

Where to Find Replacement Parts

When it comes to maintaining your office equipment, sourcing the right components is essential for optimal functionality. Whether you’re looking for specific elements or accessories, there are several reliable avenues to explore.

- Manufacturer’s Website: The official site often provides a dedicated section for accessories and replacements. It’s a good starting point for finding authentic components.

- Authorized Retailers: Many retailers specialize in office equipment and frequently carry a variety of components. Check their online inventory or visit in person.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized platforms can offer both new and used options, sometimes at reduced prices.

In addition to these sources, consider the following:

- Local Repair Shops: Some shops may have spare components or can order them for you.

- Forums and Online Communities: Engaging with users on dedicated forums can provide insights into where to find hard-to-get items.

- Third-Party Suppliers: Various companies specialize in alternative components that are often compatible and more affordable.

By exploring these options, you can ensure that your equipment remains in peak condition without unnecessary delays or expenses.

Tools Needed for Repairs

When embarking on maintenance tasks for any machine, having the right equipment is essential for a successful outcome. This section outlines the necessary instruments to effectively address common issues, ensuring efficiency and safety during the repair process.

First and foremost, a basic toolkit comprising screwdrivers, pliers, and wrenches is crucial for disassembly and reassembly. Additionally, employing specialized tools such as multimeters can help diagnose electrical components, while lubricant can assist in enhancing performance post-repair. Safety gear, including gloves and goggles, should not be overlooked to protect oneself during the operation.

Gathering these items beforehand will streamline the repair process, enabling a thorough examination and resolution of any malfunctions. This preparation ultimately contributes to maintaining optimal functionality and extending the lifespan of the equipment.

Assembly Process After Repair

Following the restoration of essential components, it is crucial to ensure that everything is correctly reassembled for optimal functionality. This process not only enhances performance but also guarantees safety during operation.

Step-by-Step Reassembly

Begin by gathering all the necessary elements, ensuring each one is clean and free from damage. Carefully follow the original configuration, placing parts in their designated positions. Pay close attention to any clips or fasteners, as they play a vital role in securing the structure.

Final Checks and Testing

Once assembly is complete, conduct thorough inspections to confirm that all connections are tight and components are aligned. Power on the unit and perform a functionality test to ensure everything operates smoothly, addressing any issues that may arise promptly.

Safety Precautions During Maintenance

Ensuring safety during the upkeep of equipment is paramount to avoid accidents and injuries. Following specific guidelines can help create a secure working environment while handling various components.

- Always disconnect the device from the power source before beginning any maintenance tasks.

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Keep the work area tidy and free from obstructions to prevent tripping hazards.

- Use tools that are in good condition and suitable for the task at hand.

Moreover, being aware of potential hazards can enhance safety during the process:

- Identify sharp edges or moving parts that may cause injury.

- Avoid wearing loose clothing or jewelry that could get caught in mechanisms.

- Ensure proper ventilation in the workspace if using any cleaning solvents.

By adhering to these precautions, individuals can minimize risks and ensure a smoother maintenance experience.

Understanding Different Shredder Models

When it comes to document destruction devices, various models cater to specific needs and preferences. Each type offers unique features, capacities, and performance levels, allowing users to select the most suitable option for their requirements. Recognizing these distinctions is essential for making an informed decision and maximizing efficiency in information security.

Types of Devices

Devices can be classified based on their cutting technology, such as strip-cut, cross-cut, and micro-cut variations. Each method provides different levels of confidentiality, influencing how well sensitive information is protected. Understanding these categories helps users assess their security needs effectively.

Key Features to Consider

When evaluating options, key features include capacity, speed, noise levels, and safety mechanisms. Some models are designed for high-volume usage, while others suit occasional tasks. Identifying the right combination of features can greatly enhance user experience and satisfaction.

Customer Support Resources for Fellowes

Accessing reliable assistance is crucial for ensuring optimal performance and longevity of your office equipment. Various resources are available to help users troubleshoot issues, find necessary components, and understand product functionality.

Available Support Options

- Online FAQs: Comprehensive answers to common inquiries.

- Email Support: Direct communication with knowledgeable representatives.

- Phone Support: Immediate assistance for urgent matters.

- User Manuals: Detailed guides for setup and maintenance.

Community and Forums

Engaging with other users can provide valuable insights. Consider exploring:

- Official community forums for shared experiences.

- Social media groups for real-time tips and advice.

- Video tutorials for visual guidance on common tasks.