Understanding the internal configuration of complex tools is crucial for ensuring proper upkeep and seamless operation. This guide offers a detailed look at the structural elements that make up this powerful equipment, allowing for better insight into its functionality and design.

By familiarizing yourself with the layout, you can easily identify individual elements and their roles within the system. This knowledge will be beneficial not only for troubleshooting but also for enhancing the longevity of the machine.

Whether you’re conducting repairs or simply learning more about the equipment, a clear understanding of the various components will provide the necessary foundation for efficient handling and maintenance.

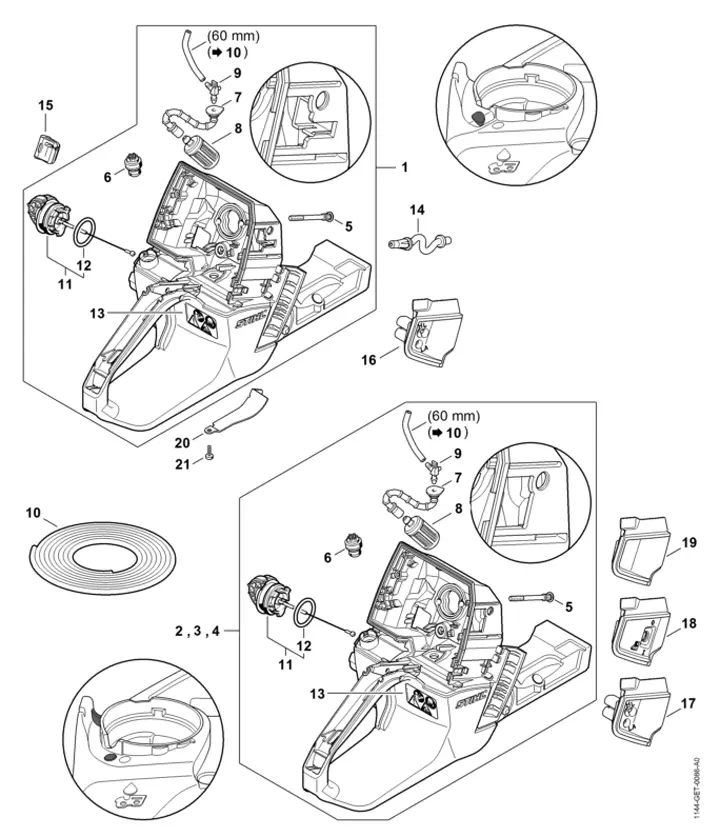

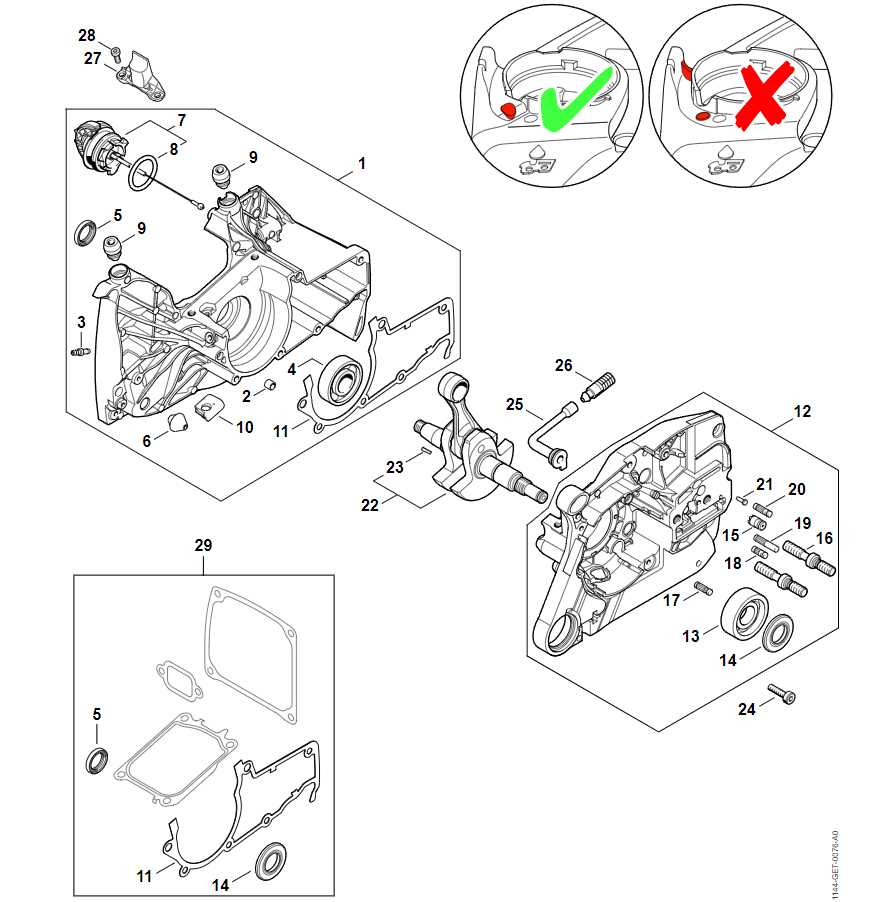

Ms661c Parts Diagram Overview

The following section offers a comprehensive look at the inner workings and components of a high-performance chainsaw. Understanding the intricate layout of its elements is key for maintenance, repair, and efficient use. Each part contributes to the overall functionality, ensuring optimal performance and longevity.

The illustration provides a detailed breakdown of essential components, highlighting their relationships within the system. From mechanical to structural pieces, every element has a specific role, designed for both durability and precision. This visual guide is indispensable for identifying individual sections, facilitating easier assembly and troubleshooting.

Key Components of the Ms661c Chainsaw

This chainsaw is built from a combination of vital elements designed for maximum performance and durability. Each of these elements contributes to the machine’s overall functionality, ensuring efficient operation under various conditions. Below, we explore the most important segments that work together to form a reliable and powerful cutting tool.

Engine Assembly

The core of any chainsaw is its motor. In this model, the engine provides robust power, driving the chain at high speeds. It includes a cylinder, piston, and crankshaft, all working in unison to generate the necessary force. These parts must be precisely tuned for optimal combustion and power delivery.

- Piston: Converts combustion into mechanical movement.

- Cylinder: Houses the piston and allows for controlled fuel ignition.

- Crankshaft: Transforms the linear motion of the piston into rotational force.

Chain and Bar Mechanism

The cutting system consists of a sharp metal chain and a guiding bar. The chain, powered by the engine, rotates around the bar, making clean cuts through wood. Proper tensioning and lubrication are critical for maintaining cutting efficiency and safety.

- Guide Bar: Supports the chain during cutting.

- Chain: Features cutting teeth that do the actual cutting.

- Chain Tensioner: Keeps the chain at the correct tension to avoid slippage.

Understanding the Ms661c Engine Layout

The engine structure of this model is designed for maximum efficiency and durability in demanding environments. It incorporates advanced technologies to ensure smooth operation and power delivery, making it a reliable choice for heavy-duty tasks. This layout is carefully engineered to balance power, cooling, and accessibility for maintenance purposes.

Key Components and Configuration

The core elements of the engine are arranged to optimize performance and longevity. The cylinder and piston are precisely aligned for efficient combustion, while the air intake system is positioned to enhance airflow and minimize dust ingress. Additionally, the fuel system is designed for consistent delivery under varying loads.

Cooling and Exhaust System

The cooling mechanism is strategically placed to prevent overheating during extended use, maintaining stable temperature levels throughout operation. The exhaust system is designed not only to direct emissions away efficiently but also to reduce noise levels, contributing to a smoother working experience.

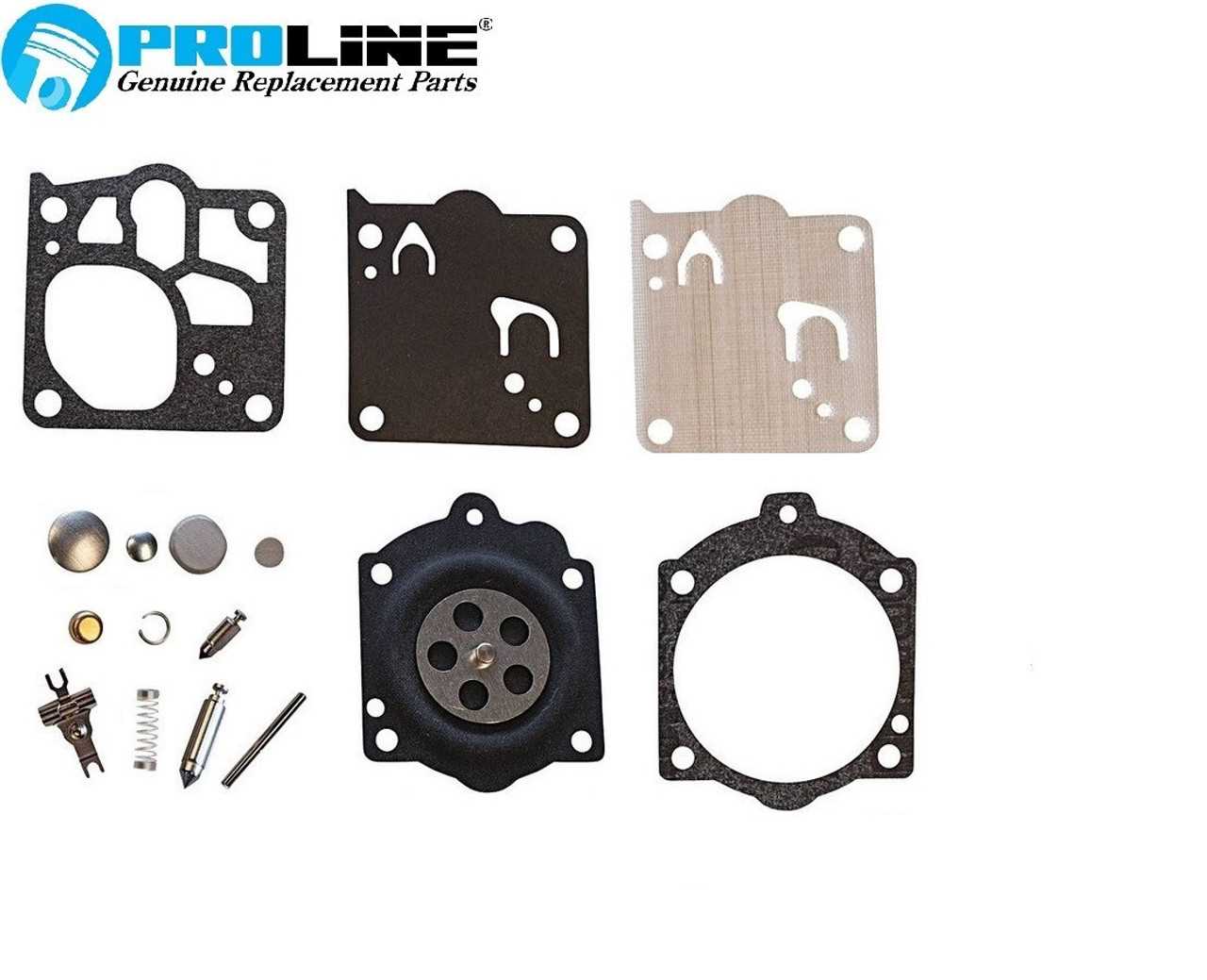

Ms661c Fuel System Breakdown

The fuel system plays a crucial role in maintaining efficient engine operation by ensuring a steady flow of fuel to the combustion chamber. This mechanism involves multiple components that work together to deliver the necessary mixture for proper performance. Understanding how this system operates can help in identifying potential issues and ensuring smooth functionality over time.

Fuel Tank serves as the primary reservoir for storing fuel, ensuring an adequate supply during operation. The fuel is drawn from the tank through the fuel lines that transport it to the engine’s carburetor, where it is mixed with air for combustion.

Fuel Filter is a critical component that removes impurities from the fuel before it enters the engine. This ensures the system remains free from contaminants, which can cause blockages or damage sensitive components.

The carburetor precisely regulates the fuel-to-air ratio, adjusting the mixture based on engine needs. Its accurate functioning is essential for optimal power output and fuel efficiency. Regular maintenance of this component ensures smooth operation and reduces the risk of engine issues.

Fuel Pump assists in maintaining the necessary pressure within the system, allowing fuel to flow consistently even during demanding operations. Without this pressure, the delivery of fuel could become erratic, affecting performance.

Exploring the Ignition System of Ms661c

The ignition setup plays a crucial role in the overall operation of the machine, directly impacting its efficiency and reliability. This system is responsible for initiating the combustion process, ensuring the engine starts and runs smoothly under various conditions. A well-maintained ignition mechanism contributes to the longevity and consistent performance of the equipment.

Key components within this configuration work together to create the spark needed to ignite the fuel mixture. From the coil to the spark plug, each element is designed to handle high voltage and precise timing. Proper functioning of this system is essential to avoid common issues like misfires or power loss during operation.

Understanding the ignition setup helps in troubleshooting potential problems, as issues within this system can lead to operational delays or even prevent the engine from starting. Regular inspection and maintenance of these elements can enhance both safety and performance, ensuring reliable functionality over time.

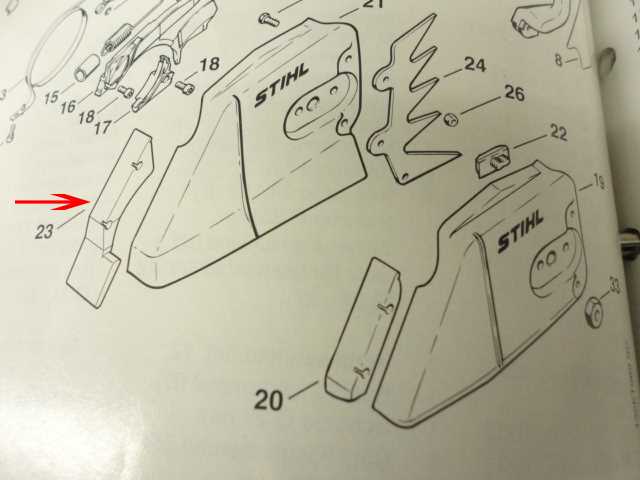

Guide to Ms661c Chain and Bar Assembly

Understanding the assembly of the cutting components is essential for optimal performance and safety. This section provides a comprehensive overview of the assembly process, including the necessary tools and techniques for proper installation and maintenance.

To effectively attach the chain and bar, ensure that all components are clean and free of debris. Following the correct procedure not only enhances performance but also extends the lifespan of the equipment. Below is a table outlining the key steps and considerations during the assembly process:

| Step | Action | Notes |

|---|---|---|

| 1 | Remove the protective cover | Always wear safety gloves. |

| 2 | Position the guide bar | Ensure alignment with the mounting holes. |

| 3 | Install the chain | Make sure the cutting edges face the correct direction. |

| 4 | Secure the nuts and bolts | Tighten firmly, but avoid overtightening. |

| 5 | Check tension | Adjust to ensure the chain is snug but not overly tight. |

By following these steps, you can ensure a safe and efficient assembly process, leading to better results during operation. Regular checks and maintenance will keep your equipment in optimal condition, contributing to longevity and performance.

Cooling System Structure in Ms661c

The cooling mechanism plays a crucial role in maintaining optimal operating temperatures within equipment designed for high-performance tasks. This system ensures that the components do not overheat during extended usage, thereby enhancing efficiency and prolonging the lifespan of the machinery.

At the core of this mechanism is a fan that circulates air around the critical areas, effectively dissipating heat generated by the engine. The system also incorporates a series of ducts and fins, which are strategically placed to maximize airflow. These elements work together to facilitate efficient thermal management, ensuring that all components remain within safe temperature limits.

Furthermore, this cooling assembly includes a reservoir for coolant, which is circulated through the system to absorb excess heat. The coolant flows through various channels, enabling it to reach all vital parts that require temperature regulation. As the heated coolant moves back to the radiator, it releases the absorbed heat before being recirculated.

The design of this thermal management system reflects careful engineering, emphasizing reliability and performance. By efficiently managing heat, the mechanism contributes significantly to the overall functionality and durability of the equipment.

Ms661c Handle and Control Parts Explained

The handle and control components of a chainsaw are crucial for its functionality and user comfort. Understanding these elements can enhance both the performance of the tool and the safety of the operator. This section delves into the various components that make up the handle and control system, offering insight into their roles and importance.

| Component | Description |

|---|---|

| Handle Grip | The part of the tool that the user holds, designed for comfort and control during operation. |

| Throttle Control | A lever that regulates the engine speed, allowing the user to adjust power output while cutting. |

| Stop Switch | A safety feature that enables the operator to quickly shut off the engine in case of an emergency. |

| Chain Brake | Activates automatically or manually to stop the chain quickly, enhancing safety during use. |

| Trigger | The mechanism that initiates the cutting action when pressed, providing immediate control over the saw’s operation. |

Air Filtration System in Ms661c

The air filtration mechanism plays a crucial role in maintaining optimal performance and longevity of any powerful equipment. It is designed to prevent harmful particles and debris from entering the engine, ensuring efficient combustion and smooth operation.

Key components of this filtration system include:

- Air Filter Element: This primary component traps dust, dirt, and other contaminants, providing clean air for combustion.

- Filter Housing: The enclosure that protects the filter element, ensuring a secure fit and preventing unfiltered air from bypassing the filter.

- Intake Duct: Connects the filter housing to the engine, directing the filtered air to the combustion chamber.

Regular maintenance of the air filtration system is essential for optimal performance. This includes:

- Inspecting the air filter for dirt accumulation.

- Cleaning or replacing the filter as necessary.

- Ensuring the integrity of the filter housing and intake duct.

By adhering to these maintenance practices, users can enhance the efficiency and lifespan of their equipment, ensuring it operates at its best.

Ms661c Starter Mechanism Detailed View

The starting system is a crucial component that ensures the smooth ignition of the engine. It operates by engaging a series of interdependent mechanisms that facilitate the initial rotation of the engine’s crankshaft. Understanding the intricacies of this assembly is essential for maintenance and troubleshooting, allowing for optimal performance and reliability.

Components of the Starting System

The starting assembly typically includes a flywheel, starter pawl, recoil spring, and various levers. Each component plays a significant role in the overall functionality, where the flywheel helps to create momentum, while the pawl engages with the starter mechanism to initiate the engine’s operation. The recoil spring provides the necessary tension to reset the starter after each pull.

Maintenance Tips

Regular inspection of the starting system is vital for preventing issues that may hinder engine ignition. Ensure that all components are free of debris and wear, as any deterioration can lead to inefficient operation. Lubricating moving parts and checking for proper alignment can also contribute to a longer lifespan and improved functionality.

Ms661c Exhaust System Components

The exhaust system plays a crucial role in the overall performance and efficiency of a machine. It is designed to manage the flow of gases generated during combustion, ensuring optimal engine function while minimizing emissions. Understanding the various components involved helps in maintaining and troubleshooting the system effectively.

Main Components

This section highlights the essential elements that comprise the exhaust assembly, each contributing to the efficient expulsion of exhaust gases and overall engine health.

| Component | Description |

|---|---|

| Exhaust Muffler | Reduces noise produced by the engine and helps control gas flow. |

| Exhaust Pipe | Channels exhaust gases from the engine to the outside atmosphere. |

| Gaskets | Seals connections between exhaust components to prevent leaks. |

| Heat Shield | Protects surrounding components from heat generated by the exhaust system. |

Importance of Maintenance

Regular inspection and maintenance of the exhaust system are essential for ensuring longevity and performance. Identifying wear or damage in these components early can prevent more significant issues and costly repairs.