In the realm of off-road vehicles, comprehending the assembly of various components is essential for both maintenance and enhancement. This section delves into the intricate structure and organization of essential elements, providing a visual guide to help enthusiasts and mechanics alike navigate their machinery effectively.

By familiarizing oneself with the layout of these crucial components, users can streamline repair processes and ensure optimal performance. The information presented here serves as a foundational tool, enabling users to identify parts and understand their respective functions within the overall system.

Whether you are a seasoned expert or a newcomer to the world of all-terrain vehicles, having access to a detailed reference of the internal mechanisms will significantly aid in your endeavors. This resource aims to empower individuals to take charge of their vehicles, enhancing both knowledge and capability in maintenance tasks.

Understanding the essential elements of an all-terrain vehicle (ATV) is crucial for both enthusiasts and those new to this mode of transportation. Each part plays a significant role in ensuring optimal performance, safety, and durability. Below are some of the primary components that contribute to the functionality and efficiency of the vehicle.

Engine and Drivetrain

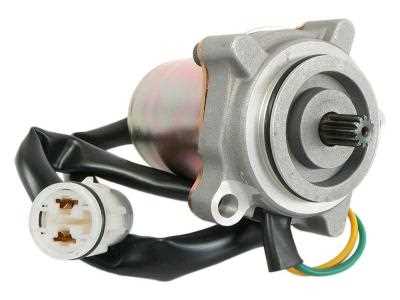

- Engine: The powerhouse that drives the vehicle, responsible for converting fuel into mechanical energy.

- Transmission: Transmits power from the engine to the wheels, allowing for smooth acceleration and deceleration.

- Drive System: This includes components such as the belt and gears that facilitate the transfer of energy to the wheels.

Suspension and Steering

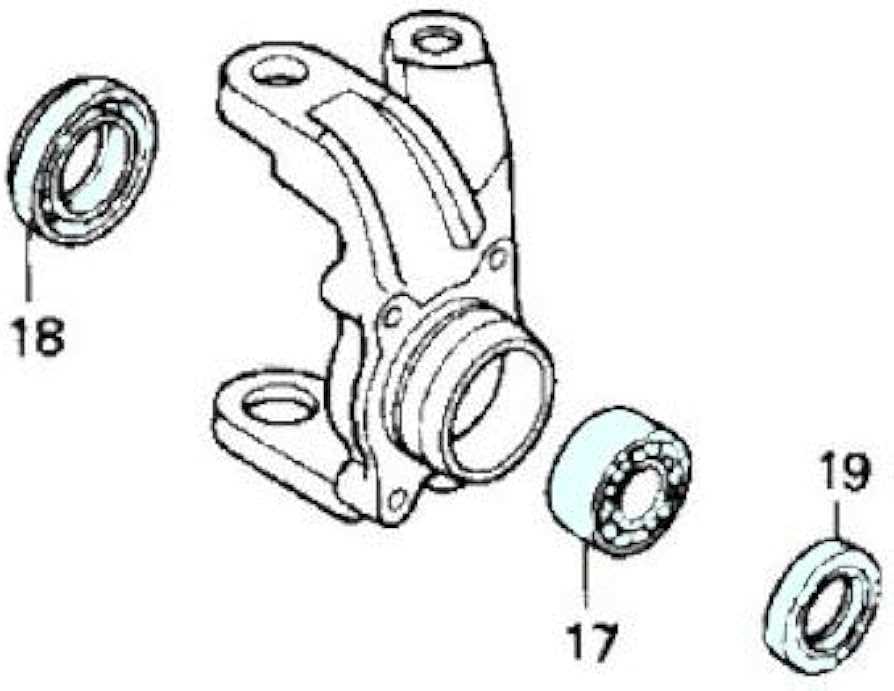

- Front Suspension: Absorbs shocks and improves handling, providing a smoother ride over rough terrain.

- Rear Suspension: Enhances stability and comfort, ensuring better control during movement.

- Steering System: Allows the operator to navigate the vehicle effectively, ensuring precision in turning and maneuvering.

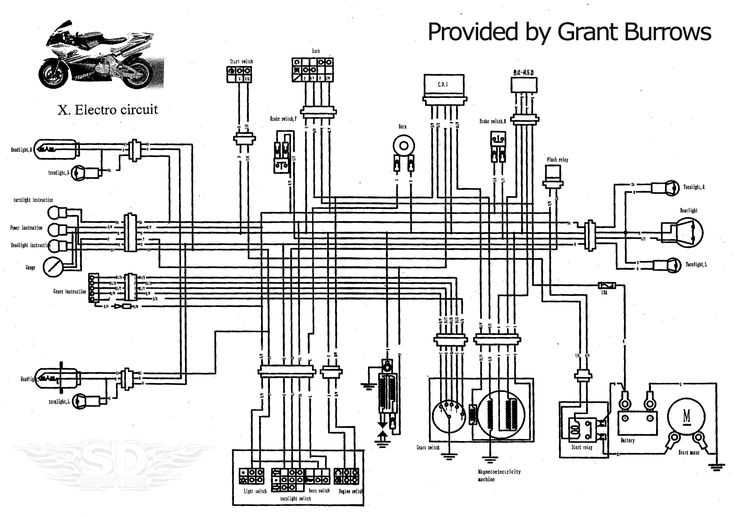

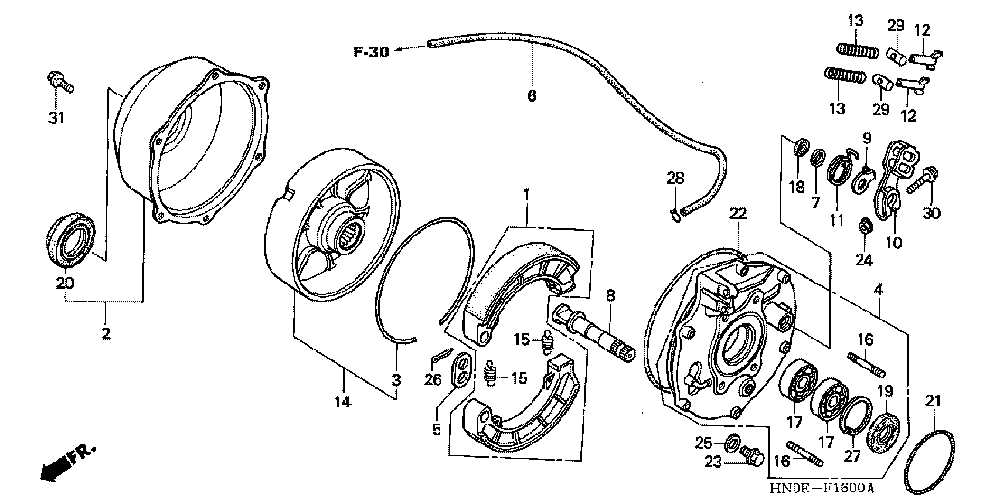

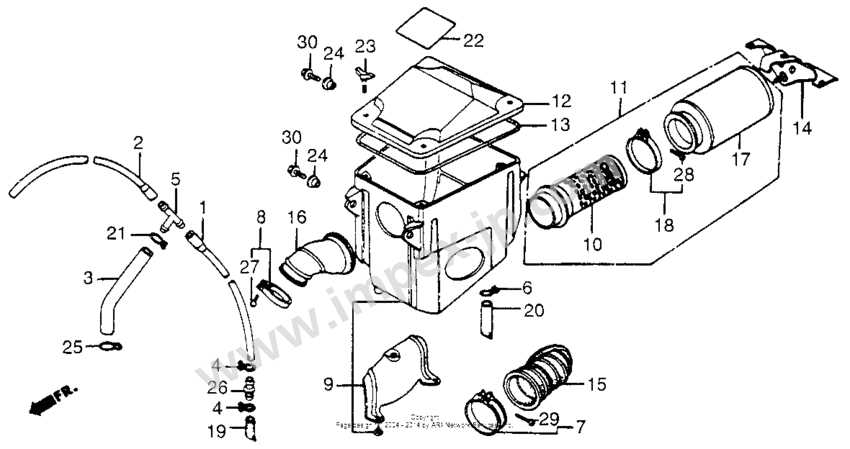

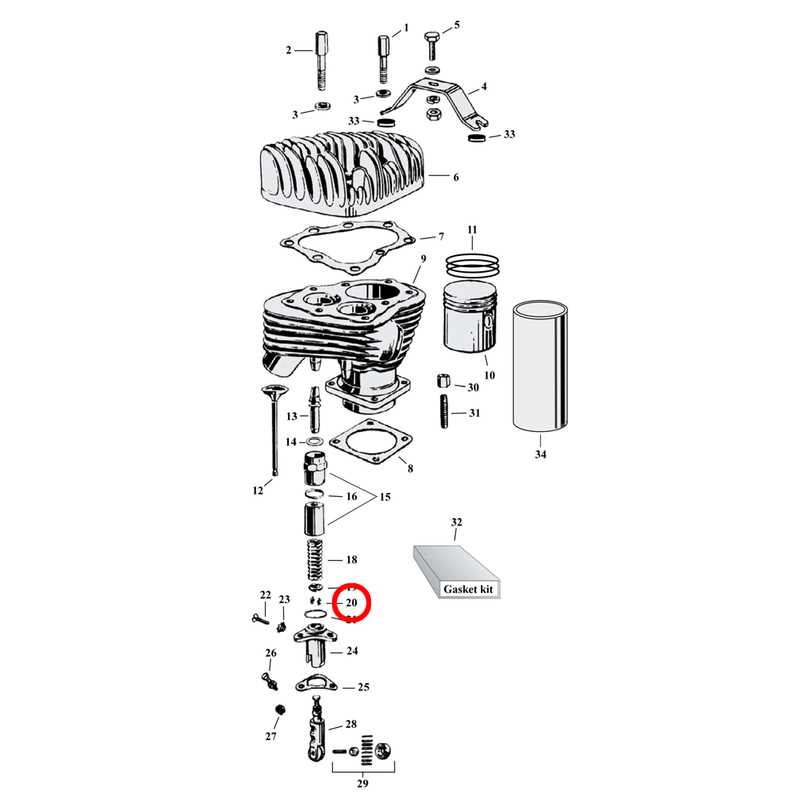

Understanding the Parts Diagram

This section aims to clarify the structure and components involved in a typical vehicle assembly. Familiarizing oneself with the visual representation of the elements can greatly enhance comprehension of how each piece fits into the overall mechanism.

In any machine, recognizing individual components and their relationships is crucial for maintenance and repairs. Here are key points to consider:

- Each item is labeled with specific numbers or letters, indicating its position.

- Connections between elements are often illustrated with lines, showcasing how they interact.

- Understanding these relationships can assist in identifying potential issues during inspections.

By delving into the representation, users can gain insights into the assembly process, which will facilitate efficient troubleshooting and enhance the longevity of the machine.

To effectively utilize this visual tool, consider the following steps:

- Start by identifying the main components of the assembly.

- Trace the connections to see how each part contributes to the overall function.

- Refer to the legend or key, if available, to decode any symbols used in the illustration.

With this knowledge, individuals can navigate through repairs or upgrades with confidence, ensuring their equipment operates smoothly.

Importance of OEM Parts

Using original equipment manufacturer components is crucial for maintaining the performance and longevity of vehicles. These components are specifically designed to meet the exact specifications of the manufacturer, ensuring optimal fit and function. When relying on high-quality parts, vehicle owners can expect better reliability and fewer issues over time.

One of the primary benefits of selecting OEM components is the assurance of quality. Unlike generic alternatives, which may vary in performance and durability, original parts undergo rigorous testing and adhere to strict quality control standards. This results in superior performance and enhanced safety.

| Advantages of OEM Components | Comparison with Aftermarket Alternatives |

|---|---|

| Guaranteed compatibility with the vehicle | May require modifications for proper fit |

| Higher reliability and performance | Variable quality and performance |

| Longer lifespan | Shorter lifespan in some cases |

| Maintains warranty coverage | Could void warranty with non-OEM parts |

In conclusion, investing in original components not only promotes vehicle efficiency but also enhances overall safety. By choosing quality over cost, owners can protect their investments and enjoy peace of mind while on the road.

Common Replacement Parts List

In this section, we will explore essential components that may require periodic replacement in your all-terrain vehicle. Keeping track of these items ensures optimal performance and longevity of the machine.

| Component | Description | Frequency of Replacement |

|---|---|---|

| Air Filter | Filters out dirt and debris to maintain engine efficiency. | Every 1,000 miles |

| Oil Filter | Removes contaminants from engine oil to prolong engine life. | Every 2,000 miles |

| Brake Pads | Friction material that helps in stopping the vehicle. | Every 5,000 miles or as needed |

| Battery | Provides electrical power for starting and accessories. | Every 3-5 years |

| Spark Plug | Ignites the air-fuel mixture in the combustion chamber. | Every 3,000 miles |

How to Read Parts Diagrams

Understanding illustrations of components is essential for effective maintenance and repair tasks. These visual aids provide crucial information about the arrangement and function of various elements within a system. By mastering the interpretation of these representations, you can enhance your ability to identify issues and make informed decisions during repairs.

Here are some tips to help you effectively interpret component illustrations:

- Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent different parts. Learning these symbols will help you navigate the visual guide more easily.

- Follow the Legend: Most diagrams include a legend or key that explains the symbols and markings. Refer to this section for clarification on what each symbol represents.

- Identify Groupings: Components are often grouped based on their functionality. Understanding these groupings can provide insights into how parts work together.

- Note the Numbering System: Many illustrations use a numbering system to reference parts. This can help you locate specific components and understand their relationships within the system.

- Cross-Reference with Manuals: Utilize repair manuals or guides alongside the illustrations. This can offer more detailed explanations and assist in troubleshooting.

By applying these strategies, you will improve your skills in interpreting component illustrations, making your repair and maintenance tasks more efficient and successful.

Tools Needed for Maintenance

Proper upkeep of your vehicle requires a set of essential instruments. These tools ensure that routine inspections and repairs are executed efficiently, helping to prolong the life of your machine. Having the right equipment at hand can make maintenance tasks simpler and more effective.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for various adjustments and repairs. A socket set is also vital, providing the flexibility needed to tackle different fasteners with ease. In addition, a reliable jack is necessary for lifting the vehicle safely, allowing access to its undercarriage.

For fluid changes and general cleaning, tools like a drain pan and funnel are indispensable. Ensuring that you have a cleaning brush and rag will help maintain cleanliness during the servicing process. Investing in quality tools can enhance your maintenance experience, making it more efficient and rewarding.

Steps for Accessing the Diagram

Obtaining a schematic for your vehicle can enhance your understanding of its components and facilitate repairs. This section outlines the necessary steps to find and view the illustration effectively, ensuring a smoother maintenance process.

1. Locate the Manufacturer’s Website

Begin by visiting the official website of the vehicle’s manufacturer. Navigate to the support or resources section, where you can typically find technical information and manuals.

2. Utilize Online Resources

In addition to the manufacturer’s site, there are various online forums and databases that host diagrams and service manuals. Using search engines, you can find user-uploaded content that might be beneficial.

When accessing these resources, it’s important to ensure that the information is relevant to your specific model for accuracy in your repair or maintenance tasks.

Troubleshooting Common Issues

Maintaining optimal performance in your all-terrain vehicle requires addressing various challenges that may arise during use. Identifying and resolving these problems can significantly enhance the longevity and reliability of your machine. Below are some common issues and their potential solutions.

Engine Not Starting: If the engine fails to ignite, check the battery connections for corrosion and ensure they are tightly secured. Additionally, examine the fuel levels and the condition of the spark plug, as these are critical for proper ignition.

Loss of Power: A noticeable decrease in power can stem from several sources, including clogged air filters or fuel lines. Regularly cleaning or replacing these components can restore performance and efficiency.

Overheating: Excessive heat can indicate issues with the cooling system. Ensure that the coolant is at the appropriate level and check for any blockages in the radiator. Regular maintenance of these parts is essential for preventing overheating.

Strange Noises: Unusual sounds can signal mechanical problems. Inspect the drive belt and other moving parts for wear and tear. Lubricating these components can also reduce noise and improve functionality.

By proactively addressing these common concerns, you can ensure a smoother and more enjoyable experience with your vehicle.

Maintaining Your Honda Rancher 400

Regular upkeep of your all-terrain vehicle is essential for ensuring optimal performance and longevity. Adhering to a systematic maintenance schedule will help prevent potential issues and enhance your riding experience.

Routine Inspections: Conducting frequent checks of essential components, such as the engine oil, air filter, and coolant levels, is vital. These inspections can help identify any irregularities before they escalate into more significant problems.

Cleaning: Keeping the exterior and mechanical parts clean is crucial. Accumulated dirt and debris can lead to wear and tear. Regularly wash the vehicle and inspect for any signs of corrosion or damage.

Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and wear. Pay special attention to the drive train and suspension systems, as they are subjected to heavy stress during operation.

Fluid Changes: Regularly replacing engine oil, brake fluid, and other essential liquids is necessary to maintain efficiency. Follow the manufacturer’s recommendations for intervals and types of fluids to use.

Tire Care: Check tire pressure regularly and inspect for any signs of damage or excessive wear. Properly inflated and well-maintained tires enhance safety and improve handling.

By following these simple yet effective maintenance practices, you can ensure that your vehicle remains in peak condition for many rides to come.

Where to Find Parts Diagrams

Finding detailed schematics for specific machinery components can significantly aid in maintenance and repairs. These illustrations provide an essential reference for understanding the arrangement and function of various elements within the equipment. Fortunately, there are multiple resources available for locating these valuable references.

Online Resources

The internet offers a plethora of websites that host comprehensive schematics and manuals for different types of machinery. Manufacturer websites often have a dedicated section for support, which includes downloadable documents. Additionally, various forums and community groups can serve as excellent sources for shared resources and advice on locating the necessary illustrations.

Local Dealers and Service Centers

Authorized dealers and service centers are another reliable source for obtaining these technical illustrations. They usually have access to the latest resources and can provide assistance in interpreting the diagrams. Moreover, they may offer printed manuals that contain the required information, ensuring you have a tangible reference during repairs.

Aftermarket vs. OEM Components

When it comes to maintaining and upgrading your vehicle, one of the key considerations is the choice between aftermarket and original equipment manufacturer (OEM) components. Each option presents its own set of advantages and disadvantages, influencing both performance and cost. Understanding these differences can help you make informed decisions for your machine.

Aftermarket components are often produced by third-party manufacturers and can vary widely in terms of quality and pricing. Here are some common characteristics:

- Typically more affordable than OEM parts.

- Available in a wide range of options, including performance enhancements.

- Quality may vary; some aftermarket products can outperform OEM, while others may fall short.

On the other hand, OEM components are made by the original manufacturer and are designed to meet specific standards. Their features include:

- Guaranteed compatibility with your vehicle.

- Manufactured to meet the exact specifications of the original parts.

- Often come with a warranty that provides peace of mind.

Ultimately, the choice between aftermarket and OEM components depends on your specific needs, budget, and preferences. Evaluating the pros and cons of each option will ensure that your vehicle performs at its best.

Assembly and Disassembly Tips

Proper assembly and disassembly techniques are crucial for maintaining the functionality and longevity of your vehicle. Understanding these methods will not only make the process smoother but also enhance your overall experience.

Here are some essential guidelines to follow:

- Prepare Your Workspace:

- Ensure you have a clean, organized area to work.

- Gather all necessary tools and equipment before starting.

- Follow a Systematic Approach:

- Document each step during disassembly to aid reassembly.

- Label components and fasteners to avoid confusion later.

- Handle Parts with Care:

- Avoid using excessive force to prevent damage.

- Inspect components for wear or damage during disassembly.

- Reassemble Methodically:

- Refer to your documentation for correct placement and order.

- Tighten fasteners to the manufacturer’s specifications.

- Test Functionality:

- After reassembly, perform a thorough inspection.

- Run the vehicle to ensure everything operates smoothly.

By following these tips, you can ensure a successful assembly and disassembly process, promoting the performance and reliability of your machine.