In the realm of agricultural equipment, understanding the various elements that contribute to its functionality is crucial for maintenance and repair. Each piece plays a vital role in ensuring that machinery operates efficiently and effectively, helping farmers achieve optimal productivity.

Having a clear representation of these elements not only aids in identifying parts but also enhances the ability to troubleshoot issues that may arise during usage. Knowledge of the intricate relationships between different components fosters a better understanding of how machinery works as a whole.

By delving into the specifics of component arrangements, users can empower themselves to perform maintenance tasks with confidence. This insight ultimately leads to improved performance and longevity of the equipment, which is essential for those relying on machinery for their agricultural endeavors.

Overview of Parts and Components

This section provides a comprehensive look at the various elements and constituents that make up the machinery. Understanding these components is essential for effective maintenance and troubleshooting. Each part plays a critical role in the overall functionality and performance of the equipment.

The following table outlines the key components, their functions, and their respective specifications:

| Component Name | Description | Specifications |

|---|---|---|

| Transmission System | Facilitates power transfer from the engine to the wheels. | Various gear ratios available |

| Engine Block | The main structure housing the engine components. | Aluminum or cast iron |

| Hydraulic System | Controls the lifting and lowering mechanisms. | Capacity of 200 liters |

| Chassis | The frame that supports all other components. | Steel construction for durability |

| Fuel System | Supplies fuel to the engine for operation. | Compatibility with various fuel types |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in understanding the complexities of mechanical systems. They serve as essential tools for both technicians and engineers, providing clarity and enabling effective maintenance and repair procedures. Without accurate representations, the risk of misinterpretation and errors increases significantly, leading to potential inefficiencies and increased costs.

Benefits of Reliable Illustrations

- Enhances comprehension of intricate structures.

- Facilitates troubleshooting by clearly showing components.

- Improves communication among team members.

- Reduces the likelihood of costly mistakes during repairs.

Key Considerations for Effective Illustrations

- Ensure clarity and detail to depict every element accurately.

- Regularly update illustrations to reflect design changes.

- Incorporate standardized symbols for universal understanding.

- Utilize high-quality materials for physical copies to prevent wear and tear.

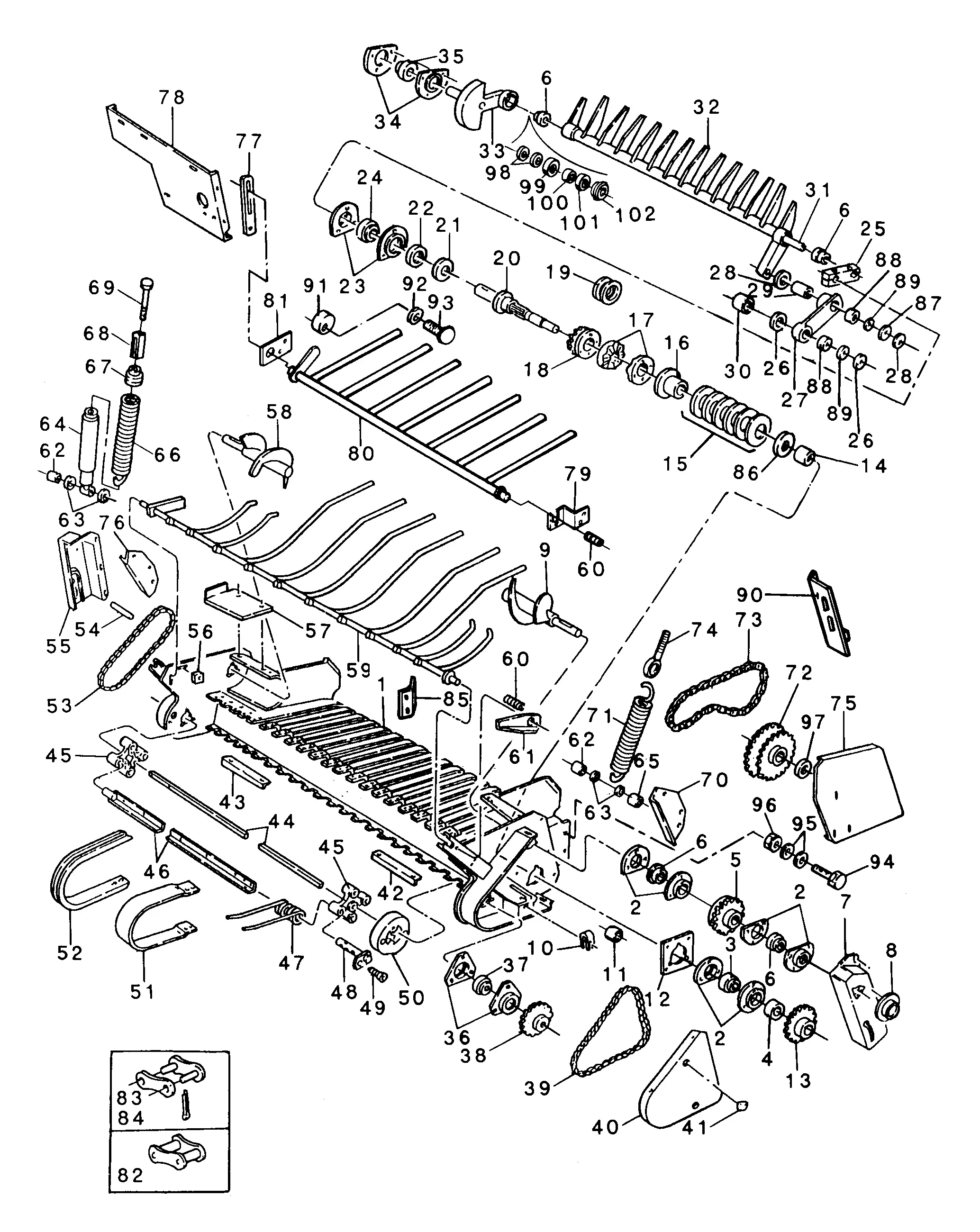

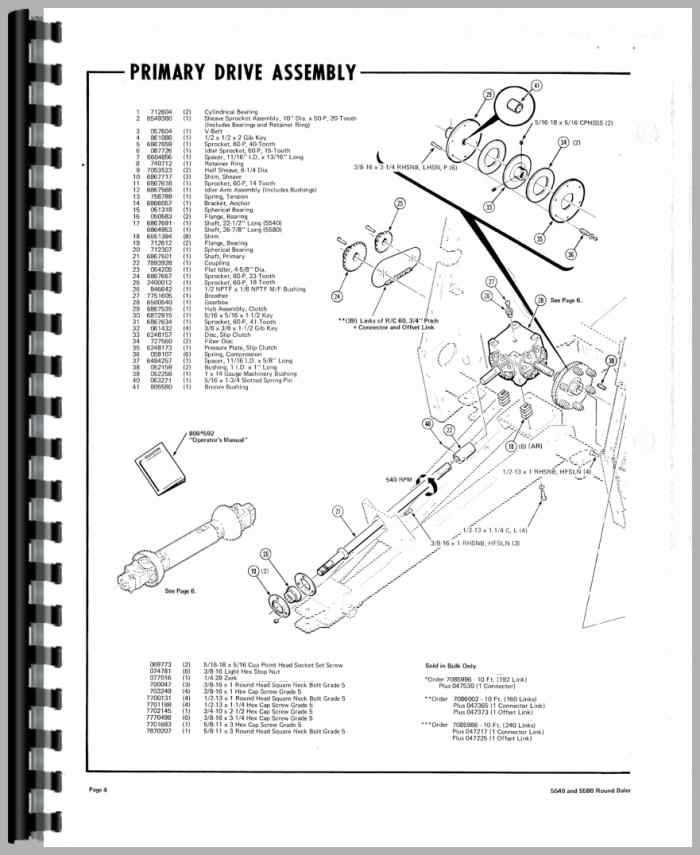

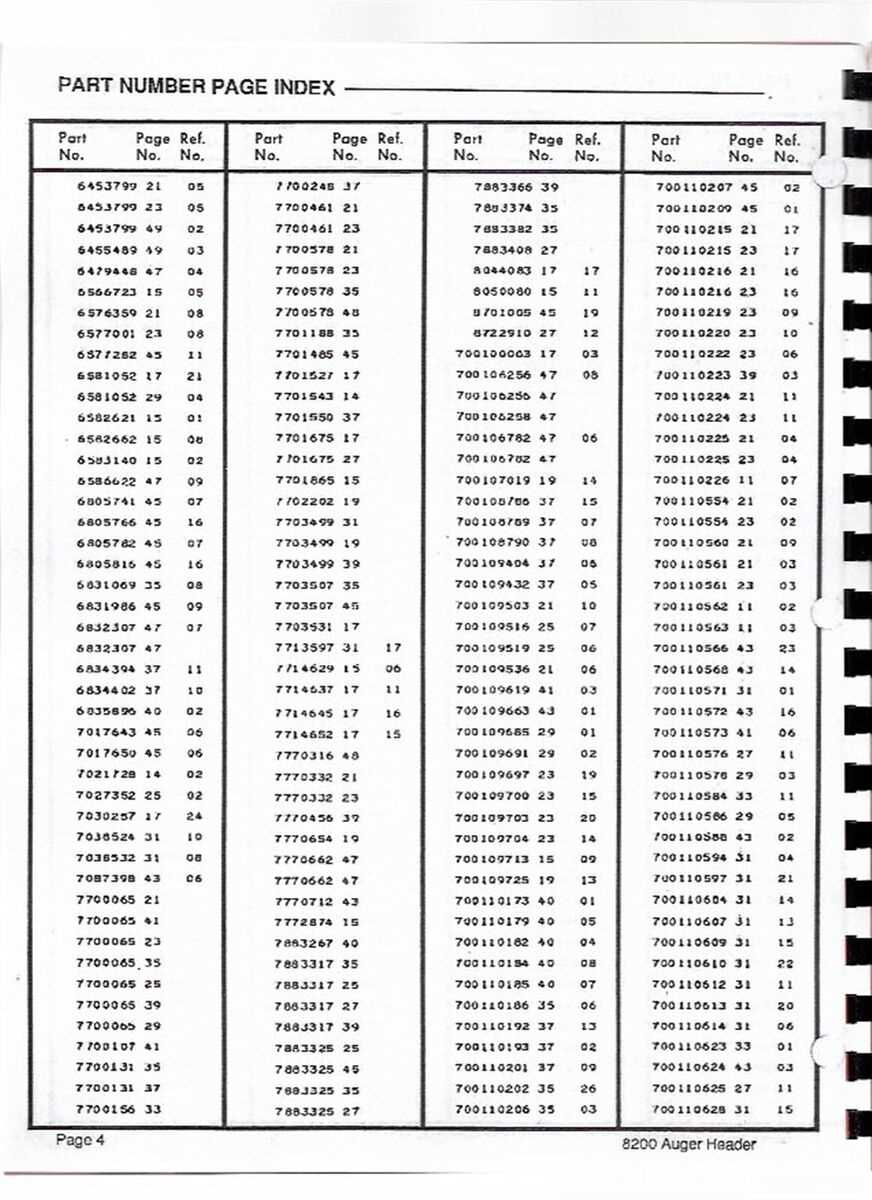

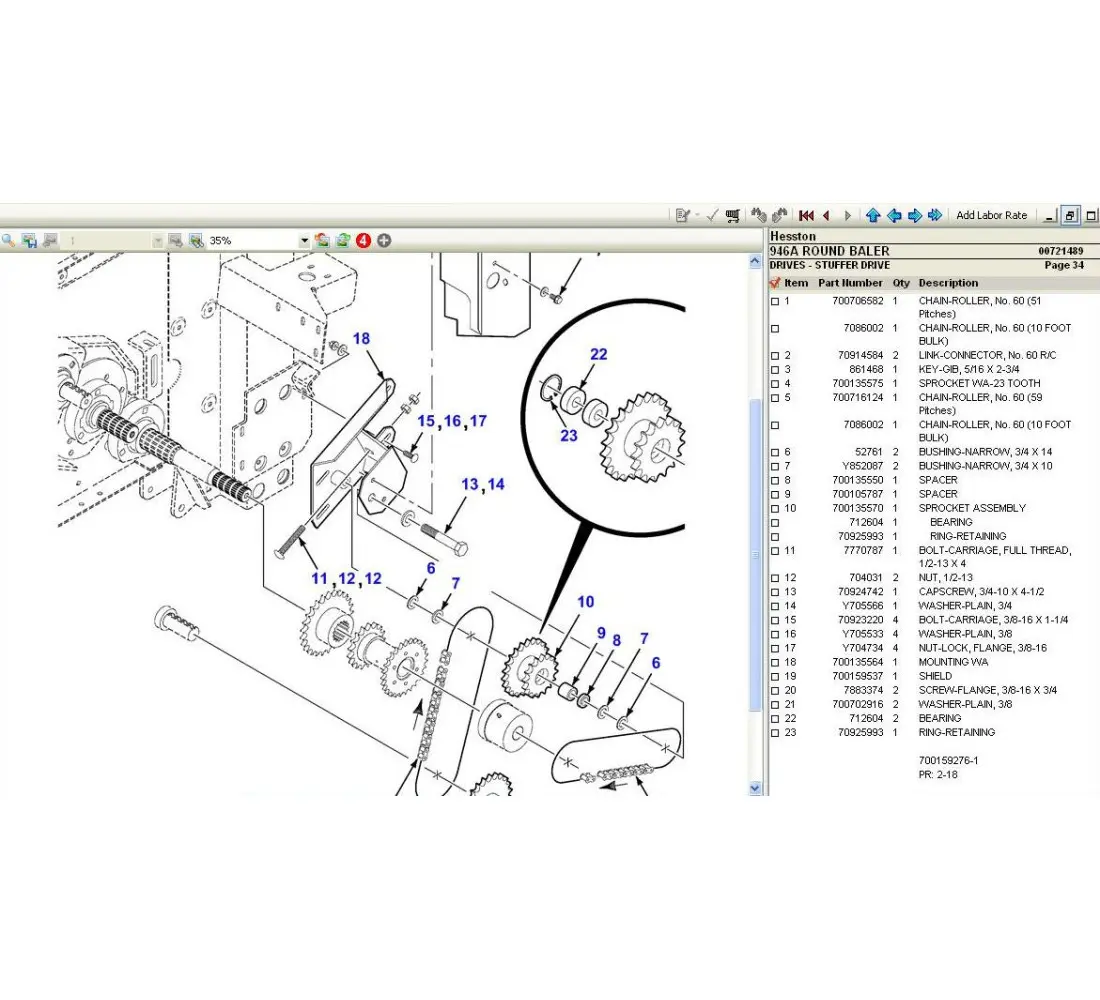

Identifying Key Parts in the Diagram

Understanding the essential components in a visual representation can significantly enhance the efficiency of any maintenance or repair task. This section will guide you through the process of recognizing crucial elements that contribute to the overall functionality of the machinery.

| Component Name | Description | Function |

|---|---|---|

| Drive Shaft | The central rod that transmits power. | Transfers rotational energy to other parts. |

| Gearbox | A mechanical unit that changes speed and torque. | Adjusts the output speed and power for optimal performance. |

| Hydraulic Cylinder | A device that converts fluid pressure into linear motion. | Enables lifting and lowering actions within the system. |

| Control Panel | The interface for operating the machinery. | Allows the user to monitor and adjust settings easily. |

Common Issues with Hesston 8200

In the realm of agricultural machinery, certain challenges frequently arise that can affect the overall performance and efficiency of the equipment. Understanding these issues is crucial for maintaining optimal functionality and ensuring a long lifespan.

One prevalent concern is mechanical wear, which can lead to reduced effectiveness and increased maintenance requirements. Regular inspections and timely replacements of worn components are essential to mitigate this problem.

Another common issue is electrical failures, which can disrupt operations and cause unexpected downtime. Ensuring proper connections and routine electrical system checks can help prevent these disruptions.

Additionally, hydraulic system leaks are often encountered, leading to decreased performance and potential damage. Addressing leaks promptly and maintaining fluid levels are vital for the proper functioning of hydraulic systems.

By being aware of these frequent challenges and taking proactive measures, operators can enhance the reliability and efficiency of their machinery.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of any machinery. By following a few fundamental guidelines, operators can extend the lifespan of their equipment and reduce the likelihood of costly repairs. This section outlines key practices that contribute to long-term performance and reliability.

Routine Inspections

Conducting regular assessments is crucial. Checking for wear and tear on critical components helps identify potential issues before they escalate. Look for signs of damage or abnormal wear during inspections, and address any concerns promptly to maintain optimal functionality.

Proper Lubrication

Lubricating moving parts is vital to minimize friction and prevent premature wear. Using the recommended type and amount of lubricant can significantly enhance performance. Regularly check lubricant levels and replace any that appears contaminated or degraded.

| Maintenance Activity | Frequency | Notes |

|---|---|---|

| Inspect wear components | Monthly | Look for cracks or signs of excessive wear. |

| Change lubricants | Every 100 hours of operation | Use manufacturer-recommended lubricants. |

| Clean air filters | Every 50 hours of operation | Ensure optimal airflow and performance. |

How to Read Parts Diagrams

Understanding assembly illustrations is essential for effective maintenance and repair of machinery. These visuals provide a comprehensive overview of components, allowing users to identify and locate various elements within a system. Grasping how to interpret these illustrations can significantly enhance the efficiency of your repair processes.

Familiarizing with Symbols

Each illustration typically features specific symbols that represent different components. Recognizing these symbols is crucial for quickly identifying what each part does. Pay attention to the legend or key often included alongside the illustration, as it will clarify what each symbol signifies.

Identifying Relationships

In addition to individual components, these visuals also depict how elements interact with one another. Understanding the connections and relationships among parts helps in comprehending the overall functionality of the system. Take note of any lines or arrows indicating movement or alignment, as these are vital for accurate assembly or disassembly.

Essential Tools for Repairs

When it comes to maintaining and fixing agricultural machinery, having the right set of tools is crucial. Proper equipment not only enhances efficiency but also ensures that repairs are conducted safely and effectively. Whether you are a professional mechanic or a DIY enthusiast, understanding which tools are indispensable for your tasks can make all the difference.

Basic Hand Tools

Wrenches, screwdrivers, and pliers are the cornerstone of any repair kit. These fundamental implements enable users to tighten, loosen, and manipulate various components with precision. Selecting high-quality hand tools is essential, as they provide durability and reliability over time.

Power Tools for Efficiency

In addition to hand tools, power tools such as drills and impact wrenches significantly speed up the repair process. These devices reduce manual labor and allow for more complex tasks to be accomplished with less effort. Investing in a good power tool set can greatly enhance your ability to tackle any maintenance project.

Replacement Parts: Where to Buy

Finding quality components for your machinery can greatly enhance its performance and longevity. When looking for reliable suppliers, it’s essential to consider a variety of sources that offer both new and refurbished options.

Online Retailers: Numerous online platforms specialize in selling machine components. These websites often provide detailed descriptions and images to help you make informed choices. Always check customer reviews and ratings to ensure reliability.

Local Distributors: Visiting local distributors can be advantageous, as they may offer personalized service and immediate availability. Establishing a good relationship with these suppliers can lead to discounts and insider information about upcoming sales.

Manufacturer Contacts: Reaching out directly to manufacturers can yield genuine components and often includes warranty benefits. They can guide you to authorized dealers or help you source specific items not commonly found elsewhere.

Auctions and Second-Hand Sales: Keep an eye on auction sites and marketplaces where used equipment is sold. While caution is necessary, these platforms can provide valuable deals on high-quality items.

By exploring these various avenues, you can secure the components needed to maintain and improve your machinery effectively.

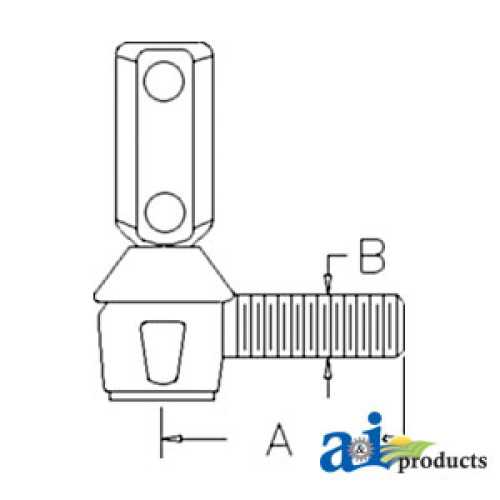

Understanding Parts Compatibility

Ensuring the correct fit of components is crucial for maintaining optimal performance in machinery. Compatibility among various elements guarantees seamless operation and minimizes the risk of malfunctions. This section highlights the significance of selecting appropriate replacements to enhance functionality and longevity.

When assessing compatibility, it’s essential to consider several factors, including dimensions, materials, and intended usage. A thorough understanding of these aspects aids in making informed decisions that align with specific operational requirements.

| Factor | Description |

|---|---|

| Dimensions | Measurements of the component that ensure a proper fit within the assembly. |

| Materials | Substances from which the component is made, affecting durability and performance. |

| Intended Usage | The specific function the component serves in the overall system, influencing selection criteria. |

By focusing on these critical aspects, users can confidently select suitable replacements that support the effective operation of their equipment.

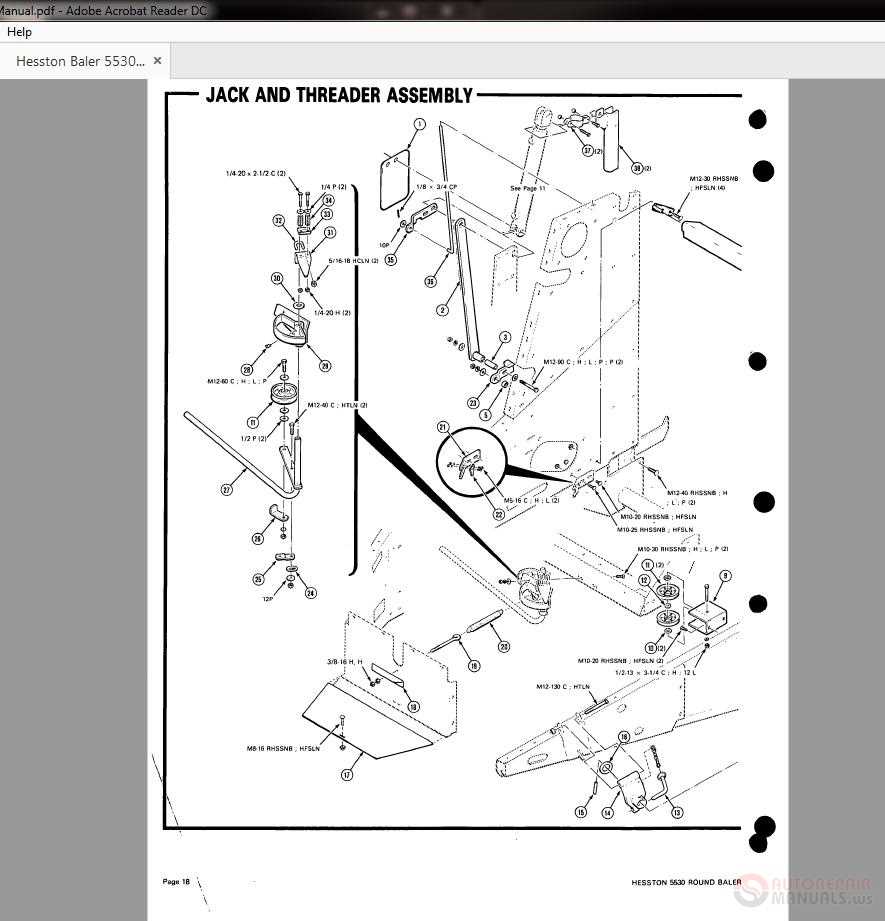

Visual Guide to Assembly

This section provides a comprehensive overview of the assembly process for various components. A clear understanding of each element’s role can enhance efficiency and accuracy during the construction phase.

Step-by-Step Overview: Begin by organizing all necessary components, ensuring each item is easily accessible. This will streamline the process and minimize delays. Each piece plays a vital role in achieving a well-functioning assembly.

Visual Representation: Utilizing diagrams or illustrations can significantly aid in comprehending the assembly layout. Visual aids can help identify where each part fits within the overall structure, making it easier to follow the assembly instructions.

Key Considerations: Always refer to the accompanying documentation for specific details on assembly techniques. Pay attention to the orientation of each component, as improper alignment can lead to complications down the line. Proper tools and equipment are essential for ensuring a secure fit.

By following this visual guide, you can navigate the assembly process with greater confidence and efficiency, leading to a successful and streamlined construction experience.

Frequently Asked Questions

This section aims to address common inquiries related to the various components and their configurations for agricultural machinery. Understanding these elements can help users enhance their maintenance and operational efficiency.

General Inquiries

- What are the main components of this equipment?

The essential elements include various mechanical and electronic parts that work together to ensure smooth functionality. Familiarizing yourself with these parts can improve your overall experience.

- How can I identify specific components?

Many users find it helpful to consult reference materials that illustrate the arrangements and functions of different elements. These resources can provide clarity on what each piece does.

Maintenance and Replacement

- What should I do if a part fails?

In case of a malfunction, it’s advisable to examine the user manual for guidance on troubleshooting and replacement procedures. Seeking assistance from a qualified technician is also recommended.

- How often should I perform maintenance?

Regular maintenance checks are crucial. It’s suggested to inspect the machinery after every significant use and adhere to the recommended service schedule outlined in your user documentation.