In the realm of mobility aids, an intricate understanding of the various elements involved is essential for ensuring seamless operation and maintenance. Each device is composed of numerous integral components, each serving a specific function that contributes to the overall effectiveness of the system.

Identifying these elements can enhance both user experience and longevity of the equipment. Familiarity with the structure allows for timely troubleshooting and efficient repairs, ultimately leading to improved accessibility for those who rely on such devices.

To fully delve into the mechanics behind these solutions, one must explore the assembly and configuration of each piece. This knowledge equips users, technicians, and caregivers with the ultimate tools for optimizing functionality and ensuring safety in daily use.

Understanding Harmar Lift Systems

This section explores the mechanisms designed to facilitate mobility for individuals facing challenges with movement. These systems play a crucial role in enhancing accessibility and independence, offering tailored solutions for various environments.

Key Components

- Structural framework

- Power supply unit

- Control interface

- Safety features

Benefits of These Mechanisms

- Enhanced accessibility in homes and public spaces

- Increased independence for users

- Improved safety measures for movement

- Customizable options for different needs

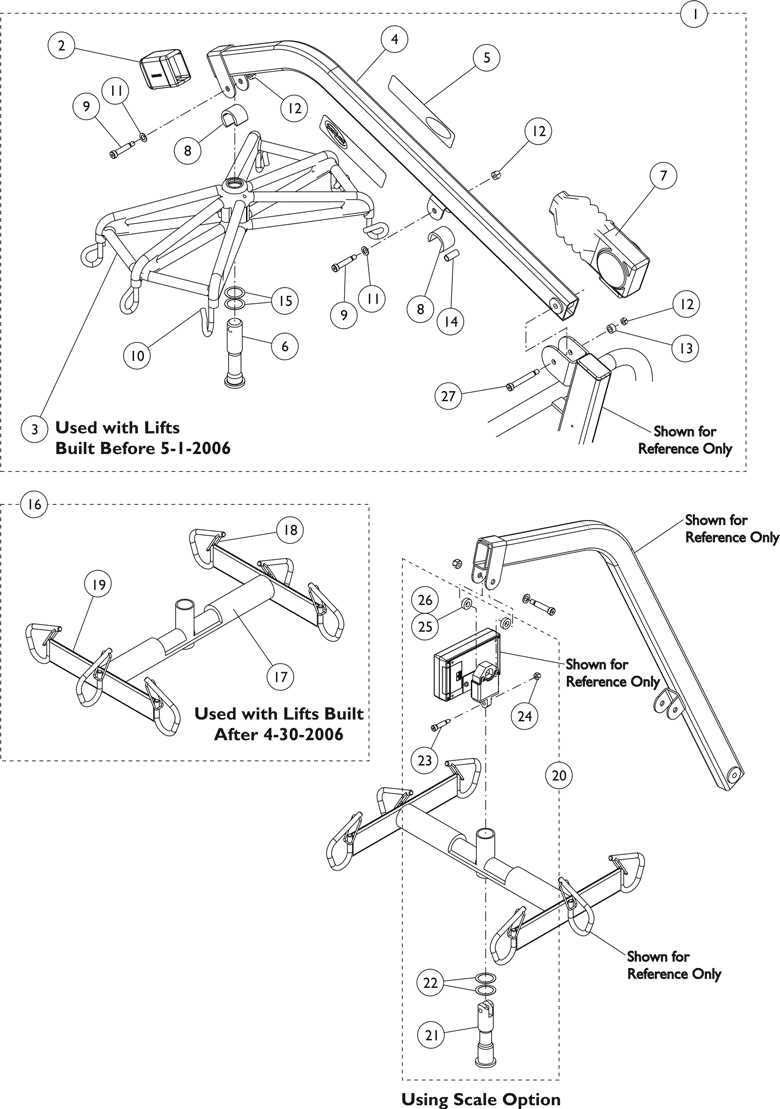

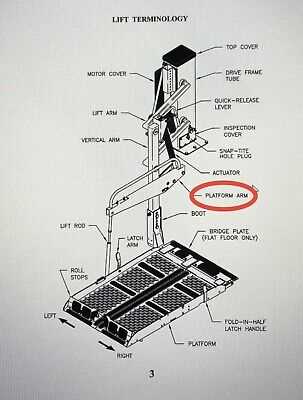

Key Components of Harmar Lifts

This section explores the essential elements that contribute to the functionality and safety of mobility solutions designed for accessibility. Understanding these components is vital for effective maintenance and optimal performance.

Core Mechanisms

These mechanisms play a crucial role in the operation of accessibility devices, ensuring smooth transitions and reliable service.

| Component | Description |

|---|---|

| Motor | Drives the movement, providing the necessary power for operation. |

| Control System | Enables users to operate the device with ease and safety. |

| Platform | Serves as the base, accommodating users comfortably during use. |

Safety Features

Safety is paramount in mobility solutions, incorporating various features to protect users during operation.

| Feature | Function |

|---|---|

| Emergency Stop | Allows immediate cessation of movement in case of an emergency. |

| Weight Sensors | Ensure the safe capacity is not exceeded during use. |

| Guardrails | Provide support and prevent accidental falls. |

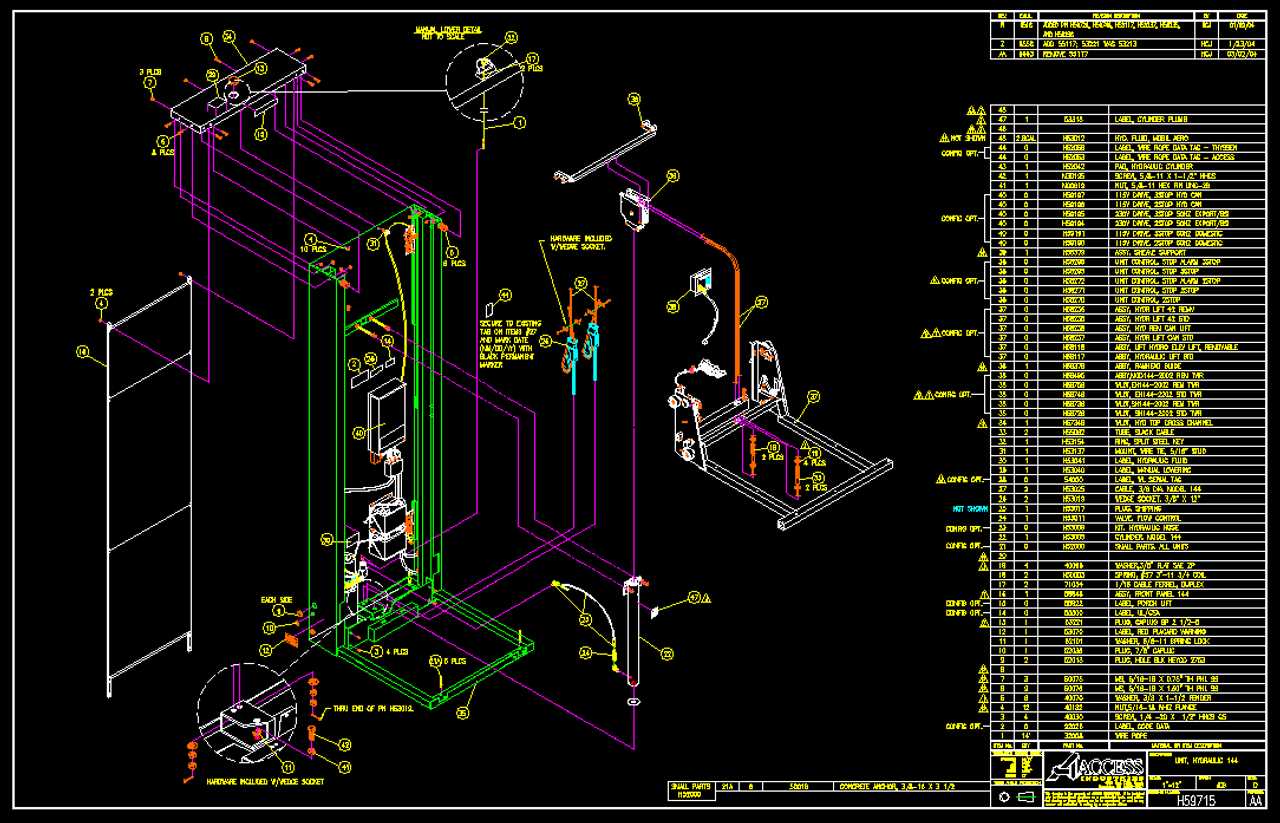

Importance of Diagrams for Maintenance

Visual representations play a crucial role in ensuring effective upkeep and repair processes. They serve as essential tools that enhance understanding and streamline complex procedures, ultimately leading to improved efficiency and safety in maintenance tasks.

Benefits of Visual Aids

- Clarity: Simplifies intricate systems, making them easier to comprehend.

- Precision: Helps technicians identify components and their functions accurately.

- Efficiency: Reduces time spent searching for information during repairs.

- Training: Assists in onboarding new personnel by providing clear reference points.

Enhancing Problem-Solving Skills

Utilizing visual guides enables maintenance teams to delve deeper into issues, allowing for quicker diagnosis and resolution. This ultimate understanding fosters confidence in handling unexpected challenges.

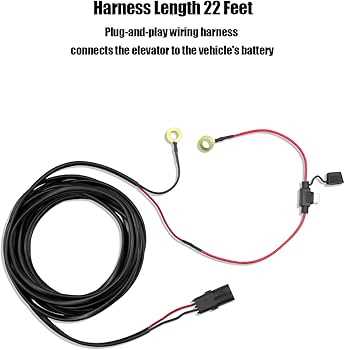

Common Issues with Lift Parts

Understanding the typical challenges associated with mobility solutions can greatly enhance their reliability and user experience. Many factors contribute to the functionality of these devices, and recognizing potential problems is crucial for maintenance and safety.

Frequent Malfunctions

Some of the most common malfunctions can stem from wear and tear, leading to inefficiencies or failures in operation. Regular inspections can help identify these issues early, ensuring smooth performance.

Maintenance Considerations

Proper upkeep is essential to avoid major setbacks. Neglecting maintenance can exacerbate minor issues, resulting in costly repairs and downtime.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Components may deteriorate over time, affecting function. | Regular inspections and timely replacements. |

| Electrical Failures | Malfunctions in wiring or connections can disrupt operation. | Check connections and replace faulty wiring. |

| Hydraulic Leaks | Fluid leaks can lead to pressure loss. | Inspect seals and hoses, and replace as necessary. |

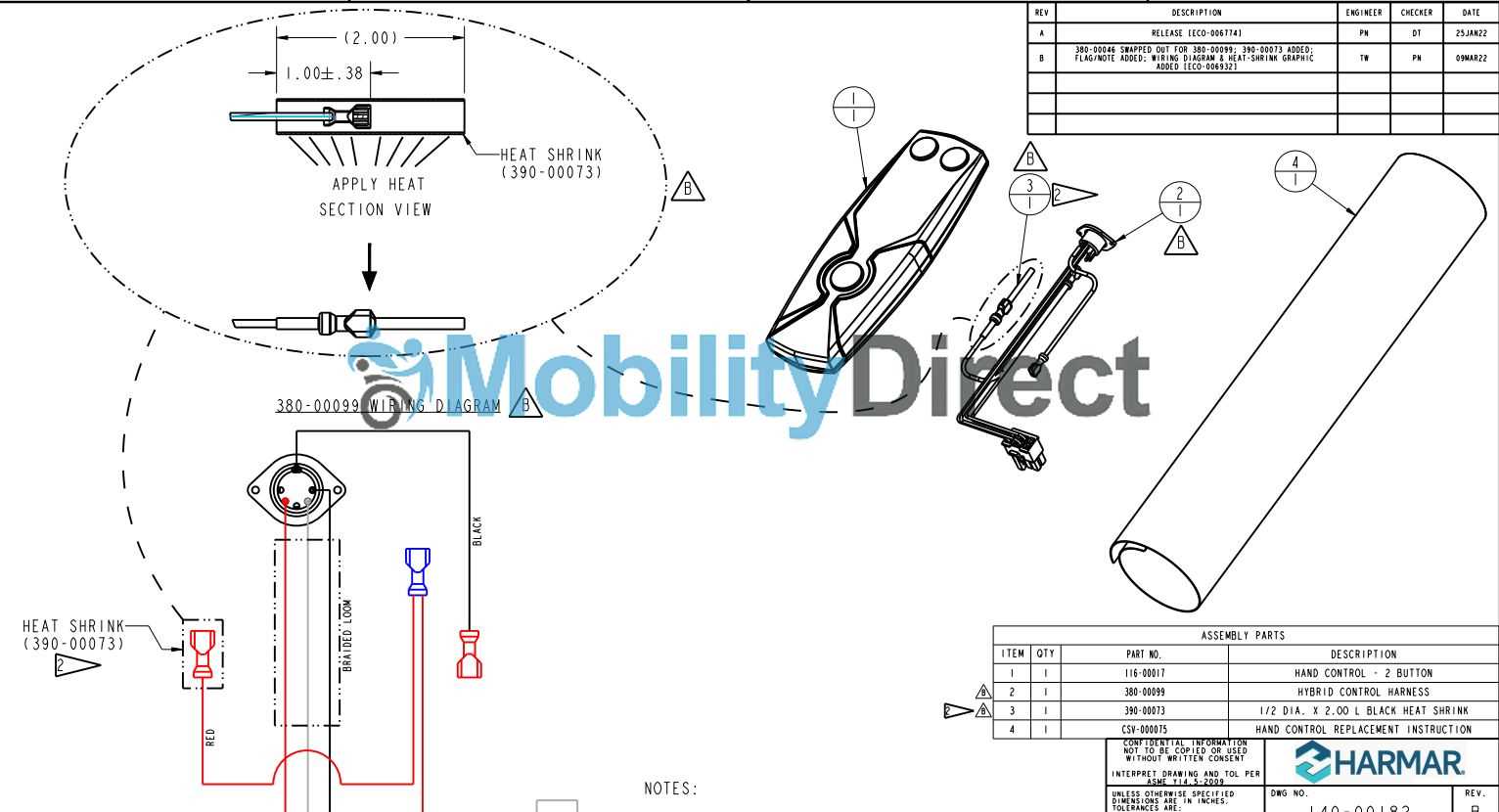

How to Interpret Lift Diagrams

Understanding the components and configurations of a mobility platform is essential for effective maintenance and troubleshooting. A well-structured visual representation can simplify the complexities involved, making it easier to identify specific elements and their relationships. By familiarizing yourself with the key features of these visuals, you can enhance your ability to work with the equipment effectively.

Key Elements to Recognize

When examining a schematic, several important aspects should be noted. Typically, these include symbols, labels, and connection lines that represent various elements and their interactions. Recognizing these components is crucial for accurate interpretation.

Understanding Symbols and Labels

Each symbol and label has a specific meaning that corresponds to the physical parts of the apparatus. Below is a simple guide to common elements you might encounter:

| Symbol | Description |

|---|---|

| Represents the main platform or surface area | |

| Indicates moving components | |

| Signifies electrical connections | |

| Represents adjustable settings or control mechanisms |

By mastering these elements, you can confidently navigate the schematic, ensuring effective service and repair of the equipment.

Finding Replacement Parts Easily

Locating suitable components for your mobility device can often feel like a daunting task. However, with the right approach and resources, the process can become significantly simpler. Understanding the various options available and leveraging the right tools can streamline your search, saving you time and effort.

Start with Identification: Before embarking on your quest, it’s crucial to identify the specific item you need. Familiarize yourself with the device’s model number and any relevant specifications. This foundational knowledge will guide you in sourcing the correct components.

Utilize Online Resources: The internet offers a wealth of information. Manufacturer websites, specialized retailers, and forums dedicated to mobility solutions can provide invaluable insights. Make use of online catalogs and search tools to filter results based on your requirements.

Connect with Experts: Engaging with professionals in the field can greatly enhance your chances of finding the right solution. Consider reaching out to technicians or customer service representatives who can offer tailored advice and may even help you locate hard-to-find items.

Explore Local Options: Don’t overlook local suppliers and repair shops. Often, these establishments have the components you need in stock or can order them for you. Building a relationship with local experts can also yield recommendations for reliable products.

Consider Compatibility: When searching for a replacement, ensure that the item is compatible with your existing setup. Review any documentation you have or consult with a professional to avoid purchasing the wrong component.

By following these steps and utilizing available resources, you can enhance your ability to find the necessary items efficiently, ensuring your mobility equipment remains functional and reliable.

Safety Precautions for Lift Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines not only protects the technician but also ensures the longevity and proper functioning of the equipment. It’s vital to be aware of potential hazards and implement measures to mitigate risks during repair work.

Personal Protective Equipment

Using appropriate personal protective equipment (PPE) is essential. This includes hard hats, gloves, and safety goggles to safeguard against falling objects and sharp components. Regularly inspect your gear to ensure it is in good condition and suitable for the job at hand.

Proper Lockout/Tagout Procedures

Implementing lockout/tagout procedures is vital before beginning any repair work. This ensures that all energy sources are deactivated, preventing accidental operation of the machinery. Always verify that the equipment is completely shut down and secure to avoid unforeseen accidents.

Benefits of Regular Maintenance Checks

Routine inspections and upkeep play a crucial role in ensuring the longevity and efficiency of various systems. These proactive measures not only enhance performance but also contribute to safety and reliability in everyday operations.

- Increased Lifespan: Regular evaluations can significantly extend the operational life of equipment, reducing the need for premature replacements.

- Enhanced Safety: Frequent checks help identify potential hazards, minimizing the risk of accidents and ensuring the safety of users.

- Cost Savings: Early detection of issues often leads to simpler and less expensive repairs, ultimately saving money in the long run.

- Improved Efficiency: Well-maintained systems operate more smoothly and efficiently, leading to better performance and productivity.

- Compliance: Adhering to maintenance schedules ensures compliance with industry regulations and standards, preventing potential legal issues.

In summary, investing time in regular maintenance checks is a proactive strategy that brings numerous advantages, fostering a safer and more efficient environment.

Comparing Harmar Models and Features

When exploring various options in mobility solutions, it’s essential to evaluate the distinct models available and their unique attributes. Each variant is designed with specific functionalities that cater to diverse needs, offering a range of benefits suited for different environments and user requirements.

One model emphasizes compact design, making it ideal for limited spaces, while another showcases enhanced weight capacity for greater stability. Additionally, features such as ease of installation and user-friendly controls significantly influence the overall experience. Users should consider which aspects align most closely with their personal preferences and mobility needs.

Moreover, safety mechanisms and durability are critical components that vary between models. Some options incorporate advanced technology for added security, whereas others focus on robust construction to withstand frequent use. By analyzing these differences, individuals can make informed choices that lead to improved accessibility and independence.

DIY vs. Professional Repair Services

When faced with the need for repairs, individuals often grapple with the decision of tackling the job themselves or seeking external expertise. Each option presents its own set of advantages and challenges that can significantly impact both the outcome and the overall experience.

Benefits of DIY

Taking on repairs independently can foster a sense of accomplishment and save money. Enthusiasts often appreciate the chance to learn new skills and delve deeper into understanding how systems operate. However, this approach requires careful planning and the right tools to ensure a successful outcome.

Advantages of Professional Help

Engaging a specialist guarantees expertise and efficiency, as these professionals are trained to handle specific issues effectively. They can provide ultimate peace of mind, knowing that repairs are conducted according to industry standards. Nonetheless, this option usually comes at a higher financial cost.

Resources for Lift Owner Support

For individuals seeking assistance with mobility solutions, having access to reliable resources is essential. Whether you require technical guidance, maintenance tips, or troubleshooting advice, a variety of options are available to ensure optimal performance and safety.

Online Forums and Communities

Engaging with online communities can provide valuable insights and shared experiences from fellow owners. These platforms often feature discussions on common issues and solutions, enabling users to learn from one another.

Manufacturer Websites

Most manufacturers offer extensive resources on their official websites. This includes user manuals, maintenance schedules, and frequently asked questions, which can serve as a comprehensive guide for proper usage and care.

Customer Support Services

Reaching out to customer support can be beneficial for personalized assistance. Many companies provide dedicated helplines and email support, ensuring that you receive expert advice tailored to your specific needs.

Local Service Providers

Finding local technicians or service providers is another effective way to maintain your mobility solution. Professional services can offer routine check-ups and repairs, ensuring that your equipment remains in top condition.

Instructional Videos

Video tutorials available on platforms like YouTube can be incredibly helpful. These visual guides often demonstrate common maintenance tasks and troubleshooting steps, making complex processes easier to understand.

By utilizing these resources, owners can enhance their understanding and management of their mobility equipment, leading to a safer and more efficient experience.