The intricacies of agricultural machinery often require a closer examination to ensure optimal performance. In this section, we will explore the essential elements that contribute to the functionality of these vital tools. By grasping how various components interact, operators can maintain efficiency and extend the lifespan of their equipment.

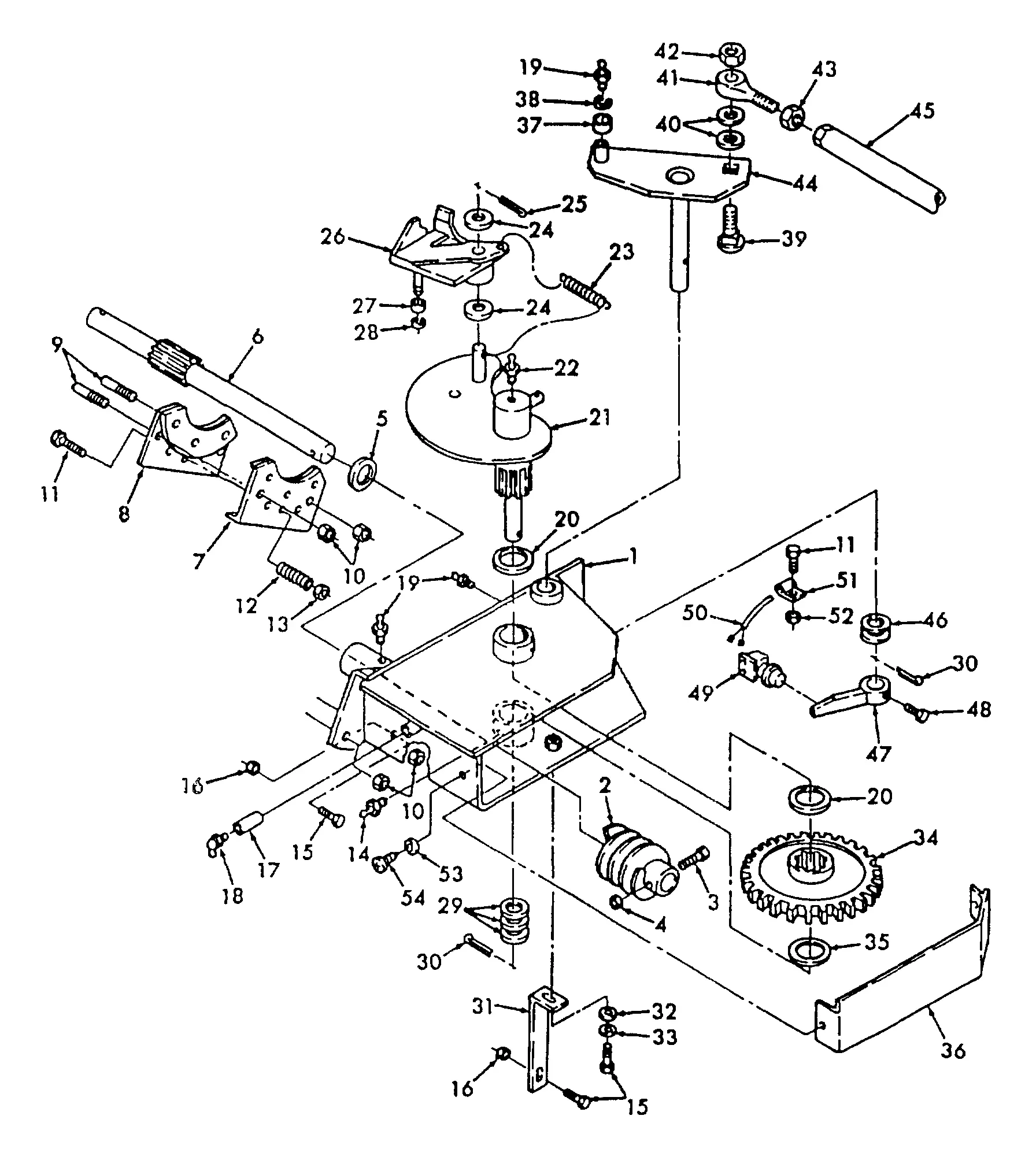

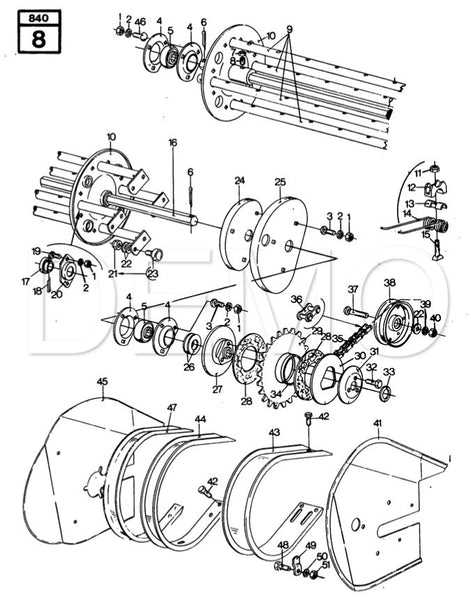

Detailed visual representations play a crucial role in identifying and understanding the assembly of each unit. Such illustrations facilitate a comprehensive understanding of how individual parts fit together and function collectively. This knowledge empowers users to perform maintenance and repairs effectively, enhancing their operational capabilities.

Moreover, delving into the specifics of these mechanical systems unveils the ultimate potential of agricultural machinery. Equipped with the right insights, users can make informed decisions that lead to improved productivity and reduced downtime. Thus, mastering the layout and relationships between different elements becomes essential for anyone involved in the agricultural sector.

Understanding Hesston 565A Machinery

This section provides an overview of a specific type of agricultural equipment designed for efficiency and reliability in fieldwork. Understanding the components and their functions is crucial for optimal performance and maintenance.

Key features of this machinery include:

- Advanced design for improved productivity.

- Durable materials ensuring longevity and resilience.

- Enhanced functionality for various agricultural tasks.

To fully grasp the workings of this equipment, it’s essential to familiarize yourself with its main elements:

- Drive System: This mechanism powers the machine, converting energy into motion.

- Cutting Assembly: Responsible for efficient harvesting and processing of crops.

- Feeding Mechanism: Ensures a smooth intake of materials, maximizing output.

- Control Panel: Allows the operator to manage settings and monitor performance.

Maintenance tips for ensuring longevity include:

- Regular inspection of moving parts for wear and tear.

- Lubrication of components to reduce friction.

- Prompt replacement of damaged parts to avoid further issues.

By understanding these aspects, operators can enhance the functionality and lifespan of their agricultural machinery, leading to better performance in the field.

Key Components of the Hesston 565A

This section explores the essential elements that contribute to the functionality and efficiency of the machine. Understanding these vital parts allows for improved maintenance and optimal performance, ensuring longevity and reliability in operation.

Main Functional Elements

Among the critical components, the drive system plays a pivotal role, providing the necessary power for operation. Coupled with the cutting mechanism, which efficiently processes materials, these elements work in harmony to deliver outstanding results.

Supporting Parts

Equally important are the auxiliary components, including the control systems and safety features, which enhance user experience and ensure safe operation. Regular checks on these parts are vital for maintaining overall functionality.

| Component | Function |

|---|---|

| Drive System | Supplies power for operation |

| Cutting Mechanism | Processes materials efficiently |

| Control Systems | Manage operation and performance |

| Safety Features | Ensure user protection |

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers significant advantages in maintenance and repair processes. These illustrations serve as essential tools for understanding complex assemblies, ensuring that technicians can efficiently identify and locate each element required for service tasks.

Enhanced Clarity and Understanding

One of the primary benefits of these visual guides is the clarity they provide. By depicting each individual piece and its relationship to other elements, users can easily grasp the overall structure. This clarity reduces confusion, allowing for quicker troubleshooting and effective decision-making.

Improved Efficiency in Repairs

Incorporating visual references can drastically streamline the repair process. Technicians can quickly pinpoint the necessary components without wasting time searching through manuals or databases. Moreover, this efficiency leads to reduced downtime, ensuring that equipment can return to operation as soon as possible.

In summary, visual representations play a crucial role in enhancing understanding and efficiency in maintenance tasks. Their clear depiction of components not only aids in effective troubleshooting but also contributes to quicker repairs and overall operational productivity.

How to Interpret Parts Diagrams

Understanding visual schematics is crucial for effective maintenance and repair. These illustrations provide essential information about individual components and their interconnections, allowing users to identify necessary replacements or troubleshoot issues efficiently.

Key Elements of Visual Schematics

- Labels: Each element is typically marked with a unique identifier, making it easier to reference parts in manuals or order systems.

- Connections: Lines and arrows indicate how various components interact, providing insight into assembly and disassembly processes.

- Views: Diagrams may offer multiple perspectives, such as top-down or side views, to enhance understanding of spatial relationships.

Steps to Effectively Read Schematics

- Familiarize Yourself: Take time to understand the symbols and notations used in the illustration.

- Identify Key Components: Locate major elements and their identifiers to understand the overall structure.

- Follow Connections: Trace lines between parts to grasp how they work together.

- Refer to Manuals: Use accompanying documentation for additional details and specifications.

Common Issues with Hesston 565A Parts

When working with agricultural machinery, certain challenges may arise that can affect performance and efficiency. Identifying these problems early can prevent costly repairs and downtime. Below are some typical complications encountered with these specific components.

Frequent Complications

- Wear and Tear: Over time, regular usage can lead to deterioration of various components, causing malfunctions.

- Improper Installation: Incorrect assembly can result in misalignment and inefficiency, leading to further complications.

- Corrosion: Exposure to moisture and harsh conditions may lead to rust and degradation of metal parts.

Maintenance Challenges

- Regular Inspection: Failing to perform routine checks can allow minor issues to escalate into significant failures.

- Part Compatibility: Using incompatible components can disrupt the functionality of the machine.

- Lubrication Problems: Insufficient lubrication can lead to overheating and increased friction among moving parts.

Addressing these issues promptly can enhance the longevity and efficiency of agricultural equipment, ensuring optimal performance in the field.

Where to Find Replacement Parts

When seeking components for agricultural machinery, it is essential to know the best sources to ensure efficiency and reliability. Numerous options exist, ranging from authorized dealers to online marketplaces that specialize in farm equipment.

Authorized Dealers are often the most reliable choice, providing genuine items that guarantee compatibility and performance. These establishments typically have extensive knowledge and can assist with any inquiries regarding the machinery.

Online Marketplaces offer a vast selection and competitive pricing. Websites dedicated to agricultural supplies frequently list new and refurbished options, making it easier to find specific components. Always check reviews and seller ratings to ensure quality before making a purchase.

Local Salvage Yards can also be a treasure trove for those looking for cost-effective solutions. These places often have a variety of equipment from which to salvage usable elements, making them a practical choice for budget-conscious buyers.

Lastly, Manufacturer Websites provide a direct source for ordering components. Many manufacturers have online catalogs and support systems that simplify the ordering process and offer additional guidance.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring maximum efficiency and longevity of machinery. By following specific guidelines, operators can enhance functionality and prevent unexpected breakdowns.

Routine Inspections

- Check all components for wear and tear.

- Inspect belts and hoses for signs of damage.

- Ensure lubricants are at appropriate levels.

Cleaning Practices

- Remove debris from the machine after each use.

- Clean filters regularly to maintain airflow.

- Wash exterior surfaces to prevent rust and corrosion.

Comparing Hesston Models and Parts

This section aims to explore the various models and their corresponding components, highlighting the similarities and differences that define their performance and usability. Understanding the nuances of these machines can assist users in making informed choices, optimizing their operations, and ensuring compatibility when seeking replacements or upgrades.

Model Characteristics

Each machine comes with distinct features tailored for specific tasks. Some designs prioritize efficiency and speed, while others emphasize durability and ease of maintenance. Analyzing these characteristics provides valuable insights into which models may be better suited for particular agricultural needs.

Component Compatibility

When it comes to replacements or enhancements, recognizing which elements can be interchanged is crucial. Compatibility across various models can streamline the maintenance process and reduce downtime, allowing operators to focus more on productivity rather than logistics.

Expert Recommendations for Repairs

When addressing maintenance issues, it is crucial to follow guidelines that ensure both efficiency and safety. By adhering to expert advice, you can enhance the longevity of your machinery while minimizing downtime. Knowledge of common failures and their solutions is paramount for effective upkeep.

Thorough Assessment: Before initiating any repair work, conduct a comprehensive evaluation of the equipment. Identify the symptoms and investigate potential underlying causes. This step is essential to prevent overlooking critical issues.

Utilize Quality Components: Always opt for high-quality replacement materials. Using subpar parts may lead to recurring problems and could compromise the overall functionality of the machine.

Follow Manufacturer Guidelines: Refer to the manufacturer’s specifications for repair procedures and part replacements. This ensures that the work aligns with the ultimate design intent and operational standards.

Engage Professionals: If the repair seems complex, consider enlisting the help of trained technicians. Their expertise can provide insights that are invaluable for effective resolutions.

Regular Maintenance: Implementing a routine maintenance schedule can significantly reduce the likelihood of unexpected breakdowns. Regular check-ups will allow you to catch potential issues early and address them promptly.

Safety Precautions During Maintenance

Ensuring safety during servicing is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the maintenance but also safeguard the equipment and surrounding personnel. Adhering to established guidelines can significantly reduce the risk of mishaps.

General Guidelines

Before beginning any maintenance task, it’s essential to familiarize yourself with the machinery and its operational requirements. Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots. Ensure the equipment is powered down and locked out to prevent unexpected start-ups.

Emergency Procedures

In case of an emergency, it is vital to know the procedures for addressing potential hazards. Establish clear communication methods and ensure that all personnel are aware of emergency exits and first aid stations.

| Safety Measure | Description |

|---|---|

| Lockout/Tagout | Implement procedures to prevent equipment from being accidentally energized during maintenance. |

| Proper Ventilation | Ensure adequate airflow to minimize exposure to harmful fumes or dust. |

| Training | All personnel should receive training on safety protocols relevant to the equipment. |

Resources for Hesston Owners

Owning agricultural machinery can be both rewarding and challenging. Access to the right information and support is essential for effective maintenance and operation. This section aims to provide valuable resources for owners looking to enhance their experience with their equipment.

Manufacturer’s Manuals: Comprehensive guides often include troubleshooting tips, maintenance schedules, and operational advice. These documents are vital for understanding the intricacies of your machine.

Online Forums: Engaging with fellow enthusiasts through dedicated online communities can offer practical insights and solutions. Sharing experiences can lead to improved performance and longevity of your machinery.

Local Dealers: Establishing a relationship with authorized distributors ensures access to quality parts and expert advice. They can assist with specific inquiries and provide tailored recommendations.

Workshops and Training Sessions: Participating in educational opportunities enhances your skills and knowledge. Hands-on experience can be invaluable for both new and seasoned owners.

Repair Guides: Numerous online resources and publications offer step-by-step instructions for common repairs and maintenance tasks. These can empower you to tackle issues independently, saving time and money.

Utilizing these resources can significantly improve the efficiency and reliability of your agricultural equipment, ensuring it meets your operational needs effectively.