The intricacies of heavy machinery often require a detailed exploration to ensure optimal functionality and longevity. This section aims to provide a comprehensive overview of the essential elements that constitute these powerful tools, focusing on their various assemblies and mechanisms.

In the realm of construction and excavation, familiarity with the components can significantly enhance maintenance efforts and repair strategies. A clear understanding of each segment’s role contributes to efficient operation and minimizes downtime.

Through an organized representation of the mechanical layout, users can effectively identify and source necessary items for restoration or upgrade. Engaging with this material enables operators to delve into the ultimate performance potential of their equipment.

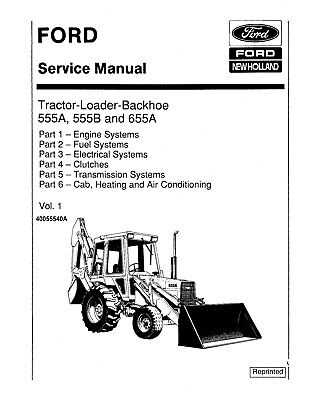

Understanding the Ford 555 Backhoe

Exploring the functionalities of a powerful digging machine reveals its intricate design and versatile applications. This equipment serves as a vital tool in construction and excavation, facilitating various tasks with ease. Knowing how these machines operate can enhance their efficiency and longevity.

Equipped with multiple attachments, this unit excels in tasks such as trenching, lifting, and loading. Understanding the specific components that contribute to its operation is crucial for effective maintenance. Knowledge of the machine’s layout and mechanisms ensures that operators can troubleshoot issues and perform necessary repairs.

Additionally, familiarity with each element allows users to optimize performance based on the demands of different projects. From the hydraulic systems to the operational controls, each part plays a significant role in the overall functionality of the machine. Investing time in learning about these aspects can lead to enhanced productivity and reduced downtime.

Key Components of the Backhoe

Understanding the essential elements of this versatile machinery is crucial for efficient operation and maintenance. Each component plays a vital role in enhancing performance, enabling tasks such as digging, lifting, and loading with ease.

The primary structure includes the chassis, which provides stability and supports various attachments. The hydraulic system is fundamental, as it powers the boom and bucket, facilitating precise movements. The operator’s cabin is designed for comfort and visibility, ensuring effective control during operation.

Additionally, the digging implement, consisting of the bucket and arm, is engineered for versatility in various terrains. The stabilizers contribute to balance when performing heavy lifting tasks, while the tires or tracks offer mobility across different surfaces. Together, these elements create a cohesive unit capable of tackling numerous challenges on job sites.

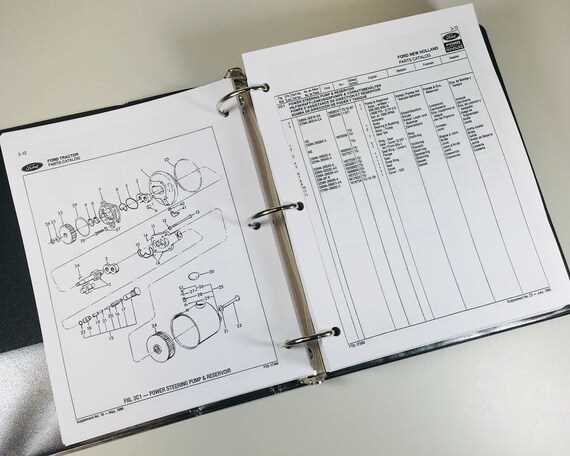

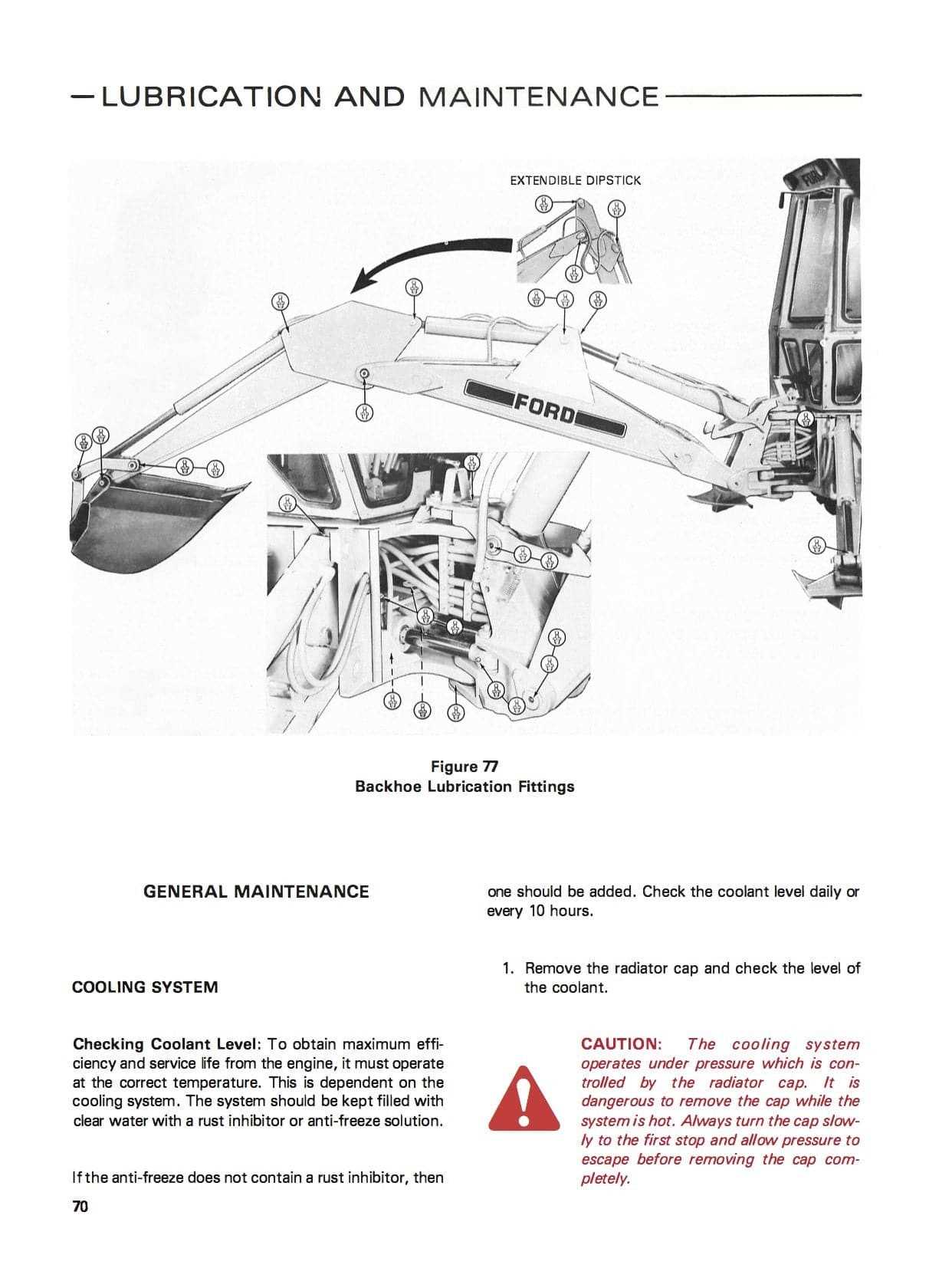

Importance of Accurate Parts Diagrams

Having precise illustrations for components is crucial for effective maintenance and repair. These visuals serve as a reference, ensuring that each element is correctly identified and understood.

- Facilitates easier troubleshooting

- Reduces the risk of misplacement or errors

- Enhances communication among technicians

- Saves time during repairs

Ultimately, accurate visual guides not only improve efficiency but also extend the lifespan of machinery through informed handling.

Common Issues with Ford 555 Parts

When working with heavy machinery, operators often encounter various challenges related to components and their performance. Understanding these common problems can help in identifying necessary repairs and maintaining optimal functionality.

Wear and Tear: One of the most frequent issues involves the gradual degradation of elements due to prolonged use. This can lead to decreased efficiency and may require timely replacement to prevent further damage.

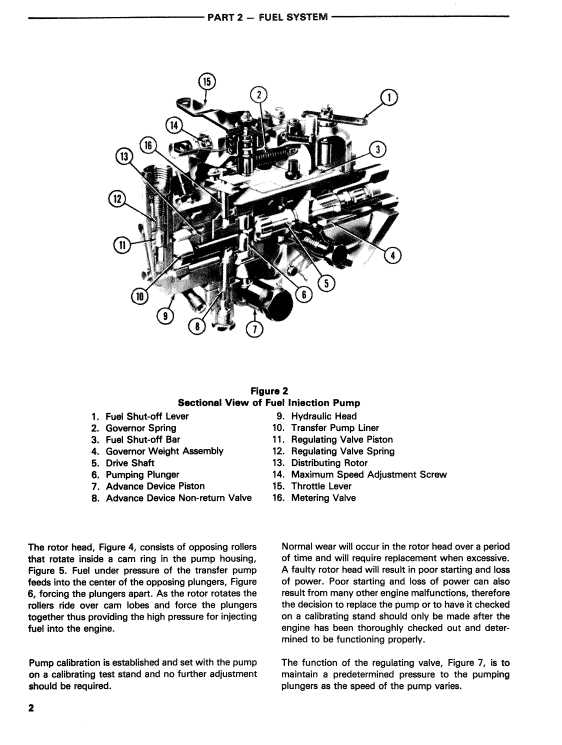

Hydraulic Leaks: Fluid leaks are a common concern, often stemming from worn seals or damaged hoses. Addressing these leaks promptly is essential to maintain hydraulic pressure and ensure the equipment operates smoothly.

Electrical Failures: Malfunctions in electrical systems can result in operational difficulties. Problems may arise from corroded connections, faulty wiring, or worn-out switches, necessitating thorough inspections and repairs.

Component Misalignment: Improper alignment of various parts can lead to increased wear and reduced performance. Regular checks and adjustments can help mitigate this issue and extend the life of the machinery.

Difficulty in Starting: Issues with ignition systems or fuel delivery can cause starting difficulties. Regular maintenance and timely troubleshooting are crucial in ensuring reliable operation.

Being aware of these potential challenges enables operators to take proactive measures, ensuring machinery remains in peak condition and minimizing downtime.

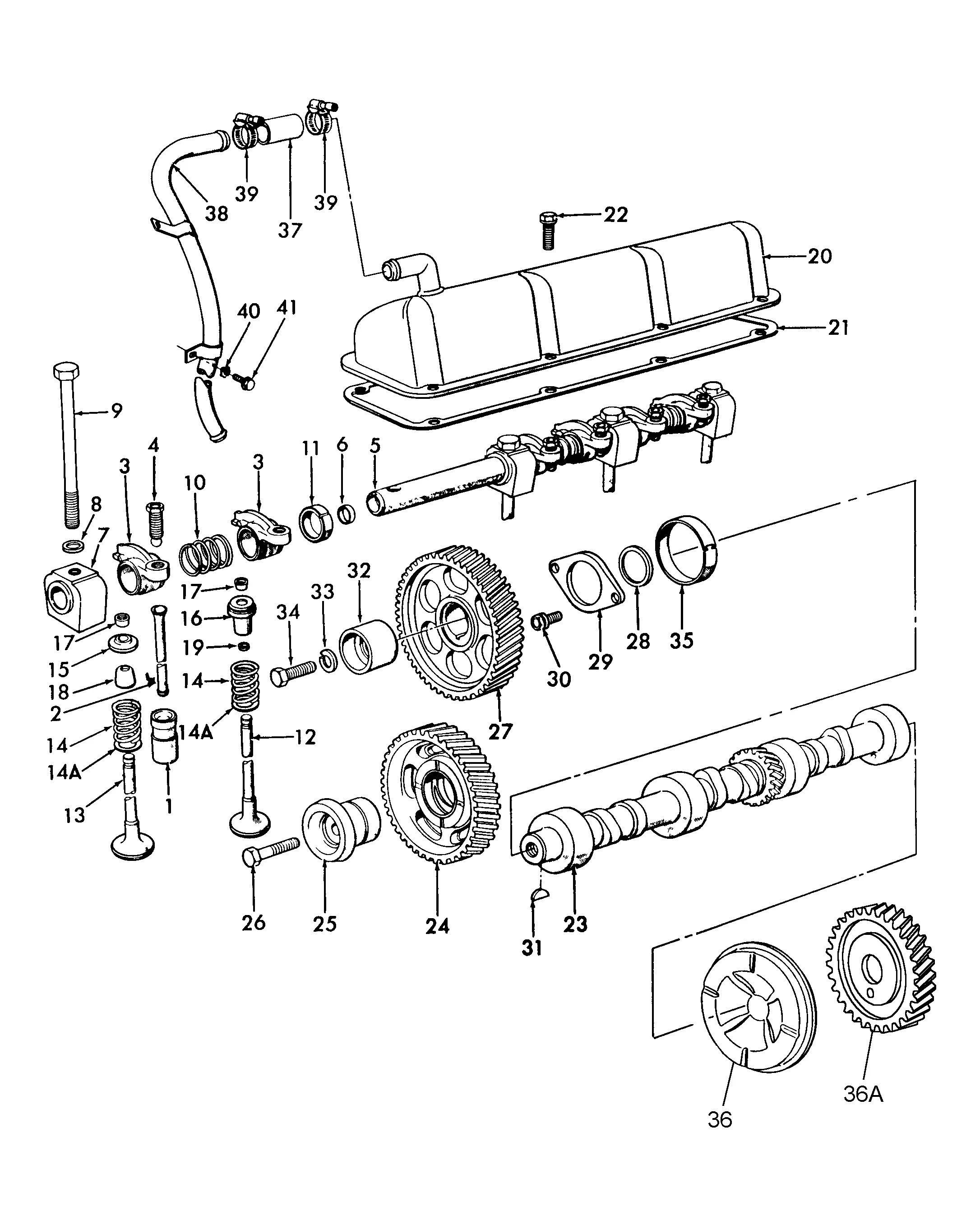

How to Read Parts Diagrams

Understanding schematic illustrations is essential for effective maintenance and repair tasks. These visual representations serve as a roadmap, guiding users through complex machinery and components. By interpreting these visuals accurately, one can identify each element’s function and its relationship to others in the system.

Familiarize yourself with the symbols: Each illustration typically employs specific symbols to represent different components. Knowing these symbols is crucial for quick reference. Often, a legend accompanies the illustration, providing clarity on what each symbol signifies.

Pay attention to the layout: The arrangement of elements in the illustration often reflects their physical positioning within the equipment. Understanding the layout helps in visualizing how parts interact during operation.

Cross-reference with manuals: Using these illustrations in conjunction with service manuals enhances comprehension. Manuals often provide additional context, specifications, and troubleshooting advice that can aid in effective repairs.

Highlight key components: As you study the illustration, it’s helpful to mark or note significant components that frequently require attention. This proactive approach ensures you’re always prepared for maintenance tasks.

Practice makes perfect: The more you engage with these visual aids, the more intuitive they become. Regularly reviewing various illustrations builds familiarity and confidence in navigating complex systems.

Finding Genuine Ford 555 Parts

When it comes to maintaining heavy machinery, ensuring the authenticity of components is crucial for optimal performance and longevity. Identifying the right sources for original pieces can significantly impact the efficiency and reliability of your equipment.

Here are some effective strategies to locate authentic components:

- Research authorized dealers who specialize in your machinery brand.

- Consult the manufacturer’s website for recommendations on trusted suppliers.

- Join online forums and communities dedicated to equipment enthusiasts for advice and leads.

- Check local equipment rental companies; they often have insights on reliable sources.

Additionally, always verify the part numbers and specifications to ensure compatibility. Engaging with certified technicians can also provide valuable guidance and assurance.

By following these steps, you can secure genuine components that will enhance the functionality and durability of your machinery.

Aftermarket vs. OEM Components

When it comes to maintaining heavy machinery, the choice between original equipment manufacturer (OEM) components and aftermarket alternatives can significantly impact performance and longevity. Each option presents unique advantages and potential drawbacks that users should carefully consider based on their specific needs and circumstances.

Advantages of OEM Components

OEM components are designed and produced by the original manufacturer, ensuring compatibility and reliability. They often come with warranties that provide peace of mind, knowing that these parts meet the exact specifications required for optimal functionality. This can lead to a lower likelihood of issues arising during operation, ultimately saving time and resources in the long run.

Benefits of Aftermarket Alternatives

Aftermarket alternatives can offer cost savings and flexibility, often providing similar or enhanced performance at a lower price. Many aftermarket manufacturers focus on improving upon original designs, potentially resulting in superior durability and efficiency. Additionally, a wider range of options can cater to specific customization needs, allowing users to tailor their machinery for specific tasks.

Maintenance Tips for Ford 555

Ensuring the longevity and performance of your construction equipment requires regular attention and care. By following a structured maintenance routine, you can avoid unexpected breakdowns and enhance the efficiency of your machinery.

Here are some essential maintenance tips:

- Regular Inspections: Conduct frequent visual checks for any signs of wear or damage. Pay attention to hydraulic hoses, connections, and any moving parts.

- Fluid Levels: Regularly monitor and change engine oil, hydraulic fluid, and coolant to maintain optimal performance.

- Filter Changes: Replace air, oil, and fuel filters as recommended by the manufacturer to ensure clean operation and prevent engine damage.

- Battery Care: Check battery terminals for corrosion and ensure a secure connection. Regularly inspect the battery charge and replace if necessary.

- Tire Maintenance: Keep tires properly inflated and inspect for any signs of wear or damage. Rotate tires as needed to ensure even wear.

Following these maintenance practices will not only improve your machine’s efficiency but also extend its operational lifespan, making it a reliable asset for your projects.

Tools Needed for Repairs

When undertaking maintenance or repairs on heavy machinery, having the right equipment is essential for efficiency and safety. Various instruments ensure that tasks are completed accurately, reducing the risk of errors and enhancing the longevity of the equipment.

Basic Tools

Start with essential hand tools, including wrenches, screwdrivers, and pliers. These instruments allow for straightforward adjustments and minor repairs, facilitating access to tight spaces and ensuring that components can be securely fastened or loosened as needed.

Advanced Equipment

For more complex tasks, consider specialized tools like hydraulic jacks, torque wrenches, and diagnostic devices. These tools help delve into intricate systems, allowing for precise repairs and effective troubleshooting, ultimately leading to a more reliable machine.

Upgrading Your Backhoe Parts

Enhancing the components of your excavation equipment can significantly boost its performance and longevity. By selecting superior elements, you not only improve efficiency but also ensure reliability in challenging environments. Upgrading can also lead to improved safety and comfort for the operator.

Benefits of Modern Components

Investing in contemporary replacements can lead to enhanced durability and functionality. Newer materials and technology often provide better resistance to wear and tear, resulting in fewer breakdowns. Ultimately, this translates to reduced maintenance costs and increased productivity.

Choosing the Right Upgrades

When considering enhancements, it’s essential to delve into your equipment’s specifications. Look for components that align with your operational needs and budget. Consulting with experts or reliable sources can guide you in selecting the most effective upgrades for optimal performance.

Resources for Parts Diagrams Online

Accessing comprehensive resources for machine schematics has become essential for effective maintenance and repairs. Numerous online platforms provide detailed visual aids, making it easier for users to identify components and understand assembly structures. These resources cater to various needs, whether for troubleshooting or replacement.

Online Databases

Several websites host extensive databases where users can find specific illustrations. These platforms often allow users to search by model or component type, ensuring accurate results for any machinery. Utilizing these databases can significantly streamline the repair process.

Community Forums

Engaging with online communities can yield invaluable insights. Many enthusiasts and professionals share their experiences and resources, including links to detailed visuals. Participating in these forums not only enhances knowledge but also connects users with like-minded individuals seeking similar information.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionalities. Whether you’re a seasoned operator or a newcomer, understanding these elements is crucial for effective maintenance and operation.

What should I consider when replacing components?

When selecting replacements, ensure compatibility with your specific model. It’s essential to check the manufacturer’s recommendations for quality and specifications to maintain optimal performance.

How can I identify the correct component for my machine?

Refer to the equipment’s service manual, which typically includes part numbers and descriptions. Additionally, consulting with a knowledgeable dealer can provide clarity on suitable options.

Are aftermarket components reliable?

Aftermarket options can vary in quality. It’s advisable to research brands and read reviews to find reputable manufacturers that offer durability and performance.

What is the best way to maintain components?

Regular inspections and timely servicing are key. Follow the maintenance schedule outlined in your manual and address any wear or damage promptly to avoid further complications.

Where can I find additional resources or support?

Online forums, manufacturer websites, and local suppliers are excellent resources for guidance and support. Engaging with community discussions can also enhance your understanding and troubleshooting skills.