In the world of outdoor equipment, the efficiency and reliability of a machine often hinge on the quality and arrangement of its individual elements. Knowing how these components interact can significantly enhance performance and extend the lifespan of the tool. This guide will delve into the intricate layout of a specific model, offering insights into its assembly and functionality.

For those who seek to maintain or repair their equipment, familiarizing oneself with the layout of its key elements is essential. This understanding not only aids in troubleshooting but also empowers users to make informed decisions when it comes to replacement or upgrades. Visual aids can be invaluable in this regard, providing a clear representation of how each piece contributes to the overall operation.

By examining the structure and relationships between different sections, users can gain a deeper appreciation for the craftsmanship involved in these machines. This knowledge is vital for both novice users and seasoned professionals, ensuring that everyone can maximize the potential of their equipment while minimizing the risk of errors during maintenance tasks.

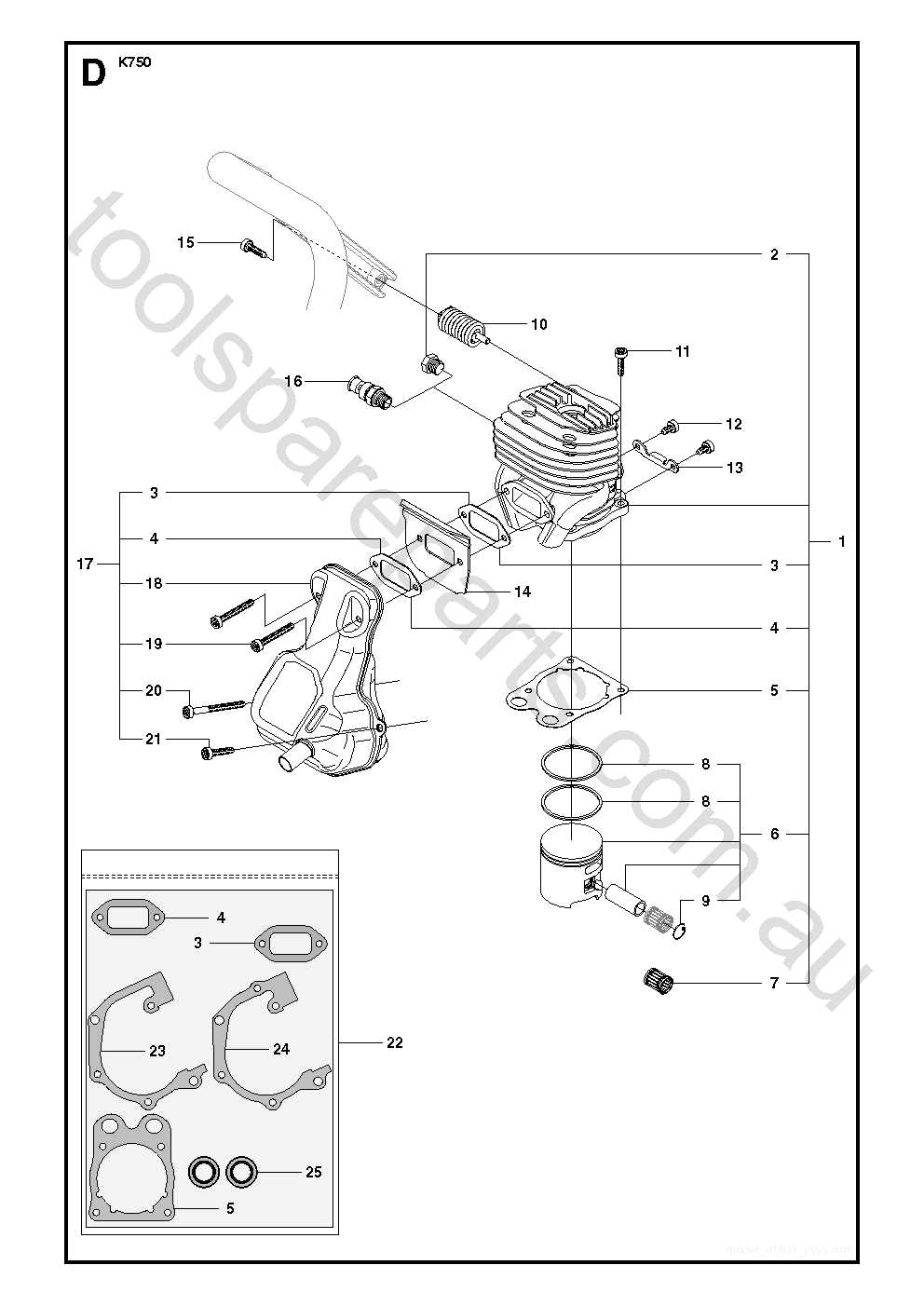

Understanding the Husqvarna K750 Model

This section explores the key features and functionalities of a prominent power tool designed for cutting and construction tasks. Known for its reliability and performance, this model is favored by professionals and enthusiasts alike.

Key Features

- High-performance engine for efficient cutting

- Lightweight design for easy maneuverability

- Durable construction materials for longevity

- User-friendly controls for seamless operation

Applications

- Construction projects

- Landscaping and yard work

- Roadwork and pavement cutting

- Demolition tasks

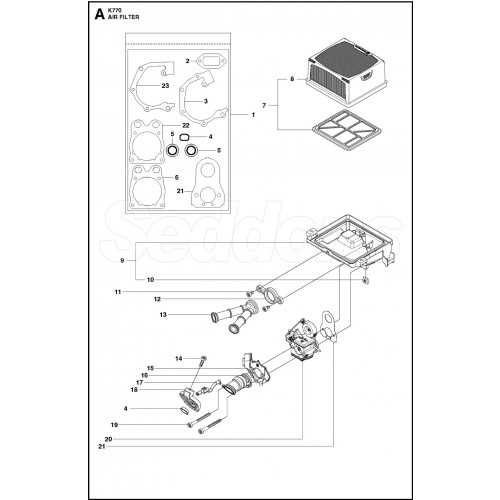

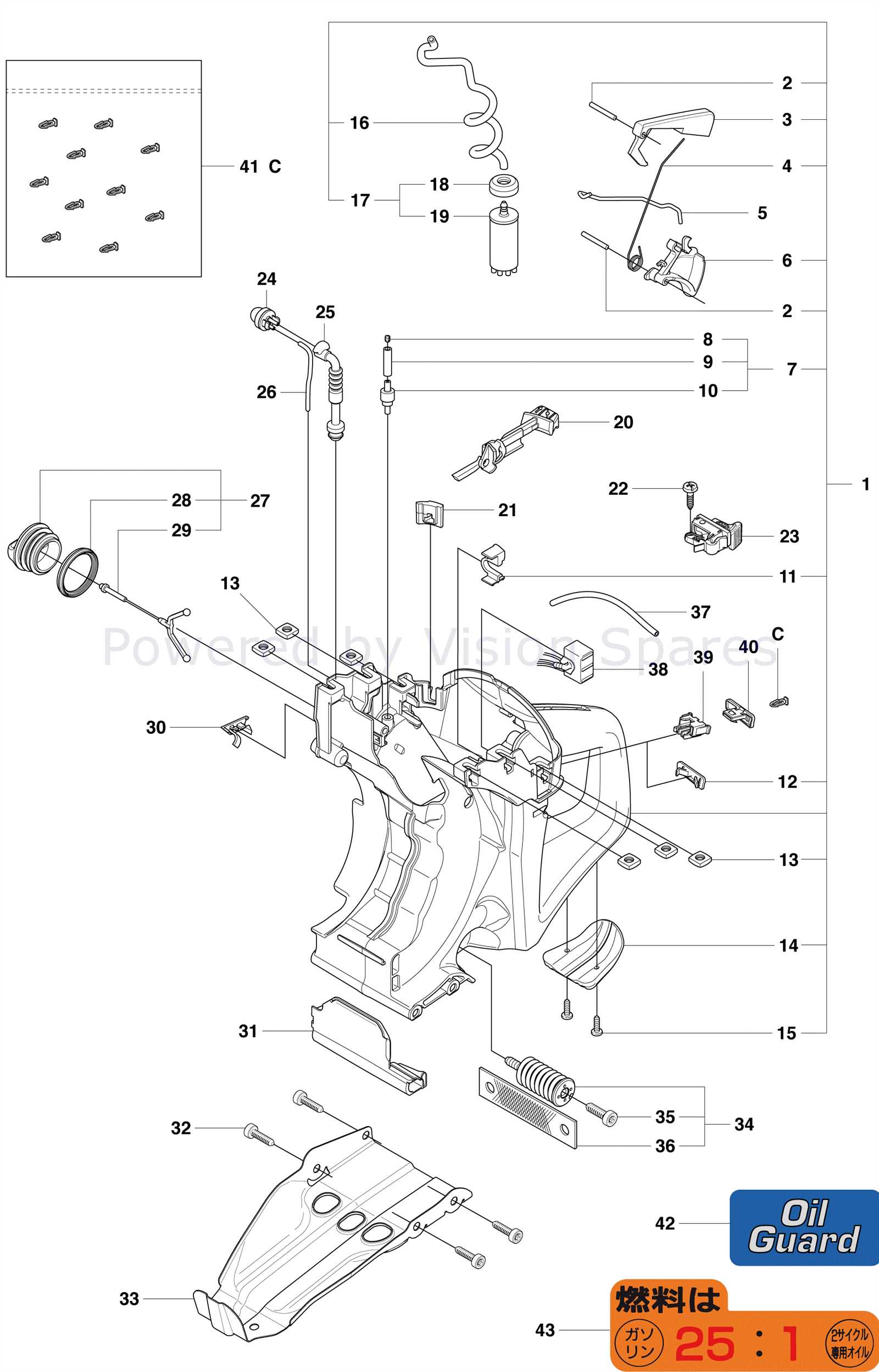

Key Components of the K750

This section explores the essential elements that contribute to the functionality and efficiency of the cutting tool. Understanding these parts enhances the user’s ability to maintain and operate the equipment effectively.

Engine Assembly

The engine assembly serves as the powerhouse of the tool, driving its performance. It is crucial to ensure proper maintenance of components such as the spark plug and air filter to optimize operation.

Cutting Mechanism

The cutting mechanism is vital for achieving precision in various tasks. Key elements, including the blade and its housing, must be regularly inspected for wear and damage to ensure safety and effectiveness. Regular checks on these components can ultimately extend the lifespan of the tool.

How to Interpret Parts Diagrams

Understanding technical illustrations is crucial for efficient maintenance and repair. These visual guides provide a detailed overview of components, allowing users to identify, locate, and replace parts effectively.

Breaking Down the Illustration

Start by familiarizing yourself with the layout. Each section typically corresponds to a specific assembly, and components are often labeled with unique identifiers. This helps in pinpointing exact items needed for repairs.

Referencing the Key

Most illustrations include a legend or key that clarifies symbols and terms used. Pay close attention to this section, as it offers essential information on component relationships and functionalities. Thorough understanding of these elements enhances repair accuracy.

Common Issues with K750 Parts

When it comes to performance machinery, understanding potential challenges with components can enhance longevity and efficiency. This section explores frequent problems that users may encounter with their cutting equipment, focusing on the functionality and reliability of individual elements.

Wear and Tear

Over time, various components experience natural degradation. Blades can become dull, leading to inefficient cutting and increased strain on the motor. Regular maintenance and timely replacement are crucial to prevent more extensive damage.

Fuel System Troubles

Another common concern arises within the fuel system. Issues such as clogs or leaks can hinder performance. Ensuring clean fuel lines and properly functioning filters can mitigate these risks, promoting smoother operation and preventing breakdowns.

Maintenance Tips for Optimal Performance

Ensuring peak efficiency in your equipment requires consistent upkeep and attention to detail. Regular maintenance not only extends the lifespan of your tools but also enhances their performance. By adopting a proactive approach, you can prevent common issues and ensure reliable operation.

1. Regular Cleaning: Keep the exterior and internal components free of debris. This minimizes wear and helps maintain optimal functionality.

2. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent overheating. This simple step is crucial for smooth operation.

3. Inspect Components: Frequently check vital elements like belts, filters, and blades for wear. Early detection of issues can save time and costs in the long run.

4. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule outlined in the user manual. This ensures you perform necessary tasks at the right intervals.

5. Store Properly: After use, store your equipment in a dry, protected area to avoid damage from moisture or environmental factors.

By implementing these strategies, you can delve deeper into maintaining your equipment’s efficiency and ultimately achieve better results in your projects.

Where to Find Replacement Parts

When it comes to sourcing components for your equipment, understanding where to look can make all the difference. There are several avenues to explore, each offering unique benefits and considerations for your needs.

| Source | Description |

|---|---|

| Authorized Dealers | These locations provide genuine components and expert advice, ensuring compatibility and quality. |

| Online Retailers | Numerous websites specialize in aftermarket options, often featuring competitive prices and customer reviews. |

| Local Repair Shops | Local technicians may have spare items on hand or can order them for you, along with installation assistance. |

| Salvage Yards | For those seeking budget-friendly alternatives, these can offer used components at lower costs, though quality may vary. |

Comparison with Other Husqvarna Models

When evaluating various models from the same manufacturer, it’s essential to consider their unique features and functionalities. Each variant is designed to cater to different needs, offering distinct advantages based on performance, durability, and ease of use. Understanding these differences can help users make informed decisions based on their specific requirements.

For instance, while some models prioritize lightweight design for enhanced maneuverability, others may focus on superior power output for heavy-duty tasks. The balance between weight and strength can greatly influence the user experience, especially in demanding environments. Furthermore, certain versions may incorporate advanced technology that improves efficiency and reduces maintenance needs.

Comparing specifications reveals differences in engine capacity, blade size, and operational speed. These factors play a critical role in determining suitability for various applications, from landscaping to construction. Users must assess their particular demands to identify which machine aligns best with their operational goals.

In addition, compatibility with accessories and attachments varies across models, affecting versatility. Some units might allow for a broader range of tools, thereby enhancing functionality for specialized tasks. Ultimately, a thorough comparison of these elements helps potential buyers choose the most appropriate option for their projects.

Identifying Genuine Parts vs. Imitations

In the realm of equipment maintenance, distinguishing authentic components from counterfeit alternatives is crucial for ensuring optimal performance and longevity. The reliability of machinery often hinges on the quality of its individual elements, making it essential for users to recognize the hallmarks of genuine products.

Key Characteristics of Authentic Components

- Branding: Genuine items typically feature consistent logos and markings that align with the manufacturer’s standards.

- Quality of Materials: Authentic products are made from superior materials, contributing to durability and performance.

- Packaging: Original components are usually packaged in a professional manner, often including detailed instructions and warranty information.

Common Signs of Imitations

- Poor Craftsmanship: Inferior construction may be evident in misalignments, rough edges, or inconsistent finishes.

- Price Discrepancy: Significantly lower prices can be a red flag, indicating a potential imitation rather than a legitimate offering.

- Lack of Documentation: Counterfeit products often come without proper documentation, such as user manuals or warranty cards.

By familiarizing oneself with these distinguishing factors, users can make informed decisions, ensuring the longevity and effectiveness of their machinery.

Assembly Instructions for K750 Components

Proper assembly of components is crucial for optimal performance and longevity of your machine. This section provides clear guidance on how to effectively put together various elements, ensuring that each part is correctly installed and functioning as intended.

Preparation Steps

- Gather all necessary tools and components.

- Ensure the workspace is clean and organized.

- Review the instruction manual for reference points.

Assembly Process

- Start by securing the base unit on a stable surface.

- Attach the primary component using the provided screws; ensure they are tightened evenly.

- Install secondary parts, following the specified order to avoid misalignment.

- Check for proper fit and alignment between all assembled components.

- Complete the assembly by attaching any remaining accessories or covers.

After assembly, it is recommended to conduct a thorough inspection and perform a test run to verify functionality.

Tools Required for K750 Repairs

Effective maintenance and repair of your equipment require a specific set of instruments to ensure efficiency and safety. Having the right tools not only simplifies the process but also enhances the overall performance of the machinery.

Essential Tools

The following instruments are crucial for performing repairs and maintenance tasks effectively:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Socket Set | For accessing hard-to-reach fasteners. |

| Screwdriver Set | For handling various screws during disassembly. |

| Pliers | For gripping and bending components. |

| Torque Wrench | For applying precise torque to fasteners. |

Safety Equipment

In addition to repair tools, having the appropriate safety gear is paramount to protect yourself during maintenance tasks:

| Equipment | Importance |

|---|---|

| Safety Goggles | To protect eyes from debris and chemicals. |

| Gloves | To prevent injuries from sharp edges and hot surfaces. |

| Steel-Toed Boots | To safeguard feet from heavy equipment. |

FAQs About K750 Parts

This section addresses common inquiries regarding components for the specific model. Understanding these elements is crucial for maintenance and effective operation. Here, we provide clarity on various questions that often arise among users.

What should I consider when replacing components?

When swapping out elements, ensure you choose items that match the specifications of your machine. Compatibility is key to maintaining performance and safety. Always consult the manual or a knowledgeable source to confirm that the replacements will work seamlessly with your equipment.

How do I identify a malfunctioning component?

Signs of wear or malfunction can include unusual noises, decreased efficiency, or visible damage. If you suspect an issue, inspect the relevant parts thoroughly. If you’re uncertain, seeking advice from a professional can help avoid further complications. Regular checks can prevent larger problems down the line.

Upgrades and Modifications Available

Enhancing the performance and efficiency of your cutting equipment can significantly impact your work quality and productivity. Various upgrades and modifications are available to tailor your machine to meet specific needs, improving both functionality and user experience.

Performance Enhancements

One of the most effective ways to boost your tool’s capabilities is through performance enhancements. Upgrading the engine components can result in improved power output and efficiency. Options such as high-performance filters and exhaust systems can enhance airflow, leading to better combustion and, ultimately, superior cutting power.

Ergonomic Improvements

Comfort during operation is essential for prolonged use. Modifications like upgraded handles and vibration-reducing grips can greatly enhance user comfort. Additionally, adjustable harnesses or padded straps can help distribute weight evenly, reducing fatigue and increasing overall productivity during extended tasks.

Safety Precautions When Working on K750

Ensuring safety during maintenance and repair tasks is crucial for effective operation and to prevent injuries. Proper precautions can significantly reduce risks associated with equipment handling.

Personal Protective Equipment

- Always wear safety goggles to protect your eyes from debris.

- Use gloves to prevent cuts and abrasions.

- Wear hearing protection to guard against excessive noise.

- Ensure appropriate footwear is worn to provide stability and protect your feet.

Work Environment

- Keep the workspace clean and free from clutter.

- Ensure proper lighting to enhance visibility.

- Maintain a stable surface to prevent equipment from tipping over.

- Be aware of your surroundings and potential hazards.