The world of precision measurement is intricate and essential for various industries, where accuracy is paramount. This section aims to explore the components that make up these remarkable instruments, shedding light on their functionality and significance in achieving exact measurements.

Delving into the inner workings of these devices reveals a carefully designed system, where each element plays a crucial role. By understanding these features, users can maximize the efficiency and effectiveness of their measurements, ultimately leading to better outcomes in their projects.

Whether for professional applications or personal hobbies, comprehending the construction and operation of these tools enhances one’s ability to achieve the ultimate precision needed for any task. This knowledge is invaluable for anyone looking to improve their measurement techniques and outcomes.

Understanding Mitutoyo Micrometers

This section delves into precision measurement tools renowned for their accuracy and reliability in various applications. These instruments are essential for anyone requiring precise thickness or diameter measurements in engineering and manufacturing contexts.

Key features of these instruments include:

- High precision in measurement

- Robust construction for durability

- Easy-to-read scale for quick assessments

- Fine adjustment mechanisms for enhanced accuracy

To fully appreciate their functionality, it’s important to recognize the main components:

- Frame: The structure providing stability and support.

- Spindle: The movable part that engages with the object being measured.

- Thimble: The rotating part that allows for fine adjustments.

- Locking Mechanism: Ensures measurements remain fixed during reading.

These tools are invaluable for quality control and precision engineering, making them a staple in professional environments. Mastery of their use can greatly enhance measurement accuracy and efficiency.

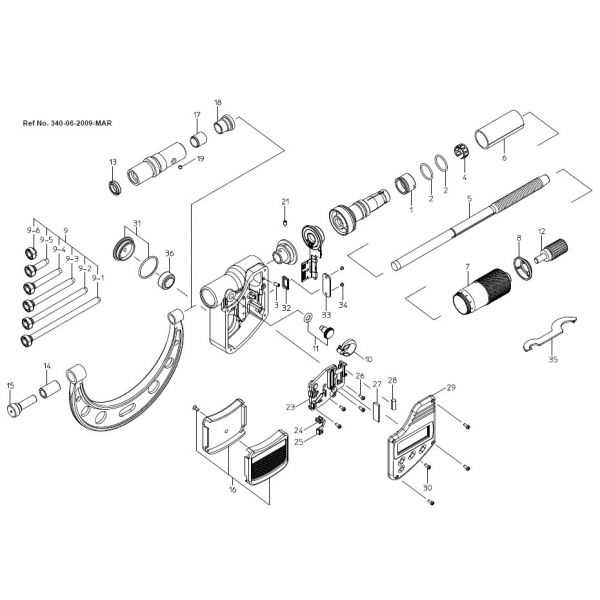

Key Components of Micrometers

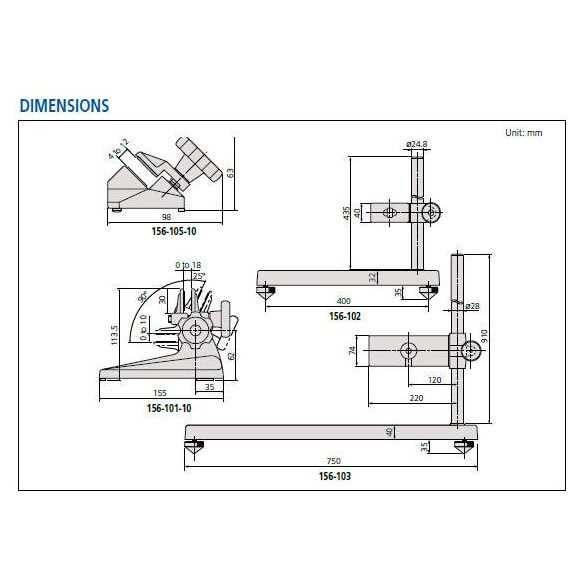

Precision measuring instruments consist of several essential elements that work together to ensure accurate and reliable measurements. Each component plays a vital role in the overall functionality and effectiveness of the tool, allowing users to obtain precise dimensions of small objects.

Main Body

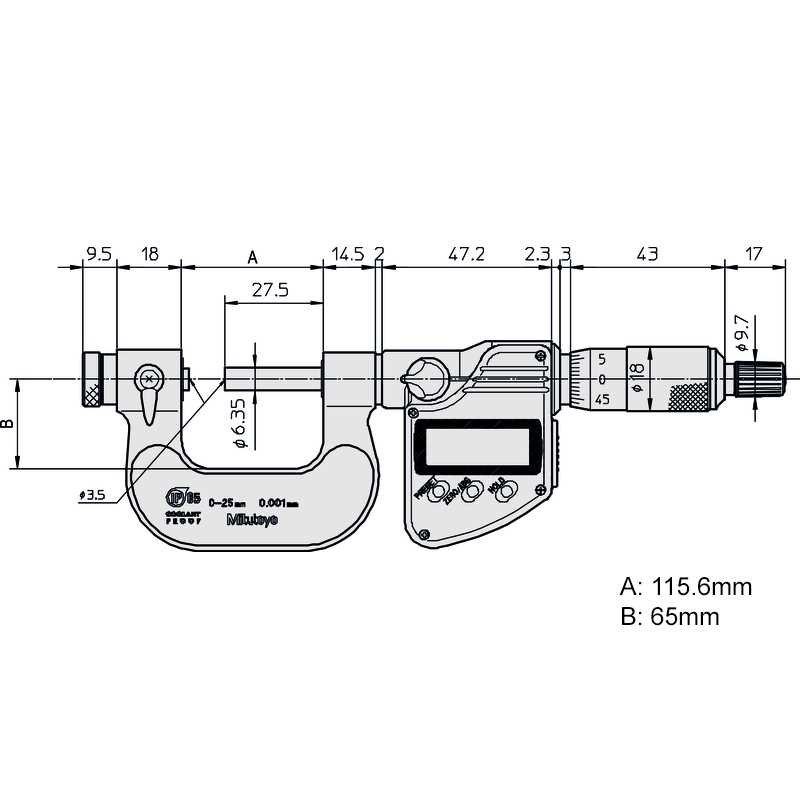

The main body serves as the foundation of the instrument, providing stability and support. It is typically crafted from robust materials to withstand frequent use while maintaining accuracy. This part often features a calibrated scale, allowing users to read measurements with ease.

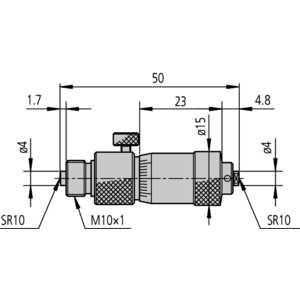

The measuring mechanism is crucial for achieving precise readings. It typically includes a movable spindle that can be adjusted to contact the object being measured. This component allows for fine adjustments, enabling users to measure with exceptional accuracy. Together with the calibrated scale, this mechanism ensures that even the smallest variations can be detected.

Function of the Thimble

The thimble serves a crucial role in the precision measurement tool, facilitating accurate readings and adjustments. Its design allows users to engage with the measuring instrument effectively, ensuring that measurements are both reliable and consistent.

Key Features

- Provides a gripping surface for easy rotation.

- Includes a scale for precise reading of measurements.

- Helps maintain consistent pressure on the object being measured.

Importance in Measurement

- Enhances user control over the measuring process.

- Contributes to overall measurement accuracy.

- Facilitates quick adjustments to achieve desired measurements.

Role of the Anvil

The anvil serves a crucial function in precision measurement instruments, acting as the stationary reference point that ensures accuracy during evaluation. Its design and material influence the reliability of measurements significantly.

Key Characteristics: The anvil is typically made from hard materials to withstand wear and maintain a smooth surface, which is essential for consistent results.

Importance of Alignment: Proper alignment between the anvil and the opposing measuring component is vital. Any misalignment can lead to erroneous readings, undermining the instrument’s ultimate purpose.

In summary, the anvil’s role is fundamental in guaranteeing that measurements are both precise and repeatable, making it an indispensable part of the measurement process.

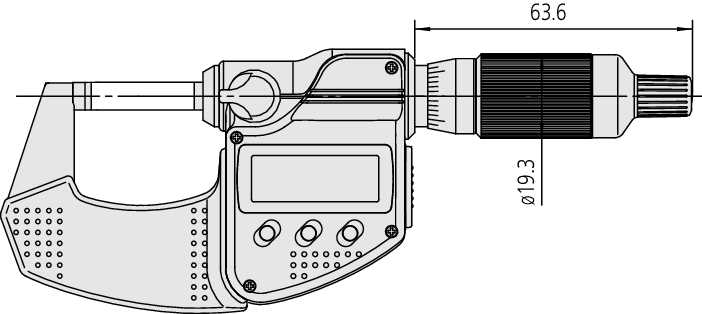

How the Barrel Works

The barrel serves a crucial function in the precision measurement tool, acting as a guide for the sliding mechanism. This component is essential for achieving accurate readings, ensuring that measurements are both reliable and consistent.

Mechanism of the Barrel

The design of the barrel allows for smooth movement, which is vital for measuring small dimensions. Here’s how it operates:

- Guidance: The inner surface of the barrel is meticulously crafted to facilitate the movement of the measuring rod.

- Graduation: The markings along the barrel provide visual reference points, enabling the user to read measurements accurately.

- Locking System: Some barrels include a mechanism that can be engaged to hold the position of the measuring rod, preventing any accidental shifts during measurement.

Importance of Precision

The integrity of the barrel directly impacts the overall functionality of the measuring instrument. Factors to consider include:

- Quality of materials used in construction, affecting durability and wear.

- Alignment of the barrel with other components, ensuring that all parts work in harmony.

- Regular maintenance to prevent dirt or debris from interfering with movement.

Overall, understanding the workings of the barrel enhances the user’s ability to perform precise measurements and maintain the tool effectively.

Importance of the Spindle

The spindle plays a crucial role in the precision measurement process. It serves as the primary component that facilitates accurate distance assessment between two surfaces. This element is integral to the overall functionality, ensuring that measurements are not only reliable but also reproducible across various applications.

Precision is paramount in measurement tools, and the spindle directly affects this accuracy. Its design allows for smooth operation, minimizing the risk of errors during the measurement process. When the spindle engages with the object being measured, it provides a stable point of reference, crucial for achieving the desired level of detail.

Moreover, the spindle’s material and construction impact its durability and performance. High-quality materials enhance its resistance to wear and tear, ensuring longevity and maintaining accuracy over time. Investing in a robust spindle ultimately leads to more reliable outcomes in any measurement endeavor, making it an indispensable part of the tool’s architecture.

Reading the Micrometer Scale

Understanding the measurement scale of precision tools is essential for accurate readings in various applications. This section explores the fundamental concepts behind interpreting these scales effectively, ensuring precision in your work.

Components of the Scale

- Main Scale: Displays whole units.

- Vernier Scale: Provides fractional measurements.

- Thimble: Contains additional measurement markings.

Steps to Take Accurate Measurements

- Align the measuring surfaces properly.

- Observe the main scale reading at the zero point of the vernier.

- Identify the line on the vernier that aligns with a line on the main scale.

- Add the values from both scales for the final measurement.

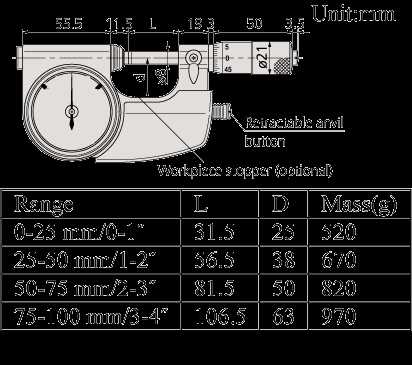

Types of Mitutoyo Micrometers

Precision measuring tools come in various forms, each designed for specific applications and accuracy requirements. Understanding the different varieties helps users select the most suitable instrument for their tasks.

Common Types

- External Measurement Tool

- Internal Measurement Tool

- Depth Measurement Tool

- Universal Tool

Specialized Variants

- Digital Version

- Vernier Type

- Specialty Tools for Specific Industries

Calibration and Maintenance Tips

Ensuring the precision and longevity of measuring instruments requires regular calibration and careful upkeep. Proper attention to these practices not only enhances accuracy but also extends the lifespan of the device, making it a reliable tool for various applications.

Routine checks and adjustments are essential to maintain the accuracy of your instrument. It is advisable to establish a regular schedule for calibration based on usage frequency and environmental conditions. Follow manufacturer guidelines for optimal results.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for signs of wear or damage. |

| Calibration Check | Quarterly | Use certified standards for verification. |

| Cleaning | After Each Use | Use a soft cloth to avoid scratches. |

| Lubrication | Annually | Apply appropriate lubricant to moving parts. |

By adhering to these tips, users can significantly improve the performance and durability of their measuring instruments. Consistent care and timely calibration will ensure that the tool remains a valuable asset in any setting.

Common Issues with Micrometers

Precision measuring tools are essential in various fields, but they can encounter several problems that affect their accuracy and usability. Understanding these common challenges can help users maintain their instruments and ensure reliable measurements.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Frequent use can lead to wear on the measuring surfaces, affecting precision. | Regularly inspect and replace worn components as needed. |

| Misalignment | Improper alignment can result in inaccurate readings. | Ensure the tool is properly calibrated and aligned before use. |

| Dust and Debris | Particles can accumulate on measuring surfaces, impacting results. | Clean the instrument with a soft cloth regularly to prevent contamination. |

| Temperature Variations | Extreme temperature changes can cause expansion or contraction of materials. | Use in a controlled environment or allow the tool to acclimate before use. |

| Improper Handling | Dropping or mishandling the instrument can lead to damage. | Handle with care and store in a protective case when not in use. |

Upgrading Micrometer Parts

Enhancing the functionality of precision measuring tools can significantly improve accuracy and user experience. Upgrading various components not only extends the tool’s lifespan but also ensures optimal performance in various applications.

- Consider replacing worn-out components for better precision.

- Explore advanced materials that offer increased durability.

- Evaluate the benefits of digital readouts for enhanced readability.

- Investigate ergonomic designs to improve user comfort during use.

Incorporating these upgrades can lead to a more efficient and reliable measuring experience, ultimately elevating the quality of work produced.

Applications in Precision Measurement

Precision measurement tools play a crucial role in various industries by ensuring accuracy and consistency in dimensions. These instruments are essential for quality control, product development, and research, providing the necessary reliability for intricate tasks.

Key Industries Utilizing Precision Instruments

- Manufacturing

- Aerospace

- Automotive

- Medical Device Production

- Electronics

Benefits of Using Precision Measuring Tools

- Enhanced accuracy in production

- Reduction of material waste

- Improved quality assurance

- Facilitation of compliance with standards

- Increased efficiency in workflows

Comparing Mitutoyo with Competitors

When evaluating precision measurement tools, understanding the distinctions between various brands is crucial for making informed decisions. This section explores how one leading manufacturer stacks up against its primary rivals, focusing on features, accuracy, and user experience.

Key Features and Specifications

| Brand | Accuracy (mm) | Measurement Range (mm) | Price Range ($) |

|---|---|---|---|

| Brand A | ±0.01 | 0-25 | 100-150 |

| Brand B | ±0.02 | 0-30 | 80-120 |

| Brand C | ±0.01 | 0-25 | 120-180 |

User Experience and Reliability

Beyond specifications, user satisfaction plays a vital role in brand loyalty. Many users report that the leading brand offers superior ergonomics and durability, leading to more consistent results over time compared to its competitors.