In the world of fluid management systems, having a clear understanding of the individual elements that comprise these intricate machines is essential for efficient operation and maintenance. Each component plays a pivotal role in ensuring the overall functionality and longevity of the system.

As we explore the various sections of these mechanisms, we will uncover the significance of each part, shedding light on their interactions and the ultimate impact on performance. This knowledge is vital for both operators and technicians, enabling them to troubleshoot and optimize the equipment effectively.

Join us as we delve into the specifics of these essential features, highlighting their characteristics and providing insights that can enhance operational excellence. Understanding these components is not just beneficial; it is crucial for anyone involved in the industry.

Understanding Goulds J5S Pumps

This section explores the essential characteristics and functionality of a specific type of fluid transfer device, emphasizing its design and operational principles.

These units are designed for reliability and efficiency, making them suitable for various applications. Key features include:

- Robust construction for durability

- Effective fluid handling capabilities

- Ease of maintenance and repair

Understanding the components and their interactions is crucial for optimal performance. Here are the main aspects to consider:

- Performance specifications

- Common applications in industry

- Maintenance practices to enhance longevity

In-depth knowledge of these aspects leads to better operational decisions and ensures the ultimate efficiency of the equipment.

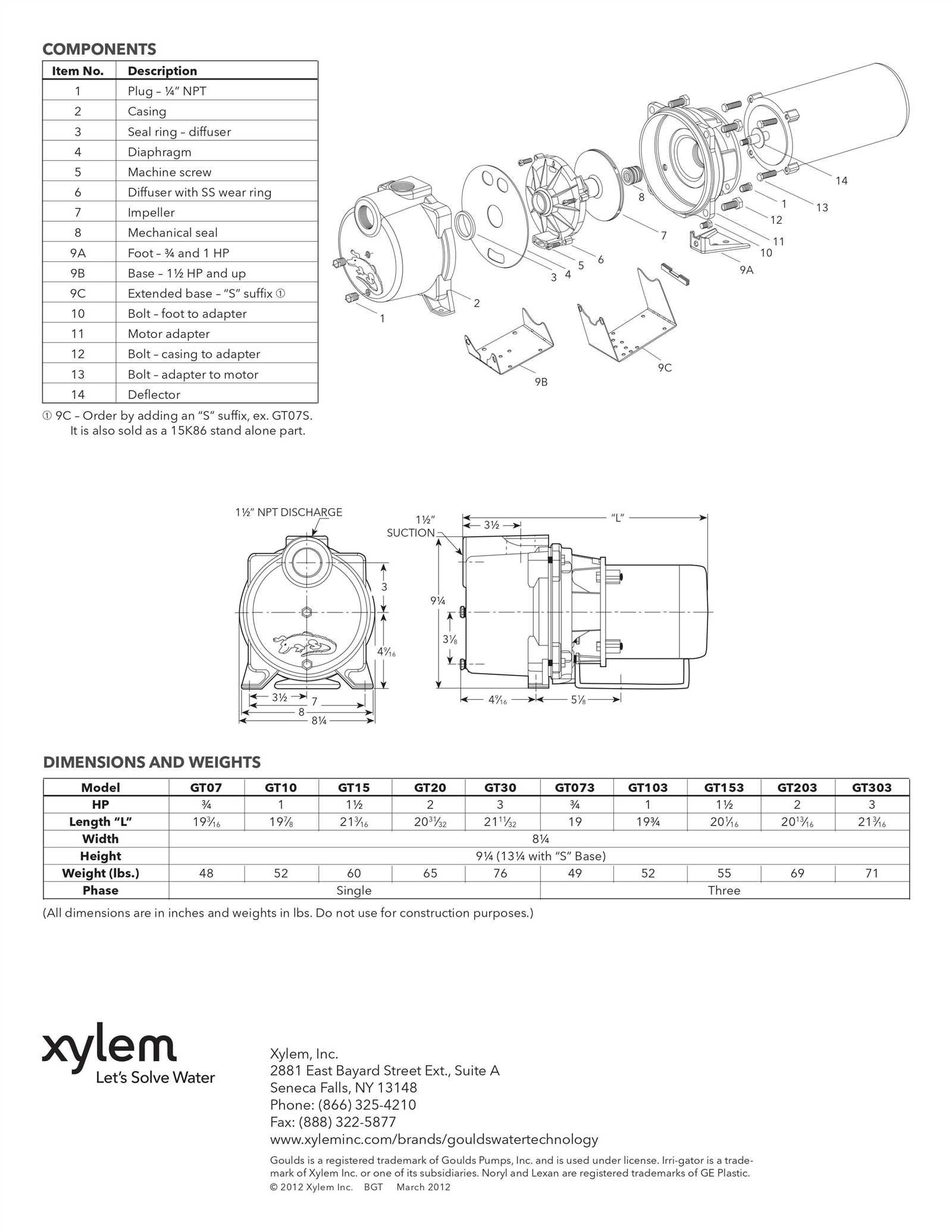

Key Components of J5S Models

The efficiency and functionality of these advanced systems rely heavily on their integral elements. Each component plays a crucial role in ensuring optimal performance, durability, and adaptability to various operational demands. Understanding these key elements is essential for effective maintenance and troubleshooting.

Main Functional Elements

At the core of the system are the primary operational units, designed to facilitate fluid movement and pressure regulation. These units are crafted for resilience and are capable of withstanding diverse environmental conditions, which is vital for long-term reliability. Their design is often optimized to enhance energy efficiency, making them suitable for both industrial and commercial applications.

Complementing the main units are several support mechanisms that enhance the overall functionality. These components include control systems and monitoring devices that ensure precise operation and safety. They provide valuable data insights, allowing for timely adjustments and maintenance, thereby extending the lifespan of the entire assembly.

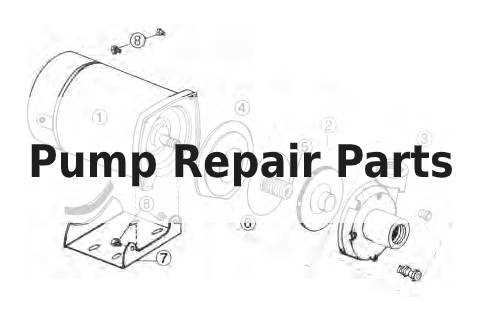

Importance of Parts Diagrams

Understanding the components of complex machinery is crucial for effective maintenance and troubleshooting. Visual representations serve as essential tools, allowing users to quickly identify and locate various elements within a system, thus streamlining repair processes and enhancing efficiency.

Enhancing Clarity

- Visual aids provide a clear overview of assemblies.

- Facilitate better communication among technicians.

- Reduce the risk of errors during maintenance.

Streamlining Maintenance

- Speed up identification of faulty components.

- Enable effective planning of repair actions.

- Support inventory management of necessary supplies.

How to Read the Diagram

Understanding a schematic can seem daunting at first, but with a structured approach, it becomes much clearer. These visual representations are designed to convey complex information in a simplified manner, enabling users to identify components and their interconnections.

Begin by familiarizing yourself with the symbols used; each icon represents a different element, and knowing these is crucial for interpretation. Next, locate the key or legend, which explains the meaning behind each symbol, providing essential context.

As you analyze the layout, trace the lines that connect various elements, as these indicate the flow of information or energy. Finally, pay attention to any annotations or notes included, as they often provide additional insights that enhance your understanding.

Common Issues with J5S Parts

When dealing with equipment components, various challenges can arise that affect performance and longevity. Identifying these common problems is essential for maintaining optimal functionality and ensuring efficient operation.

Frequent Problems Encountered

Several issues are often reported, including wear and tear, misalignment, and improper installation. Understanding these can help in troubleshooting and preventing further complications.

Table of Common Issues

| Issue | Description | Possible Solutions |

|---|---|---|

| Wear and Tear | Components may degrade over time due to constant use. | Regular inspections and timely replacements. |

| Misalignment | Parts may become misaligned, leading to inefficient operation. | Realignment and recalibration as needed. |

| Improper Installation | Incorrectly installed components can lead to malfunctions. | Review installation procedures and guidelines. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a proactive approach to maintenance. Regular inspections and timely interventions can significantly enhance performance and extend the lifespan of machinery. Implementing a consistent maintenance routine is essential for preventing costly breakdowns.

Regular Inspection

Frequent checks are vital for identifying potential issues before they escalate. Look for wear and tear, unusual noises, or leaks. Establish a schedule for inspections to ensure nothing is overlooked.

Proper Lubrication

Maintaining appropriate lubrication levels is crucial for reducing friction and wear. Use recommended lubricants and follow the manufacturer’s guidelines for application frequency.

| Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Lubrication | Monthly |

| Comprehensive Maintenance | Quarterly |

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process when you know where to look. There are several reliable sources that provide a wide variety of alternatives to keep your machinery running smoothly.

- Authorized Distributors: Check with certified dealers who specialize in the specific machinery brand.

- Online Retailers: Websites dedicated to industrial supplies often carry a comprehensive selection.

- Manufacturer’s Website: Visit the official site for direct access to original components and support.

- Local Supply Stores: Many physical stores offer essential equipment and can assist with special orders.

By exploring these options, you can ensure you have access to the right replacements when needed.

Upgrades for Enhanced Performance

Improving operational efficiency and reliability is crucial for maximizing the output of any fluid handling system. By implementing targeted enhancements, users can achieve significant performance gains, reduce maintenance needs, and extend the lifespan of the equipment. This section outlines various upgrades that can elevate the performance of your system, ensuring optimal functionality.

Key Enhancement Areas

Focus on several critical areas to achieve meaningful improvements:

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Efficiency Impellers | Replacements designed to reduce energy consumption and increase flow rates. | Lower operating costs and improved fluid dynamics. |

| Advanced Sealing Solutions | Upgraded seals that minimize leakage and enhance durability. | Reduced downtime and increased reliability. |

| Smart Monitoring Systems | Integration of sensors to provide real-time performance data. | Enhanced predictive maintenance and quicker troubleshooting. |

| Variable Frequency Drives (VFDs) | Control devices that adjust motor speed according to demand. | Energy savings and improved process control. |

Implementation Considerations

When planning for upgrades, assess compatibility with existing systems, potential disruptions during installation, and budget constraints. A strategic approach to enhancements can lead to improved performance and reliability in your fluid management operations.

Comparing J5S with Other Models

This section explores the distinctions and similarities among various pump systems, focusing on performance, efficiency, and design features. By understanding these differences, users can make informed decisions based on their specific needs.

Performance Metrics

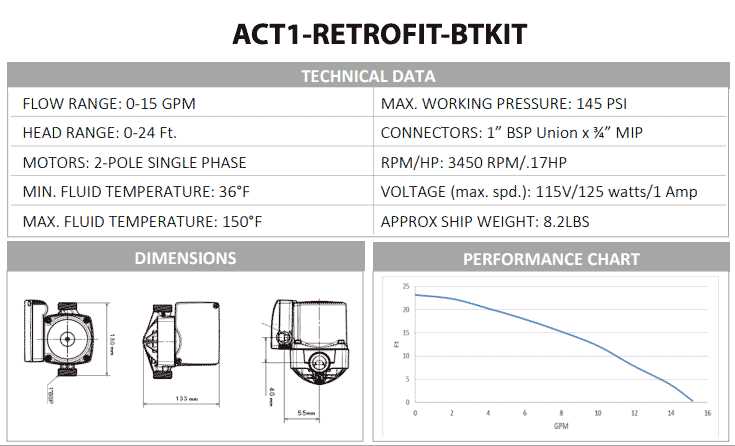

When evaluating different models, performance is a crucial aspect. Some systems offer higher flow rates, while others excel in pressure delivery. It’s essential to consider how these metrics align with the intended application.

Efficiency and Design

Efficiency is another vital factor, as it directly impacts operational costs. Models vary in design, influencing maintenance requirements and longevity. Opting for a model with a robust design can lead to significant savings over time, making it a wise investment.

Assembly Process Overview

The assembly process is a crucial stage in the manufacturing of equipment, ensuring that all components fit together seamlessly to create a fully operational unit. This overview outlines the key steps involved in the integration of various elements, emphasizing precision and attention to detail throughout the procedure.

Key Steps in the Assembly Procedure

Each stage of the assembly is vital for achieving optimal performance. The process typically involves the following phases:

| Step | Description |

|---|---|

| 1. Preparation | Gathering all necessary components and tools for efficient workflow. |

| 2. Assembly of Subunits | Connecting smaller sections together to form larger, functional assemblies. |

| 3. Integration | Combining all subunits into the final configuration, ensuring compatibility and alignment. |

| 4. Quality Check | Conducting inspections to verify that all parts meet specified standards and function correctly. |

| 5. Final Adjustments | Making necessary modifications to enhance performance and reliability. |

Importance of Precision

Attention to detail during the assembly process significantly impacts the overall quality and functionality of the finished product. Each component must be correctly positioned and securely attached to ensure longevity and optimal performance in real-world applications.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance work is essential to prevent accidents and injuries. Adopting appropriate measures protects both the technician and the equipment, fostering a secure environment for effective repairs. This section outlines vital guidelines to follow before and during the repair process.

Personal Protective Equipment

Wearing suitable personal protective gear is crucial. This includes gloves, goggles, and hard hats, which shield against potential hazards. Ensuring that all equipment is in good condition further enhances safety and reduces risks.

Proper Tools and Environment

Utilizing the correct tools is fundamental for efficient and safe repairs. Always inspect tools before use, and keep the workspace organized and free of clutter. A clean environment minimizes the likelihood of accidents, allowing for a focused approach to the task at hand.

Frequently Asked Questions on J5S

This section addresses common inquiries related to the specific model, focusing on operational aspects, maintenance, and troubleshooting. The goal is to provide clear and concise answers that enhance user understanding and ensure efficient use of the equipment.

Operational Queries

Users often seek clarification on the functionality and features of the equipment. Below are some typical questions:

| Question | Answer |

|---|---|

| What is the maximum flow rate of this model? | The maximum flow rate is typically specified in the product manual, varying based on the application and conditions. |

| Can it operate under extreme temperatures? | Yes, it is designed to function effectively within a specified temperature range; refer to the guidelines for exact limits. |

Maintenance and Troubleshooting

Regular upkeep is essential for optimal performance. Here are frequently asked questions regarding maintenance and potential issues:

| Question | Answer |

|---|---|

| How often should maintenance be performed? | It is recommended to perform maintenance checks at regular intervals, as detailed in the user manual. |

| What should I do if the unit fails to start? | First, check the power supply and ensure all connections are secure. If the issue persists, consult the troubleshooting guide. |