The intricate world of agricultural machinery plays a vital role in modern farming, enhancing productivity and efficiency. This section explores the various elements that comprise these powerful machines, focusing on their design and functionality. A thorough comprehension of these components can greatly assist operators in optimizing their equipment.

By examining the schematics of different models, users can gain valuable insights into the interrelations of each element. Such knowledge not only aids in effective maintenance but also empowers operators to make informed decisions regarding repairs and upgrades. Emphasizing the importance of each segment, we delve into the ultimate guide for understanding these mechanisms.

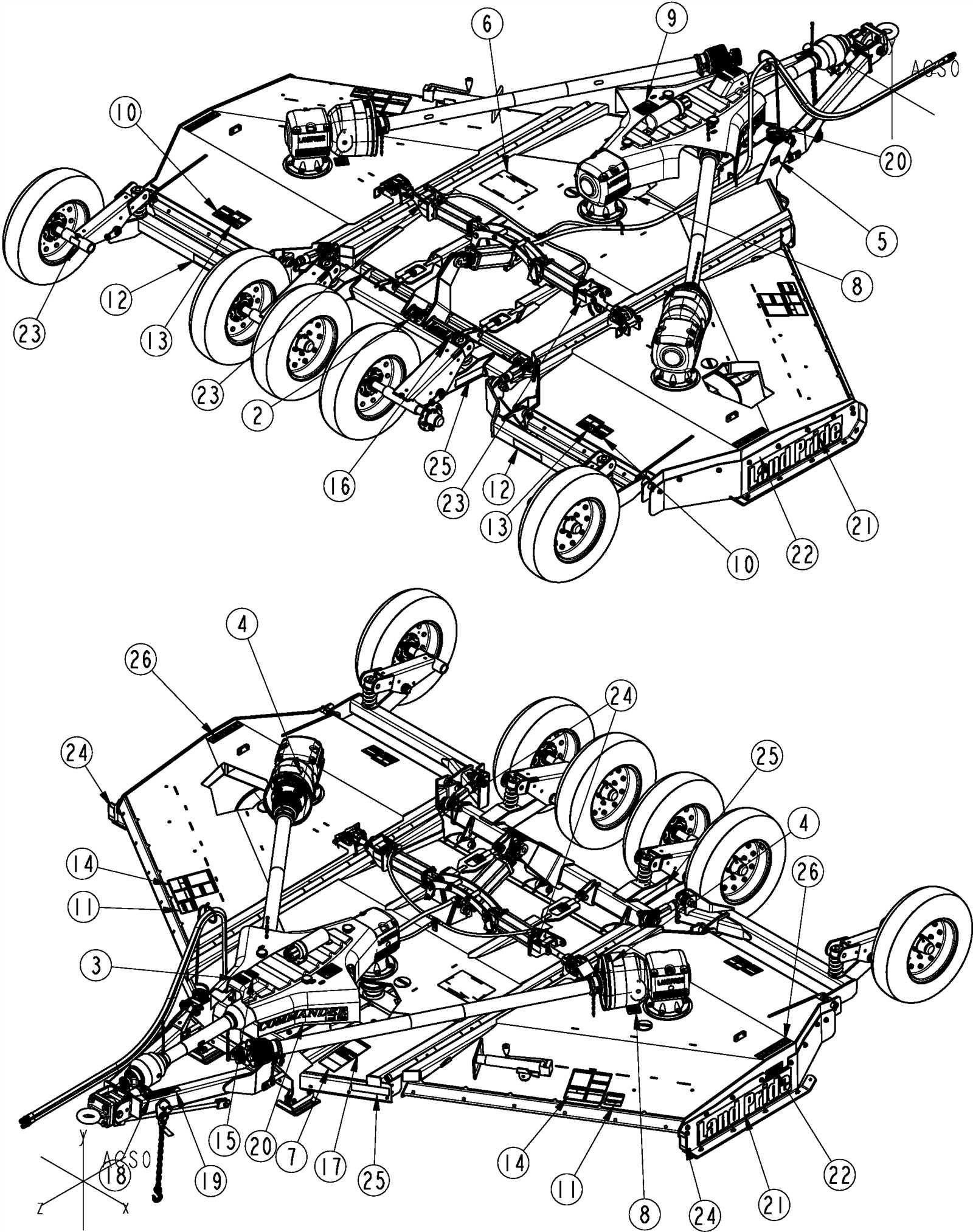

For those engaged in agricultural operations, a clear visual representation of these components is essential. It enables a more profound appreciation of how each part contributes to the overall performance of the machinery. Understanding this relationship can ultimately lead to enhanced agricultural practices and improved outcomes.

Overview of International 475 Disc Parts

This section provides a comprehensive examination of the components essential for the efficient operation of a specific agricultural implement. Understanding the various elements involved is crucial for maintenance, repair, and overall functionality.

Key Components: The implement consists of several critical elements, including the frame, blades, and hydraulic systems. Each of these components plays a significant role in ensuring optimal performance.

Frame: The structure serves as the backbone, providing stability and support for all other components. A robust frame is vital for durability during operation.

Blades: The cutting edges are designed to penetrate the soil effectively, enabling the implement to perform its intended function. Regular inspection and maintenance of these elements are essential for longevity.

Hydraulic Systems: These systems control the movement and adjustment of the implement, allowing for precision in operation. Proper functioning of the hydraulics is critical for achieving the desired results.

By delving into the specifics of each component, users can gain valuable insights that lead to improved performance and reduced downtime.

Key Components of the Disc Harrow

The efficiency of soil preparation is largely determined by the essential elements of a tilling implement. Understanding these components can greatly enhance the performance of the equipment, making the task of land cultivation more effective and streamlined.

Blades: These sharp surfaces are designed to cut through soil, breaking it up and creating a finely tilled bed. Their shape and size can vary, impacting the depth and intensity of soil disturbance.

Frame: The sturdy structure provides support and stability, ensuring that the implement maintains its integrity while in use. A well-designed frame can also facilitate easier maneuverability.

Bearings: These are crucial for allowing smooth rotation of the blades. High-quality bearings reduce friction and wear, contributing to the longevity of the equipment.

Hitch: This component connects the implement to the tractor, playing a vital role in the transfer of power and ensuring proper alignment during operation.

Weight: Additional mass can enhance penetration into the soil, allowing the implement to perform more effectively in tougher conditions.

By delving into these fundamental aspects, operators can better appreciate the ultimate functionality of their tilling equipment, leading to improved agricultural outcomes.

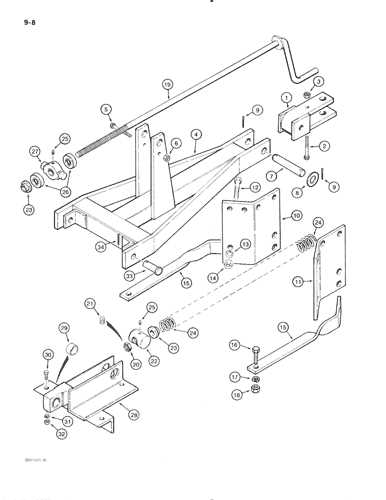

Understanding the Parts Diagram

Grasping the layout of a machinery schematic is crucial for effective maintenance and repair. This visual representation aids users in identifying individual components and their relationships within the overall structure, streamlining troubleshooting processes and ensuring proper functionality.

Key Components Explained

Each element in the schematic serves a specific purpose, contributing to the machine’s efficiency. Familiarity with these elements enables operators to recognize wear and tear, allowing for timely replacements and minimizing downtime.

Utilizing the Schematic for Maintenance

By referring to the layout, technicians can efficiently pinpoint issues and execute repairs with precision. Understanding the schematic not only enhances operational efficiency but also fosters a proactive approach to machinery upkeep.

Importance of Each Component

Understanding the significance of each element within a machinery assembly is crucial for optimal performance and maintenance. Each part plays a vital role in ensuring the system operates efficiently and reliably.

- Functionality: Each component contributes to the overall functionality, allowing the machinery to perform specific tasks effectively.

- Durability: High-quality materials enhance the lifespan of the equipment, reducing the frequency of repairs and replacements.

- Interconnectivity: The relationship between components ensures seamless operation, as they rely on each other to function correctly.

- Maintenance: Knowing the role of each part aids in troubleshooting and streamlining maintenance processes, ultimately leading to improved productivity.

By delving into the importance of each element, operators can ensure their equipment remains in peak condition and maximizes its potential.

Common Issues with Disc Parts

Understanding the frequent challenges that can arise with agricultural implements is crucial for maintaining optimal performance. Various components may experience wear and tear or malfunction, leading to inefficiencies in operation. Recognizing these issues can help in timely intervention and prolonging the lifespan of the equipment.

Wear and Tear

One of the most prevalent concerns is the gradual degradation of essential components. Friction during operation can lead to significant wear, resulting in reduced effectiveness. Regular inspection is vital to identify signs of deterioration, allowing for proactive measures such as replacement or repair.

Misalignment and Adjustment

Improper alignment can cause uneven pressure distribution, leading to uneven performance. Incorrect settings may also contribute to increased wear, making it essential to ensure that all elements are correctly calibrated. Regular maintenance checks can help identify these issues early, ensuring smooth functionality.

Addressing these common challenges through diligent maintenance and timely repairs can greatly enhance the efficiency and longevity of your agricultural machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of machinery. By implementing regular care routines, operators can enhance efficiency and extend the lifespan of their equipment.

- Conduct routine inspections to identify wear and tear.

- Clean components regularly to prevent buildup of debris.

- Lubricate moving parts to reduce friction and wear.

- Replace worn or damaged elements promptly to avoid further issues.

- Follow the manufacturer’s recommendations for maintenance schedules.

Adhering to these practices will lead to improved functionality and reduced downtime, ultimately maximizing investment returns.

How to Replace Worn Parts

Maintaining machinery is crucial for optimal performance, and replacing deteriorated components is a key aspect of this process. Understanding the signs of wear and knowing when to take action can help prevent further damage and ensure the longevity of your equipment. Here’s a concise guide to assist you in effectively replacing those essential components.

First, identify the specific components that require attention. Look for visible signs of wear such as cracks, excessive play, or unusual noises during operation. Regular inspections can help catch these issues early.

Once you have pinpointed the worn components, gather the necessary tools and replacement items. Having everything on hand before starting the process can save time and reduce frustration.

Follow these general steps for replacing the components:

| Step | Description |

|---|---|

| 1 | Ensure the equipment is turned off and disconnected from power sources. |

| 2 | Remove any coverings or shields to access the worn components. |

| 3 | Carefully detach the old component using the appropriate tools. |

| 4 | Install the new component, ensuring it is properly aligned and secured. |

| 5 | Reassemble any coverings or shields removed earlier. |

| 6 | Test the machinery to confirm proper operation and check for any issues. |

By following these steps, you can effectively replace worn components and maintain the functionality of your equipment, ensuring it runs smoothly for years to come.

Tools Needed for Repairs

Proper maintenance and repairs require a selection of essential implements that ensure efficiency and accuracy. Having the right tools on hand not only simplifies the process but also enhances safety and effectiveness during the task.

Basic Hand Tools

Fundamental hand tools, such as wrenches, screwdrivers, and pliers, are crucial for any repair job. These versatile implements enable users to tighten, loosen, and manipulate components with precision.

Specialized Equipment

For more intricate tasks, specialized equipment like torque wrenches and diagnostic tools become necessary. These devices allow for detailed assessments and adjustments, ensuring that every aspect of the machinery functions optimally.

Comparative Analysis with Other Models

This section explores the distinctions and similarities between various agricultural machinery designs, focusing on their functionalities, efficiencies, and user experiences. By examining these differences, we can better understand the unique advantages and potential limitations of each system.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weight | 3,200 lbs | 3,500 lbs | 3,000 lbs |

| Working Width | 12 ft | 10 ft | 14 ft |

| Horsepower Requirement | 60 HP | 75 HP | 55 HP |

| Operating Speed | 6 mph | 5 mph | 7 mph |

| Durability | High | Medium | High |

Ultimately, understanding these comparative aspects can guide potential buyers in making informed decisions that align with their operational needs and preferences.

Upgrading Your Disc Harrow

Enhancing the efficiency and performance of your soil cultivation equipment can significantly improve your farming operations. Upgrades not only prolong the lifespan of your machinery but also increase productivity, making it easier to achieve optimal soil conditions for planting. Investing in modern components can transform your implement into a more effective tool, allowing for better soil penetration and mixing.

Choosing the Right Components

Selecting appropriate enhancements is crucial. Consider replacing worn-out elements with high-quality alternatives that offer improved durability and performance. Components such as blades, bearings, and frames should be evaluated based on material and design to ensure compatibility and effectiveness in various soil types.

Installation and Maintenance Tips

Proper installation is key to maximizing the benefits of your upgrades. Follow manufacturer guidelines carefully, and ensure that all fittings are secure to prevent future issues. Regular maintenance checks will help maintain performance, as well as identify any potential problems before they escalate. Keeping your equipment in top shape will lead to better yields and a more efficient workflow.

Frequently Asked Questions

This section aims to address common inquiries regarding the components and mechanisms related to agricultural machinery. Understanding these elements can significantly enhance operational efficiency and maintenance practices.

What are the key components I should be aware of?

Familiarity with essential parts, such as blades, frames, and bearings, is crucial for effective management and troubleshooting.

How can I identify the right replacement for a worn-out component?

Consulting the manufacturer’s specifications or a reliable catalog can help you find the correct substitutes for damaged or outdated elements.

Are there any recommended maintenance practices?

Regular inspections, proper lubrication, and timely replacements can prolong the lifespan of your machinery and improve performance.

Where can I find detailed information about specific components?

User manuals and online resources often provide in-depth insights and diagrams that can assist in understanding each part’s function.

What should I do if I encounter a problem during operation?

It’s advisable to stop using the equipment immediately and consult a qualified technician to diagnose and resolve any issues safely.

Resources for Further Reading

This section provides a curated list of valuable materials that can enhance your understanding of agricultural machinery components. Whether you are a professional, a student, or simply an enthusiast, these resources will offer deeper insights and practical knowledge.

| Resource Type | Title | Author/Publisher | Link |

|---|---|---|---|

| Book | Farm Equipment Maintenance | John Smith | Link |

| Article | Understanding Tillage Tools | Agricultural Journal | Link |

| Video | How to Service Farm Implements | YouTube Channel | Link |

| Guide | Complete Guide to Equipment Setup | Tech Publishing | Link |