In any complex system, a thorough comprehension of the individual elements and their arrangement is crucial for efficient functioning and maintenance. This section aims to explore the intricacies of a specific model, offering insights into the various components and their roles within the overall structure.

Knowledge of each part enables users to troubleshoot issues effectively, ensuring optimal performance. By visualizing how each piece interacts with others, one can better appreciate the design’s ingenuity and the importance of each element in the assembly.

Furthermore, having a clear representation of the layout aids in identifying potential upgrades or replacements, enhancing the longevity and reliability of the system. This guide serves as a valuable resource for anyone seeking to deepen their understanding of the configuration and improve their experience.

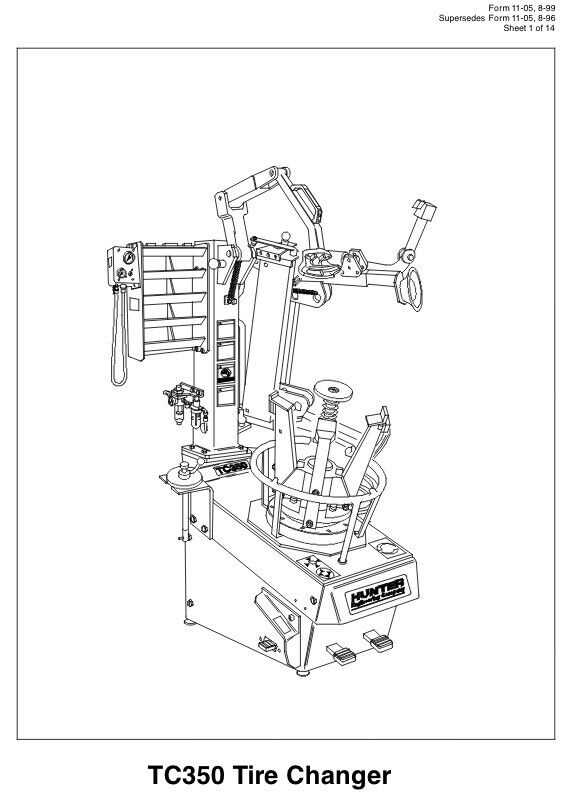

Understanding Hunter TC3250 Parts Diagram

The intricacies of machinery can often be daunting, but a clear visual representation can significantly enhance comprehension. This section aims to elucidate the importance of a schematic that delineates various components and their interrelations within a specific model. Such illustrations serve as invaluable tools for maintenance, troubleshooting, and enhancing overall operational efficiency.

Familiarity with the layout of individual elements is essential for anyone involved in the upkeep or operation of complex systems. Recognizing each piece’s role allows for quicker identification of potential issues, facilitating timely interventions. This proactive approach not only saves time but also minimizes the risk of more severe malfunctions.

Moreover, understanding these representations can empower users to make informed decisions regarding repairs or replacements. When one can visualize how parts fit together and function collaboratively, it paves the way for a deeper appreciation of the entire assembly and its efficiency.

Ultimately, a comprehensive grasp of these visual aids fosters a sense of confidence in managing equipment, ensuring optimal performance and longevity. This knowledge is indispensable for technicians and operators alike, enabling them to navigate challenges with ease and precision.

Key Components of the TC3250

This section delves into the essential elements that make up a specific model of irrigation equipment, highlighting their functions and importance in overall performance. Understanding these components is crucial for effective operation and maintenance.

- Engine: The heart of the machine, providing the necessary power for various operations.

- Transmission: Facilitates the transfer of power from the engine to the wheels, ensuring smooth movement.

- Control Panel: The interface that allows users to manage settings and monitor performance metrics.

- Pump: Responsible for moving water, it plays a vital role in irrigation efficiency.

- Chassis: The structural framework that supports all other components, ensuring stability and durability.

Each of these parts contributes to the overall functionality and effectiveness, making them indispensable for optimal performance.

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This guide will provide insights into interpreting the schematic, enabling you to identify various elements and their relationships.

First, familiarize yourself with the symbols and labels used in the illustration. Each symbol typically corresponds to a specific component, and recognizing these will aid in quick identification. Pay attention to any color coding or numbering, as these often indicate functional groups or assembly order.

Next, trace the connections between different elements. Arrows or lines usually denote how components interact or are linked together. Understanding these connections can reveal the ultimate flow of operation within the system.

Finally, refer to the accompanying legend or key, if available. This section will clarify any unfamiliar symbols and provide additional context, enhancing your overall comprehension. By mastering these steps, you will be well-equipped to navigate and utilize the schematic effectively.

Common Issues and Solutions

Understanding frequent challenges and their remedies can significantly enhance the performance and longevity of your equipment. This section delves into typical problems faced by users and provides practical solutions to ensure smooth operation.

Issue 1: Inconsistent Performance

One common issue is erratic functionality, which may stem from blockages or faulty components. Solution: Regularly inspect and clean all relevant parts to eliminate debris. If problems persist, consider replacing damaged elements to restore optimal performance.

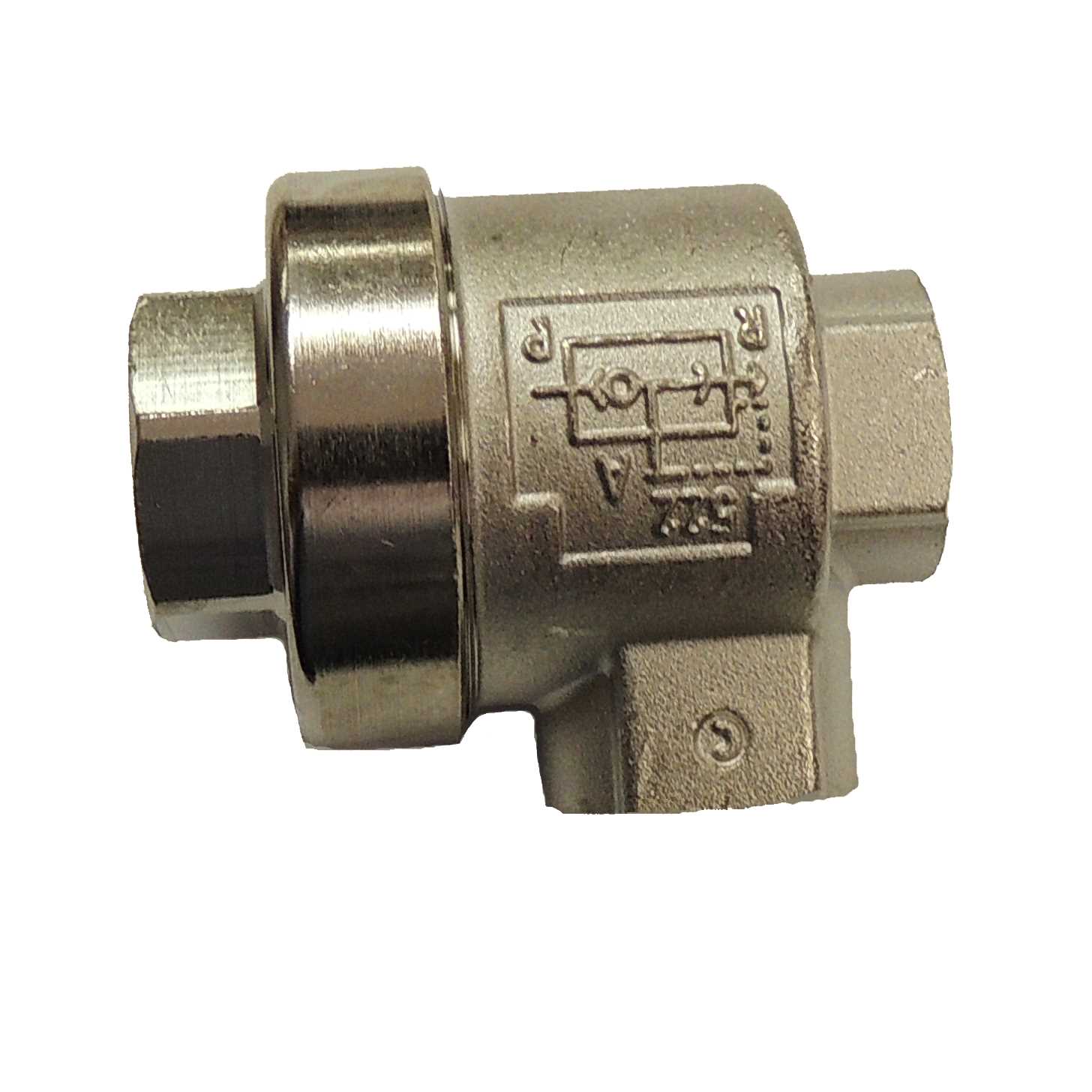

Issue 2: Leaks and Drips

Leaks can be a frustrating experience, often caused by worn seals or loose fittings. Solution: Tighten connections and check seals for wear. Replacing worn components can effectively resolve leaks and improve overall efficiency.

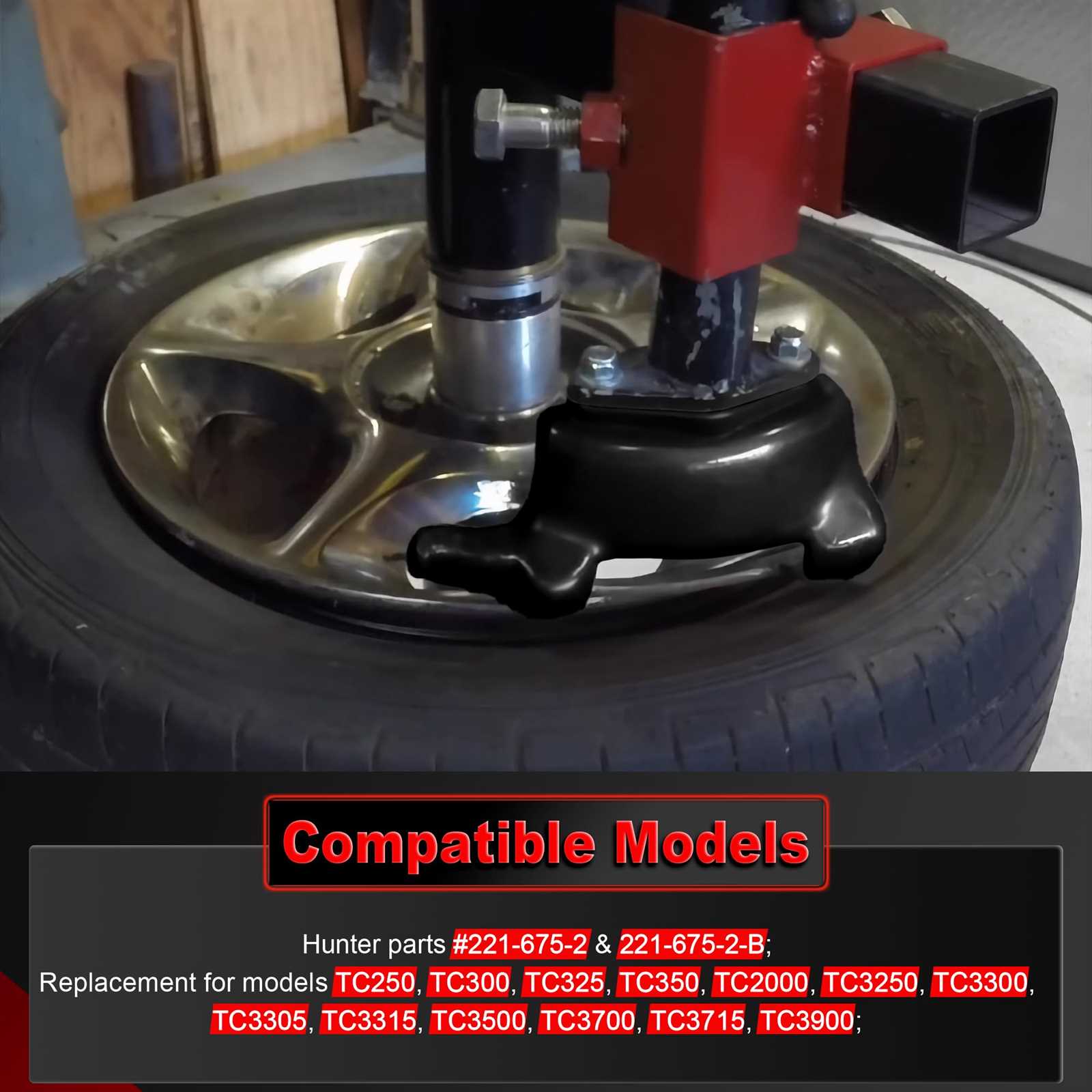

Identifying Replacement Parts

Understanding how to find suitable substitutes for components is crucial for maintaining the efficiency of your equipment. Whether you are performing routine maintenance or addressing a malfunction, knowing how to identify the necessary items can save both time and resources.

Common Challenges in Identification

One of the primary difficulties individuals face is distinguishing between similar-looking components. Variations in size, shape, and functionality can lead to confusion, resulting in incorrect purchases. Familiarizing yourself with the specific features of each item can greatly enhance your ability to select the correct replacement.

Utilizing Resources for Accuracy

Leveraging available resources is essential for accurate identification. Online manuals, support forums, and retailer catalogs often provide detailed information, including model numbers and specifications. Consulting these resources can significantly aid in ensuring that you acquire the right elements for your needs. Additionally, visual aids such as photographs can help in making precise comparisons.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and care. By implementing simple practices, you can enhance performance and prevent premature wear.

- Conduct routine inspections to identify any signs of wear or damage.

- Keep components clean to prevent dirt accumulation that can lead to malfunctions.

- Lubricate moving parts regularly to reduce friction and improve efficiency.

- Check and replace filters as needed to maintain optimal airflow and function.

- Store the equipment in a dry, protected environment to avoid corrosion.

By following these essential tips, you can delve into effective maintenance strategies that promote the ultimate durability of your machinery.

Where to Buy Genuine Parts

Finding authentic components for your machinery is crucial for maintaining performance and longevity. Numerous sources offer these essential items, ensuring quality and reliability in every purchase.

- Authorized Dealers: Always start with official distributors. They provide certified items and can offer expert advice.

- Manufacturer’s Website: Many brands have online stores where you can order directly, ensuring authenticity.

- Specialty Retailers: Look for stores specializing in equipment parts; they often carry a wide selection of genuine items.

- Trade Shows: Attending industry events can connect you with vendors offering authentic components at competitive prices.

By exploring these avenues, you can ensure you acquire high-quality items that meet your needs and uphold the integrity of your equipment.

Importance of Using Original Components

Utilizing authentic parts in machinery and equipment is crucial for ensuring optimal performance and longevity. Genuine components are designed to meet specific standards, providing reliability and efficiency that aftermarket alternatives often cannot match.

Reliability and Performance

Original components are rigorously tested and manufactured to precise specifications, resulting in enhanced functionality. This reliability minimizes the risk of breakdowns and extends the operational lifespan of the equipment.

Cost-Effectiveness

While the initial investment in authentic parts may be higher, they often lead to lower maintenance costs over time. Their durability reduces the frequency of replacements and repairs, ultimately saving money in the long run.

DIY Repair vs. Professional Help

When faced with the challenge of fixing equipment, individuals often weigh the option of tackling the job themselves against hiring an expert. Each choice presents its own advantages and drawbacks, which can significantly impact the outcome of the repair process. Understanding these aspects is crucial for making an informed decision.

| Aspect | DIY Repair | Professional Help |

|---|---|---|

| Cost | Typically lower, as it involves no labor fees. | Generally higher, factoring in service charges. |

| Time | May take longer due to learning curves. | Often quicker, leveraging expertise. |

| Skill Level | Requires a certain level of knowledge and practice. | Expertise ensures quality results. |

| Outcome | Success depends on individual capability. | High likelihood of effective resolution. |

Step-by-Step Assembly Guide

This section provides a detailed approach to assembling your equipment efficiently and effectively. Following these instructions will ensure that every component is fitted correctly for optimal performance.

- Gather Your Tools:

- Wrenches

- Screwdrivers

- Safety gloves

- Prepare the Workspace:

Ensure your workspace is clean and organized. Lay out all parts for easy access.

- Start with the Base:

Begin by securing the base to ensure stability. Use the appropriate fasteners as indicated.

- Attach the Main Components:

Proceed to connect the main sections, ensuring each fits snugly and is aligned properly.

- Install Additional Features:

Once the main parts are connected, add any optional features according to your preference.

- Final Checks:

Inspect all connections and tighten any loose fittings. Ensure everything is secure before operation.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and component identification for specific equipment. Here, you will find answers that can assist you in troubleshooting and ensuring optimal performance.

What should I do if I can’t identify a component?

If you’re having trouble recognizing a part, consult the user manual or seek online resources that provide detailed images and descriptions to aid in identification.

Where can I find replacement components?

You can source replacements from authorized dealers, online retailers, or specialized repair shops that focus on your type of machinery.

Resources for Further Information

Exploring a variety of reliable sources can enhance your understanding of specific components and their functionalities. Accessing the right materials is crucial for anyone seeking to deepen their knowledge in this field.

- Manufacturer Websites: Official sites often provide detailed documentation and guides.

- User Manuals: Comprehensive manuals can offer insights into installation and maintenance.

- Online Forums: Engaging with communities can yield practical tips and shared experiences.

- Technical Support: Reaching out for expert assistance can clarify complex issues.

- Educational Videos: Visual content can simplify the learning process significantly.

Utilizing these resources will enable you to delve deeper into the subject and achieve a more thorough understanding of your equipment.