The functionality of agricultural machinery relies heavily on the correct arrangement and condition of its various elements. Each component plays a vital role in ensuring efficiency and productivity on the field. Familiarity with these components can lead to better maintenance practices and improved performance.

In this section, we will explore the intricacies of a specific piece of machinery, focusing on its individual components and their placements. Understanding how these parts interact will aid operators in troubleshooting and enhancing overall equipment functionality.

By delving into the specifics of the machinery’s structure, we aim to equip users with the knowledge needed to identify issues and implement solutions effectively. This knowledge is essential for anyone looking to optimize their equipment’s capabilities and prolong its lifespan.

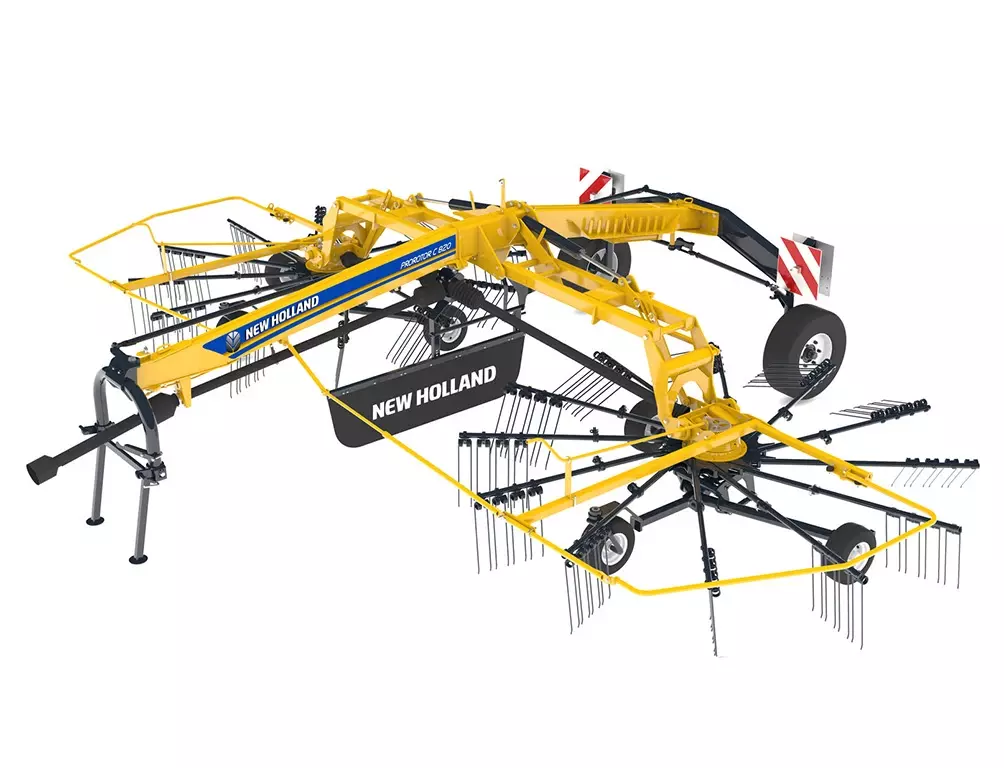

tags: Overview of New Holland 55 Hay Rake”>

tags: Overview of New Holland 55 Hay Rake”>

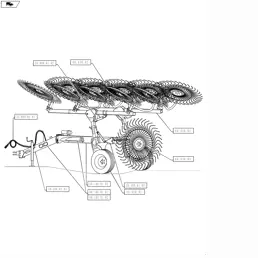

This section aims to provide a comprehensive understanding of a specific agricultural implement’s structure and functionality. By exploring its various components, users can gain insights into the overall design and operation of this essential farming tool.

Key Components and Their Functions

- Frame: The main structure providing support and stability.

- Wheels: Essential for mobility across different terrains.

- Teeth: Crucial for collecting and managing the crop.

- Gearbox: Responsible for power transmission and control.

- Hydraulic System: Facilitates lifting and lowering mechanisms.

Maintenance Tips for Longevity

- Regularly inspect all components for wear and tear.

- Keep moving parts lubricated to reduce friction.

- Clean the equipment after each use to prevent build-up.

- Store in a dry place to avoid rust and corrosion.

Key Features of the Hay Rake

This essential agricultural implement is designed to enhance the efficiency of fieldwork. Its innovative design and robust construction contribute significantly to optimizing the process of collecting and organizing vegetation. Here, we explore some of its most notable characteristics that make it indispensable for farmers.

- Durable Construction: Crafted from high-quality materials, this implement ensures longevity and reliability under various working conditions.

- Adjustable Settings: Users can easily modify its configurations to suit different types of crops and terrain, enhancing versatility.

- Efficient Performance: The design promotes smooth operation, allowing for effective collection with minimal effort.

- Ease of Maintenance: Components are designed for simple upkeep, reducing downtime and ensuring consistent operation.

- Compatibility: This implement can be paired with various tractors, making it a flexible choice for different agricultural setups.

Importance of Proper Maintenance

Regular upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to inefficiencies, breakdowns, and costly repairs. Implementing a consistent maintenance routine not only enhances productivity but also contributes to the safety of operators and the surrounding environment.

Enhancing Efficiency

Routine checks and servicing of equipment help identify potential issues before they escalate. By addressing minor problems early on, operators can maintain high efficiency levels and reduce the risk of unexpected downtime during critical operations. This proactive approach ensures that machinery operates at its peak capabilities, maximizing output.

Extending Equipment Lifespan

Proper care significantly extends the lifespan of machinery. Regular inspections, lubrication, and timely replacement of worn components prevent excessive wear and tear. By investing time in maintenance, operators can safeguard their equipment, ensuring it remains reliable for years to come and ultimately reducing replacement costs.

Common Issues with Hay Rakes

Equipment used for managing and collecting crops can face a variety of challenges that affect their efficiency and performance. Understanding these frequent problems can help operators maintain their machinery effectively and ensure optimal results during operation.

One prevalent issue is wear and tear on components, which can lead to decreased functionality over time. Regular inspections are essential to identify any parts that may require replacement to avoid unexpected breakdowns.

Another common concern is mechanical failures, which may arise due to inadequate lubrication or misalignment of moving elements. Ensuring that all moving parts are properly aligned and well-lubricated can significantly reduce the risk of these failures.

Debris accumulation is also a frequent problem that can hinder performance. Leaves, twigs, and other materials can become lodged in the machinery, affecting its operation. Regular cleaning and maintenance can help prevent this issue and maintain efficiency.

Lastly, adjustment difficulties can arise if operators are not familiar with the settings and configurations of their equipment. Properly understanding and adjusting the settings according to the specific crop conditions can enhance performance and productivity.

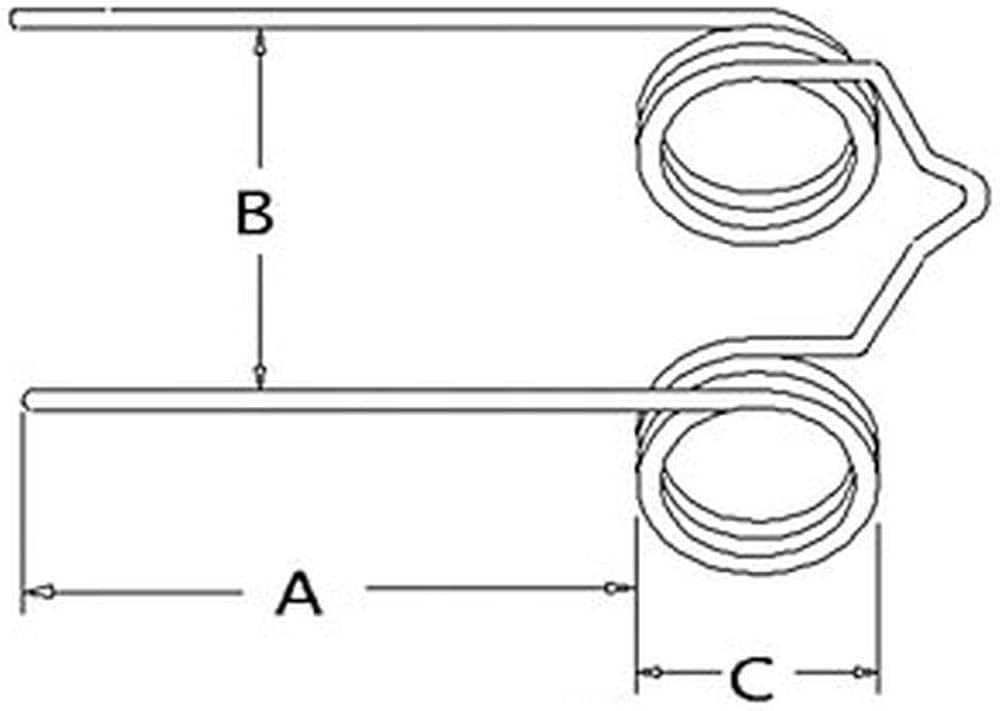

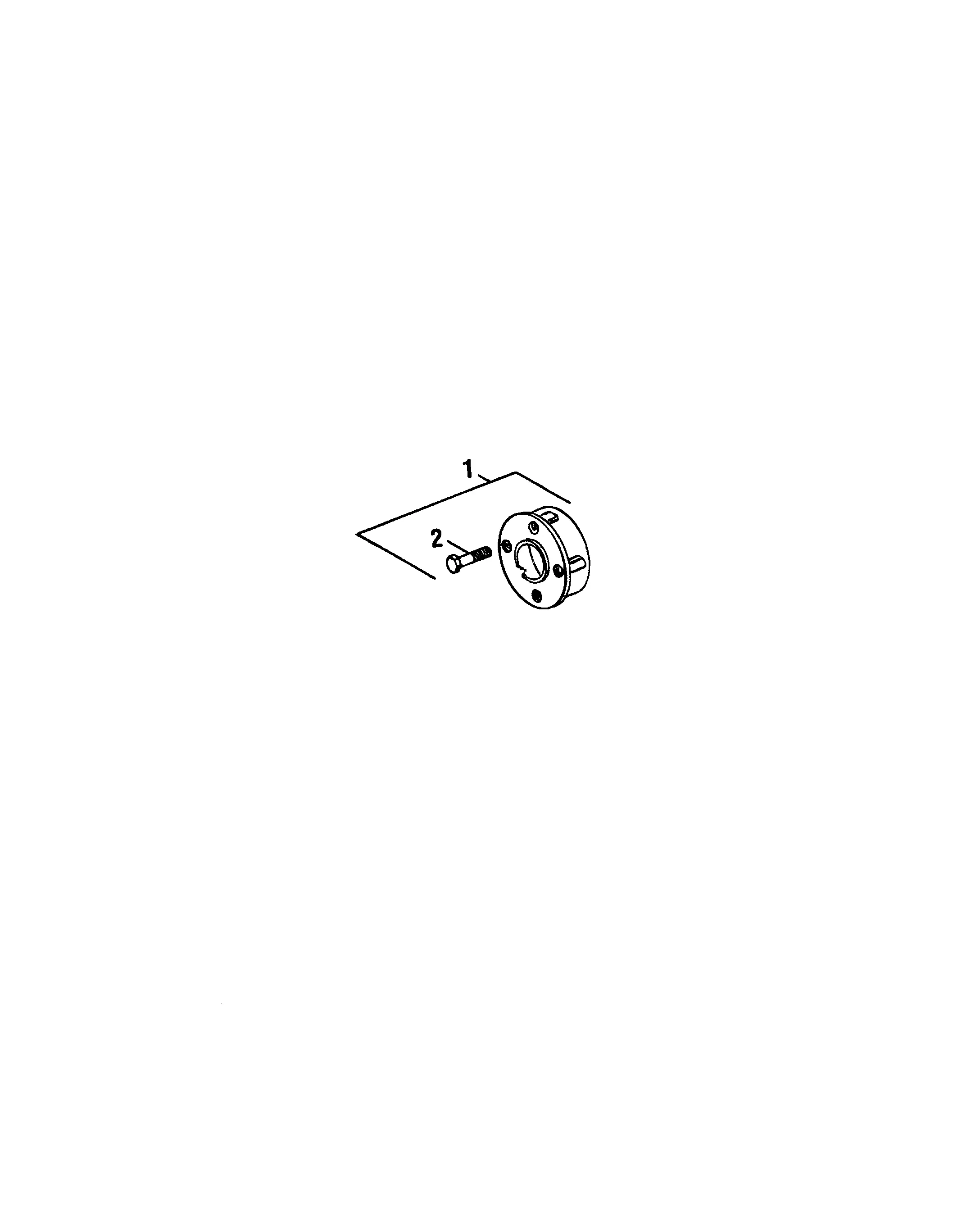

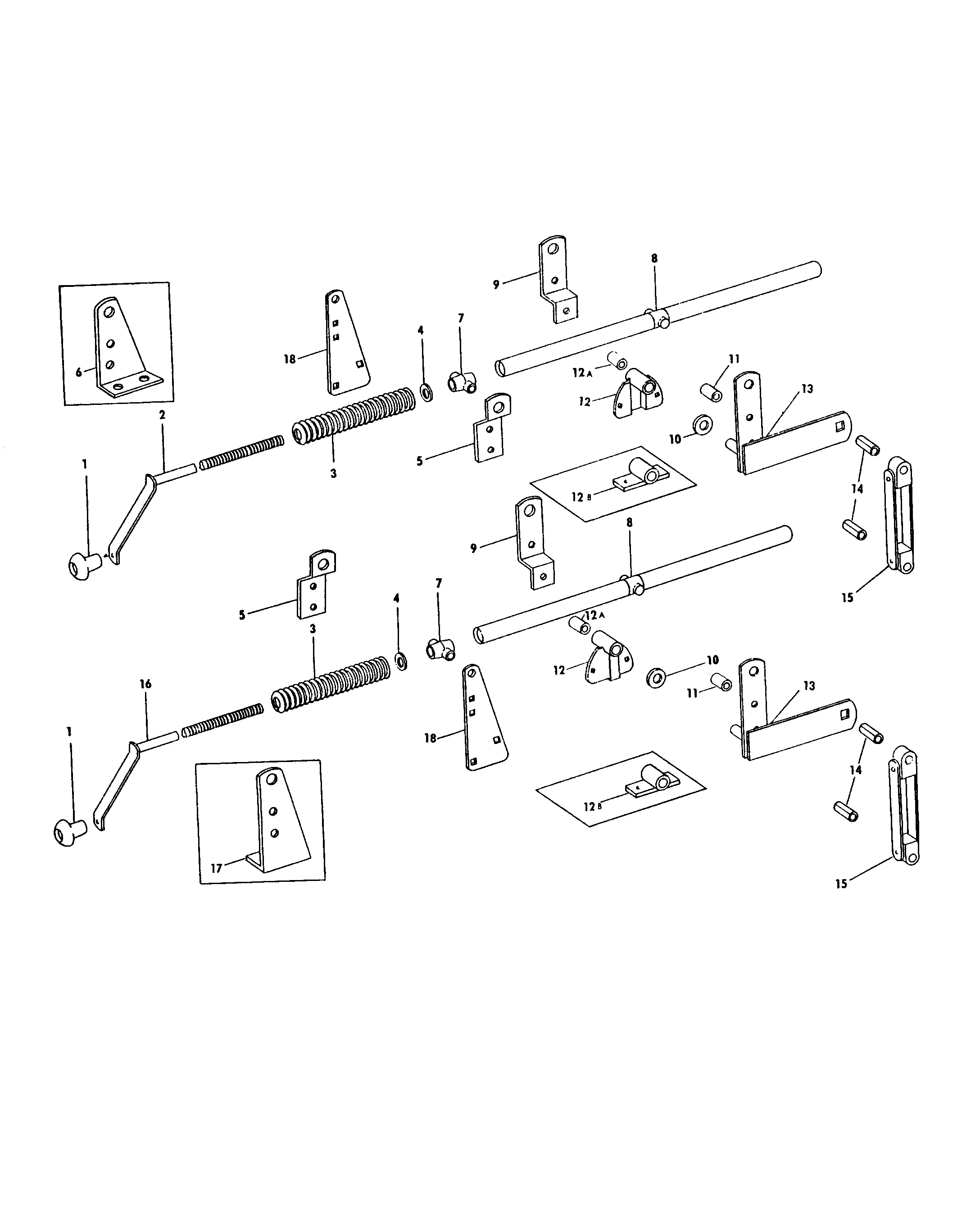

Essential Replacement Parts List

When maintaining agricultural equipment, understanding the key components that may require replacement is crucial for optimal performance. A comprehensive overview of essential elements ensures that users can effectively address wear and tear, leading to enhanced functionality and longevity of the machinery.

Key Components:

- Tines – Critical for the effective collection of material.

- Wheel Assemblies – Vital for mobility and stability during operation.

- Drive Belts – Important for transferring power from the engine to the working mechanisms.

- Frame Supports – Provide structural integrity and ensure durability under load.

- Adjustment Handles – Essential for configuring working height and angle.

Identifying and sourcing these components can significantly reduce downtime and enhance productivity, making it essential for operators to keep a close eye on the condition of these vital elements.

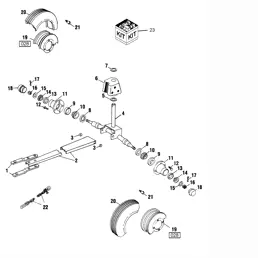

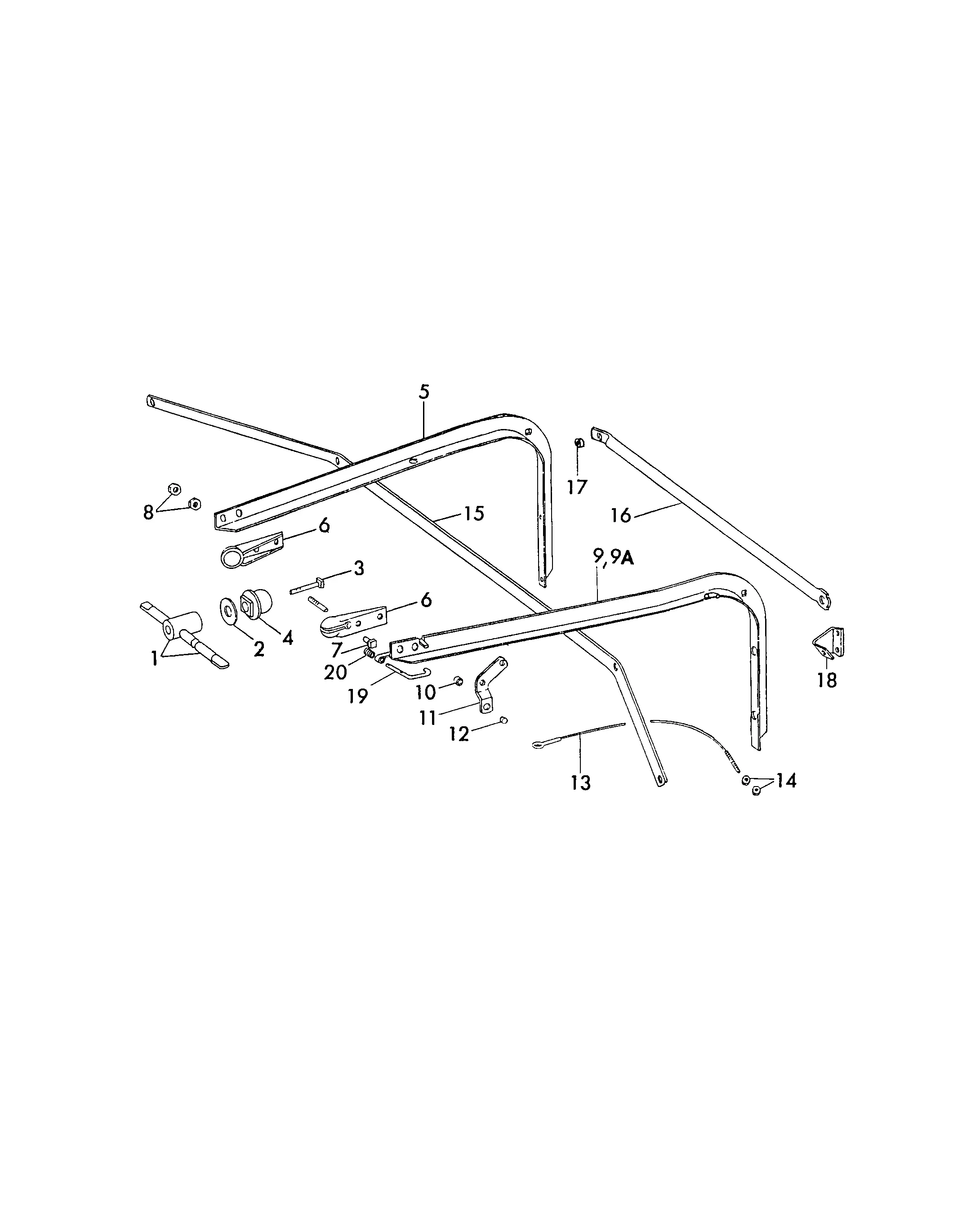

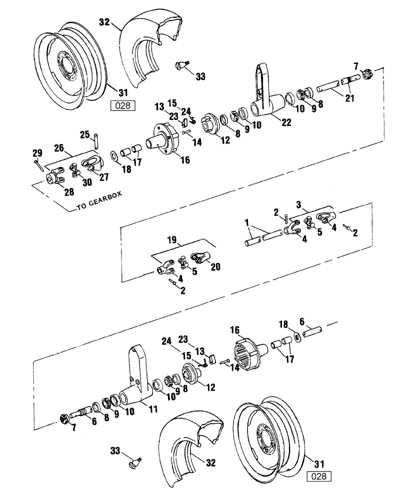

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repairs. This visual representation serves as a guide, allowing users to identify various elements and their functions within the machinery. By examining this illustration, one can gain insights into how different pieces interact and contribute to overall performance.

Key Components Overview

The illustration typically includes essential elements that play crucial roles in the functionality of the machine. Each component is marked with a unique identifier, which corresponds to a specific item in the parts list. This systematic approach simplifies locating and ordering replacements when necessary.

Benefits of Using a Visual Guide

Utilizing a graphical representation streamlines the troubleshooting process. It aids in recognizing potential issues by highlighting worn or damaged components. Furthermore, this reference can enhance understanding during assembly or disassembly, ensuring that everything is put together correctly.

| Component | Description | Function |

|---|---|---|

| Frame | Main structural element | Provides support and stability |

| Wheel | Rolling element | Facilitates movement |

| Collector | Gathering component | Collects material from the ground |

| Drive Shaft | Power transmission part | Transfers energy from the engine |

Identifying Worn Components

Recognizing deteriorated elements in agricultural machinery is crucial for maintaining optimal functionality. Over time, various components may exhibit signs of wear, affecting the overall efficiency of operations. Regular inspection and awareness of potential issues can prevent costly repairs and downtime.

Common indicators of degradation include unusual noises, vibrations, and reduced performance. Pay attention to any inconsistencies in the machinery’s operation, as these may signal the need for further examination. Elements such as bearings, gears, and belts are often susceptible to wear, so prioritize their assessment during routine checks.

Additionally, visual inspections can reveal cracks, corrosion, or other physical damages. Keeping a detailed log of these observations can assist in tracking wear patterns and aid in timely replacements. By proactively identifying worn components, you can ensure the longevity and reliability of your equipment.

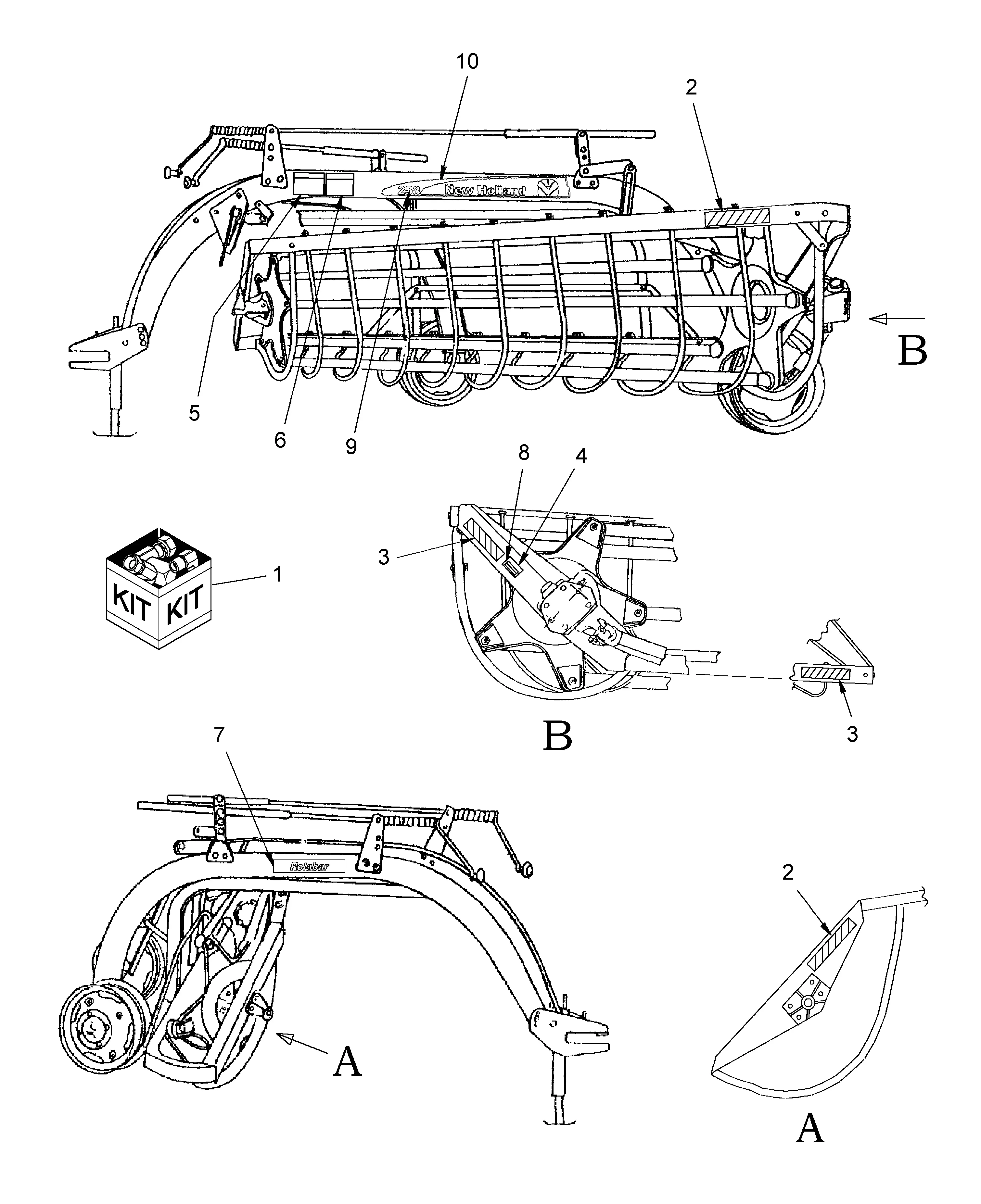

Step-by-Step Assembly Guide

This section provides a comprehensive guide to the assembly process of a specific agricultural tool. By following the instructions outlined here, you can efficiently piece together the equipment to ensure optimal performance in your tasks. Each step has been designed to facilitate a smooth assembly experience, allowing you to work effectively and confidently.

Begin by organizing all components in a designated area, ensuring that you have everything at hand. Review the assembly sequence carefully, as this will save time and reduce frustration. Familiarize yourself with each element’s functionality, as understanding their roles will aid in constructing the apparatus correctly.

Start with the base frame, securing it firmly. Proceed to attach the necessary support structures, making sure they align precisely. As you advance through the process, double-check connections to maintain stability and reliability. Utilize the appropriate tools for tightening fasteners and adjusting components, as this will enhance the overall durability of the assembly.

Once the primary structure is complete, integrate any additional features according to the instructions. Ensure all moving parts operate smoothly and make necessary adjustments. After the assembly is finalized, conduct a thorough inspection to confirm that every aspect meets safety and operational standards.

By adhering to this detailed guide, you will successfully assemble the equipment, ready for efficient use in your agricultural endeavors. Take pride in your work, knowing that proper assembly contributes significantly to the effectiveness and longevity of your tools.

Tools Required for Repairs

When undertaking maintenance tasks on your agricultural equipment, having the right tools is essential for achieving optimal results. These instruments not only enhance efficiency but also ensure safety during the repair process. Familiarity with each tool’s purpose can make the job easier and help prevent damage to the machinery.

Essential hand tools include wrenches, pliers, and screwdrivers. These items are crucial for loosening and tightening various components. Additionally, a reliable socket set can simplify the removal of bolts and nuts, providing access to hard-to-reach areas.

For more specialized tasks, consider incorporating power tools such as drills and impact wrenches. These devices can significantly speed up the process, particularly when dealing with stubborn or corroded fasteners. Furthermore, a torque wrench is necessary for ensuring that connections are tightened to the manufacturer’s specifications, which is vital for maintaining the equipment’s integrity.

Finally, do not overlook the importance of safety equipment. Items like gloves, goggles, and ear protection should be part of your toolkit to safeguard against potential hazards during repairs.

Best Practices for Storage

Effective preservation of agricultural equipment and tools is crucial for ensuring longevity and optimal performance. Proper storage techniques not only protect these items from environmental factors but also facilitate easier access and maintenance. By following a few essential guidelines, one can enhance the durability and reliability of their equipment.

Essential Storage Tips

To maximize the lifespan of your machinery, consider the following recommendations:

| Tip | Description |

|---|---|

| Clean Thoroughly | Remove dirt, debris, and residue after each use to prevent rust and corrosion. |

| Dry Completely | Ensure that all components are completely dry before storage to avoid moisture buildup. |

| Use Protective Covers | Invest in durable covers to shield equipment from dust, dirt, and pests during periods of inactivity. |

| Store in a Climate-Controlled Area | If possible, keep machinery in a location with stable temperature and humidity levels. |

Regular Maintenance Checks

Conducting routine inspections and servicing is vital for maintaining the efficiency of your equipment. Check for signs of wear and tear, and perform necessary repairs to ensure everything is functioning correctly. This proactive approach can help avoid costly repairs in the future and keep your tools ready for use when needed.

Where to Buy Replacement Parts

Finding reliable sources for spare components is crucial for maintaining the efficiency of your agricultural equipment. Whether you’re looking for specific items or general supplies, knowing where to shop can save you time and money.

Authorized Dealers

One of the most dependable options is to purchase from authorized distributors. These vendors often carry genuine replacements, ensuring compatibility and quality.

- Visit local dealerships for personalized service.

- Check the official website for a list of authorized vendors.

- Ask for recommendations from fellow farmers or equipment users.

Online Marketplaces

Many online platforms offer a wide variety of components for agricultural machinery. Shopping online provides convenience and often competitive pricing.

- Amazon and eBay are popular for various options.

- Specialized agricultural supply websites may offer exclusive items.

- Be sure to read reviews and check seller ratings for reliability.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding the machinery designed for agricultural applications. Feedback from actual users provides valuable insights into the efficiency, durability, and overall performance of the equipment, allowing potential buyers to make informed decisions.

User Experiences

Many customers have expressed satisfaction with the reliability of the equipment. Users often emphasize how well the machinery handles various tasks, enhancing productivity on their farms. Positive remarks frequently mention ease of operation and maintenance, contributing to a smoother workflow.

Suggestions for Improvement

While the overall feedback is favorable, some users have pointed out areas that could benefit from enhancements. A few have suggested improvements in design features for better usability. Constructive criticism often revolves around wanting additional options that cater to specific needs, demonstrating the desire for continuous advancement in these agricultural tools.