The intricate world of farming equipment encompasses a variety of elements that work in unison to achieve optimal performance. For operators and technicians, familiarizing themselves with the assembly of these mechanisms is crucial for efficient operation and maintenance.

In this section, we will explore the essential structures and functions of various components within a specific model of agricultural machinery. By examining the layout and interconnections of these elements, one can gain a deeper understanding of how they contribute to the overall functionality of the machine.

Whether you’re a seasoned professional or a novice, this exploration aims to provide valuable insights into the mechanical design, aiding in both troubleshooting and enhancement of productivity. Let’s delve into the specifics and discover the ultimate relationships between the different parts of this agricultural equipment.

Overview of New Holland 488

This section provides a comprehensive look at a prominent agricultural machine, exploring its features, capabilities, and significance in modern farming practices.

Key Features

- Efficient cutting technology

- Durable construction for longevity

- User-friendly controls for easy operation

Importance in Agriculture

- Enhances productivity during harvest.

- Reduces labor costs significantly.

- Contributes to sustainable farming practices.

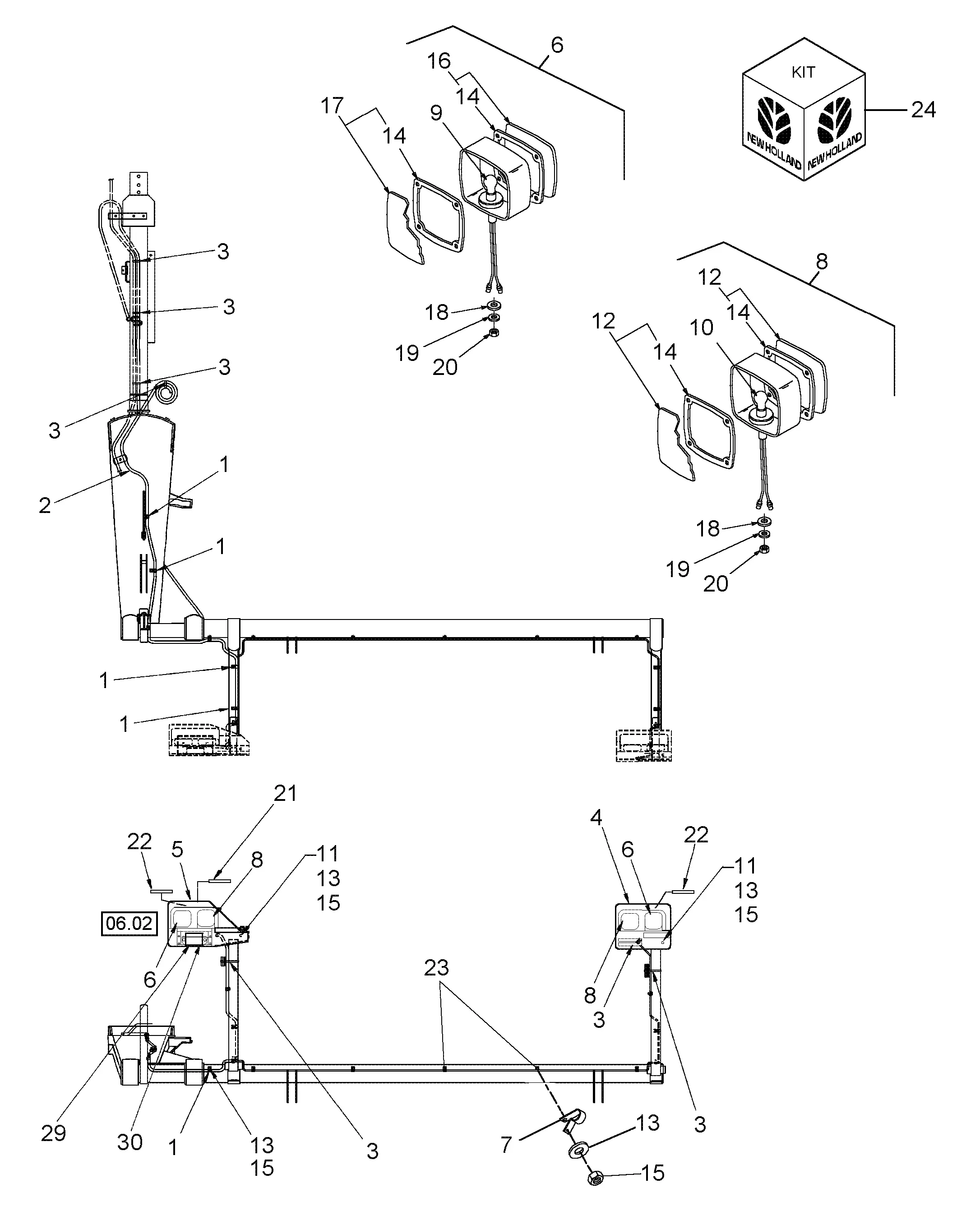

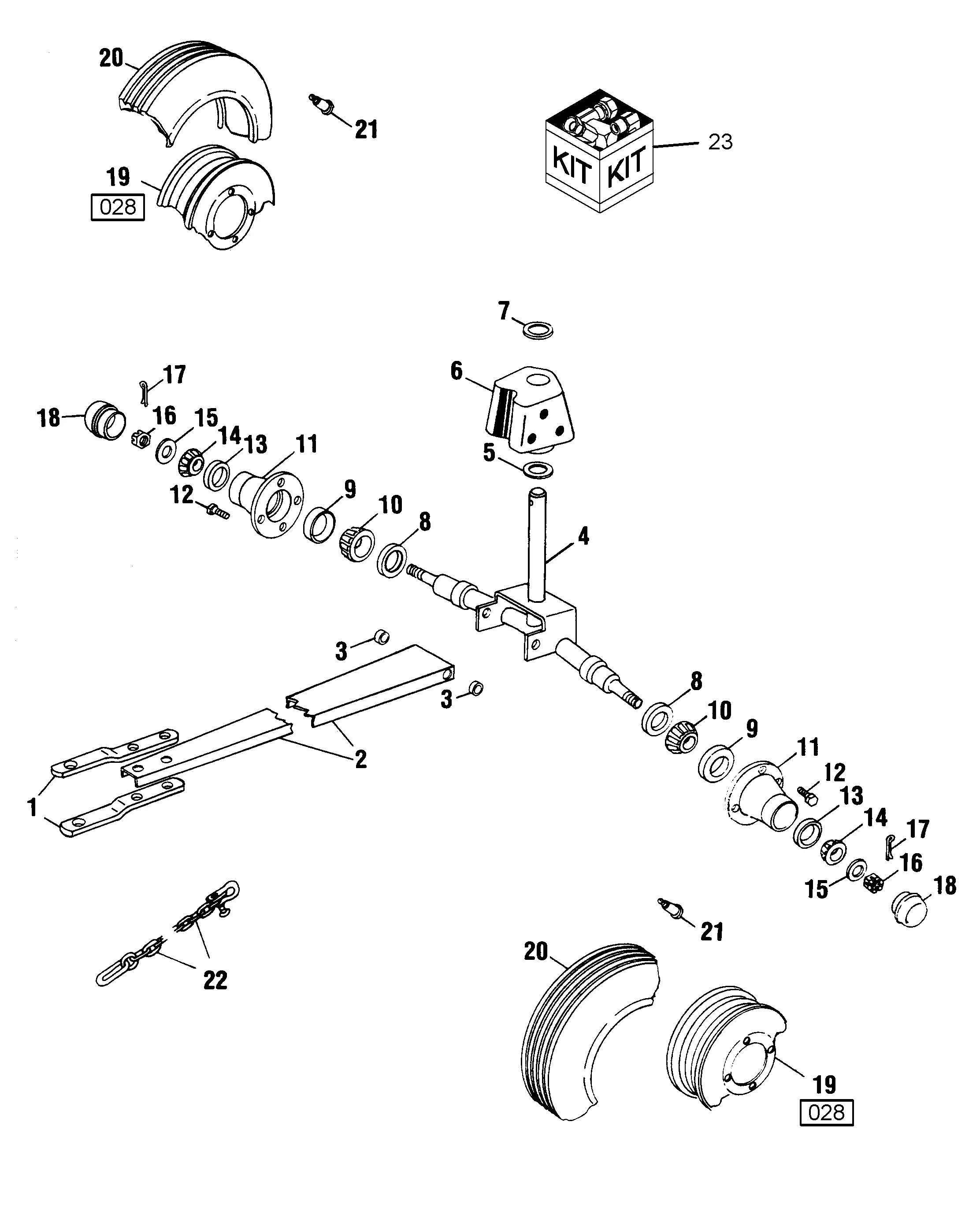

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. They simplify the process of identifying necessary elements, enabling efficient organization and handling of mechanical systems.

Such illustrations serve multiple purposes, including:

| Purpose | Description |

|---|---|

| Identification | Facilitates recognition of specific elements within a machine. |

| Organization | Helps in arranging components systematically for easier access. |

| Instruction | Guides users through the repair or assembly processes step-by-step. |

| Communication | Enhances understanding among technicians and operators about component functions. |

Ultimately, these visuals are invaluable tools that enhance efficiency and accuracy in mechanical operations.

Key Components of the 488 Model

This section explores the essential elements that contribute to the functionality and efficiency of this agricultural machine. Understanding these components is crucial for effective maintenance and operation.

- Engine: The powerhouse of the machine, providing the necessary torque and power.

- Transmission: Essential for controlling speed and power distribution to various parts.

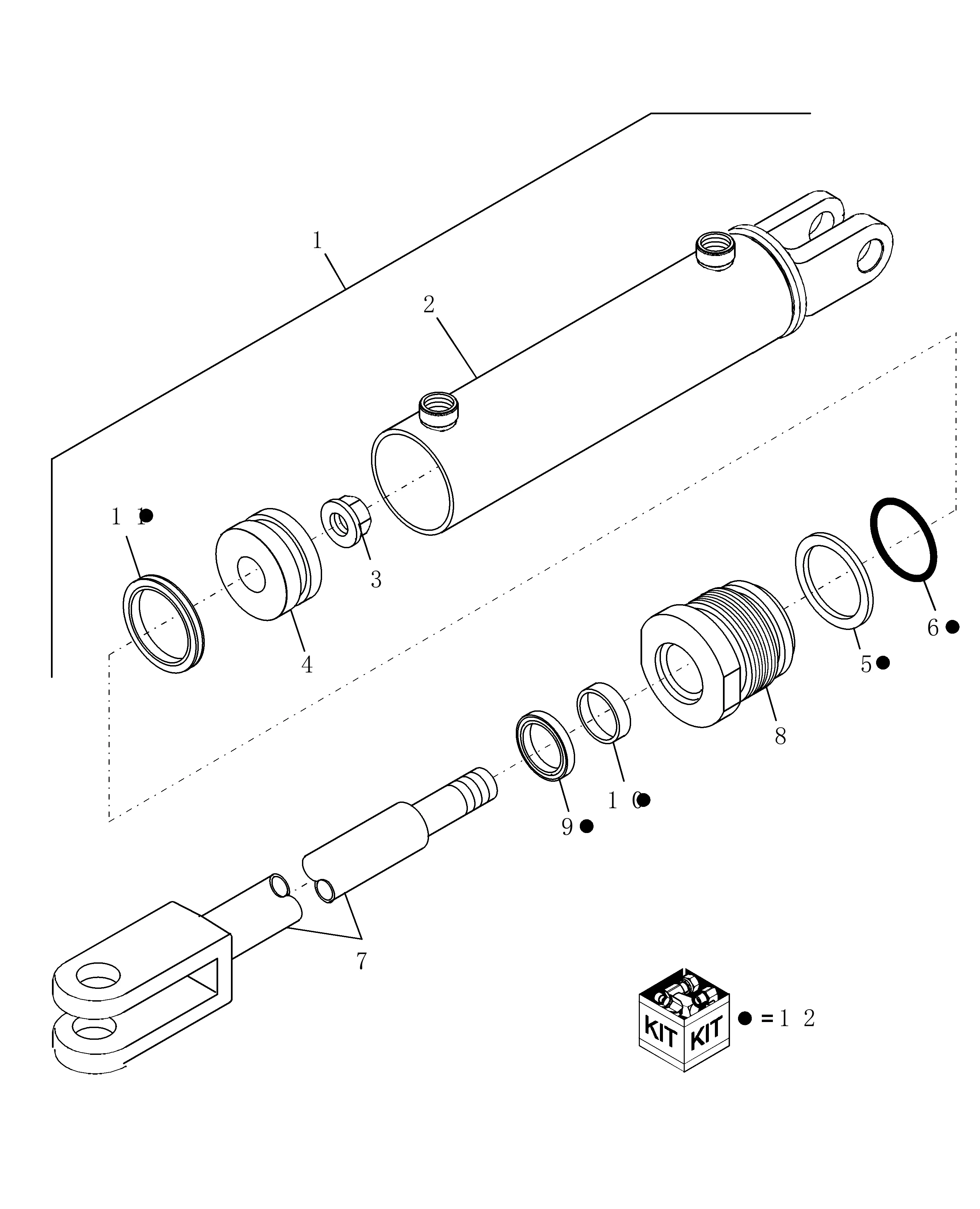

- Hydraulic System: Facilitates lifting and lowering mechanisms, ensuring smooth operation.

- Cutter Bar: Vital for harvesting, designed to enhance cutting efficiency.

- Feed System: Moves material into the machine, optimizing productivity.

Each of these components plays a critical role in the overall performance, making their understanding and care paramount for users.

How to Read a Parts Diagram

Understanding an illustration of components can significantly enhance your ability to identify and source the necessary elements for your machinery. These visual representations are designed to simplify the complex relationships and functions of various parts, making it easier for users to locate what they need for maintenance or repairs.

To effectively interpret these visuals, it’s crucial to familiarize yourself with the common symbols and labels used. Each element is typically numbered or labeled, corresponding to a list that provides detailed descriptions and specifications. Here’s a basic breakdown of how to approach reading these illustrations:

| Step | Description |

|---|---|

| 1 | Start by examining the entire layout to understand the general configuration and relationship between the components. |

| 2 | Identify the numbers or letters next to each part, which will guide you to the detailed list for specific information. |

| 3 | Refer to the accompanying documentation or list to gather specifications such as part numbers, dimensions, and compatibility. |

| 4 | Take note of any additional notes or warnings related to installation or maintenance that might be included. |

By following these steps, you can efficiently navigate the visual representation of components, ensuring that you acquire the right elements for your project. Familiarity with this process not only saves time but also enhances the overall effectiveness of your maintenance and repair efforts.

Common Issues and Solutions

This section addresses frequent challenges encountered with agricultural machinery, providing effective remedies to enhance performance and longevity.

Common Challenges

- Engine performance issues

- Hydraulic system malfunctions

- Worn-out belts and chains

- Electrical failures

Effective Solutions

- Regular maintenance and inspections.

- Replacing faulty components promptly.

- Using high-quality lubricants and fluids.

- Consulting the manual for troubleshooting tips.

Finding Replacement Parts Easily

Locating suitable components for machinery can be a daunting task, but with the right approach, it becomes much more manageable. Understanding where to look and what resources to utilize is key to ensuring efficient repairs and maintenance.

Utilizing Online Resources

- Manufacturer Websites: Directly visit the official sites for authentic components.

- Online Marketplaces: Platforms like eBay and Amazon often have a wide selection.

- Specialized Retailers: Look for stores focused on agricultural equipment for niche offerings.

Engaging with the Community

- Forums: Join online discussion groups where users share insights and recommendations.

- Social Media: Follow relevant pages for updates on availability and deals.

- Local Workshops: Connect with mechanics who may provide valuable leads.

Benefits of Genuine New Holland Parts

Utilizing authentic components ensures optimal performance and longevity of your machinery. These elements are specifically designed to meet the rigorous demands of agricultural work, resulting in enhanced efficiency and reliability.

Quality Assurance: Genuine components are manufactured to the highest standards, guaranteeing durability and consistency. This minimizes the risk of breakdowns and costly repairs.

Perfect Fit: Each part is engineered to seamlessly integrate with your equipment, ensuring smooth operation and reducing wear on other systems.

Warranty Protection: Using authentic components often helps maintain warranty coverage, protecting your investment and providing peace of mind.

In conclusion, opting for original components ultimately leads to improved performance, reliability, and value for your agricultural machinery.

Understanding Maintenance Requirements

Proper upkeep of machinery is essential for optimal performance and longevity. A thorough grasp of maintenance needs ensures that equipment operates efficiently, minimizing the risk of breakdowns and costly repairs. Regular attention to specific components not only enhances functionality but also contributes to safety in operations.

Each machine has unique specifications that dictate its maintenance schedule. Key areas often include fluid levels, filters, belts, and bearings. Monitoring these elements at recommended intervals helps in identifying potential issues before they escalate into serious problems. Additionally, keeping a detailed log of maintenance activities aids in tracking performance trends and planning future interventions.

Utilizing a systematic approach to maintenance fosters a proactive mindset. By prioritizing routine checks and addressing minor repairs promptly, operators can significantly extend the lifespan of their equipment. Moreover, adhering to manufacturer guidelines and using quality replacement parts further supports reliable operation.

Investing time and resources into maintenance not only protects machinery but also enhances overall productivity. An informed understanding of maintenance requirements empowers operators to make sound decisions, ensuring that equipment remains a valuable asset in various applications.

Upgrades and Modifications Available

Enhancing the performance and efficiency of agricultural machinery can significantly impact productivity. Various improvements and alterations can be implemented to tailor equipment to specific farming needs. These adjustments not only optimize functionality but also extend the lifespan of the machinery.

Performance Enhancements: Upgrading engines and transmission systems can lead to better power delivery and fuel efficiency. Additionally, incorporating advanced technology, such as GPS or precision farming tools, can streamline operations.

Durability Improvements: Replacing standard components with high-quality materials ensures longevity and reduces maintenance frequency. Options such as reinforced frames and upgraded belts contribute to overall resilience.

Ergonomic Modifications: Adjustments to operator controls and seating can enhance comfort during long working hours. Features like adjustable seats and user-friendly interfaces improve overall operator experience.

Attachment Options: Adding specialized implements can diversify the functionality of machinery. Whether it’s a new mower or a cultivator, these attachments can increase versatility for various farming tasks.

Where to Purchase Parts Online

Finding reliable sources for equipment components online can significantly streamline maintenance and repairs. Numerous platforms offer extensive catalogs, allowing users to browse, compare, and select suitable items for their machinery. Understanding where to look is essential for ensuring quality and efficiency.

Popular marketplaces like eBay and Amazon provide a variety of listings from different sellers. Specialized websites focusing on agricultural and industrial machinery often feature original or aftermarket offerings, enhancing the chances of finding specific components. It’s advisable to check customer reviews and ratings to gauge the reliability of both the seller and the product.

For those seeking a more personalized experience, contacting local dealers or authorized retailers online can be beneficial. Many of these businesses have user-friendly websites that facilitate easy ordering and offer valuable support regarding compatibility and installation.

Additionally, online forums and communities dedicated to equipment enthusiasts often share insights about trustworthy vendors and exclusive deals. Engaging with fellow users can lead to discovering lesser-known sources that provide quality items at competitive prices.

DIY Repairs: Tips and Tricks

Engaging in self-repairs can save both time and money while enhancing your mechanical knowledge. By understanding the components and functions of your equipment, you can tackle issues with confidence and efficiency. Here are some practical strategies to help you succeed in your repair endeavors.

Essential Tools and Supplies

Before diving into any repair project, ensure you have the necessary tools at hand. Here’s a checklist of essential items:

- Wrenches and sockets

- Screwdrivers (flathead and Phillips)

- Pliers and wire cutters

- Safety goggles and gloves

- Lubricants and cleaners

- Replacement components as needed

Step-by-Step Approach

Adopting a systematic method can greatly improve your chances of success. Consider the following steps:

- Identify the issue and gather information about the equipment.

- Disconnect power sources for safety.

- Carefully dismantle parts, labeling each component to simplify reassembly.

- Inspect each piece for wear and damage, making notes on what needs replacement.

- Reassemble in reverse order, ensuring everything is securely fastened.

- Test the equipment before full operation to confirm repairs were successful.

By following these guidelines, you can enhance your DIY repair skills and maintain your machinery effectively.

Community Resources and Support Groups

Finding the right assistance and shared knowledge can significantly enhance the experience of maintaining and repairing agricultural machinery. Engaging with local and online communities allows individuals to tap into a wealth of expertise, share experiences, and access valuable resources that can aid in troubleshooting and acquiring necessary components.

Online Forums and Discussion Boards

Numerous online platforms provide spaces where enthusiasts and professionals alike can discuss various topics related to machinery upkeep. These forums often feature sections dedicated to specific models and issues, making it easier for users to find relevant information. Members frequently share manuals, repair tips, and recommendations for trusted suppliers. Participating in these discussions can also help in building connections with others who share similar interests.

Local Clubs and Meetups

Joining local clubs or attending meetups offers a more personal approach to support. These groups often organize events where members can showcase their machinery, share repair techniques, and learn from each other’s experiences. Engaging with a local community not only provides practical insights but also fosters friendships and collaborations that can lead to further learning opportunities. Many of these gatherings also include guest speakers who can provide expert knowledge on specific maintenance practices.

Overall, leveraging community resources can enhance one’s ability to manage machinery effectively and efficiently, ensuring that owners can keep their equipment running smoothly for years to come.