When it comes to efficient outdoor maintenance during harsh weather conditions, having a clear understanding of the essential elements of your distribution apparatus is crucial. Each component plays a significant role in ensuring that the machine operates smoothly, providing optimal performance when you need it most.

By exploring the intricate relationships between these various sections, users can gain insights into how to maintain and enhance the functionality of their machinery. A thorough knowledge of these components not only aids in troubleshooting but also empowers operators to execute their tasks with confidence.

As we delve into this topic, we will examine the ultimate configuration of the equipment, allowing for improved management and longevity. This exploration will facilitate a deeper appreciation for how every element contributes to the overall efficiency of the operation.

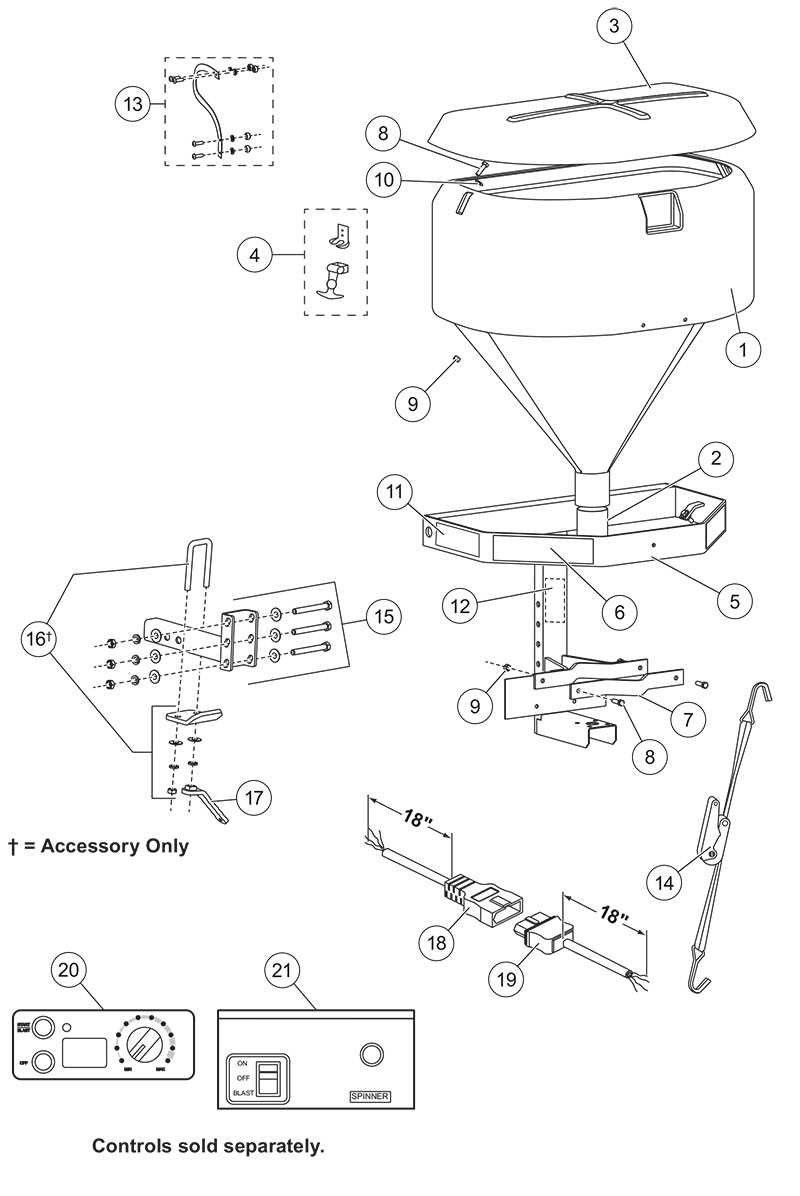

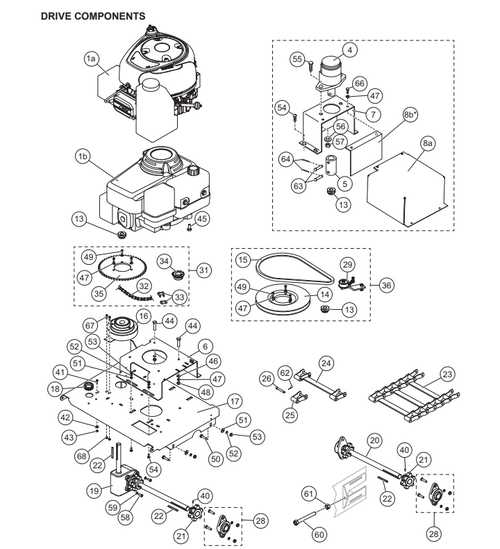

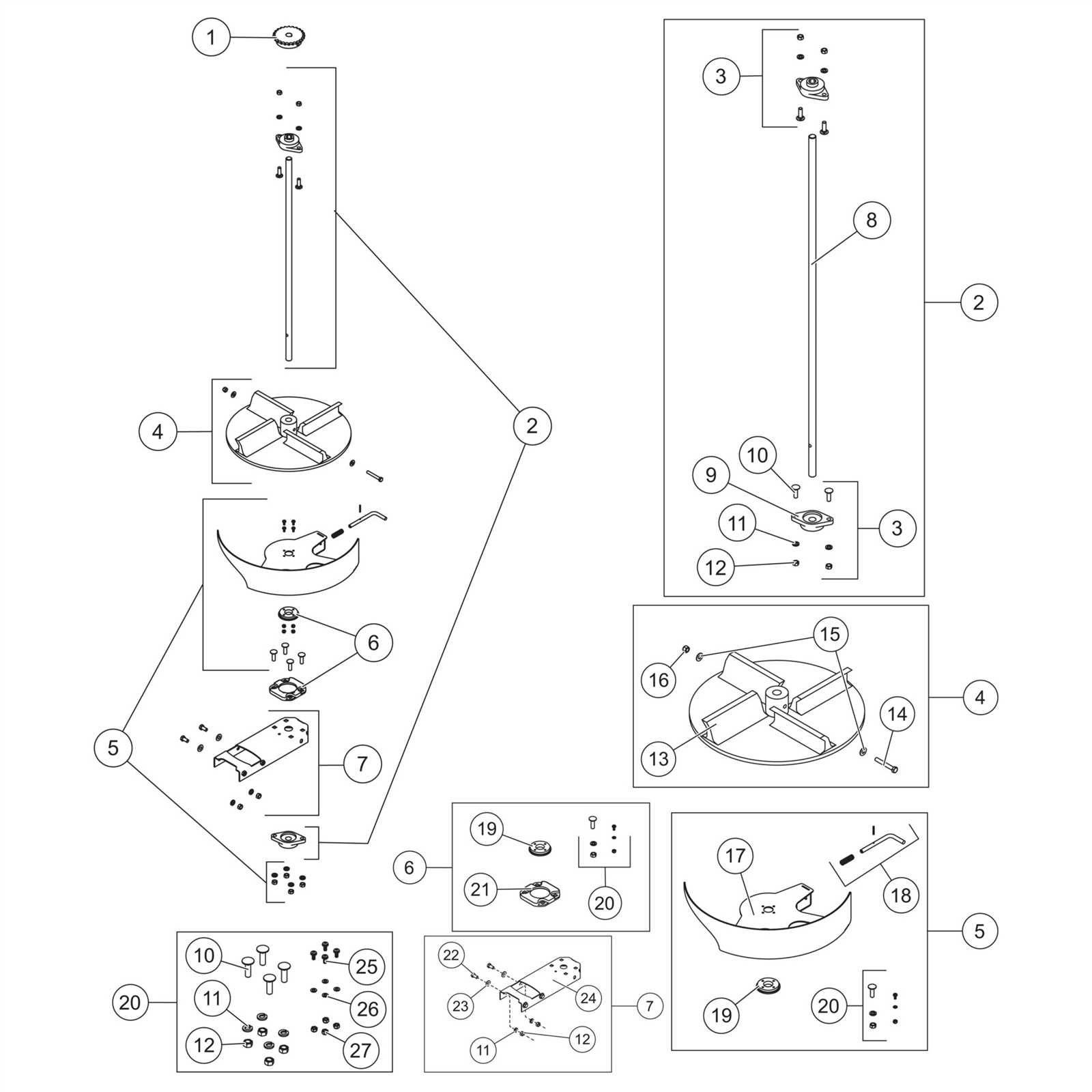

Understanding Fisher Salt Spreader Components

This section aims to provide insights into the various elements that contribute to the functionality of a winter maintenance machine. A thorough comprehension of these components is essential for ensuring optimal performance and longevity of the equipment.

Key Elements

At the core of this machinery are several crucial elements, including the hopper, motor, and distribution system. Each component plays a vital role in the efficient application of materials to maintain safe surfaces during icy conditions.

Maintenance Considerations

Regular inspection and maintenance of these components can significantly enhance the operational lifespan of the device. Paying attention to wear and tear on the moving parts can prevent larger issues and ensure seamless performance when needed the most.

Importance of Salt Spreader Maintenance

Proper upkeep of de-icing equipment is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of breakdowns during critical operations. By investing time in routine checks and servicing, operators can maintain reliable functionality, especially during harsh winter conditions.

Benefits of Regular Maintenance

- Increased Efficiency: Well-maintained machinery performs better, allowing for uniform distribution of materials.

- Cost Savings: Preventative care can reduce repair costs and extend the lifespan of the equipment.

- Safety Assurance: Regular inspections help identify potential hazards, ensuring safe operation.

- Enhanced Reliability: Consistent upkeep leads to dependable performance when it is most needed.

Key Maintenance Tasks

- Inspecting and lubricating moving parts to prevent wear and tear.

- Checking and adjusting the calibration for even material application.

- Cleaning the equipment to remove any residue that could impede functionality.

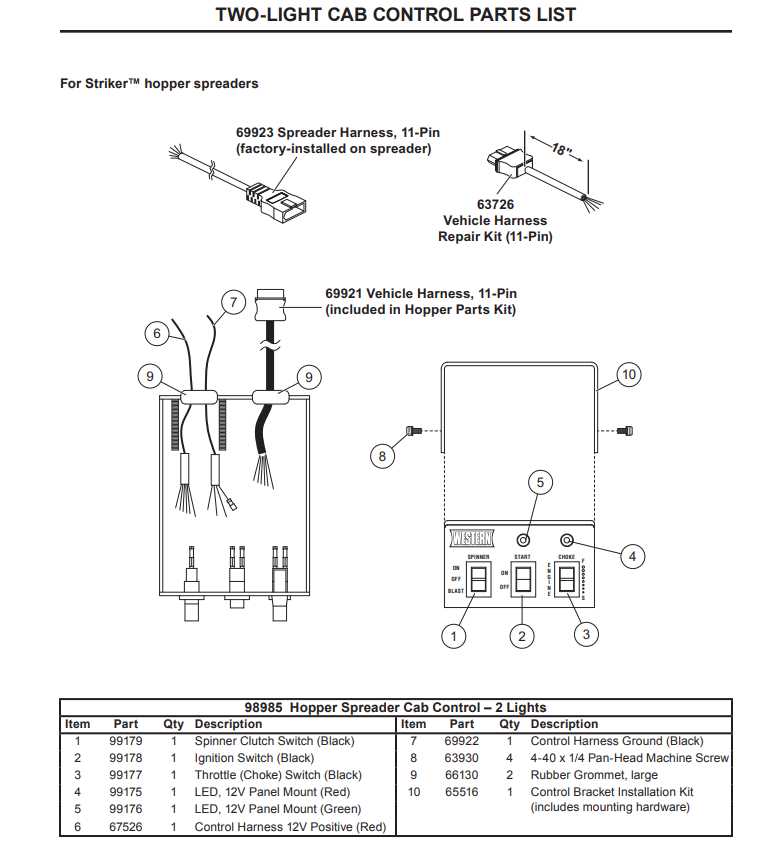

- Examining electrical components for any signs of damage or wear.

By adhering to a diligent maintenance schedule, operators can ensure their equipment remains in top condition, ready to perform efficiently when the weather demands it most.

Key Parts of a Salt Spreader

This section outlines the essential components that contribute to the efficient functioning of a material distribution system. Understanding these elements is crucial for optimal performance and maintenance.

| Component | Description |

|---|---|

| Hopper | The container that holds the granulated substance before distribution. |

| Agitator | A mechanism that ensures the material flows smoothly from the hopper. |

| Spinner | The rotating element that spreads the material evenly across the desired area. |

| Chassis | The frame that supports all components and provides stability during operation. |

| Drive System | The mechanism that powers the movement of the entire apparatus. |

| Controls | The interface used by the operator to manage the distribution rate and coverage. |

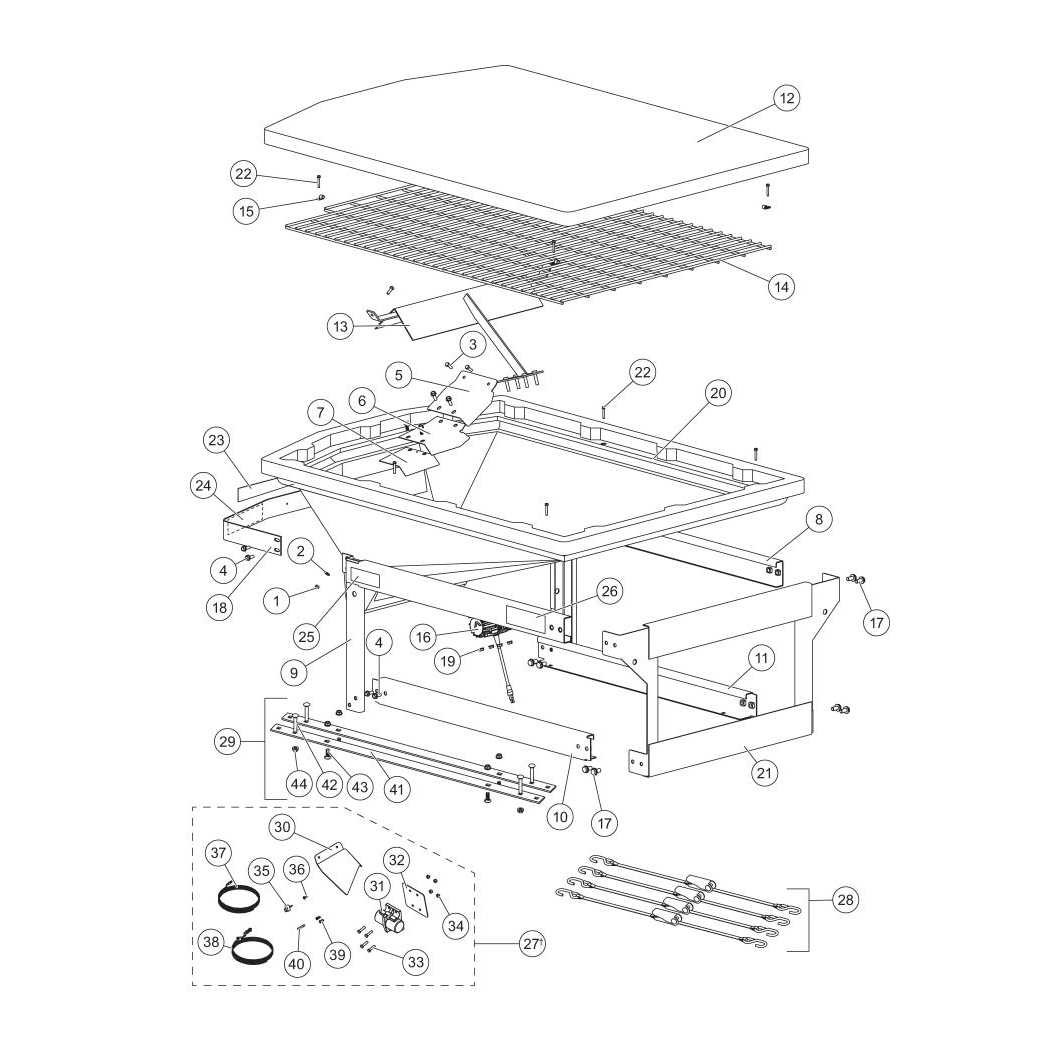

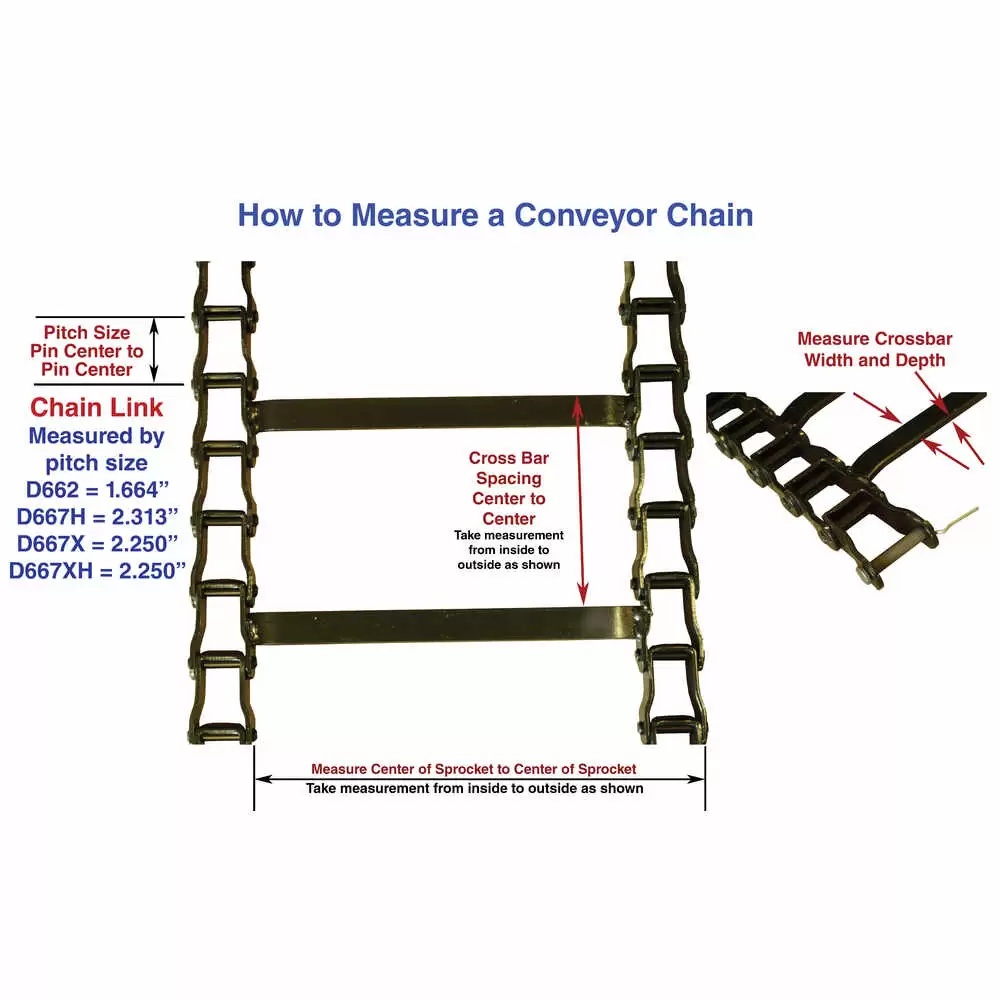

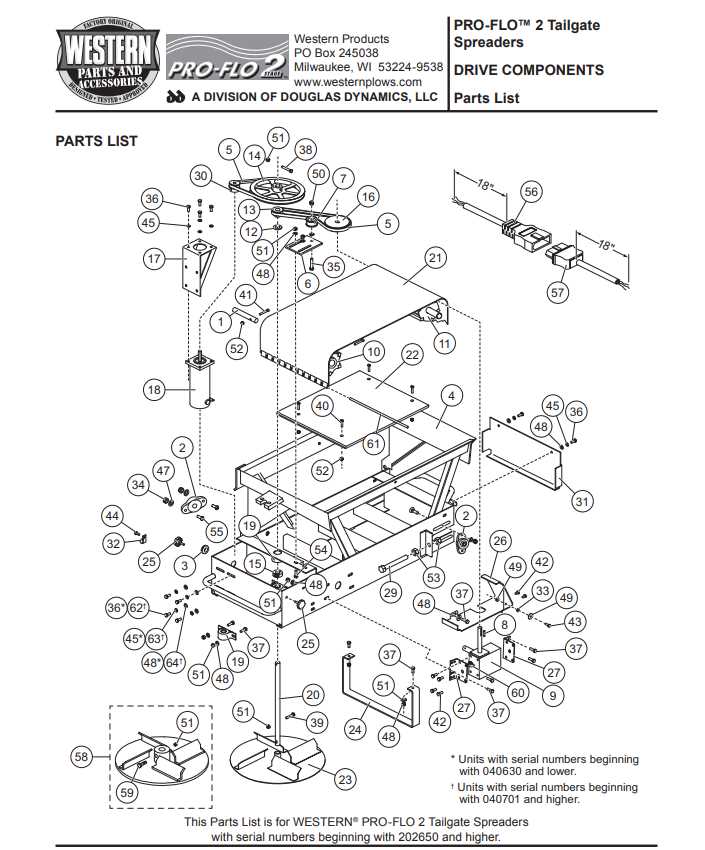

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and manage various elements of a machine. This type of illustration provides a clear layout, enabling users to locate each part efficiently and comprehend how they interact within the system.

To begin, familiarize yourself with the overall structure of the illustration. Each component is typically labeled with a number or letter that corresponds to a key or legend. This guide is essential for pinpointing specific items, so take a moment to study it closely.

Next, pay attention to the arrangement of components. Often, related parts are grouped together, which can help you understand their functions and connections. Recognizing patterns in the layout can also assist in visualizing the assembly process, making it easier to grasp how everything fits together.

When examining individual components, note any additional details provided, such as dimensions or specifications. These notations are crucial for ensuring compatibility when ordering replacements or making adjustments.

Lastly, don’t hesitate to cross-reference the illustration with the user manual or online resources for further clarification. Familiarity with these visuals will not only enhance your maintenance skills but also empower you to tackle repairs confidently.

Common Issues with Spreader Components

Equipment used for the distribution of materials often encounters various challenges that can hinder performance. Understanding these frequent complications can help in maintaining efficiency and prolonging the lifespan of the machinery.

Wear and Tear: Over time, components may suffer from wear due to constant movement and exposure to harsh elements. This can lead to reduced efficiency and potential breakdowns.

Clogging: Accumulation of debris or materials can cause blockages, affecting the flow and distribution process. Regular cleaning and maintenance are essential to prevent this issue.

Corrosion: Exposure to moisture and chemicals can lead to rust and degradation of parts, compromising structural integrity. Using protective coatings can mitigate this risk.

Mechanical Failures: Components like motors and gears may experience failures due to fatigue or lack of lubrication. Routine inspections can help identify and address these problems early.

Calibration Issues: Improper adjustments can lead to uneven distribution. Regular calibration checks are necessary to ensure optimal performance and accurate material application.

By recognizing these common challenges, operators can implement proactive measures to enhance functionality and reliability of their equipment.

Replacing Worn-Out Spreader Parts

Ensuring optimal performance requires timely replacements of deteriorated components in your equipment. Addressing wear and tear not only extends lifespan but also enhances efficiency.

Identifying which components need replacement is crucial. Here are some common signs of wear:

- Visible cracks or breaks

- Inconsistent operation

- Excessive noise during use

When preparing for replacements, follow these steps:

- Gather necessary tools and new components.

- Refer to the manufacturer’s guidelines for disassembly.

- Carefully remove the old parts.

- Install new components, ensuring proper alignment.

- Test the equipment to confirm functionality.

Regular maintenance checks can prevent unexpected failures and ensure everything runs smoothly. Consider scheduling these assessments to keep your gear in peak condition.

Tools Needed for Spreader Repairs

Effective maintenance and repairs of your equipment require the right set of instruments. Having the proper tools not only enhances efficiency but also ensures that tasks are completed safely and correctly. Whether you are conducting routine check-ups or addressing specific issues, being well-prepared is essential for successful outcomes.

Essential Tools

To begin with, a good quality wrench set is crucial for loosening and tightening various components. Additionally, pliers, both needle-nose and standard, are invaluable for gripping and maneuvering smaller parts. A reliable screwdriver set, including both flat-head and Phillips, will allow you to access screws and fasteners with ease. Furthermore, a torque wrench is important for achieving the correct tightness, ensuring that everything remains secure during operation.

Specialized Equipment

In some cases, you may need specialized tools, such as a multimeter for electrical diagnostics or a hydraulic jack for lifting heavier sections of the machinery. A lubricant or grease gun is also beneficial for maintaining smooth operation of moving parts. Lastly, don’t forget safety gear, including gloves and goggles, to protect yourself during any maintenance tasks.

Safety Tips for Using Spreaders

Ensuring safety while utilizing these devices is paramount for both effectiveness and personal well-being. Adhering to best practices can prevent accidents and enhance operational efficiency, allowing for a smooth application process.

Pre-Operation Checks

Before commencing work, inspect the equipment thoroughly. Check for any signs of wear or damage, ensuring that all components are functioning correctly. Proper maintenance can significantly reduce the risk of malfunctions during use.

Personal Protective Equipment

Always wear appropriate gear when handling these machines. Protective eyewear, gloves, and sturdy footwear are essential to shield against potential hazards. Additionally, consider using a face mask to avoid inhaling any fine particles.

By following these precautions, you can create a safer environment for yourself and others while optimizing the application process.

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is crucial to ensure optimal performance and longevity. With numerous options available, it can be challenging to identify the most suitable replacements. This section will guide you through the essential factors to consider when making your decision.

Key Considerations

- Compatibility: Ensure that the chosen items match the specifications of your machinery. Refer to the manufacturer’s guidelines for compatibility information.

- Quality: Opt for high-quality materials to enhance durability and performance. Investing in reliable components can prevent frequent replacements.

- Brand Reputation: Choose components from reputable manufacturers known for their reliability and customer support.

- Cost: While it may be tempting to go for cheaper options, consider the long-term costs associated with lower quality, which may lead to more frequent replacements.

Where to Find Reliable Options

- Authorized dealers: They often stock genuine items that ensure perfect compatibility.

- Online retailers: Look for well-reviewed platforms that provide detailed descriptions and customer feedback.

- Local repair shops: They can offer insights on the best choices based on experience with various brands.

By considering these factors and sourcing from trusted suppliers, you can ensure that your machinery operates efficiently and effectively for years to come.

Differences Between Spreader Models

When evaluating various models for distributing materials, it’s essential to understand the nuances that differentiate them. Each variant is designed with specific functionalities, catering to diverse needs and environments.

Key Features

- Capacity: Varies significantly, influencing the amount of material handled.

- Mechanism: Different designs affect the distribution pattern and efficiency.

- Durability: Materials used in construction can impact longevity and performance.

Usage Scenarios

- Residential: Smaller units suited for home applications.

- Commercial: Larger options designed for heavy-duty tasks.

- Agricultural: Specialized models for farm use, promoting even distribution.

Seasonal Preparation for Salt Spreaders

Preparing your equipment for the changing seasons is crucial to ensure optimal performance and longevity. As winter approaches, it is essential to check and maintain your machinery to guarantee efficiency and reliability during harsh weather conditions. This involves a thorough inspection and necessary adjustments to ensure everything operates smoothly when needed most.

Start by cleaning all components to remove any debris or residue from previous use. Inspect the mechanical parts for signs of wear and tear, as well as ensuring that moving elements are well-lubricated. Additionally, verify the electrical systems, ensuring that all connections are secure and functioning correctly.

Next, calibrate the distribution mechanism to achieve the desired spread rate. This step is vital for maintaining effectiveness while avoiding unnecessary waste. Stocking up on materials in advance also ensures you are ready to tackle any snowfall without delays.

Lastly, familiarize yourself with the operational guidelines to maximize the effectiveness of your equipment. Regular maintenance and preparation can significantly enhance your performance, making it easier to handle challenging conditions efficiently.

Enhancing Performance with Upgrades

Improving the efficiency and effectiveness of your equipment is essential for optimal results. By investing in enhancements, you can significantly boost performance and extend the lifespan of your machinery. Upgrades can range from simple modifications to comprehensive overhauls, providing a tailored approach to meet specific operational needs.

Quality Components play a vital role in achieving superior functionality. Replacing outdated elements with high-quality alternatives can lead to enhanced durability and reliability. Consider selecting upgraded materials that withstand wear and tear, ensuring your equipment operates smoothly under various conditions.

Technological advancements offer opportunities to integrate innovative features into your setup. Modern systems may include advanced controls, improved efficiency mechanisms, or enhanced monitoring tools that provide real-time data. Such enhancements not only streamline operations but also facilitate better decision-making based on accurate performance metrics.

Regular maintenance combined with thoughtful upgrades can lead to increased productivity. Addressing potential issues proactively ensures that your machinery operates at peak efficiency, reducing downtime and operational costs. Ultimately, a well-maintained and upgraded setup results in superior outcomes, allowing for a more effective approach to any task at hand.

Resources for Parts and Repairs

When maintaining equipment, access to quality components and reliable repair guidance is essential. Understanding where to find the right resources can enhance performance and longevity. Numerous avenues exist for obtaining necessary items, ranging from authorized distributors to online platforms.

Official Distributors: Authorized sellers often provide authentic components, ensuring compatibility and reliability. It’s advisable to consult their catalogs or websites for the most accurate offerings.

Online Marketplaces: E-commerce platforms host a variety of vendors, presenting a broad selection of options. Be sure to check reviews and ratings to ensure the credibility of the sellers.

Repair Guides: Numerous websites and forums offer detailed manuals and troubleshooting tips. These resources can empower users to perform maintenance effectively and tackle common issues.

Community Forums: Engaging with fellow enthusiasts in online communities can yield valuable insights and recommendations. Members often share experiences and suggest trustworthy sources for components.

Local Repair Shops: Seeking assistance from nearby technicians can provide hands-on expertise. They may also have access to parts or can recommend reliable suppliers.