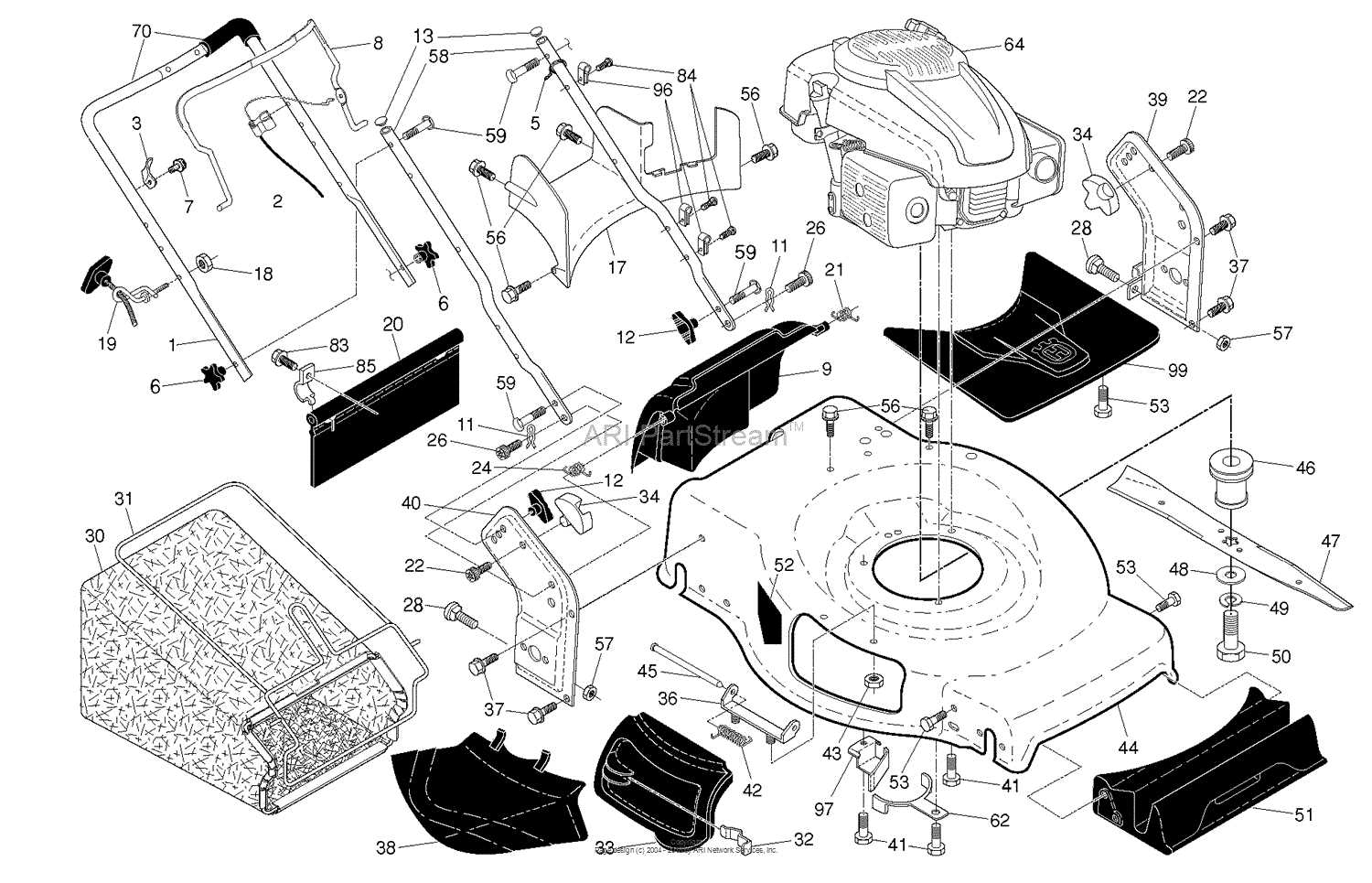

When maintaining or repairing outdoor machinery, having a clear visual representation of its internal structure is crucial. This guide focuses on the intricate elements that make up a widely used model in the landscaping and gardening community. Understanding the layout of these components can significantly aid in troubleshooting and ensuring optimal functionality.

In this section, we will explore the various sections and mechanisms that comprise this popular device. Each component plays a vital role in its overall performance, and recognizing how they interconnect allows users to diagnose issues more effectively. Whether you’re a seasoned technician or a novice enthusiast, familiarizing yourself with the structure will enhance your maintenance skills.

Additionally, having access to detailed illustrations can streamline the process of sourcing replacements or upgrades. This information not only assists in the immediate task at hand but also promotes a deeper understanding of how the equipment operates. By delving into the specifics, users can cultivate a more comprehensive approach to equipment care and longevity.

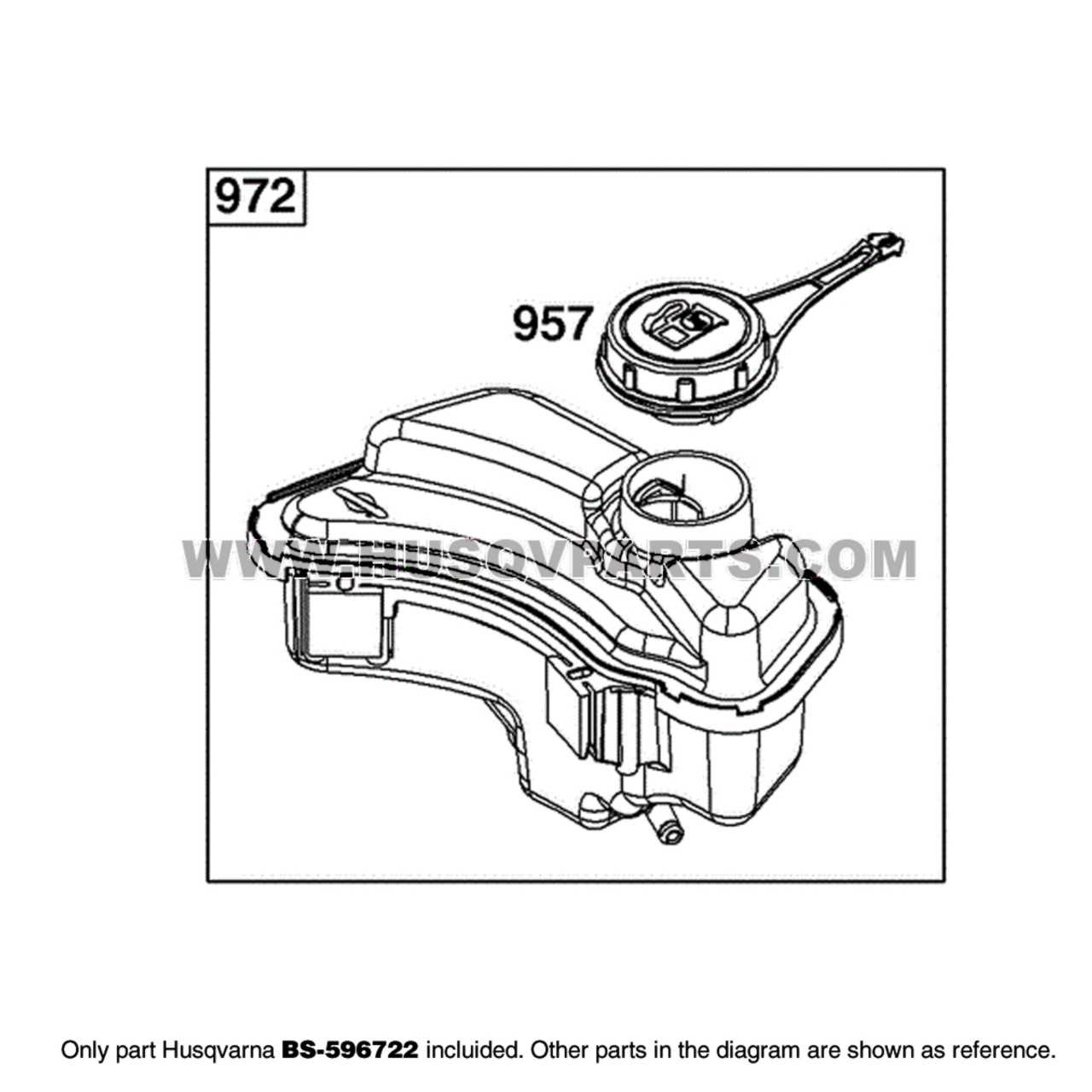

Understanding Husqvarna 775EX Components

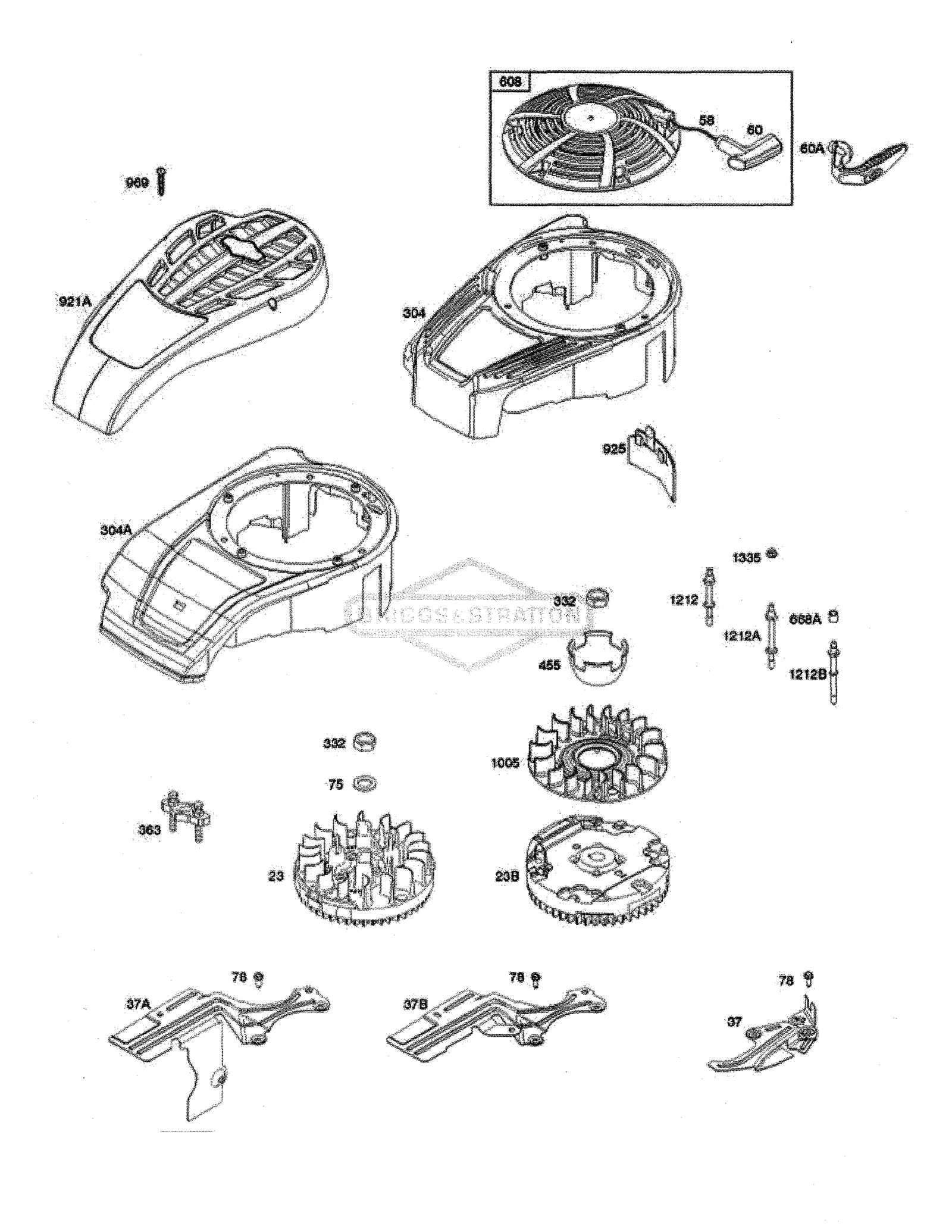

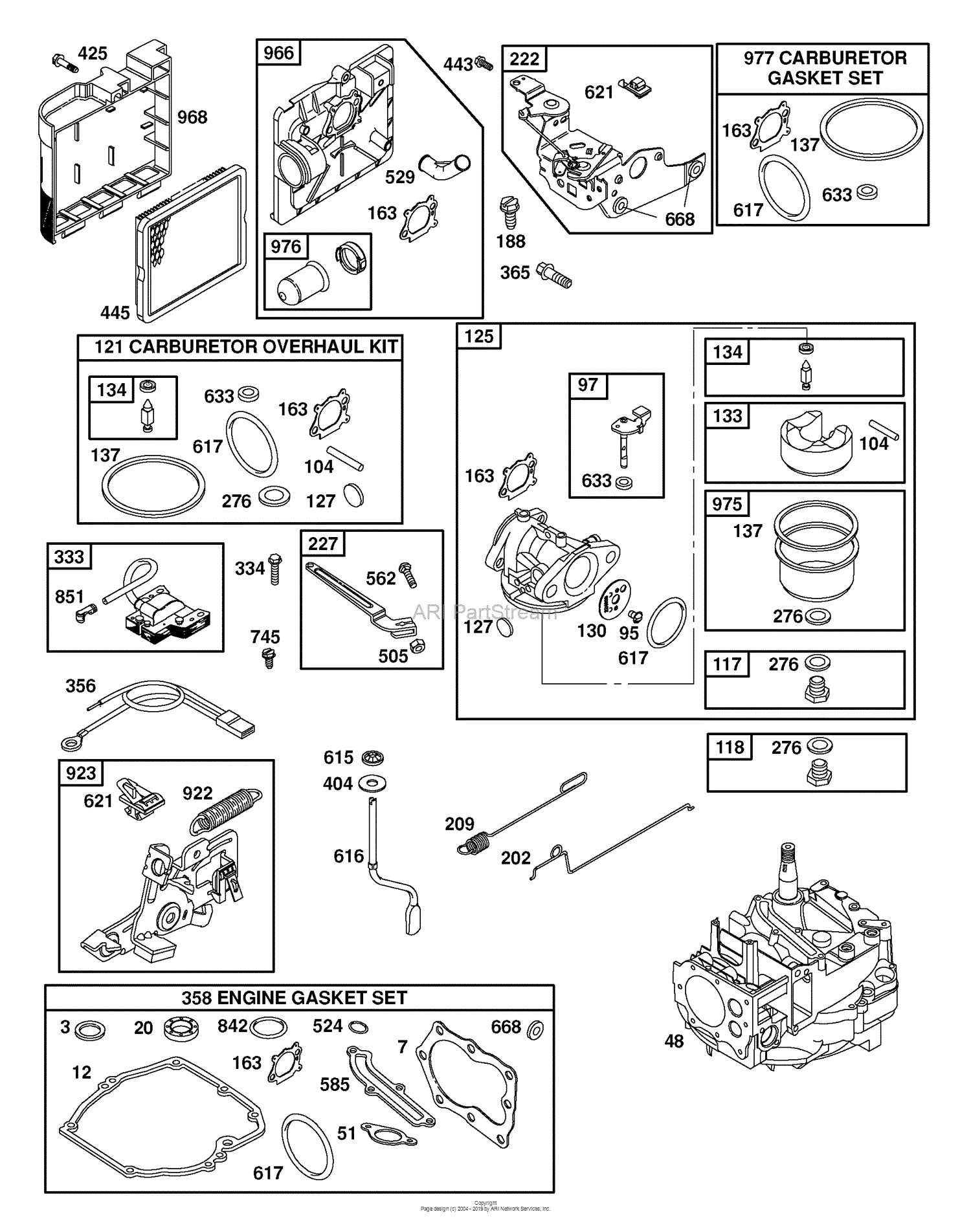

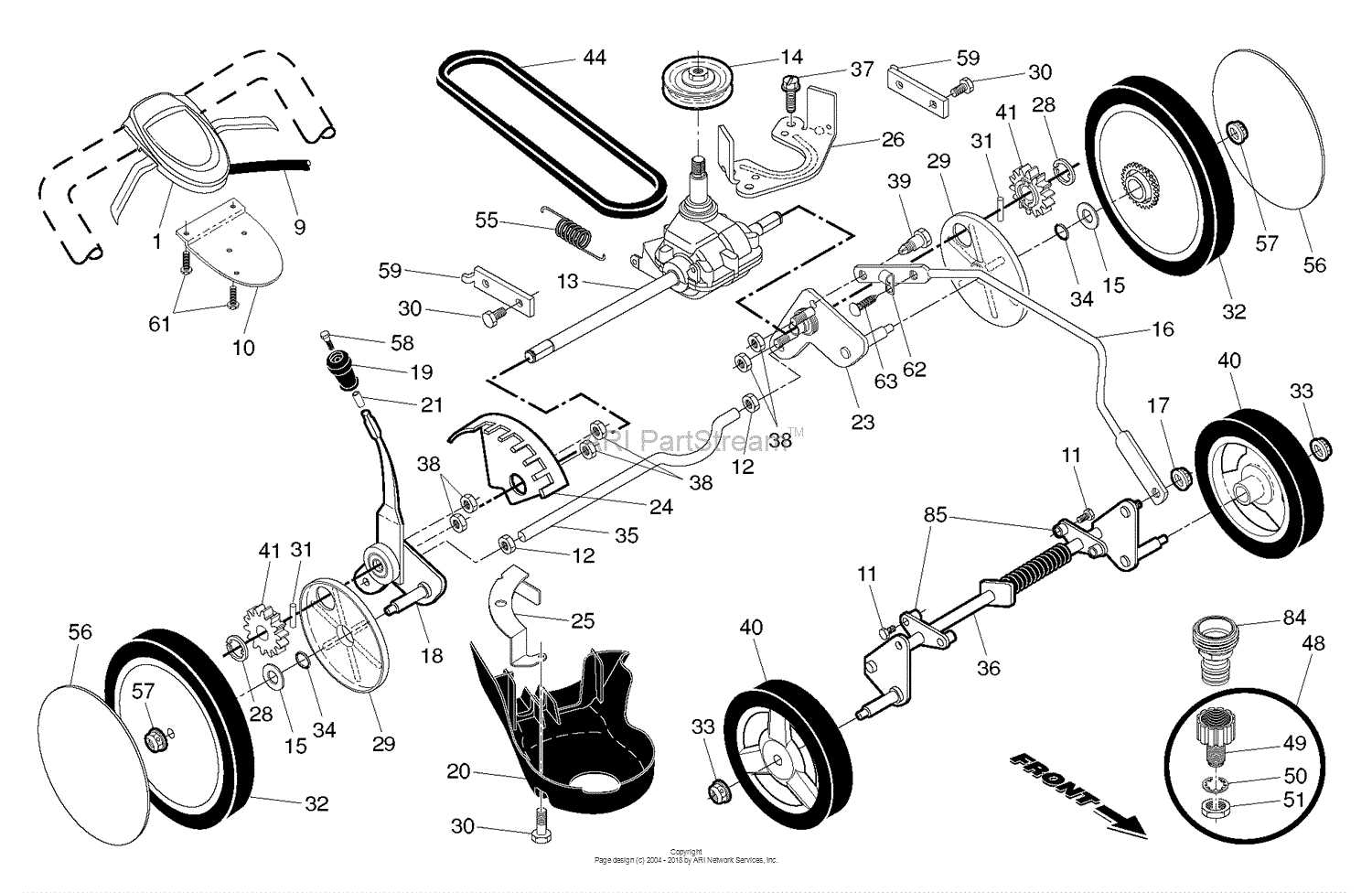

Grasping the intricacies of a small engine’s components is essential for effective maintenance and troubleshooting. Each element plays a vital role in the overall functionality and performance of the machine, contributing to its operational efficiency. Familiarity with these parts enables users to identify potential issues and understand how to address them effectively.

At the core of the assembly lies the power unit, which converts fuel into mechanical energy. Connected to this are various systems responsible for fuel delivery, air intake, and exhaust management. These systems must work in harmony to ensure optimal combustion and energy output.

The ignition mechanism initiates the combustion process, relying on a reliable spark to ignite the fuel-air mixture. Surrounding components, such as the carburetor and fuel lines, manage the fuel flow, ensuring the engine receives the correct mixture for efficient operation.

Moreover, understanding the cooling system is crucial, as it prevents overheating and maintains optimal operating temperatures. The fan and cooling fins play significant roles in dissipating heat generated during operation.

By becoming acquainted with these elements, users can better maintain their equipment, extending its lifespan and enhancing performance. Regular inspections and knowledge of each component’s function can lead to proactive measures, reducing the likelihood of breakdowns and costly repairs.

Key Features of Husqvarna 775EX

This model is designed with various standout characteristics that enhance its performance and usability. It combines advanced engineering with user-friendly elements, making it suitable for a range of applications.

- Powerful Engine: The robust motor provides exceptional efficiency, ensuring that tasks are completed quickly and effectively.

- Lightweight Design: Its streamlined construction allows for easy maneuverability, reducing user fatigue during prolonged use.

- Ergonomic Handle: The comfortable grip promotes better control and reduces strain on the hands, making operation smoother.

- Durable Materials: High-quality components are used to withstand wear and tear, ensuring longevity and reliability.

- Easy Maintenance: The design facilitates straightforward servicing, allowing users to keep the machine in optimal condition without hassle.

- Versatile Applications: Suitable for various tasks, from landscaping to maintenance, adapting well to different user needs.

These features collectively contribute to a reliable and efficient tool, ideal for both professionals and hobbyists alike.

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations of each segment not only facilitate easier identification but also enhance the overall comprehension of the assembly process. These illustrations serve as invaluable resources for both professionals and enthusiasts alike.

Enhanced Clarity

Visual guides provide a clear overview of how individual elements fit together within a larger system. By simplifying complex structures, these resources enable users to quickly grasp the relationships between different parts, leading to more efficient troubleshooting and assembly.

Streamlined Maintenance

Regular upkeep is essential for optimal performance. Accessing a visual reference allows users to identify worn or damaged elements swiftly, ensuring timely replacements. This proactive approach minimizes downtime and extends the lifespan of the equipment.

Common Issues with 775EX Parts

Understanding the frequent challenges associated with specific components is essential for maintaining optimal performance and longevity. Various factors can lead to wear and tear, impacting efficiency and functionality. Identifying these common issues helps in timely interventions and repairs.

Wear and Tear: Over time, certain elements may experience degradation due to prolonged use. This deterioration can manifest as reduced performance or failure to operate effectively.

Fuel Delivery Problems: Inconsistent fuel supply can result in starting difficulties or erratic performance. Checking the fuel lines and filters regularly can mitigate these issues.

Electrical Failures: Wiring or ignition system malfunctions can lead to operational disruptions. Ensuring connections are secure and free of corrosion is crucial for reliable functionality.

Excessive Vibration: Components that are not properly secured may cause excessive movement during operation. This can lead to further damage, requiring immediate attention to prevent cascading failures.

Clogged Filters: Air and fuel filters can become blocked, hindering performance. Regular maintenance and cleaning are essential to maintain optimal airflow and fuel delivery.

Replacement Parts Availability

Access to quality components is crucial for maintaining and repairing outdoor machinery. Ensuring the availability of these items can enhance performance and extend the lifespan of the equipment. Users should be aware of various sources where they can obtain reliable replacements.

| Source | Description |

|---|---|

| Authorized Dealers | Certified retailers provide genuine components and expert advice. |

| Online Retailers | Websites dedicated to machinery offer a wide selection and often competitive prices. |

| Local Hardware Stores | Community shops may stock essential items for quick repairs. |

| Aftermarket Suppliers | Third-party vendors can provide alternatives that may be more cost-effective. |

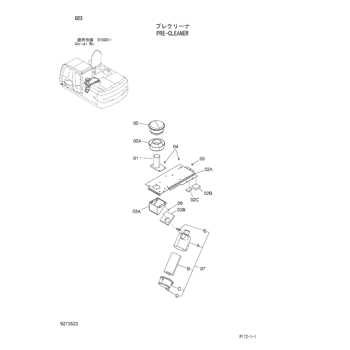

Identifying Component Functions

Understanding the roles of various elements in machinery is essential for effective maintenance and troubleshooting. Each part contributes to the overall performance, and recognizing their specific functions can enhance operational efficiency. This section will delve into the significance of key components within the system, providing insights into their responsibilities and interactions.

Engine: The core of the device, the engine is responsible for converting fuel into mechanical energy, powering all other functions.

Air Filter: This component prevents dirt and debris from entering the engine, ensuring clean air intake for optimal combustion.

Fuel System: Comprising the tank, pump, and lines, this system delivers fuel to the engine, maintaining the necessary flow for consistent operation.

Ignition System: Essential for starting the engine, this system generates the spark needed for combustion, influencing overall performance and efficiency.

Exhaust System: Responsible for directing harmful gases away from the engine, this system also helps regulate temperature, contributing to engine longevity.

Cutting Mechanism: This part is crucial for the primary function of the machinery, efficiently slicing through materials with precision and power.

By familiarizing yourself with these components and their functions, you can better diagnose issues and optimize the performance of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. By following some simple yet effective maintenance practices, you can significantly extend the lifespan of your machine, allowing it to perform at its best for years to come.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the exterior and interior free from debris and dirt. This prevents build-up that can hinder performance. |

| Oil Changes | Frequent oil changes are crucial. This helps maintain engine health and reduces wear on internal components. |

| Check Filters | Inspect air and fuel filters regularly. Replace them when necessary to ensure optimal airflow and fuel delivery. |

| Inspect Belts and Cables | Regularly check for wear and tear on belts and cables. Replace any that show signs of damage to prevent failure. |

| Sharpen Blades | Maintain sharp blades to enhance cutting efficiency. Dull blades require more power and can strain the engine. |

| Store Properly | When not in use, store the machine in a dry, sheltered area to protect it from the elements. |

Implementing these maintenance tips can lead to improved functionality and longevity of your equipment, ensuring that it remains reliable for various tasks ahead.

How to Read Parts Diagrams

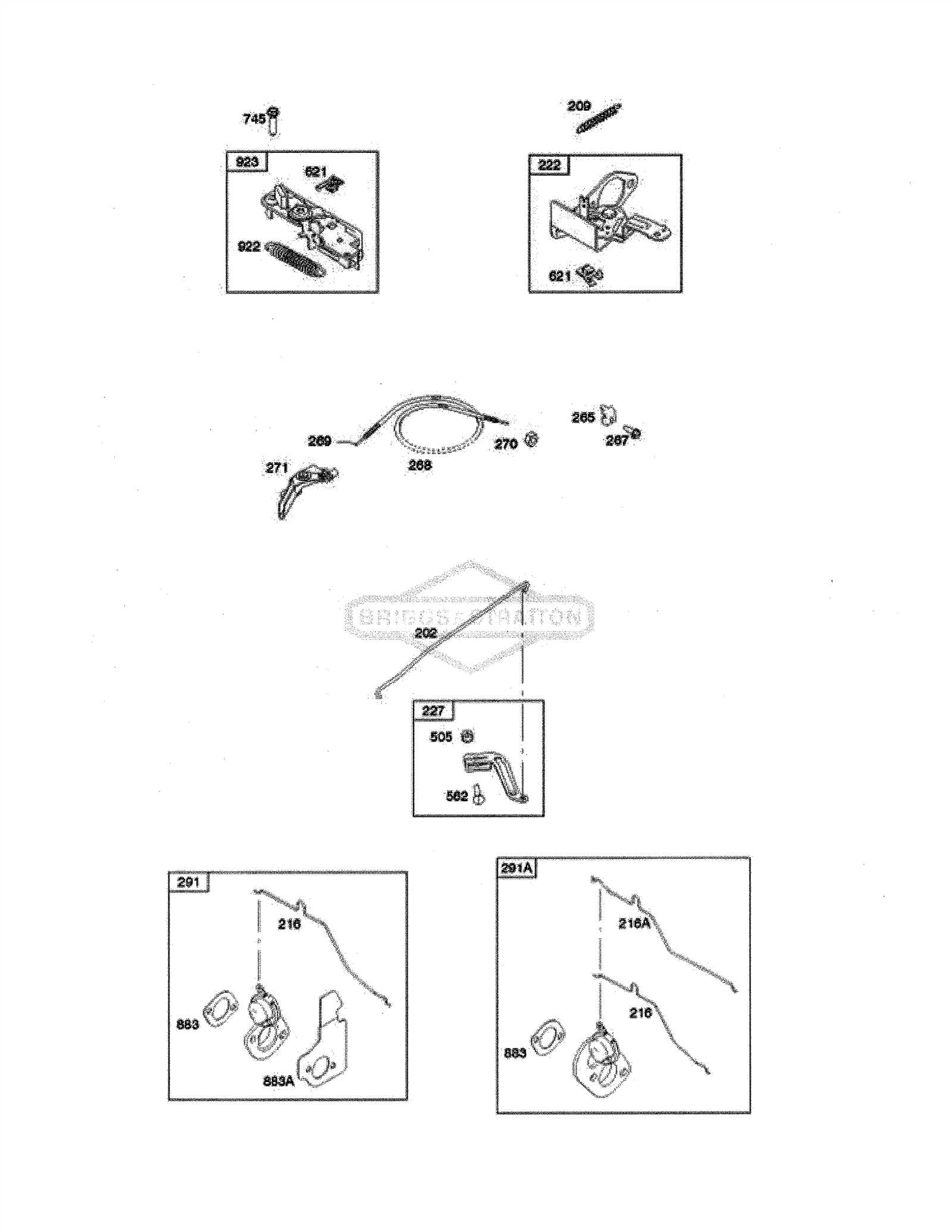

Understanding illustrations that display component layouts is essential for efficient maintenance and repair. These visuals serve as a guide, helping users identify and locate individual elements within a machine.

Here are some key steps to effectively interpret these illustrations:

- Familiarize Yourself with Symbols: Different representations may indicate specific types of components. Recognizing these can simplify the process.

- Follow the Numbering System: Components are often labeled with numbers or letters. Cross-reference these with the accompanying list for clarity.

- Identify Groupings: Components may be organized into sections based on their function or location. This can aid in understanding the overall layout.

- Take Note of Connections: Pay attention to how parts interact with each other. Understanding these connections is vital for assembly and disassembly.

By following these guidelines, users can enhance their ability to navigate and utilize these informative visuals effectively.

Tools Required for Assembly

Assembling machinery can be a straightforward task when equipped with the right instruments. Having a well-organized toolkit not only simplifies the process but also ensures that all components fit together correctly. Below is a list of essential tools that will aid in efficient assembly.

Essential Hand Tools

- Screwdrivers: Both flathead and Phillips varieties are necessary for securing screws.

- Wrenches: A set of adjustable wrenches will help tighten nuts and bolts effectively.

- Pliers: Useful for gripping, twisting, and cutting wires or components.

- Hex keys: Often required for specific fasteners that need precise tightening.

Power Tools

- Drill: A cordless drill can facilitate quick assembly and disassembly.

- Impact driver: Useful for driving screws with greater torque and speed.

- Saw: Depending on the task, a circular or reciprocating saw may be needed for cutting materials.

Having these tools on hand will ensure a smoother assembly experience, allowing for greater efficiency and accuracy throughout the process.

Frequently Asked Questions

This section aims to address common inquiries related to the components and maintenance of your equipment. Understanding these elements can enhance your experience and ensure optimal performance.

What are the main components I should check regularly?

Key elements to monitor include the engine, air filter, fuel lines, and spark plug. Regular inspections can help identify wear and prevent potential issues.

Where can I find replacement components?

Replacement items can typically be sourced from authorized dealers, online retailers, or specialized service centers. Always verify compatibility with your specific model to ensure proper functionality.

Best Practices for Repairs

Effective maintenance and restoration of equipment can significantly enhance performance and extend longevity. Adhering to certain guidelines can facilitate smoother repairs and minimize potential setbacks. This section outlines key approaches to ensure a successful repair process.

Begin by thoroughly assessing the issue before disassembly. Understanding the underlying problem allows for a more targeted approach to fixing it. Utilize an organized workspace to keep tools and components easily accessible, reducing the risk of misplacing essential items during the repair.

Consult manufacturer manuals or reliable online resources for detailed information on the equipment. This documentation often contains valuable insights regarding specific components and troubleshooting tips. When replacing parts, opt for high-quality replacements to ensure compatibility and durability.

Additionally, keep a detailed record of all repairs conducted. This practice not only aids in tracking performance over time but also assists in diagnosing recurring issues more efficiently. Finally, prioritize safety by using appropriate protective gear and ensuring that the equipment is powered off before initiating any repairs.

Upgrading Components for Performance

Enhancing machinery efficiency often involves optimizing specific elements for improved functionality. By focusing on key components, users can achieve significant gains in overall performance, making tasks easier and more efficient. This section explores potential upgrades that can lead to better operational results.

When considering enhancements, it’s essential to evaluate the most critical areas that impact performance. Below is a table summarizing common upgrades and their benefits:

| Component | Upgrade Option | Performance Benefit |

|---|---|---|

| Air Filter | High-Flow Filter | Improved airflow, better combustion |

| Spark Plug | Performance Spark Plug | Enhanced ignition efficiency |

| Fuel System | Upgraded Carburetor | Increased fuel delivery, optimized power |

| Exhaust | Performance Muffler | Reduced backpressure, improved exhaust flow |

| Blades | High-Performance Blades | Sharper edges, better cutting efficiency |

Implementing these upgrades can lead to a noticeable difference in the functionality of the equipment. Regular assessments and modifications ensure that the machinery operates at its peak, delivering exceptional results for users.