The effective functioning of agricultural machinery relies heavily on the intricate assembly of its various elements. Each component plays a crucial role in ensuring optimal performance, which is essential for efficient farming operations. Grasping the relationship between these pieces can significantly enhance maintenance and repair efforts.

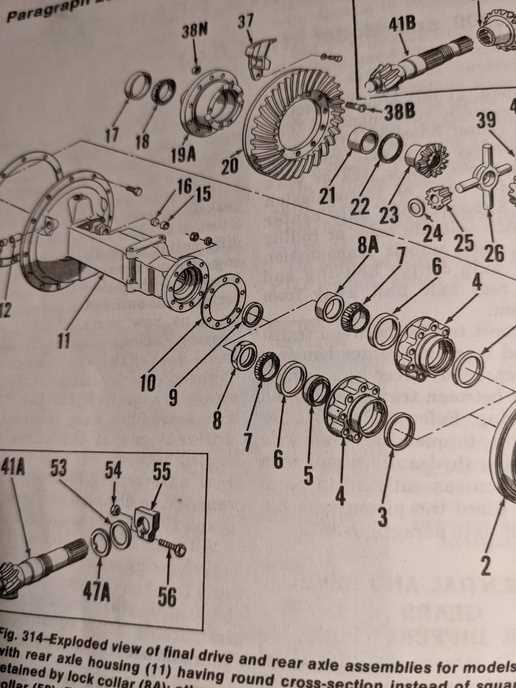

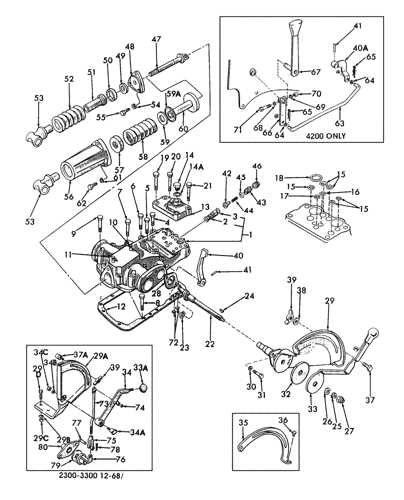

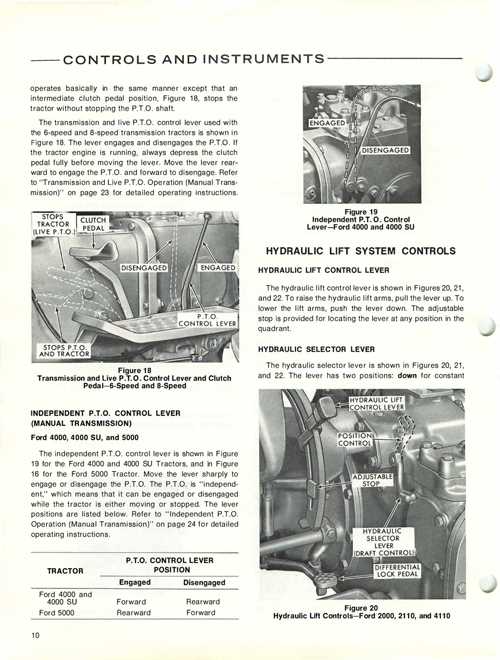

For those seeking to explore the intricacies of machinery assembly, visual representations can serve as invaluable tools. By examining detailed illustrations, one can identify and locate individual parts, facilitating a deeper understanding of how each section contributes to the overall functionality. This knowledge empowers operators and technicians alike, paving the way for better troubleshooting and repair.

In this section, we will delve into the specifics of a well-known agricultural model, focusing on the layout and interaction of its components. Whether you’re a seasoned professional or a novice enthusiast, comprehending these details can lead to more informed decisions and ultimately enhance the longevity of your equipment.

Understanding the Ford 3000 Parts Diagram

Grasping the layout of components within a machinery model is essential for effective maintenance and repair. By exploring the intricate relationships between various elements, one can enhance operational efficiency and ensure longevity. This section aims to illuminate the key aspects of the schematic representation for optimal comprehension.

Key Components

Identifying critical elements within the schematic can significantly streamline the troubleshooting process. Understanding each component’s function allows for targeted interventions, thereby minimizing downtime and enhancing performance.

Utilizing the Representation

Mastering the layout not only aids in repairs but also fosters a deeper appreciation for the machinery’s engineering. Employing this knowledge can empower operators to make informed decisions regarding upgrades and modifications, ultimately leading to improved functionality.

Key Components of the Ford 3000

This section explores the essential elements that contribute to the functionality and performance of the iconic tractor model. Understanding these components is crucial for maintenance and repair, ensuring that the machine operates efficiently for various agricultural tasks.

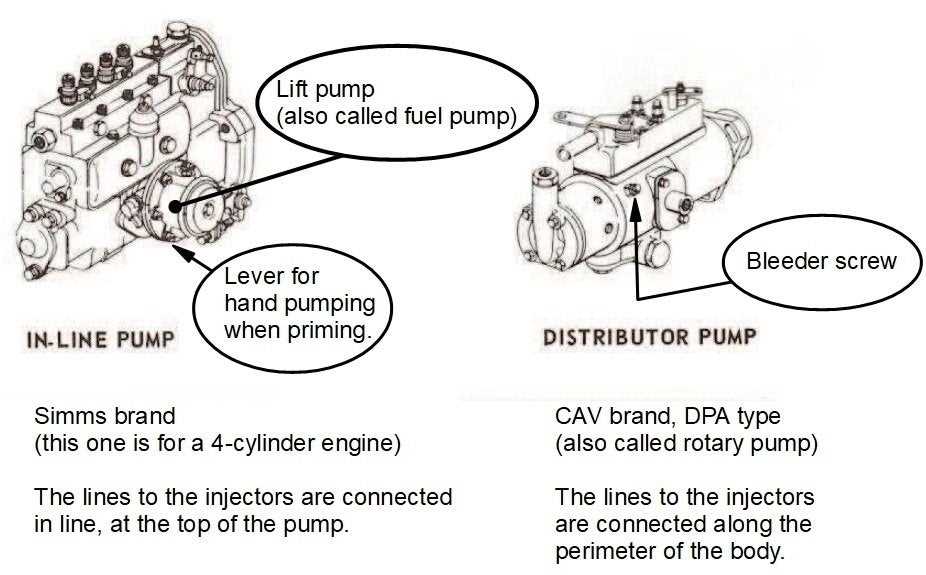

Engine Assembly

The heart of any agricultural vehicle is its engine assembly, which powers the entire machine. This component consists of various parts, including the cylinder block, pistons, and crankshaft, all working in unison to provide the necessary horsepower. Regular maintenance of the engine ensures optimal performance and longevity.

Transmission System

The transmission system plays a vital role in the operation of the vehicle by controlling the speed and torque delivered to the wheels. This includes the gearbox, clutch, and differential. A well-functioning transmission system allows for smooth gear shifts, enhancing the overall driving experience and operational efficiency.

Benefits of Using Official Diagrams

Utilizing authorized visual schematics for machinery offers numerous advantages that enhance the maintenance and repair process. These resources are specifically designed to provide clarity and precision, ensuring users can accurately identify components and their functions.

Reliability is a key benefit, as official illustrations are created based on the manufacturer’s specifications. This means they reflect the most current design and engineering standards, reducing the risk of errors during repairs.

Another significant advantage is efficiency. Accessing these structured layouts saves time, allowing technicians to quickly locate parts and understand assembly without unnecessary guesswork. This streamlined approach can lead to faster repairs and less downtime for equipment.

Additionally, using authorized resources fosters knowledge retention. Familiarity with these official representations can enhance a technician’s skills, leading to improved confidence and expertise in handling complex tasks. This educational aspect is invaluable for both novice and experienced workers.

Moreover, using authentic illustrations ensures compatibility. Each part is designed to work seamlessly within the system, minimizing the risk of using incorrect components that could lead to operational failures.

In conclusion, leveraging official visual aids not only simplifies the repair process but also contributes to long-term efficiency and reliability in equipment management.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective assembly and maintenance. These illustrations serve as guides, helping users identify and locate various elements within a system. By mastering this skill, you can streamline repairs and ensure everything functions smoothly.

Here are some key elements to focus on when interpreting these visuals:

| Element | Description |

|---|---|

| Labels | Annotations that provide names or numbers for components. |

| Lines | Connections that indicate how parts are linked or interact. |

| Symbols | Icons that represent specific functions or types of components. |

| Legend | A guide explaining the meaning of different symbols and colors used. |

By paying attention to these aspects, you can effectively navigate and utilize these resources for optimal outcomes.

Common Issues and Solutions

This section addresses frequent problems encountered with agricultural machinery and offers practical solutions to enhance performance and longevity. Understanding these challenges can aid operators in effective maintenance and timely repairs.

Frequent Challenges

- Engine starting difficulties

- Overheating issues

- Transmission problems

- Hydraulic system malfunctions

Recommended Solutions

- Check battery condition and connections for starting issues.

- Ensure proper coolant levels and radiator function to prevent overheating.

- Inspect fluid levels and filters for transmission efficiency.

- Examine hoses and fluid levels in the hydraulic system for leaks.

Aftermarket vs. OEM Parts

The choice between replacement components from original manufacturers and those produced by third parties is a significant consideration for many. Understanding the benefits and drawbacks of each option can lead to more informed decisions that ultimately affect performance and longevity.

Quality and Performance

Original manufacturer items typically adhere to strict quality standards, ensuring compatibility and reliability. In contrast, third-party alternatives can vary widely in quality, with some exceeding original specifications and others falling short.

Cost Considerations

Generally, third-party items are more affordable, making them an attractive option for budget-conscious consumers. However, this lower price may come at the expense of durability or fit, which can result in additional costs over time.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | High and consistent | Variable |

| Cost | Generally higher | Usually lower |

| Warranty | Often includes warranty | Varies |

| Availability | Limited to manufacturer | Widely available |

Finding Reliable Replacement Parts

Locating dependable components for machinery can significantly enhance performance and longevity. Whether you’re restoring an old model or conducting routine maintenance, ensuring that you acquire high-quality elements is crucial for optimal functioning. Understanding where and how to source these items can make a substantial difference in your project’s success.

Key Considerations

When searching for reliable components, several factors come into play. Authenticity, compatibility, and supplier reputation are paramount. Investing time in research can lead to finding suppliers who offer genuine or high-quality aftermarket alternatives, which often ensures that you receive durable and effective replacements.

Sources for Components

There are numerous avenues to explore when seeking out components. Here are some of the most common sources:

| Source Type | Description |

|---|---|

| Authorized Dealers | These establishments provide genuine components, ensuring compatibility and quality. |

| Aftermarket Suppliers | Specialized businesses offering alternatives that can be more cost-effective while maintaining quality. |

| Online Marketplaces | Websites that facilitate buying and selling can provide access to a vast selection, but it’s essential to check seller ratings. |

| Local Salvage Yards | These locations may have used components available at lower prices, often in good condition. |

By carefully evaluating these options and focusing on quality, you can ensure that the components you choose will meet your needs and help maintain the efficiency of your machinery.

Step-by-Step Repair Process

When it comes to fixing machinery, a systematic approach can make all the difference. By breaking down the task into manageable steps, you ensure that each part is addressed thoroughly, reducing the likelihood of future issues. This process not only enhances the longevity of the equipment but also improves overall efficiency.

Step 1: Assessment

Begin by conducting a thorough evaluation of the equipment. Identify any visible signs of wear or damage and take note of any unusual noises or performance issues. This initial assessment will guide your repair strategy.

Step 2: Gather Necessary Tools

Compile all required tools and materials before starting. This includes wrenches, screwdrivers, lubricants, and replacement components. Having everything on hand will streamline the repair process and minimize interruptions.

Step 3: Disassembly

Carefully disassemble the relevant parts, taking care to document the order of removal. This can be done through notes or photographs, which will help during reassembly. Keep track of screws and small components to avoid losing them.

Step 4: Inspection and Cleaning

Once disassembled, inspect each component for damage. Clean any parts that show signs of dirt or debris buildup. Proper maintenance can prevent many issues and enhance performance.

Step 5: Replacement and Repair

Replace any damaged components with new ones, ensuring they match the specifications needed for compatibility. For parts that can be repaired, follow the appropriate procedures to restore them to working condition.

Step 6: Reassembly

Carefully reassemble the machine in the reverse order of disassembly. Refer to your notes or photos to ensure every piece is placed correctly. Tighten all fasteners to the manufacturer’s recommended torque settings.

Step 7: Testing

After reassembly, conduct a thorough test to confirm that the repair was successful. Monitor the equipment closely during this phase to detect any irregularities immediately.

Step 8: Documentation

Finally, document the entire process, including any parts replaced and adjustments made. This record will be valuable for future maintenance and repairs, helping to build a comprehensive history of the equipment’s condition.

Essential Tools for Maintenance

Proper upkeep of machinery requires a specific set of instruments that facilitate efficient and effective servicing. These essential tools not only enhance performance but also ensure longevity and reliability.

- Wrenches: Adjustable and socket types are vital for loosening and tightening various fittings.

- Screwdrivers: A variety of flathead and Phillips screwdrivers is necessary for a range of applications.

- Pliers: Needle-nose and slip-joint pliers help grip and manipulate small components.

- Oil Filter Wrench: Essential for easy removal and replacement of oil filters.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

Investing in high-quality tools leads to better maintenance outcomes and ultimately extends the lifespan of the equipment.

Comparing Ford 3000 Models

This section aims to explore the various versions of a renowned tractor, highlighting their unique features and specifications. By examining these variations, users can make informed decisions based on their specific needs and preferences.

Key differences to consider include:

- Engine performance and efficiency

- Transmission types available

- Weight and overall size

- Hydraulic system capabilities

- Fuel consumption rates

Each model serves different agricultural tasks, so understanding these distinctions is essential for optimal usage.

- Base Model: Suitable for light to moderate tasks.

- Deluxe Version: Enhanced features for more demanding applications.

- Utility Variant: Designed for versatility across various farming activities.

Delving into these aspects provides the ultimate insight into choosing the right machinery for your requirements.

Tips for Long-Term Care

Maintaining machinery for extended periods requires attention and diligence. Proper upkeep ensures optimal performance and longevity, preventing costly repairs and replacements.

Regular inspections are essential; check for wear and tear on components and address any issues promptly. Cleanliness plays a critical role; keep surfaces free from debris and contaminants to promote efficiency.

Utilize high-quality lubricants to reduce friction and protect moving parts. Always follow the manufacturer’s recommendations regarding fluid changes and maintenance schedules.

Store equipment in a dry, sheltered location to prevent rust and corrosion. Consider seasonal maintenance tasks to prepare for varying environmental conditions.

Lastly, keep detailed records of maintenance activities and repairs to monitor performance trends and identify recurring issues, allowing for informed decision-making.

Resources for Further Information

This section aims to provide valuable references for those seeking more knowledge about machinery components and their maintenance. Accessing the right information can significantly enhance your understanding and repair capabilities.

- Manufacturer Manuals: Official documents that outline specifications and maintenance guidelines.

- Online Forums: Community platforms where enthusiasts share tips and experiences.

- Parts Retailer Websites: Sites that offer detailed listings and images of various components.

- Video Tutorials: Visual guides available on platforms like YouTube, demonstrating repair processes.

- Technical Support Hotlines: Direct contact options for expert advice and troubleshooting assistance.

Utilizing these resources can help deepen your knowledge and improve your overall experience in handling machinery effectively.

Community Forums and Support Groups

Engaging with a community dedicated to machinery enthusiasts can significantly enhance your experience and knowledge. These platforms provide a space for users to share insights, seek advice, and troubleshoot issues collaboratively. They are invaluable resources for both newcomers and seasoned operators alike.

Benefits of Joining Online Communities

- Access to a wealth of shared knowledge and expertise.

- Opportunities to connect with other enthusiasts and professionals.

- Timely support for specific inquiries and challenges.

- Exchange of tips and tricks for maintenance and operation.

Popular Platforms to Consider

- Dedicated forums focused on machinery topics.

- Social media groups where users discuss experiences and solutions.

- Online marketplaces that also offer community features.

- Local clubs that hold meet-ups and discussions.

By participating in these forums and groups, you can not only solve problems more effectively but also contribute to a community that thrives on shared passion and knowledge.