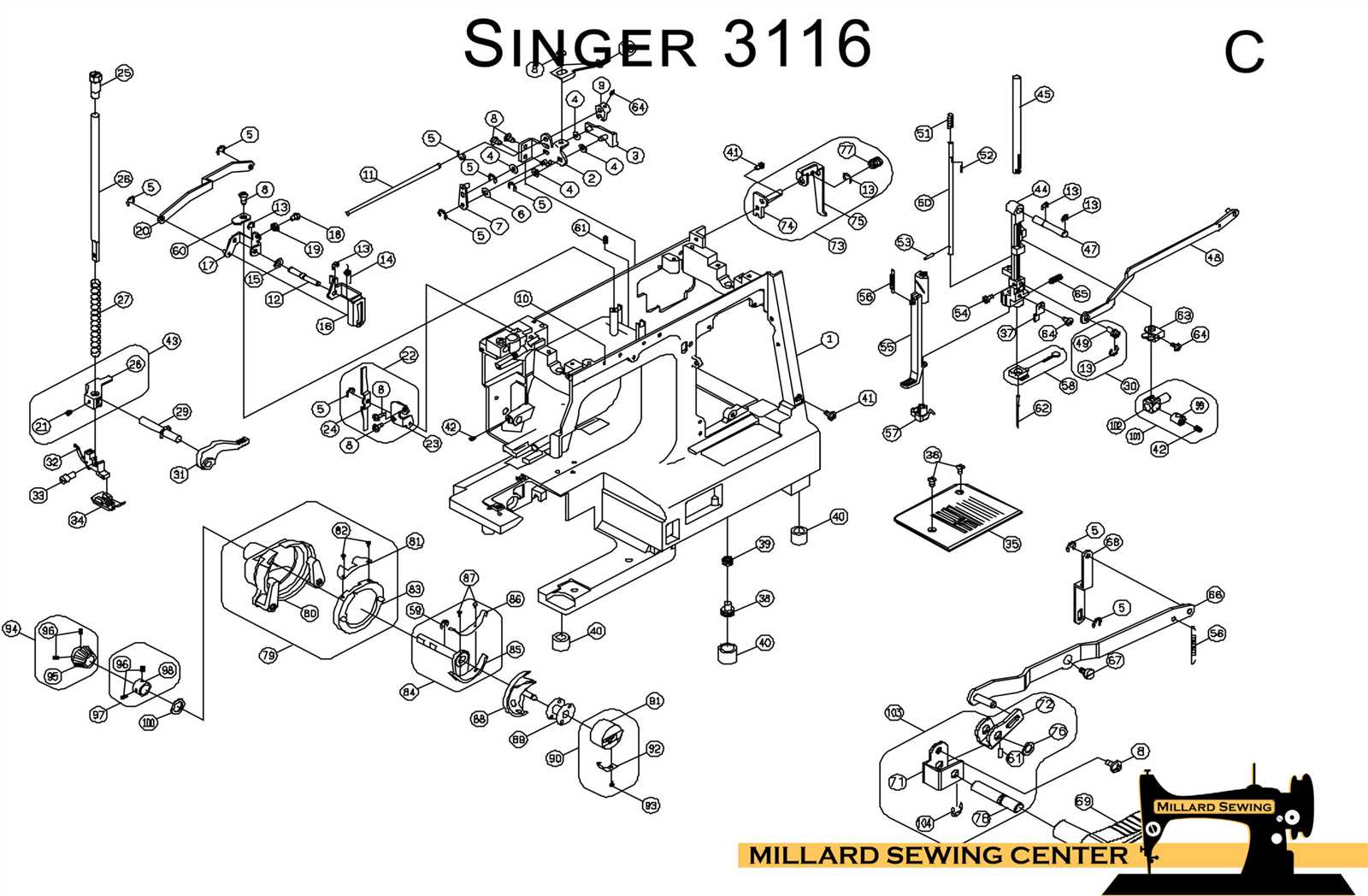

In the realm of textile machinery, comprehending the intricate relationships between various elements is crucial for optimal performance. A clear representation of these components aids in effective maintenance and troubleshooting. This guide seeks to illuminate the essential connections that ensure smooth operation and longevity of your equipment.

By examining the configurations and interdependencies of individual units, users can gain insight into the functionality and design of their machinery. Whether you are a novice or an experienced operator, mastering this knowledge can significantly enhance your ability to address issues promptly.

In the following sections, we will explore detailed schematics that break down the assembly, making it easier to navigate and identify each segment. With this foundational understanding, you will be better equipped to undertake repairs and replacements, ensuring your equipment remains in peak condition.

Understanding Husqvarna Viking Machines

In the realm of sewing technology, certain brands stand out for their innovation and reliability. This section delves into the intricacies of these remarkable machines, emphasizing their design, functionality, and the benefits they offer to both novice and experienced users.

Key Features and Innovations

These machines are equipped with advanced functionalities that cater to a variety of sewing needs. From user-friendly interfaces to robust stitching capabilities, each model is crafted to enhance creativity and efficiency. The incorporation of technology ensures that users can achieve professional results with ease, making it a favored choice among enthusiasts.

Maintenance and Support

Proper upkeep is essential for longevity and performance. Understanding the components and their roles can significantly aid in troubleshooting and maintenance. With a wealth of resources available, users can easily access information and support, ensuring their equipment remains in optimal condition for years to come.

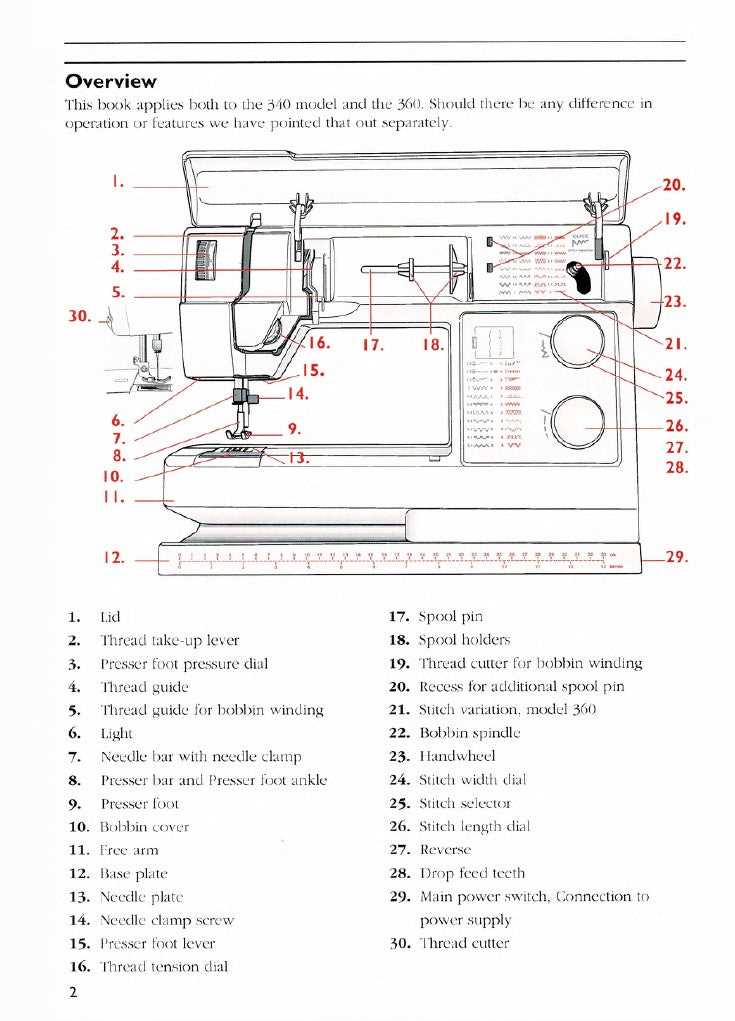

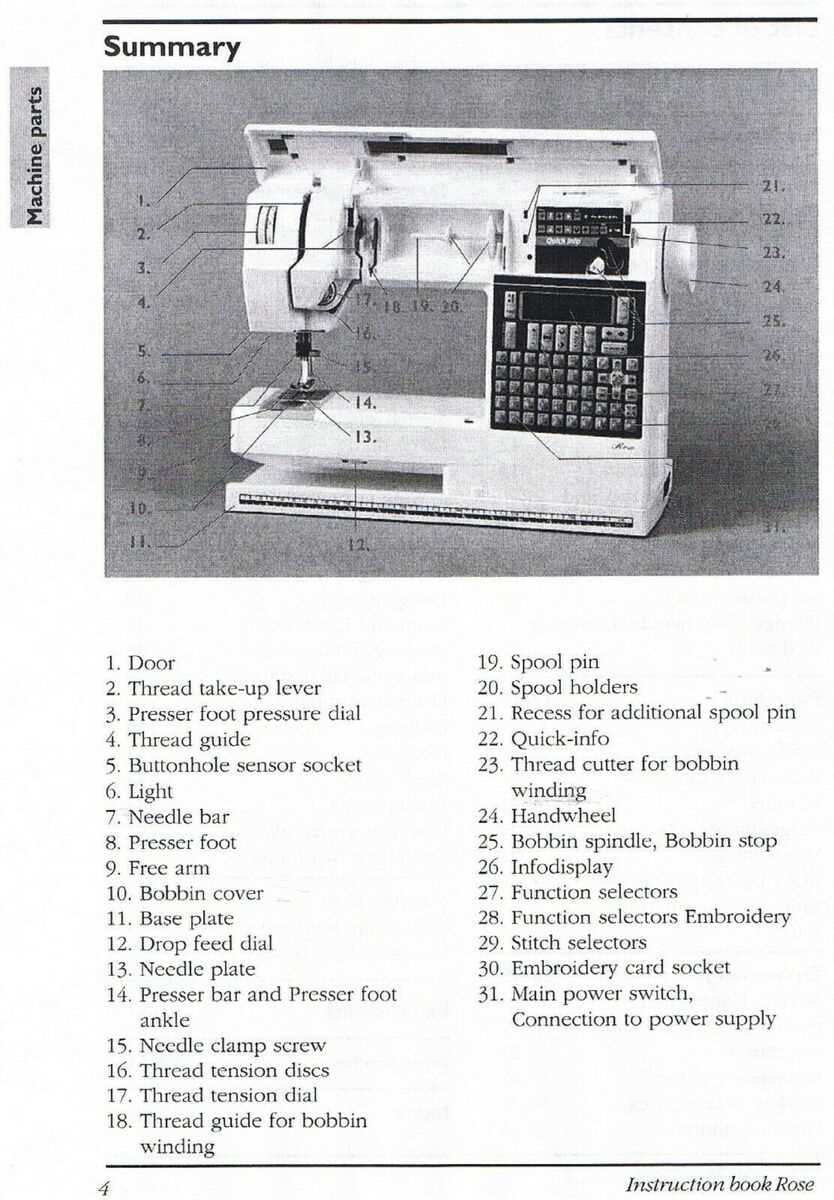

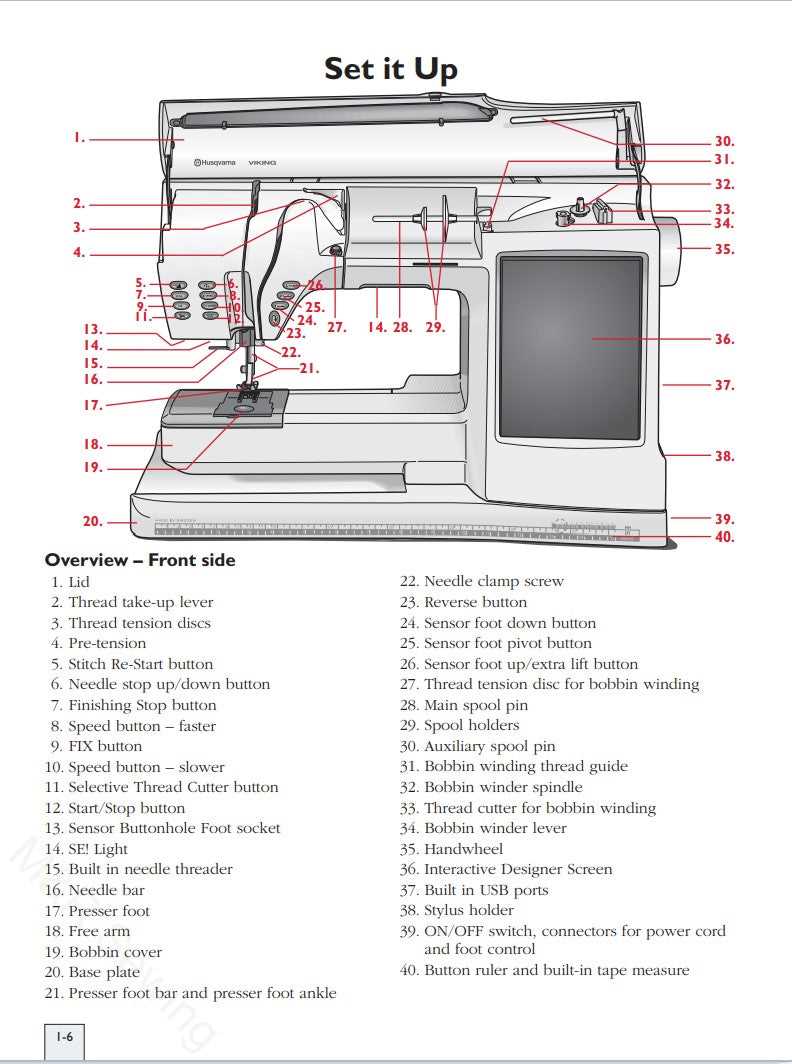

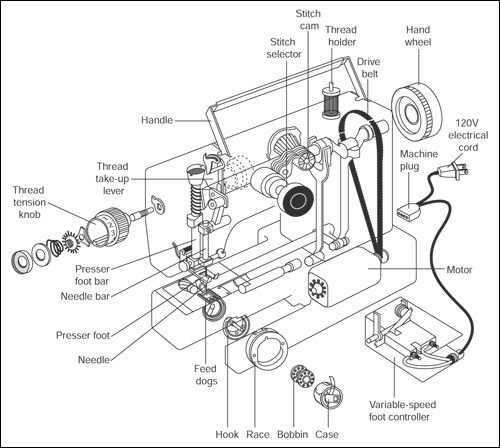

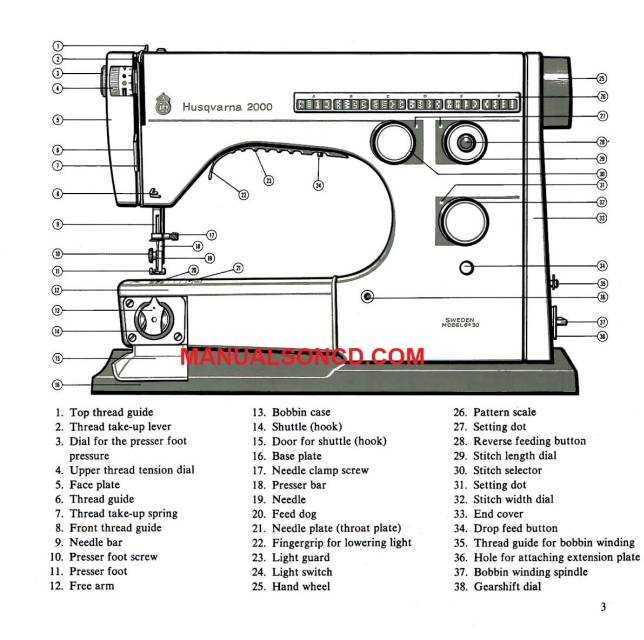

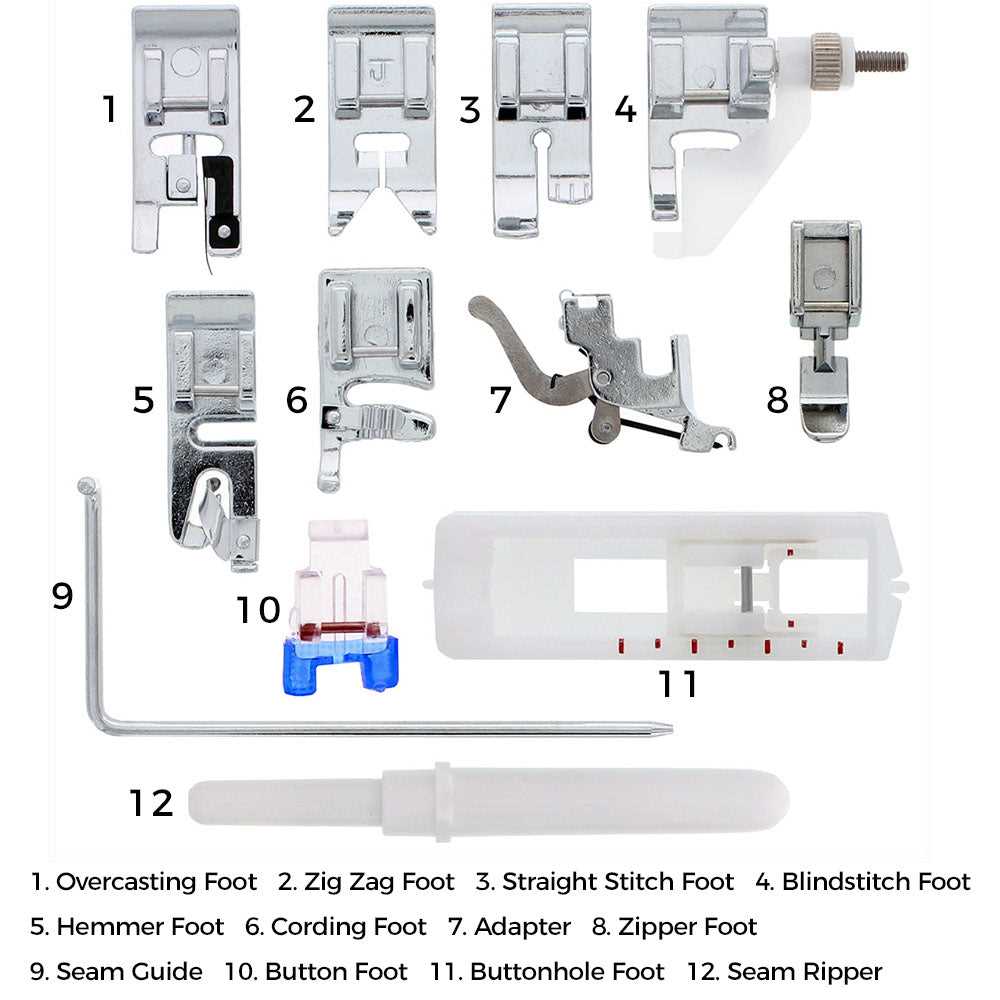

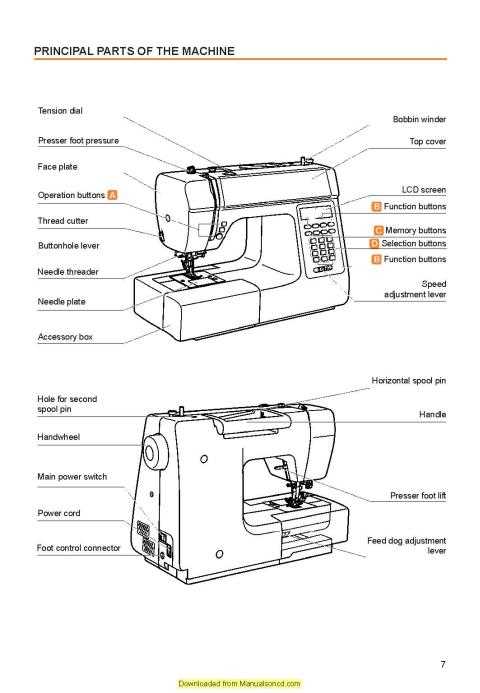

Key Components of Sewing Machines

Understanding the essential elements of stitching devices is crucial for both beginners and experienced users. These fundamental components work in harmony to create the intricate process of sewing fabric together, making it important to grasp their functions and interrelationships.

Essential Mechanisms

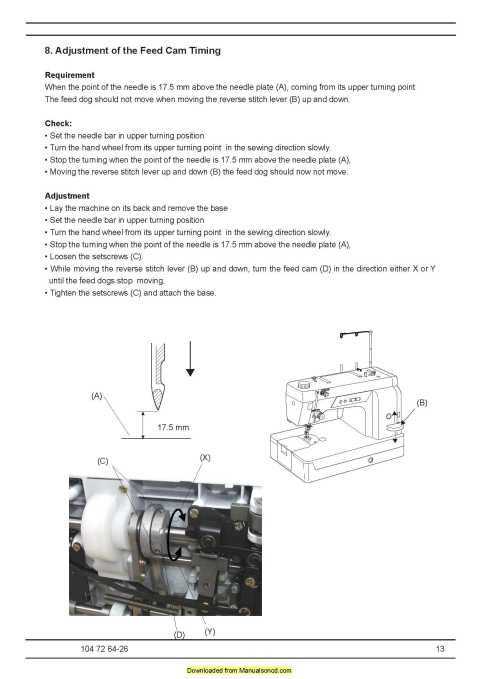

At the heart of every sewing machine lies the drive mechanism, which powers the entire unit. This system typically includes a motor, gears, and belts that work together to enable smooth operation. Additionally, the needle plays a vital role, as it pierces the fabric to form stitches, while the bobbin supplies the thread necessary for this task. A well-functioning needle and bobbin assembly is essential for achieving high-quality results.

Supporting Elements

Other important features include the presser foot, which holds the fabric in place as it moves through the machine, and the feed dogs, which help to guide the material during the stitching process. Adjusting these elements can greatly affect the outcome of your projects. Familiarity with these key components enhances not only the sewing experience but also improves the quality of the finished work.

Benefits of Using Original Parts

Utilizing authentic components in machinery and equipment offers numerous advantages that contribute to overall performance and longevity. These genuine items are designed to fit perfectly and work seamlessly with the systems they are intended for, ensuring optimal functionality and reliability.

Quality Assurance

Original components are manufactured to meet stringent quality standards, which enhances the durability and efficiency of the equipment. When you choose these high-quality items, you minimize the risk of malfunctions and breakdowns, leading to fewer repairs and downtime.

Perfect Compatibility

Using genuine items guarantees perfect compatibility with your machine. This compatibility ensures that every part functions together harmoniously, which is crucial for maintaining peak performance. Non-genuine alternatives may lead to improper fitment, potentially causing further issues down the line.

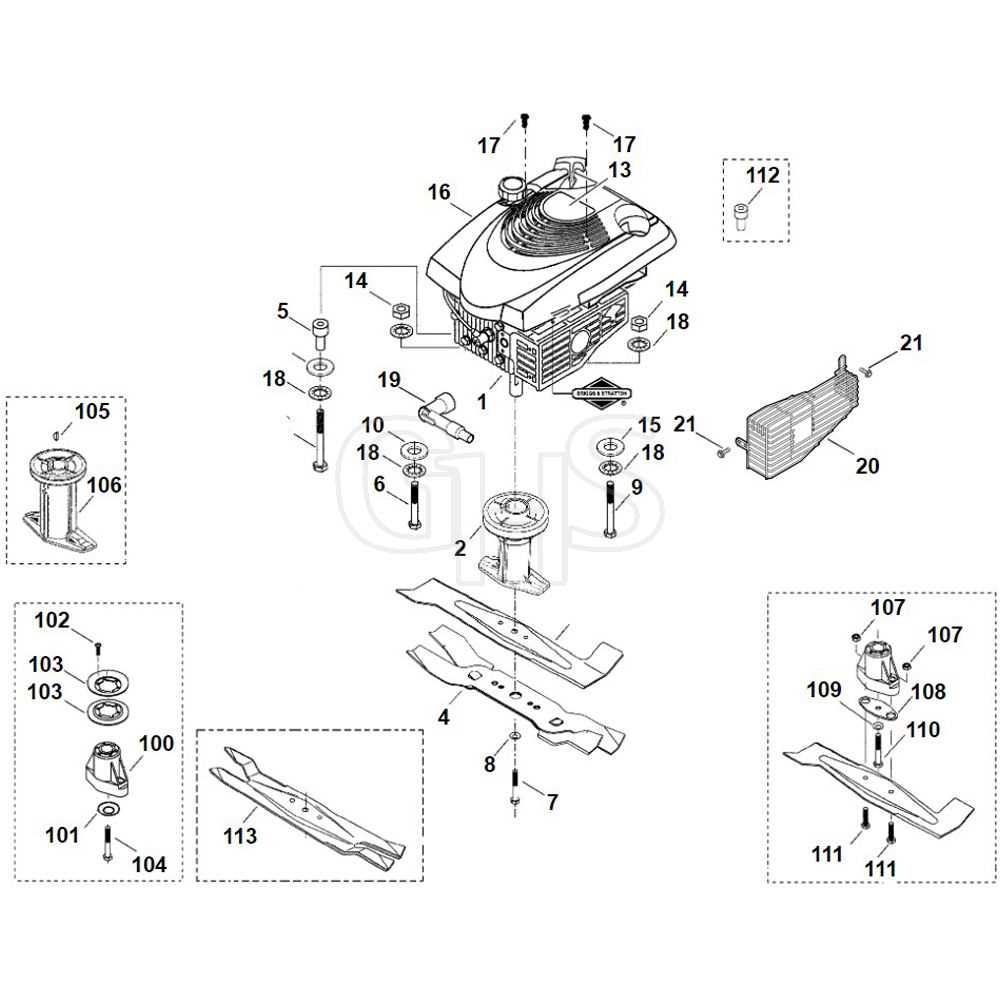

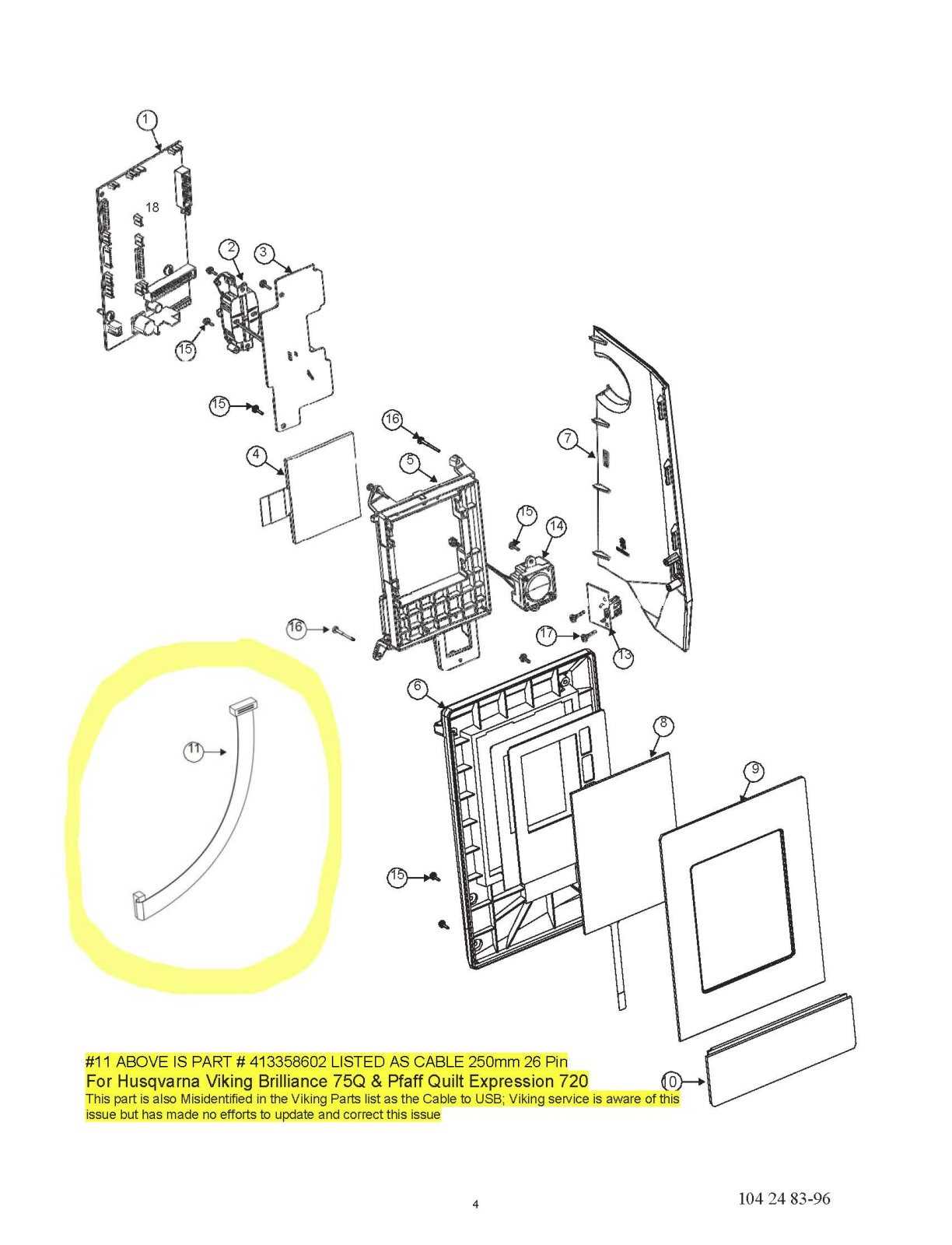

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual representations offer valuable insights into the components of machinery, allowing users to identify and locate each piece accurately. By mastering the art of interpretation, one can streamline the repair process and ensure optimal performance.

Key Elements of Illustrations

Typically, these visuals include numbered references that correspond to lists, providing clarity on individual components. Familiarize yourself with the legends and annotations, as they often highlight specific features or installation instructions.

Tips for Effective Interpretation

Take your time to study each section carefully. Cross-reference the visual with any accompanying documentation to deepen your understanding. Practice makes perfect, so don’t hesitate to revisit and delve into different illustrations to enhance your skills over time.

Common Issues with Husqvarna Vikings

Every sewing machine can encounter challenges that affect its performance and reliability. Understanding these frequent problems can help users maintain their equipment and ensure a smooth sewing experience. Below are some typical concerns that owners may face.

Thread Tension Problems: One of the most common issues is improper thread tension. If the tension is too tight or too loose, it can lead to uneven stitches and frustration during projects.

Bobbin Issues: Problems with the bobbin can cause jamming or uneven stitching. It’s essential to check that the bobbin is wound correctly and placed securely.

Needle Concerns: Using the wrong type or size of needle can significantly impact the sewing process. Regularly changing needles can prevent many issues related to skipped stitches or fabric damage.

Motor Overheating: Overworking the machine can lead to motor overheating, causing it to shut down. It’s crucial to take breaks and avoid excessive use to prolong the machine’s life.

Feed Dogs Malfunction: If the feed dogs are not functioning correctly, fabric may not move through the machine smoothly. Regular cleaning and maintenance can help prevent this problem.

Where to Find Replacement Parts

Locating suitable components for your sewing machine can significantly enhance its performance and longevity. Understanding the various sources available will help you make informed decisions.

- Authorized Dealers: Visit local retailers that specialize in sewing equipment to find original components.

- Online Marketplaces: Websites such as eBay and Amazon offer a wide range of options, often at competitive prices.

- Manufacturer’s Website: Many companies provide direct access to their inventory, ensuring you get authentic items.

- Repair Shops: Local repair technicians can be a valuable resource for sourcing components, as they often have connections.

By exploring these avenues, you can ensure that your machine remains in excellent condition with the ultimate replacements it requires.

Maintaining Your Sewing Machine

Proper upkeep of your stitching device is essential for optimal performance and longevity. Regular maintenance not only enhances the functionality but also prevents potential issues that could disrupt your creative projects. By following a few simple steps, you can ensure that your equipment remains in excellent condition.

Cleaning is the first step in preserving your machine. Dust and lint can accumulate in various areas, affecting operation. Make it a habit to clean the exterior and interior after each use. Utilize a soft brush to remove debris from the feed dogs and bobbin area, ensuring smooth operation.

Lubrication is equally important. Many models require periodic oiling to maintain their moving parts. Consult your user manual for specific instructions on which parts need lubrication and the appropriate type of oil to use. This will reduce friction and prevent wear over time.

Needle care should not be overlooked. Regularly check for signs of wear and replace needles as needed. A dull or damaged needle can cause skipped stitches and fabric damage, affecting the quality of your work. Keep a variety of needle sizes on hand to accommodate different materials.

Storage is also crucial. When not in use, cover your machine to protect it from dust and potential damage. Store it in a safe, dry place away from direct sunlight and extreme temperatures to maintain its functionality.

By incorporating these simple practices into your routine, you can extend the life of your stitching device and enjoy seamless crafting experiences for years to come.

Upgrading Parts for Better Performance

Enhancing the efficiency of your machine can significantly impact its overall functionality. By replacing or upgrading certain components, you can achieve improved reliability, speed, and precision in your tasks.

Consider the following upgrades:

- Motors: Switching to a high-performance motor can provide increased power and durability.

- Blades: Opting for sharper or specialized blades enhances cutting precision and reduces strain.

- Belts: Upgrading to reinforced belts ensures better power transfer and longevity.

Regular maintenance and thoughtful enhancements lead to optimal operation, ensuring your equipment meets your highest standards.

Identifying Model-Specific Components

Understanding the unique elements of each machine model is crucial for effective maintenance and repair. Recognizing the specific components that belong to a particular design can help users ensure they are sourcing the correct replacements and making informed decisions during servicing.

Common Components Across Models

While various machines may share similarities, each model often has distinct features that set it apart. Being familiar with these unique characteristics enables users to identify what is essential for their specific machine. The table below outlines some common components and highlights the differences among models.

| Component Type | Model A | Model B | Model C |

|---|---|---|---|

| Motor Type | AC Induction | Brushless | Universal |

| Needle System | System 2020 | System 134 | System 16 |

| Foot Control | Electronic | Mechanical | Wireless |

Importance of Accurate Identification

Accurately identifying components is essential not only for repairs but also for optimizing performance. Using incorrect parts can lead to inefficiencies or even damage. Therefore, consulting user manuals and manufacturer resources is recommended to ensure compatibility and reliability.

Resources for Troubleshooting Guides

Accessing effective resources can significantly enhance your ability to resolve issues with sewing machines. Whether you’re encountering mechanical glitches or software malfunctions, a well-curated selection of guides can streamline the process of finding solutions.

Online Forums and Communities

Engaging with online communities can provide invaluable insights. These platforms often feature discussions, troubleshooting tips, and shared experiences from other users facing similar challenges.

Official Manufacturer Documentation

Consulting the official documentation is crucial. These manuals typically include detailed instructions and troubleshooting sections that address common problems and offer step-by-step guidance. Make sure to reference the correct model for the most accurate information.

Connecting with Husqvarna Communities

Engaging with fellow enthusiasts and experts can enhance your experience and understanding of your sewing and crafting equipment. These communities offer valuable insights, support, and a shared passion for creativity. By connecting with others, you can explore resources, share tips, and delve into discussions about techniques and innovations.

Online Platforms

Numerous online forums and social media groups are dedicated to sewing aficionados. Here, members share their experiences, troubleshooting advice, and project ideas.

Local Meetups

Participating in local events can foster connections with nearby crafters. Workshops and classes provide hands-on learning opportunities and a chance to build relationships.

| Community Type | Benefits |

|---|---|

| Online Forums | 24/7 access to a wealth of information and support. |

| Social Media Groups | Instant updates and vibrant discussions on trends. |

| Local Workshops | Hands-on experience and personal connections. |