When it comes to small engines, comprehending the arrangement and functionality of various components is essential for effective maintenance and repair. A clear representation of these elements can greatly enhance one’s ability to troubleshoot issues, perform upgrades, or replace worn-out parts. Having a visual guide aids in grasping the interconnections and operational roles of each element within the system.

In this section, we will explore a detailed visual reference that showcases the essential components of a specific engine model. This reference not only serves as a helpful tool for mechanics and enthusiasts but also offers insights into the engineering behind the design. By familiarizing oneself with the layout, users can ensure a smoother operation and longer lifespan of the equipment.

Understanding the configuration of engine elements allows for better decision-making when it comes to repairs and modifications. Whether you are a seasoned technician or a novice hobbyist, having access to such resources can significantly improve your skill set and confidence in handling mechanical tasks. Dive into the intricacies of engine layouts and empower yourself with knowledge for future projects.

Understanding Honda GXV120 Components

In the realm of small engine mechanics, a comprehensive grasp of each element’s function is vital for optimal performance and maintenance. This knowledge not only enhances efficiency but also aids in troubleshooting potential issues. Familiarity with the various components empowers users to make informed decisions when it comes to repairs and upgrades.

Key Elements of Engine Design

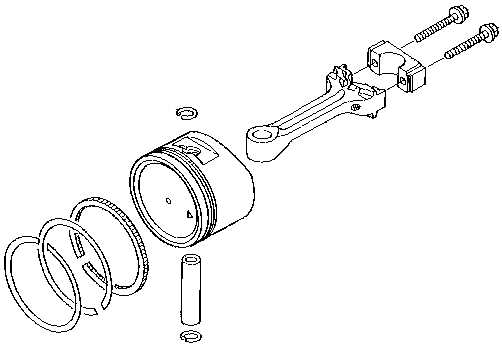

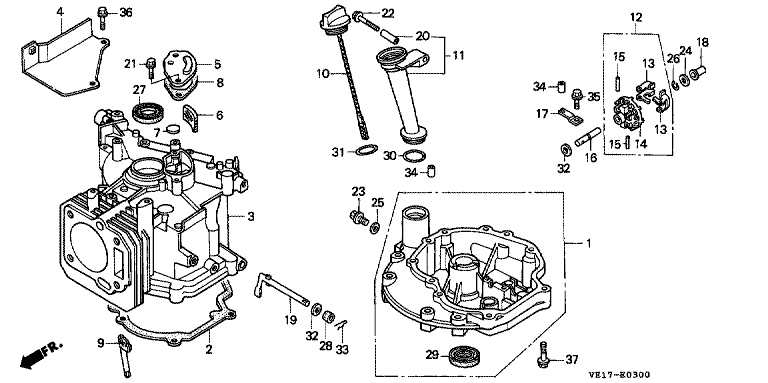

Every engine comprises several essential elements, each playing a distinct role in its overall operation. For instance, the cylinder serves as the core area where fuel combustion occurs, while the crankshaft converts linear motion into rotational power. Understanding how these parts interact is crucial for diagnosing problems and ensuring longevity.

Importance of Maintenance

Regular upkeep of engine components is imperative to maintain performance and reliability. Lubrication of moving parts reduces friction and wear, while periodic inspections can identify wear and tear before they lead to serious malfunctions. Knowing the specific needs of each part aids in establishing a consistent maintenance routine.

Importance of Parts Diagrams

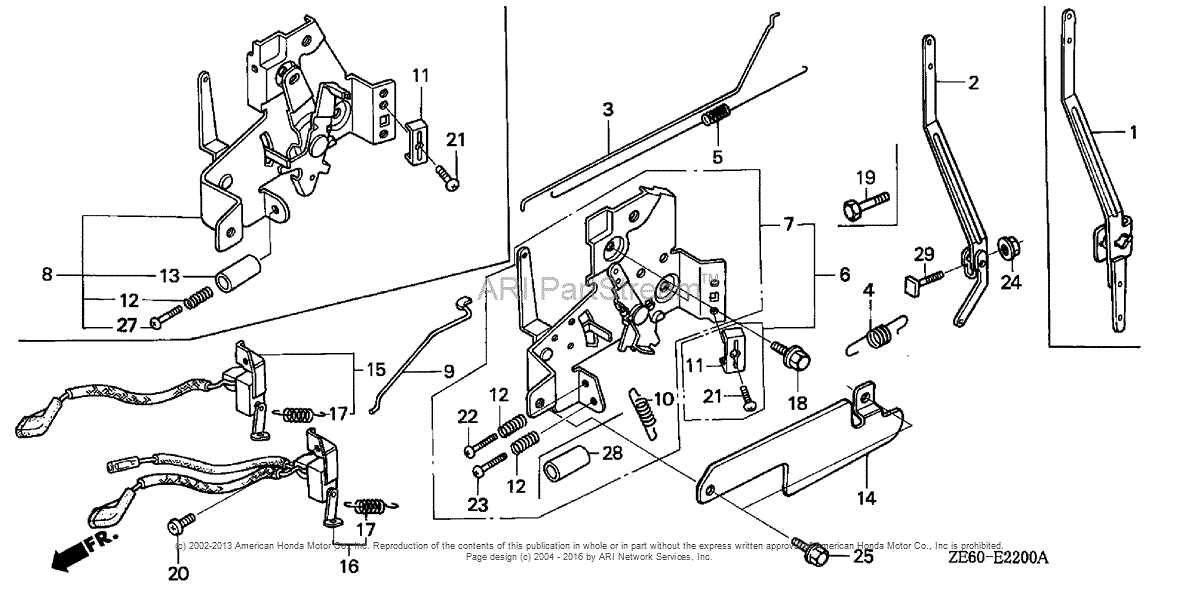

Visual representations of components play a crucial role in the maintenance and assembly of machinery. They provide a clear overview of individual elements, making it easier to identify, replace, or repair specific parts. Understanding these illustrations enhances efficiency and accuracy in any mechanical work.

Enhancing Understanding

These visual aids offer an intuitive grasp of how different elements fit together. By examining the layout, users can quickly familiarize themselves with the structure, streamlining the troubleshooting process.

Facilitating Maintenance

Clear depictions significantly simplify routine upkeep and repairs. With accurate visuals, technicians can easily locate necessary components, ensuring timely service and reducing downtime.

| Benefit | Description |

|---|---|

| Clarity | Helps in understanding complex assemblies. |

| Efficiency | Reduces time spent on repairs and replacements. |

| Accuracy | Minimizes errors in assembly and disassembly. |

Common Issues with GXV120 Engines

Engines of this type can experience various problems that may affect their performance and longevity. Understanding these common issues can help in timely maintenance and repairs, ensuring optimal operation.

- Starting Problems:

- Faulty spark plug

- Clogged air filter

- Fuel delivery issues

- Overheating:

- Insufficient coolant

- Blocked radiator

- Worn-out thermostat

- Noisy Operation:

- Loose components

- Worn bearings

- Improper lubrication

- Performance Loss:

- Dirty fuel injectors

- Worn piston rings

- Exhaust system blockages

Regular inspections and maintenance can mitigate these issues and prolong the engine’s life.

Identifying Key Parts and Functions

Understanding the essential components and their roles within a small engine can significantly enhance performance and maintenance. Each element serves a unique purpose, contributing to the overall functionality and efficiency of the system. Recognizing these elements can aid in troubleshooting and repairs, ensuring optimal operation.

Major Components Overview

Among the critical elements, certain parts are fundamental to the engine’s operation. These components include the cylinder, carburetor, and ignition system, each fulfilling specific tasks that are vital for the engine’s performance.

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, converting fuel into mechanical energy. |

| Carburetor | Mixes air and fuel in the correct ratio for combustion. |

| Ignition System | Initiates the combustion process by igniting the fuel-air mixture. |

Supporting Elements

In addition to the main components, several supporting parts enhance performance and reliability. These include the cooling system, fuel tank, and exhaust, all of which play a crucial role in maintaining optimal operating conditions.

How to Use a Parts Diagram

Understanding an assembly visual can significantly enhance your repair and maintenance efforts. By utilizing this reference, you can identify components, streamline the ordering process, and ensure a smoother reassembly. This guide will help you navigate the visual effectively for optimal results.

Follow these steps to maximize your experience:

| Step | Description |

|---|---|

| 1 | Locate the specific section related to your device. |

| 2 | Identify and label each component for clarity. |

| 3 | Cross-reference with your user manual for additional context. |

| 4 | Make a list of needed items before placing an order. |

| 5 | Keep the visual handy during assembly for easy reference. |

Replacing Components in GXV120

Maintaining the functionality of small engines requires periodic replacement of various elements. This process ensures optimal performance and longevity. Understanding how to effectively swap out these parts is crucial for keeping your equipment running smoothly and efficiently.

Identifying Worn-Out Parts

Recognizing signs of wear is the first step in the replacement process. Components such as filters, spark plugs, and gaskets may show visible damage or reduced efficiency. Regular inspections can help you spot issues early, allowing for timely replacements and minimizing potential downtime.

Step-by-Step Replacement Process

Once you have identified the components that need replacing, gather the necessary tools and follow a systematic approach. Start by disconnecting the power source to ensure safety. Then, carefully remove the faulty element, taking note of its placement and any connecting parts. Install the new component by reversing the removal steps, ensuring a secure fit to avoid future problems.

Recommended Maintenance Practices

Proper upkeep of machinery is essential for ensuring longevity and optimal performance. Adhering to a regular maintenance schedule can prevent unexpected breakdowns and enhance efficiency. This section outlines best practices to maintain your equipment effectively, helping you achieve reliable operation over time.

Regular Inspection

Frequent checks are vital for identifying wear and tear before it leads to significant issues. Consider the following components during inspections:

| Component | Frequency of Inspection | Action Required |

|---|---|---|

| Air Filter | Every 25 hours | Clean or replace as needed |

| Oil Level | Every use | Top up or change if necessary |

| Fuel System | Every 50 hours | Check for leaks and clean filters |

Fluid Management

Maintaining appropriate fluid levels is critical for performance. Regularly monitor and change fluids based on usage to ensure smooth operation. Use high-quality oils and fuels to enhance the lifespan of the machine.

Aftermarket Parts vs. OEM Options

When it comes to replacement components for machinery, users often face a crucial decision: whether to choose original manufacturer offerings or to explore alternative solutions. Each option presents distinct advantages and potential drawbacks that can influence performance, cost, and longevity.

Original equipment manufacturer (OEM) components are designed specifically for the equipment, ensuring compatibility and reliability. These products often come with warranties and are typically made from high-quality materials. However, they tend to be more expensive.

- Advantages of OEM:

- Guaranteed compatibility

- High reliability

- Warranty coverage

- Disadvantages of OEM:

- Higher cost

- Limited availability

On the other hand, aftermarket options can offer cost savings and a wider selection. These products may be manufactured by third parties and can sometimes exceed OEM specifications. However, the quality can be inconsistent, and compatibility issues may arise.

- Advantages of Aftermarket:

- Cost-effective solutions

- Variety of choices

- Disadvantages of Aftermarket:

- Potential quality concerns

- Risk of compatibility issues

Ultimately, the decision between OEM and alternative components will depend on individual priorities, including budget constraints and the specific requirements of the equipment in question.

Resources for GXV120 Parts

When it comes to maintaining and repairing small engines, having access to reliable sources is crucial for enthusiasts and professionals alike. Numerous platforms offer a wealth of information and components to ensure optimal performance and longevity of your equipment.

| Resource Type | Description | Website |

|---|---|---|

| Online Retailers | Major e-commerce sites provide a vast selection of replacement components. | www.example.com |

| Manufacturer’s Website | The official site often includes catalogs and guides for genuine items. | www.example.com |

| Forums and Communities | Online communities can offer advice and share experiences regarding maintenance. | www.example.com |

| Local Dealers | Authorized retailers can provide personalized assistance and recommendations. | www.example.com |

Troubleshooting Common Engine Problems

When facing issues with small engines, identifying the root cause can often be a challenge. A systematic approach to diagnosing the problem is essential for effective resolution. This section outlines common symptoms and potential solutions, helping you restore optimal performance.

Engine Won’t Start: If the power unit is unresponsive, check the fuel level and quality first. Stale or contaminated fuel can lead to starting difficulties. Ensure that the fuel is fresh and free of impurities. Additionally, inspect the spark plug for wear or damage; replacing it may resolve ignition issues.

Rough Idle: An uneven or unstable idle can indicate problems with the air-fuel mixture. Examine the carburetor for blockages or malfunctions. Cleaning or adjusting the carburetor can often restore smooth operation. Furthermore, check for any vacuum leaks that might disrupt the mixture.

Overheating: Excessive heat can result from inadequate lubrication or cooling. Verify that the oil level is sufficient and that the oil is clean. Additionally, ensure that the cooling fins are free from debris and that the cooling system is functioning properly to prevent overheating.

Poor Performance: If the engine lacks power, it may be suffering from fuel delivery issues or air intake restrictions. Inspect the fuel filter for clogs and clean or replace it if necessary. Also, check the air filter; a dirty filter can significantly hinder performance.

By following these troubleshooting steps, you can effectively diagnose and address common engine issues, ensuring reliable operation and longevity.

Tools Needed for Repairs

Effective maintenance requires a variety of instruments to ensure smooth operation and longevity of equipment. Having the right tools on hand can significantly ease the repair process, making tasks more efficient and manageable.

Essential Instruments

Key instruments include wrenches, screwdrivers, and pliers. Wrenches allow for tightening or loosening fasteners, while screwdrivers are crucial for removing or securing screws. Pliers offer versatility in gripping, twisting, and cutting wires or other materials.

Specialized Equipment

In addition to basic tools, specialized equipment such as torque wrenches and multimeters may be necessary. A torque wrench ensures components are fastened to the manufacturer’s specifications, while a multimeter helps diagnose electrical issues, providing valuable insights during troubleshooting.

Finding Reliable Repair Manuals

When seeking dependable guides for maintenance and troubleshooting, it’s essential to identify resources that provide clear instructions and accurate information. A thorough understanding of the machinery at hand can significantly enhance repair efficiency and ensure longevity.

Here are some key points to consider when looking for trustworthy manuals:

| Criteria | Description |

|---|---|

| Source Credibility | Opt for manuals from established manufacturers or reputable publishers known for technical accuracy. |

| Detail Level | Choose resources that offer comprehensive breakdowns and diagrams to facilitate the repair process. |

| User Reviews | Look for feedback from previous users to gauge the effectiveness and clarity of the guide. |

| Format Accessibility | Consider the format that best suits your needs, whether digital or printed, for ease of use during repairs. |

Tips for Extended Engine Life

Ensuring the longevity of an internal combustion engine involves several critical practices that contribute to its overall performance and durability. By adhering to these recommendations, you can significantly reduce wear and tear, ultimately enhancing efficiency and reliability.

Regular Maintenance

Routine upkeep is essential for preventing issues before they arise. Change the oil and filters regularly to keep the engine clean and reduce friction. Additionally, inspect and replace worn components to avoid catastrophic failures.

Optimal Operating Conditions

Always operate the engine within its designed limits. Avoid excessive loads and maintain appropriate temperatures to prevent overheating. Using high-quality fuel and lubricants also contributes to better performance and reduced wear.