In the realm of farming machinery, having a comprehensive grasp of the various elements that make up your equipment is essential for optimal performance and maintenance. Each piece plays a crucial role in the overall functionality, ensuring that operations run smoothly and efficiently. Whether you are a seasoned operator or new to the field, familiarizing yourself with these components can greatly enhance your understanding of the machinery you depend on.

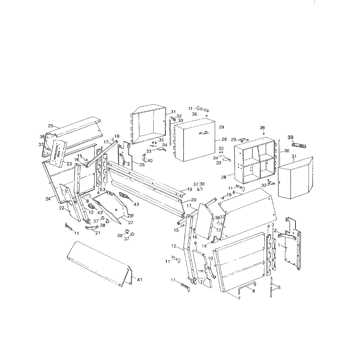

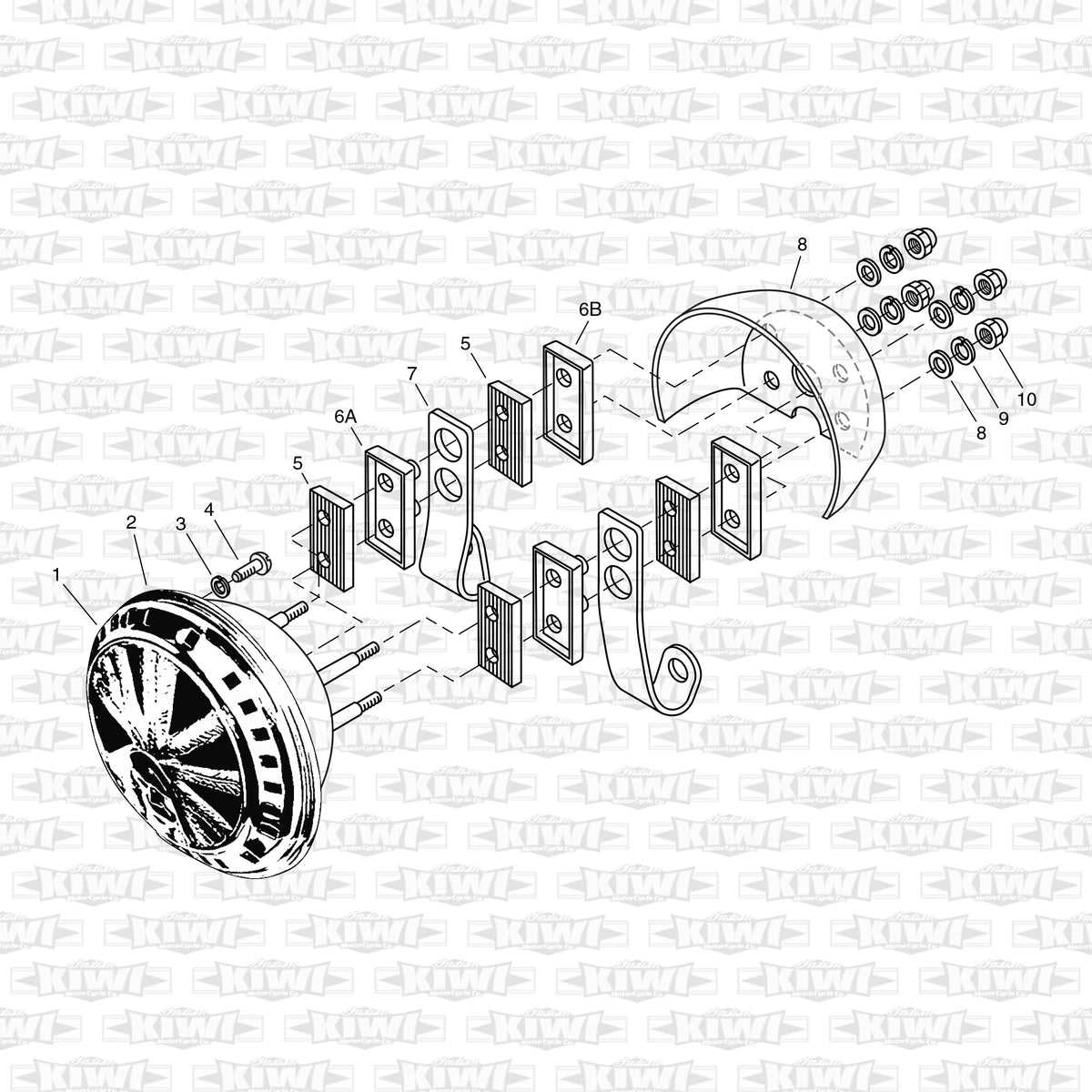

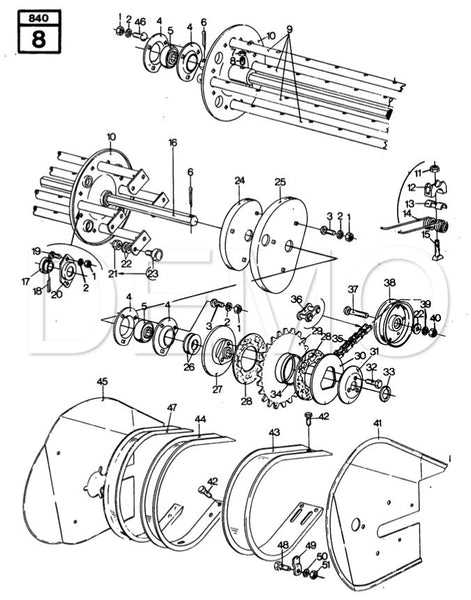

Visual aids can be invaluable in this process, providing a clear representation of how individual elements interact and contribute to the system as a whole. A detailed illustration can guide you in identifying specific sections and understanding their purpose, which is especially helpful during troubleshooting or repairs. This knowledge not only empowers operators but also fosters a more effective approach to machine upkeep.

As you delve into the intricacies of your equipment, consider the importance of maintaining each component in peak condition. Regular inspection and awareness of the parts involved can prevent unexpected breakdowns and prolong the lifespan of your machinery. By investing time in understanding the layout and functionality, you can ensure that your agricultural tasks are carried out with precision and reliability.

Understanding New Holland 855 Baler

This section aims to provide insights into a specific type of agricultural machinery designed for efficient crop processing. By exploring its components and functionality, users can better appreciate its significance in modern farming practices.

- Functionality: This equipment is crucial for collecting and compressing harvested materials.

- Design: Engineered for durability and efficiency, featuring a range of innovative elements.

- Maintenance: Regular upkeep is vital for optimal performance and longevity.

Understanding the intricacies of this machinery can enhance operational effectiveness and yield quality.

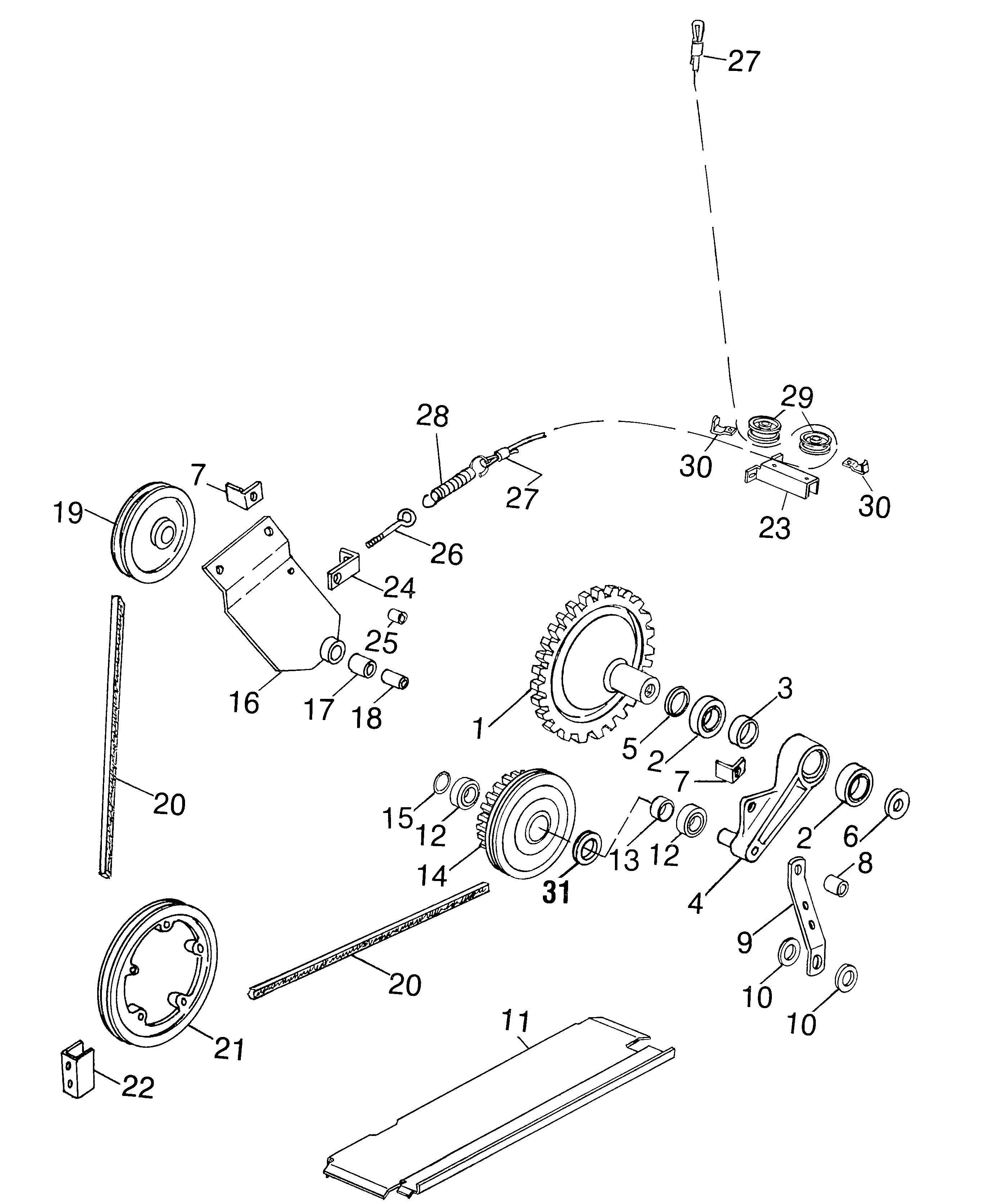

Key Components of the Baler

The efficient operation of a hay compression machine relies on several essential elements that work in harmony to achieve optimal performance. Understanding these components is crucial for effective maintenance and troubleshooting, ensuring that the equipment runs smoothly and reliably during use.

Feeding Mechanism

The feeding mechanism is the first point of contact for the material. It plays a vital role in gathering and directing the forage into the machine. Rollers and augers are typically employed to facilitate a steady flow, preventing blockages and ensuring consistent feeding rates.

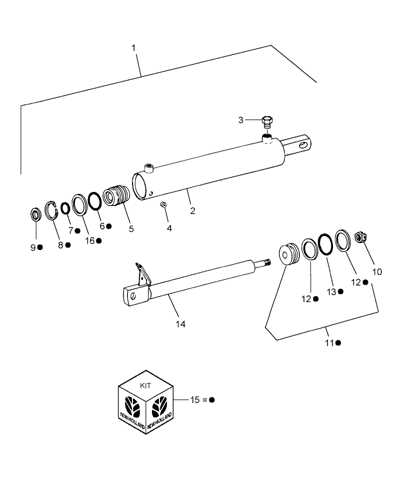

Compression Chamber

Within the compression chamber, the gathered material undergoes the compacting process. This area utilizes pistons or cylinders to apply significant pressure, transforming loose forage into tightly packed bales. The design of the chamber is crucial for achieving the desired bale density and size.

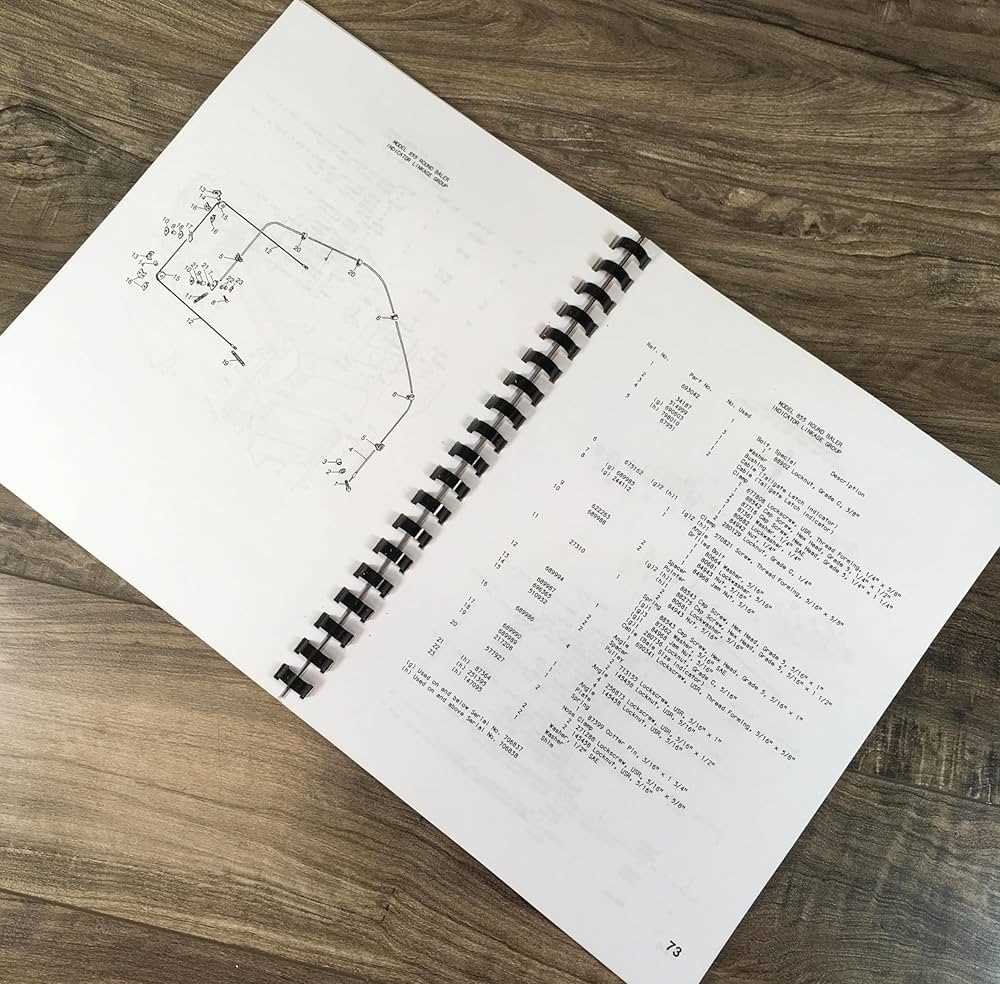

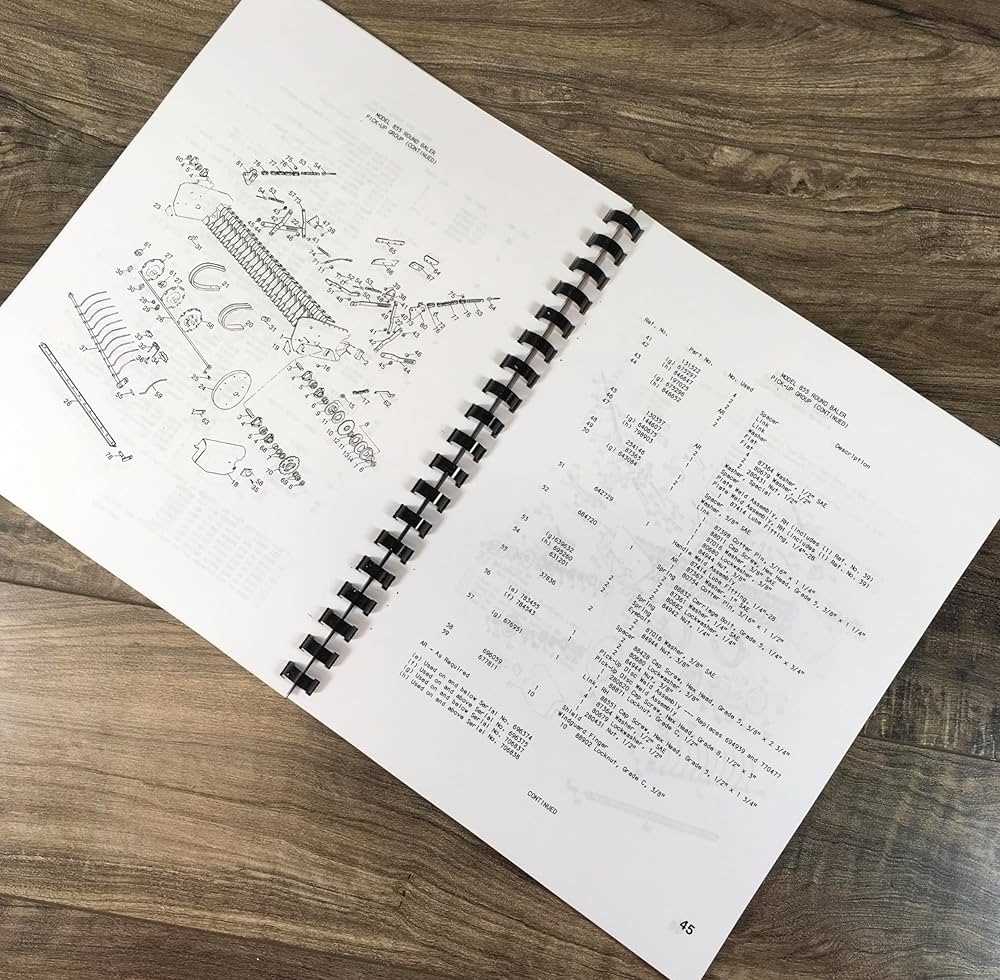

Importance of a Parts Diagram

Understanding the layout and components of machinery is crucial for effective maintenance and repair. A visual representation serves as a roadmap, guiding users through the intricate assembly of equipment. This clarity not only enhances efficiency but also reduces the likelihood of errors during servicing.

Facilitating Repairs

With a comprehensive illustration, technicians can quickly identify components that require attention. This expedites the repair process, ensuring that machinery remains operational and minimizing downtime.

Enhancing Knowledge

Studying a schematic can deepen one’s understanding of mechanical systems. It allows individuals to delve into the function of each element, ultimately fostering a greater appreciation for the technology at work.

Common Issues with Baler Parts

Understanding the frequent challenges faced by machinery components is crucial for optimal performance and longevity. Identifying these common issues helps operators maintain equipment efficiency and prevent costly repairs.

Wear and Tear

Components are subject to significant stress and can degrade over time. Regular inspection is essential to spot signs of wear, ensuring timely replacements and minimizing operational downtime.

Misalignment Problems

Improper alignment can lead to inefficient functioning and increased strain on mechanical systems. Ensuring precise calibration during installation and maintenance is vital to avoid these complications.

How to Read the Diagram

Understanding the schematic representation of machinery components is essential for effective maintenance and repair. A well-organized visual guide offers insights into how different elements interact, facilitating easier troubleshooting and part identification.

Key Elements to Identify

Familiarize yourself with the essential components illustrated in the guide. Each part is typically labeled with unique identifiers that correspond to a list of descriptions. Pay attention to the layout, as it often follows a logical flow that mirrors the assembly or operation of the equipment.

Using the Reference Table

The accompanying reference table enhances your comprehension by providing detailed information about each component. It often includes specifications such as part numbers, descriptions, and compatibility details.

| Part Number | Description | Compatibility |

|---|---|---|

| 001 | Drive Belt | Model A, Model B |

| 002 | Feed Roller | Model A |

| 003 | Knives Assembly | Model B, Model C |

Replacement Parts for New Holland 855

Ensuring optimal performance of agricultural machinery requires timely updates and substitutions of worn components. Understanding which elements need attention can significantly enhance efficiency and extend the lifespan of your equipment.

| Component | Description | Importance |

|---|---|---|

| Cutting Knife | Essential for effective material handling. | Maintains cutting efficiency. |

| Chain Assembly | Transfers power between gears and drives. | Ensures smooth operation. |

| Rollers | Facilitate movement and compression of materials. | Critical for performance. |

| Drive Belts | Transmit power from the engine to moving parts. | Key for reliable function. |

Maintenance Tips for Baler Components

Regular upkeep of agricultural machinery is essential for optimal performance and longevity. Ensuring that each element is in top condition not only enhances efficiency but also minimizes downtime during critical harvesting periods. Implementing a consistent maintenance routine can significantly extend the lifespan of your equipment.

Routine Inspections

Conduct thorough assessments of all mechanical components at regular intervals. Look for signs of wear, corrosion, or any irregularities that may impact functionality. Pay close attention to belts and chains, as these are often prone to wear.

Lubrication Practices

Keep all moving parts adequately lubricated to reduce friction and prevent overheating. Use the recommended lubricants, and ensure that grease fittings are accessible and regularly serviced. Proper lubrication is crucial for maintaining the smooth operation of critical components.

Finding Genuine Replacement Parts

When it comes to maintaining agricultural machinery, sourcing authentic components is crucial for optimal performance and longevity. Identifying reliable suppliers can make all the difference in ensuring that equipment runs smoothly and efficiently. This section explores essential steps to help you secure the best replacements available.

Why Authenticity Matters

Using original components ensures compatibility and reliability, which can significantly reduce the risk of malfunctions. Genuine items are designed to meet specific operational standards, enhancing the overall functionality of your machinery.

Where to Look

There are several avenues to explore when seeking quality replacements. Consider authorized dealers, reputable online marketplaces, and manufacturer websites for trustworthy options. Always verify the authenticity of the products you choose.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers who provide genuine items with warranties. |

| Online Marketplaces | Established platforms that offer a variety of products; check seller ratings. |

| Manufacturer Websites | Direct source for original components; often includes detailed catalogs. |

Benefits of Using Original Parts

Utilizing authentic components for agricultural machinery offers numerous advantages that significantly enhance performance and longevity. These elements are specifically engineered to fit seamlessly and operate efficiently within the designated systems, ensuring optimal functionality and reliability.

Enhanced Performance

Genuine components are designed to meet the exact specifications of the machinery. This precision contributes to improved efficiency, enabling equipment to operate at its best. Users often experience fewer breakdowns and maintenance issues, translating to better productivity in the field.

Longevity and Durability

Authentic components are manufactured from high-quality materials, providing increased resistance to wear and tear. This durability means that machinery remains operational for longer periods, ultimately reducing the need for frequent replacements and repairs.

| Advantage | Description |

|---|---|

| Quality Assurance | Original components are subjected to rigorous testing to ensure reliability. |

| Compatibility | Designed to fit perfectly, reducing the risk of installation issues. |

| Warranty Protection | Using genuine parts often preserves warranty coverage on the equipment. |

| Resale Value | Maintaining machinery with authentic components can enhance its resale value. |

Identifying Worn-Out Components

Recognizing the signs of deterioration in machinery is crucial for maintaining optimal performance and longevity. Regular inspections can help you spot components that may be nearing the end of their functional life.

Visual Inspection: Start with a thorough visual check. Look for cracks, excessive wear, or any signs of damage. Discoloration may also indicate overheating.

Functional Testing: Operate the machine and listen for unusual sounds. Any abnormal noises can signal issues within critical parts. Pay attention to vibrations that differ from the normal operation.

Performance Monitoring: Keep an eye on productivity metrics. A decrease in efficiency can be a red flag that some components require attention or replacement.

Upgrading Baler Parts Effectively

Enhancing the functionality of your machinery can lead to significant improvements in efficiency and productivity. By selecting the right components, you can ensure optimal performance and extend the lifespan of your equipment. This section explores effective strategies for upgrading your systems.

Assessing Current Components

Before making any upgrades, it’s essential to evaluate the existing elements of your machinery. Consider the following:

- Identify any worn-out or outdated components that may be hindering performance.

- Review maintenance records to determine which parts require immediate attention.

- Gather feedback from operators regarding performance issues or inefficiencies.

Choosing Upgraded Components

When selecting new components, keep these factors in mind:

- Opt for high-quality replacements that match or exceed original specifications.

- Consider compatibility with existing systems to avoid installation issues.

- Evaluate suppliers for reliability and support services.

By carefully assessing your machinery and making informed choices, you can effectively enhance its overall performance and reliability.

Resources for Baler Owners

Owning agricultural machinery requires not only skillful operation but also access to reliable information and support. For enthusiasts and operators alike, having the right resources at hand can enhance maintenance, troubleshooting, and overall efficiency. Below are valuable tools and references designed to assist machinery owners in maximizing their equipment’s performance.

- Manufacturer Manuals: Comprehensive guides provided by the manufacturers often contain essential information on operation, maintenance, and troubleshooting. These documents can usually be found online or through local dealers.

- Online Forums: Engaging with communities of fellow operators can yield practical insights and solutions. Forums dedicated to agricultural machinery often feature discussions on common issues, tips, and modifications.

- YouTube Tutorials: Visual learning is beneficial for many. Numerous channels offer step-by-step tutorials on repairs, maintenance routines, and best practices, making it easier to tackle issues independently.

- Parts Suppliers: Identifying reliable suppliers is crucial for timely access to components. Many websites specialize in equipment parts, providing detailed catalogs and diagrams for easier navigation.

- Local Workshops: Establishing a relationship with nearby service centers can provide quick assistance. Professionals can offer expertise, spare parts, and timely repairs.

Utilizing these resources will not only prolong the lifespan of your equipment but also enhance your overall productivity and confidence in handling agricultural tasks.